How to make a sofa with your own hands?

Sofa in modern apartments is an essential design element. Often, for good quality furniture that fits the interior in color and shape, retail stores charge a very high price. Making a sofa with your own hands is much cheaper, and its manufacture will not cause difficulties.

Materials used

Depending on the desired model of the piece of furniture being created, the place where it will be installed in the future and its purpose, you can choose completely different materials. For the manufacture of a simple sofa, you can use several wooden pallets or pallets. The furniture of them is done quite simply, is cheap and today is just at the peak of popularity. One has only to supplement the resulting sofa from the pallet with soft pillows, and it will turn into an excellent resting place for a room in the Loft style or will become an indispensable piece of furniture for installation on the veranda of a rural house.

The material for the manufacture of one of the most simple and low-cost options for a homemade sofa can be the most ordinary cardboard. Old cardboard boxes, for example, from household appliances, pieces of binding cardboard, corrugated cardboard - everything can be used. The main difference of such a sofa will be that in this model not a single nail and a screw will be used, the parts of the sofa will be fastened to each other with the help of wood glue. Since the cardboard is fairly easy to cut, you can get furniture of any shape and size. In addition, this design will weigh less than a sofa on a full-fledged wooden frame.

Wooden boards as a material open a huge field for creativity. Of these, you can create a full-fledged fold-out sofa with any selected mechanism, make both frameless version and furniture on a sturdy wooden frame, create a comfortable sleeping bed, or just a place to sit together with friends. The abundance of types of wood offered for sale in specialized stores and the thickness of the boards used allows you to adjust the weight of the finished product, its strength and functional features.Interesting non-standard models of furniture for rest can be made of wood. So, you can easily make a hanging sofa swing. It can be an excellent option, for example, for a gazebo or a veranda. Slow wiggle and soft pillows will create a relaxing effect and will give a real rest from the pressing problems.

It is possible to make a completely new piece of furniture with the help of the restoration of an old frame. Sanding and impregnating wood with a special solution will help to update the old wood material and create the basis for a future project.

In addition to the material for the frame, depending on the model produced, you may need more material for upholstery. Here come to the aid of dense upholstery materials, which are most often used for the production of upholstered furniture. The choice will be determined by the interior design, the amount that the master will be ready to allocate for materials and functions assigned to the sofa.

The most popular materials for upholstery:

- Genuine Leather - one of the most durable and durable materials, gives the sophistication and solidity of furniture produced, however, has a high cost and requires special tools to connect parts.

- Eco-leather - material with all the advantages of natural leather, among the advantages can be distinguished by a lower cost and a larger range of colors.

- Leatherette - the cheapest analogue of the skin, quite durable, eco-friendly and stylish. Among the minuses - the fear of mechanical damage.

- Chenille - Comfortable fabric for craftsmen who do not have much experience in sewing, as it does not stretch and does not slip, but at the same time has a high degree of wear resistance.

- Velours - soft and pleasant to the touch material, also refers to materials that are convenient for sewing, but it also has a significant disadvantage - it is quite difficult to remove stains from such fabric and it is very capricious in care.

- Tapestry - dense and durable two-sided material with a pattern. You can buy it in absolutely any fabric store, but you need to remember that a sofa with such upholstery does not tolerate direct sunlight, as the fabric fade quickly.

- Jacquard - durable, pleasant to the touch material resembling silk. It has a characteristic shine. When choosing, it should be borne in mind that when stitching, the material may slip and you will have to make some effort to make the product to be beautiful and neat.

When choosing a material, it is also worth considering how the upholstery will be stitched.If you plan to sew a case on a regular sewing machine, rather than on an industrial one, it is more appropriate to choose thinner fabric materials. Bonding parts from thick furniture leather or leatherette on a machine that is not intended for heavy materials, there is a risk that the machine will not sew them or it will break.

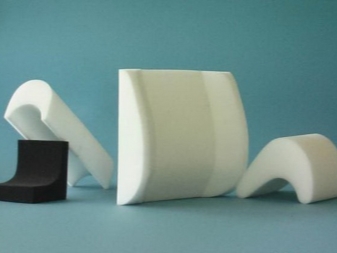

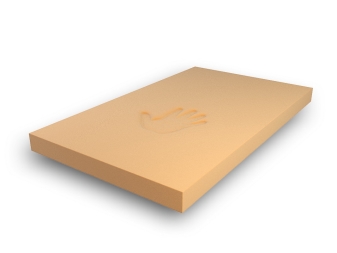

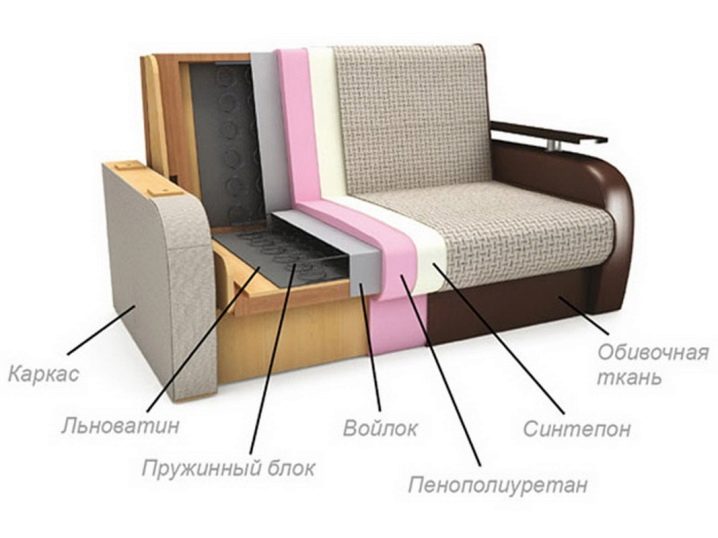

A home-made sofa, if this suggests an idea, should have a soft comfortable seat. For this you need a special material - filler. As it can be used:

- Foam rubber - one of the softest furniture fillers, besides, it has a low cost and is available for purchase in retail stores.

- Polyurethane or PPU - a relative of foam rubber, however, has a more dense structure, and therefore the furniture with a filler made of polyurethane foam is quite rigid.

- Sintepon - soft synthetic material of white color, most often used as a heater or as a cheap way to soften the surface.

- Batting - soft filler with a high content of cotton, and therefore is a material that is well breathable.

Everything else inside the sofa seat, you can install a spring unit, which will extend the life and improve the functional quality of furniture.Springs for such a unit can be dependent and fasten to each other on the principle of a snake, and can be independent - in this embodiment, each spring exists separately and has its own individual cover.

If you plan to make a sofa sliding, be sure to purchase a layout mechanism. They are of the following types:

- "book";

- "Eurobook";

- Tick-tac;

- "accordion";

- "withdrawable";

- "dolphin";

- "Conrad."

In addition, you need to stock up with screws, wood glue, which will easily and firmly glue the wooden frame, you will need thick threads for stitching upholstery details.

Of the tools will be useful electric jigsaw, screwdriver, furniture stapler, as well as a sharp knife for cutting foam rubber.

How to make at home?

Any homemade project should be started with an idea - choosing a model and defining the purposes for which this piece of furniture will be used. If you plan to use the sofa as the main or additional bed, it is better to stop the choice on the sliding model, therefore you need to take care of the purchase of the layout mechanism, the selection of a more dense and high-quality upholstery material, as well as the use of a full-fledged spring unit at the base of the furniture.If the homemade sofa will be used strictly for sitting either as an element of the cottage furnishing, garden house or on the terrace, you can experiment with materials like upholstery and, in principle, the entire sofa. Massive sofas from a bar, topical from a pallet, unusual from a cardboard, with armrests and without - any option may be appropriate and successfully created with your own hands.

So, when the type of the future sofa is chosen, its purpose is indicated, the general plan is drawn, dimensions are outlined, you can start purchasing materials and creating the desired one directly.

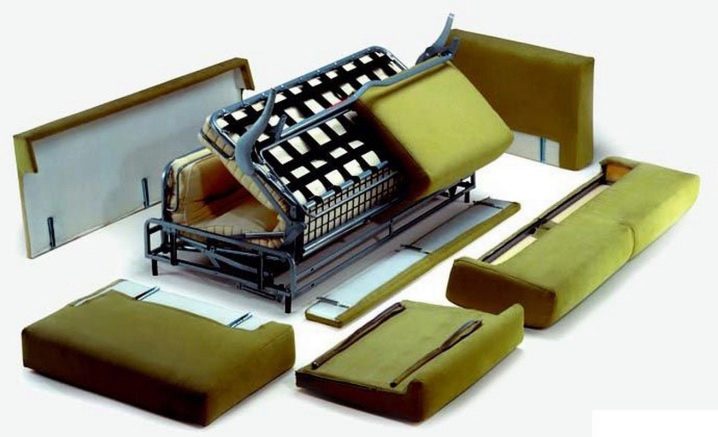

Creating a sofa with your own hands includes the following steps:

- selection and purchase of materials;

- frame creation;

- upholstery.

Of course, depending on the type of construction chosen, actions may vary, be added or completely eliminated.

From pallet

So, in order to make a sofa out of pallets, the most minimal set of materials and tools is required. It will take several pallets, if desired, they can be sanded and painted in the desired color, screwdriver, screws and jigsaw, plus material for pillows that will serve as a soft back and seat of such a sofa.For the armrests, it is necessary to trim the ends of the pallet with thick wooden inserts. These short parts need to be stacked on each other and fastened with screws, then attach the finished armrests to the already prepared base. The best option is 3 cuts, made up of each other, but if desired, their number can be changed, which will help to achieve the desired height of the armrests.

At the base there can be either one pallet or several screws connected to each other, the choice will depend on the size of the sofa you plan to get in the end.

Further, from foam rubber or other selected material it is necessary with a sharp knife to cut two rectangles to fit the size of the future sofa. After the foam rubber is successfully cut, it is necessary to proceed to close-fitting the seat. Here there are several ways: you can sew upholstery using a typewriter or manually, and also fix it with a furniture stapler. The same manipulations must be repeated in the manufacture of foam pillows for the back of the sofa.

If the sofa will stand against the wall, then you can complete its production here, but if you don’t lean the sofa against the wall, then you need to attach the back to the finished frame.To do this, you need to take another one or two pallets, depending on the number used for the manufacture of the seat, and fasten it with self-tapping screws and a screwdriver to the back of the sofa, then install the pillows in place and enjoy the home-made interior renovation.

Homemade "book"

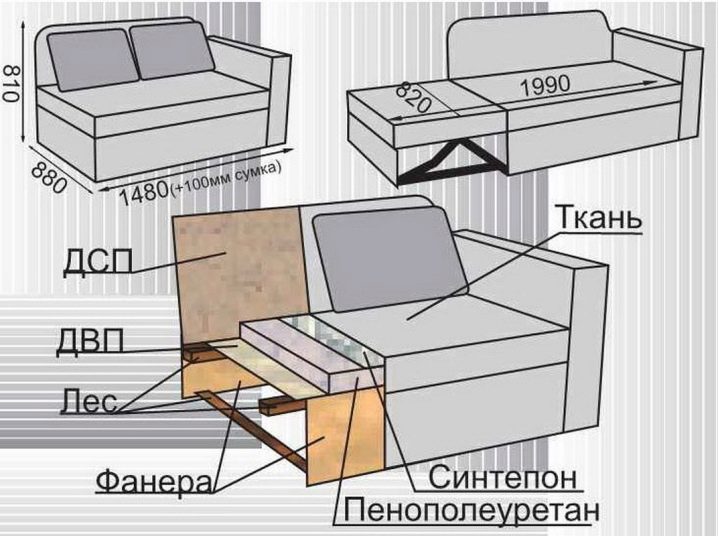

This is a more complex production option, requiring more materials, time and effort. It is necessary to start manufacturing with the determination of the exact dimensions of the future element of the interior, for convenience, they must be written on the sketch prepared in advance. In addition, you need to stock up on materials, you will need:

- boards 25-30 mm thick for the manufacture of the frame;

- timber;

- foam rubber;

- padding polyester or batting;

- upholstery fabric;

- plywood;

- legs for a sofa;

- mechanism for a sofa;

- wooden slats;

- glue;

- self-tapping screws;

- staples for furniture stapler.

In addition to the above materials, you need to stock a certain set of tools. So, you need:

- jigsaw or hacksaw;

- furniture stapler;

- screwdriver;

- roulette;

- pencil.

When there are all the listed materials and tools, you can begin to manufacture.This production involves a fairly large amount of garbage and dust, so all the work is best done on the garden plot, the street, or in the garage.

First of all, it is necessary to assemble the frame of the future box for laundry; for this, it is necessary to assemble a rectangle from boards of the required length (the length of the box is 30 cm, less than the final length of the sofa with armrests). After the main frame is assembled, it is necessary to reinforce it with transverse rails; a sheet of plywood is attached to the bottom of the frame with self-tapping screws. From the boards of the same length it is necessary to assemble two more rectangles with transverse reinforcing slats - these will be the frame of the seat and the back of the future sofa. To these frames it is necessary to attach wooden lamellae - the basis for the future mattress with the help of a screwdriver. It should be remembered that all the lamellae must necessarily be located at an equal distance from each other.

The next stage - the manufacture of armrests. Four pods of the selected size and shape are cut out of plywood, then a bar is installed around the perimeter to strengthen the structure in two copies, after which the two remaining shapes are fixed on top of the bar.Further, separate parts of the sofa frame are assembled into one whole, at the same stage a special layout mechanism is attached.

There are some simple rules that will help in the assembly:

- In the unfolded state, the distance between the back and the seat of the sofa should not be less than 1 cm;

- In the folded design, the seat should in no case be protruding beyond the attached armrests.

Next, the finished frame is covered with foam, which must be chosen based on personal preferences, since there is a different structure and thickness of the material. After foam rubber for greater strength and softness of furniture, the frame is sheathed with padding polyester or batting. At this stage, the most creative part of the work begins. With the help of a sewing machine, you must sew a cover made from upholstery fabric. Such covers are usually sewn under the dimensions of the details of the sofa and put on them, shrinking occurs with the help of lightning.

An alternative to this method is to adjust the upholstery fabric directly to the frame using staples and a furniture stapler. This method allows you to attach the fabric evenly on the frame at a lower time cost. Sofa book is ready.It only remains to install it on the most prominent place in the room, perhaps even having built a special podium for it, because a thing made with own hands should arouse the pride of the inhabitants and the envy of those who do not have such an exclusive piece of furniture.

New furniture from old

When at home there is an old, sold out and uncomfortable, but beloved sofa, which is a pity to throw out, you can create a new piece of furniture and from it. First you need to remove the old upholstery, carefully, so as not to tear, because in the future it will become a pattern for a new one. Next, filler (foam, ppu, or any other) from the frame, if a berth on the spring block, then remove it.

To clean off the remains of the old filler from the frame and to sand with the help of the skin - that’s the frame is already completely new. Next comes the replacement of the springs, if required by the sofa model.

After the new spring unit takes its place, it is necessary to return the filling to the sofa - the frame is glued with foam sheets of the required size. The final stage of the transformation will be the constriction of the sofa with new material. To do this, you need to cut out the material according to the old pattern, sew the parts, put the finished cover on the workpiece and fix it with a furniture stapler.If desired, you can add new clothes with soft pillows from a suitable fabric.

Where to place?

The location of the home-made sofa is determined by some factors, such as:

- The style of the room;

- Functional features of the piece of furniture;

- Taste preferences of the host.

So, today the sofa from the pallet, which is so relevant today, will fit perfectly onto a balcony or terrace, a comfortable stylish seat will enliven the interior and you will want to spend evenings more often in it, wrapped in a rug and contemplating the stars in the sky. In addition, such sofas can be a highlight of the room in the style of Loft.

The wooden sofa swing, created by your own hands, can be placed in the gazebo in the country, you should only remember that since it will be influenced by natural factors, the tree used for manufacturing must be treated with special protective impregnation. Folding, full-size sofas with boxes for linen, created by yourself, can be placed in the bedroom or in the garden house, you only need to choose for the manufacture of suitable upholstery material that will look harmoniously in the interior room.

Simple frameless non-folding sofas will be an excellent option for the kitchen or living room, especially if such a sofa will have an angular shape. Here it is necessary to pay special attention to the selection of fabric - it should not absorb odors and be not picky about cleaning. You can also handle upholstery special coating, which will repel water and reduce the flammability of the material. In addition, in the guest room or on the loggia, you can put furniture made by yourself from cardboard. However, it is worth remembering that such models are sensitive to moisture and do not accept wet cleaning or ingress of liquids on them.

However, if the sofa is created with your own hands, you don’t really need to hide it, you must boldly place it in the most prominent place in the room, if, of course, you used materials suitable for the general interior of the room.

Expert advice

First of all, it is necessary to develop a detailed project of the future sofa. Determining the overall dimensions, the exact height of the backrest, armrests, seat depth and other important elements should be reflected on the plan.It is great if it exists in both written and electronic versions. When determining the size, it must be remembered that, for example, the height of the seating position directly depends on the location of the furniture, and the kitchen corners are usually somewhat higher than the pieces of furniture used for recreation. When a plan is developed, you can pay attention to the materials. To create the framework, experts advise to pay attention to the wooden bars or cuts of the profile furniture pipe. With it, the frame will turn out even more durable, and the sofa will last a long time.

If foam rubber was chosen for internal filling, it is necessary to choose loose and rather thick cuts. The thickness, ideal for home-made furniture, starts from 15 cm, otherwise it will be necessary to replace the foam rubber too quickly, for which you will have to disassemble the entire structure. The same rule applies to the restoration of old furniture. As for the alteration of old furniture, the main point here is that the sofa needs to be photographed before disassembly, plus, photos of the disassembly process itself will be useful.

If the idea of assembling a sofa independently comes for the first time and there is no experience in it, you should not chase after complex structures, it is better to start with the simplest straightforward forms. And in order to feel the wood, the tools and the fabric, it is better to begin to take up an ordinary stool, so to speak, to test its strength. After all, it is better, in case of anything, to remake a smaller form than large-sized furniture.

How to make a sofa with your own hands, see the next video.