The details of the installation of the furnace in the bath

Comfort and safety during bath procedures depend on the correct installation of the furnace equipment in the bath.

In order to effectively warm the steam room, you need to correctly select the location of the furnace structure. Compliance with the rules and safety regulations for the placement of heating equipment will allow for many years not to worry about the alteration of the bath structure.

Special features

When building a new bath, first of all, they design the place of the furnace and the location of the furnace. The main room that needs warming up is a steam room. It is located in the furnace equipment.

When choosing a furnace design are guided by the following parameters:

- size of the heating unit;

- rate of heating for a given area;

- steam produced;

- consumption and type of heating oil.

The dimensions of the stove are selected for the area of the heated room. From the heating rate depends on the time that will be spent on heating the entire space. With rapid heating with high temperatures, steam production increases. And also on the production of water vapor depends on the amount of the heater and the weight of the stones. Steam is needed for bathing procedures and drying wet rooms.

For the furnace can use different types of fuel. The most common - wood, you can stoke coal, gas, pellets. The quantity and cost of combustible fuel depends on the amount of heat generated and the efficiency of furnace equipment.

The feature of the placement of sauna stoves is to meet certain criteria:

- ensuring safety against fire;

- ventilation planning in the steam room;

- have free access to service all elements of the furnace design;

- think over competent output of combustion products.

Species

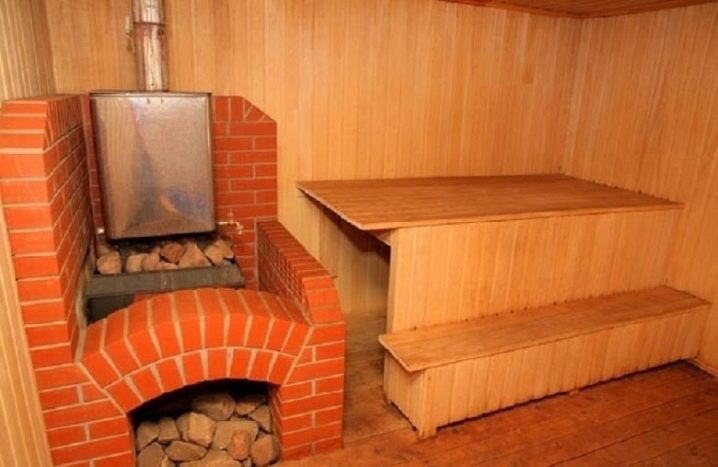

The material of manufacture defines two types of furnace units - brick and metal. The brick oven is made of fireclay fireclay bricks, lined with ceramic.Metal construction can be made of different metal alloys.

The most available in the bath to put an iron oven. Metal warms up quickly with low fuel consumption. The weight of the furnace design varies from the dimensions of the firebox and the heater, on average 100 - 400 kg. The cast iron furnace is characterized by a large weight and increased heat accumulation.

The advantage of such units is obvious:

- economical and fast installation;

- small labor costs during installation;

- compact size and weight;

- tightness of the design increases safety, reduces carbon monoxide leakage.

The downside of using a metal furnace is a quick cooling, unequal heating of the room. When fuel burns out, the metal cools quickly and ceases to give off heat. The stove heats up to 500 degrees, which can cause burns if it is not touched.

The farther the distance, the lower the temperature. Disadvantages can be neutralized by installing a brick case.

Furnace constructions from a brick are deprived of the negative sides of metal units. Uniform and long heat will persist for several hours after the fire. But to heat a brick oven, it will take a lot of wood and at least 2 hours to heat a brick.

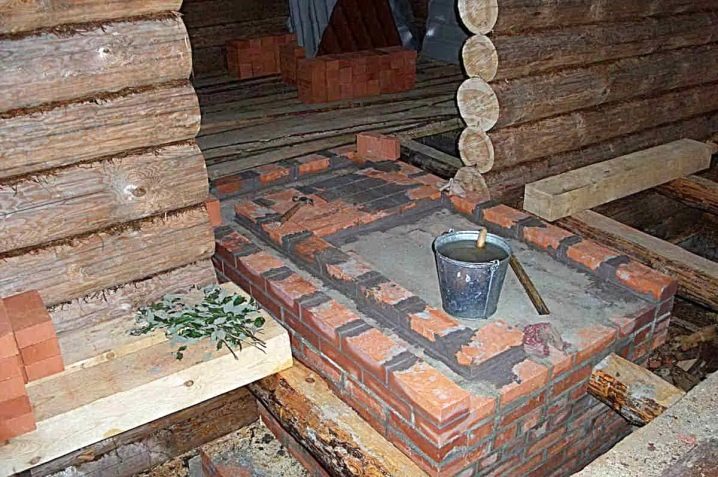

Mastery of masonry, preparation of a solid foundation and impressive dimensions make it difficult to install a brick kiln.

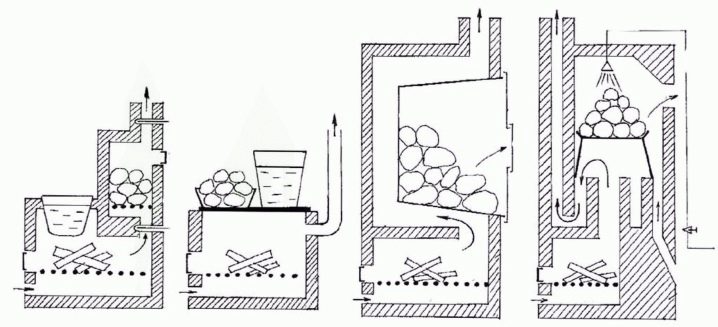

Depending on the place of fuel loading in the design of the furnace, there are separate types of heating units:

- Fuel is loaded from the steam room.. When installing stove equipment in the steam room, proper installation and additional ventilation is necessary. If the bath is from a bar, then the furnace is placed according to the rules of fire safety. When the firebox is open, oxygen is burned out of the room, so you need to provide high-quality ventilation. Plus the location of the furnace in the steam room - constant monitoring and the ability to quickly regulate the heating.

- The furnace is located in the waiting room.. This location is important for a wood-burning stove. This is optimal in terms of cleanliness and ease of loading the fuel. In this case, the construction of a frame wall between the steam room and the waiting room is envisaged.

- Fuel is supplied from the street.. This option is suitable for mini-baths or seasonal bath country buildings for heating.in coal. Fuel is loaded from the street, which can cause inconvenience when loading and controlling the furnace.

Furnace structures can be of various shapes - cylindrical, rectangular, barrel-shaped, with high or low sides. In addition to the furnace, the furnace design can include a tank for heating water and a container for the heater.

Where to install?

The location of the furnace depends on the layout and number of rooms in the bath. The main rooms needed are the steam room and the dressing room. In addition, a rest room, shower room, changing room, and pool can be included. Ideally, the stove should heat most rooms in the bath..

Oven equipment is installed so that at least two rooms in the bath are warm. This can be achieved if the structure is located in the wall between the steam room and the dressing room.. In the steam room there is a heater, a tank with water, the furnace body. In the dressing room place the combustion compartment with the ash chamber and access to the fire door.

To position the furnace design correctly, you need to know the features when heating the premises. Heat from the stove with the air flow moves throughout the space, uniformly warming the room. therefore in the way of warm air masses it is impossible to put obstacles and to do blocking.

The entry of air into the furnace through the ash pan will improve the combustion and heating of the structure. For a better supply of oxygen, the firebox should be installed at the level of the floor or slightly lower.

The safe location of the furnace equipment will ensure compliance with the installation rules of fire safety:

- There should be a distance of at least 50 cm between the stove and the wood paneling in the steam room.

- There must be at least 120 cm between the ceiling and the heater.

- There should be free access to the elements of the furnace structure - a heat exchanger, a heater, a chimney in case of an emergency. They must be kept at an acceptable distance from combustible materials.

- The walls and the ceiling around the body of the stove can be protected by fireproof screens. In this case, installation is possible at a distance of 38 cm from the wall and 80 cm from the ceiling.

- The partition in place of the fuel channel should be of non-combustible materials with a thickness of 12 cm.

- A distance of 120 cm is maintained between the firebox and the neighboring wall.

When planning a location, a brick kiln must be provided with a solid foundation.Lightweight iron structures are located on a non-combustible base.

Preparation of the base and walls

The amount of work on the preparation of the base depends on the material of manufacture of furnace equipment and the total weight of the structure. When calculating the total weight of the sum of the mass of the stove, the stones in the heater, the volume of water in the tank, the weight of the brick screen around the body, the mass of smoke pipes.

If the indicator is less than 700 kg, the installation is made on a wooden floor.by pre-mounting the fireproof floor screen. It can be made of metal sheet with a thickness of 0.5 mm. Under the metal enclosed insulation material. This may be a heat-resistant silicon ceramic plate, heat-resistant ceramic fiber plate, asbestos cloth. Protection from the heat will also serve as a brick substrate, facing the site with granite or ceramic tiles. You must first calculate the load on the floor beams, depending on their size.

If the weight of the whole structure falls on one beam of small section, then it is necessary to build a foundation. The area of the base depends on the dimensions of the furnace device; the foundation should extend up to 10 cm from the edge of the body.

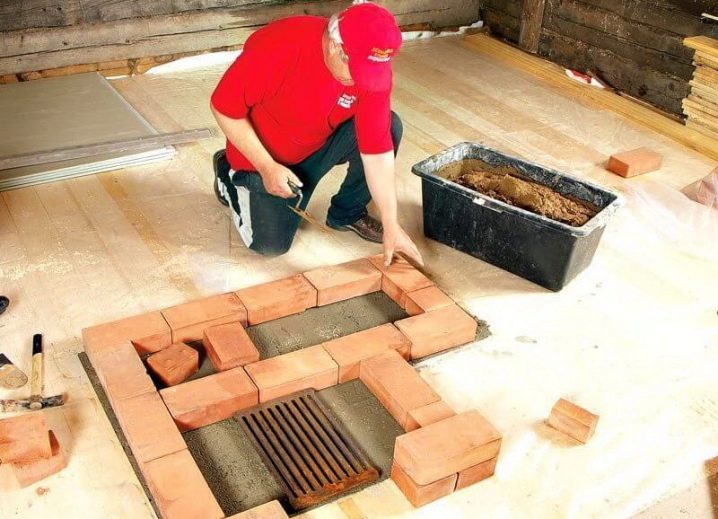

Depending on the type of soil on the site, they build a foundation on a monolithic slab, on screw piles, connected with the foundation of a bath with a shallow concrete base. For high-quality and reliable installation, step-by-step instructions are used to fill the furnace base.

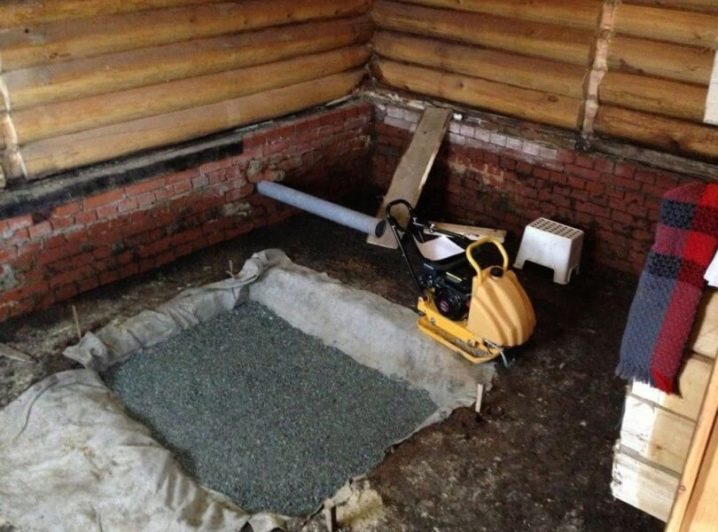

To install the stove on a monolithic foundation, you need to dig a pit with a depth of 120-150 cm, depending on the level of soil freezing. The bottom is leveled with sand and small fractional gravel, followed by pouring liquid cement. On a gravel pad lay waterproofing layer. The walls of the pit are made formwork of boards or slabs.

The entire volume of the foundation must be filled with a reinforcement cage. Then everything is poured concrete solution to the level of the floor. After a long drying period, it is necessary to dismantle the formwork, filling the voids with sand.

For loose soil with a high rise of melt water make pile foundation. Work begins with a marking of the necessary site, alignment of corners. Piles are twisted in the corners to the depth of the basement of the bath. At the base of each pile, heads and channels are welded, aligning with height. The steel sheet is laid on the channels and fastened.On the basis of a layer of concrete is poured.

The foundation with shallow deepening up to 60 cm is possible only on solid grounds. It is made similarly with a monolithic base, only a layer of concrete will be 30-40 cm without a reinforcing component.

The preparation of the walls next to the stove is to protect them from the heat. For this walls can be plastered with a thickness of 2-3 cm, hang a protective fireproof screen of non-combustible material, put a brick wall. Brick protection is performed with a clearance of a few centimeters from the wall.

To provide better ventilation behind the wall, convection holes are made in the brickwork.

As fireproof screens for steam room walls metal sheets and heat-resistant mineral plates can be used. On refractory plates, you can apply a finishing finish of natural stone, ceramic tile, mosaic, porcelain stoneware.

If the furnace equipment is located in the wall of the dressing room and steam rooms with a portable firebox, then before installation it is necessary to prepare a niche in the wall. The size is determined depending on the material used to make the wall and the dimensions of the combustion channel.

Installation Guide

The layout of the furnace equipment varies in each case.

Consider the following installation options:

- the furnace design is in the steam room;

- The furnace body is located in the steam room, the firebox in the adjacent room.

When you need to put the stove in the steam room, equipment is installed on the prepared base in compliance with the fire distance from the walls. To the base of the foundation or refractory pedestal, the legs of the case are attached with hinges fixed by anchors. Before the firebox, a steel sheet 50 cm by 50 cm is laid on the floor. Then proceed to the installation of the chimney.

When the chimney comes out horizontally, a hole is punched in the wall that is equal to the diameter of the flue pipe. If the pipes extend vertically, mounting windows are made in the ceiling and roof.

The installation of the chimney can be carried out by several materials: metal, ceramics, brick. Manufacturers of metal bath furnaces recommend installing a sandwich pipe with a thermal insulation layer inside.. You can install the sandwich structure yourself, following the instructions for the manual.

When installing the chimney with a conclusion on the roof, on the ceiling and the attic of the bath, galvanized sheets with a hole for the pipe are attached. The chimney pipe is discharged through the lumen. Fire-resistant material (expanded clay, vermiculite, sand, foam glass) is poured into the space between the ceilings or basalt wool is laid.

The optimum location of the furnace equipment is the place between two rooms of the bath.. The location of the firebox door in a separate room will allow equipping a protected area with free access to fuel. But you can also install a firebox below the floor to improve the flow of air into the combustion chamber.

The prepared opening for the channel of the firebox can be made inside the wall or partition. If the wall is brick, it is enough to make a window for a remote fuel receiver. If the wall is made of timber, an opening is cut out.

The size is determined by measuring the perimeter of the combustion channel, then added on each side of 20 - 30 cm. When the wall is frame, it is necessary to disassemble the casing between the posts on both sides to a height of 1 - 1.5 meters.

In the steam room, the furnace is mounted on a ready-made base, the fuel receiver is placed in the opening, and the door opens into the adjacent room.The space around the canal is bricked up. Between the wall and brickwork leave a gap of 1 cm, in which they lay a damper tape and insulation. The area between the brick and the fuel outlet is sealed with refractory sealant.

Tips and tricks

Before installing the furnace equipment in the bath, it is necessary to heat the metal body in the street. To do this, temporarily attach the chimney, set the design on a solid flat surface. Carry out the loading of fuel and heat the furnace to 200-300 degrees for an hour. Under the influence of temperature, the flame retardant paint will polymerize on metal, burn out anti-corrosive impregnation, therefore a strong smell and smoke can be emitted. After all the wood has been burned down, the equipment should be allowed to cool down by itself.

A high-quality modern material for protecting walls and ceilings from fire and high temperatures is a fiber cement plate (minerite), a magnesite panel (magnesite), a fire-resistant shield of silicate calcium, a vermiculite substrate.

On average, the thickness of the plates is 1-3 cm, quickly mounted on the crate with screws, does not take up much space.A small weight of fire retardant plates will not make the furnace construction heavier, will relieve the load from the flooring.

The body of the metal furnace is heated to 400-500 degrees. To avoid injury and burns when handling the instrument with carelessness, a brick screen is placed around the furnace structure, which serves as a protective sheath against high temperatures. From the heat of the hot furnace, the brickwork heats up and accumulates heat, gradually giving it away to the surrounding space.

About all the intricacies of installing the furnace in the bath is described in the following video.