Corner sofa do it yourself

Many people want to make pieces of furniture on their own, but not everyone knows where to start and how to approach the matter. After all, this is a time-consuming process, requiring tremendous care and accuracy. Furniture that is made by hand, will fit perfectly into the room, because it will be made according to individual drawings. She will have upholstery and filler selected by the master himself. If we talk about the financial side of the issue, then we can safely say that the independent collection of furniture will cost a little less than the purchase in the furniture salon. Many people prefer to make a corner sofa with their own hands, rather than spending money on expensive furniture.

pros

To cope with the manufacture of a corner sofa is capable of every person who knows how to handle the tools and understands some of the nuances. The corner sofa will be an ornament to even the simplest room, and in quality it will be able to surpass the store options.

The advantages of creating your own furniture:

- Cash savings. Buying goods in furniture stores or ordering furniture in the workshop, you overpay not only for the work of craftsmen, but also for transportation, rental of premises, for the salary of the staff.

- Personal quality control. You buy the materials yourself, so you will be 100% sure of their quality.

- Own design. If the store has to choose a product from what is offered, then independent manufacturing allows you to come up with your own size, shape and design.

- Acquisition of useful skills (for example, hauling). Sooner or later, furniture has to be tugged down, and turning to professionals can significantly hit the family budget.

- Getting pleasure from the process and pride in the result. There is nothing better than receiving enthusiastic feedback from relatives and guests who admire your abilities.

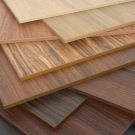

Selection of materials

To achieve reliability and durability of the product, you need to take a responsible approach to the choice of materials. Beginners should not stop the choice on complex drawings and expensive materials.For a beginner in this matter, it is better to use a fiberboard or chipboard, birch plywood and coniferous timber. Before work, you need to prepare bolts, screws, nails, sintepon (P = 150 g / dm), batting, foam rubber (2-4 cm), fabric for furniture, wooden legs (5 cm), a mechanism for lifting the structure. Fix the fabric and foam need to use special adhesives.

In order for the product to last several years, it is necessary to use self-tapping screws for fastening. Nails will not be able to hold on for a long time in sheets of chipboard or fiberboard, with time they will loosen and fall out. Adhesive is allowed to use only after the master is convinced of the accuracy of the assembly.

If non-laminated plates are used in the work, they should be coated on top with a special varnish.

Instruments:

- hand saw with simple stuslom;

- electric drill;

- quality stapler;

- sewing machine;

- sharp knife to cut foam;

- the simplest wort.

If you do not cut at home, it can be ordered.

Step-by-step instruction

If you are going to make a corner sofa with your own hands, you need to decide exactly where the product will be located in order to create the desired design.It is better for a beginner to dwell on a simple sofa, without complicated structures. For example, you should not start with a folding sofa, because it is quite difficult. All dimensions and details must be indicated on the drawing so that there are no errors in the process.

- Make armrests. For the manufacture of the product, prepare two armrests 90 × 20 × 55 cm. A large sheet of chipboard and two beams are taken. Screws need to be screwed into the chipboard, fixing them with a bar. The distance between the fixings should be approximately 20 cm. It turns out that in each bar there will eventually be four screws, and at the end of the bar - 2. Next, use two nails to attach the fiberboard - up to 15 cm apart. It is advisable to fasten the nails with wood glue to make the structure more durable. When the armrests are ready, coat them with foam rubber. To do this, first cut down rough and sharp places in the upper part of the structure, and then paste foam rubber on the front section. On the back of the need to stick a batting.

- Work with the left side. With the help of plywood sheets, two parts of chipboard are fixed on the screws, lubricating them with solar glue on top. Each half should have 4 screws.Next, screw two wooden pillars, make a screed from a bar. The upper timber should fit well to the lower one in order to create a solid support. To assemble the frame of the sitting part, you will need an even bar without bulges. The diagonal frame must be the same size. The frame is assembled on the same principle as the back. The finished frame is installed on the frame. For this place, the fastening of the front bar is made slightly weaker, all surfaces are coated with glue. Then all the screws (7-9 cm). Plywood is mounted on screws and glue. The distance between them should be about 15-20 cm. Fiberboard is attached to the back (using nails and glue), foam is glued on top.

- Collect the right side. Details fasten plywood sheets. Screwed around the perimeter of the bars, which later put the storage box. The bottom is made of chipboard. For the lifting mechanism it is necessary to draw the markup, then the drill will need to make holes for the bolts that should look out from the side of the bar. Foam is glued on top.

- Work with filler.To accurately cut the foam, you need to take measurements from all sides. Having cut one part, it is better to glue it immediately into place.It is necessary not to get confused. The thickness of the foam pad for the seat should be 12 cm.

- Upholstery. To cover the sofa, you have to make patterns. To do this, the product is measured, visually dividing it into parts. All sections should have a rectangular shape so that it is easier to cover them with a cloth. Next, you need a pattern. All its details need to be cut out, and then the fabric should be cut out. It is necessary to cut fabric from the wrong side, leaving allowances of 5 cm - for future seams.

Fabric should be ironed in advance so as not to be mistaken with the calculations and not to spoil the overall look of the upholstery.

With the help of pins, the fabric is attached to the sofa, and its pieces must be sewn by hand with colored thread. This is important in order to make the perfect case. Then the cover is carefully removed from the product, make sketches on the sewing machine.

Cover cover the sofa with a bright side and straighten. To fix it on the product, use a stapler. If you do not have a sewing machine at hand or a person does not know how to work with patterns at all, then you can buy divandeks. These covers will give the product uniqueness and create an atmosphere of comfort. Divandeki can be used as a cover, which is thrown over the main upholstery. This process of creating a corner sofa can be considered complete.Now you can put it on the balcony or in the gazebo. It depends on what it was originally intended for. Having made a simple corner sofa with your own hands, you can get accustomed to working with wood and tools. This skill will help to assemble a more complex product or to remake an already finished sofa.

Tips

The decision to make a corner sofa at home should be carefully thought out so that there will be no change in the plans. It must be remembered that not all people are able to work with a saw or a drill. Therefore, a person who has decided to make a sofa, should correctly and objectively assess their strength. In order not to puzzle over difficult tasks (for example, cutting), you can buy ready-made parts. The same goes for the upholstery. It can be ordered in the furniture store, taking measurements and drawings with it. Nowadays almost any newcomer can try himself as a furniture master. After all, on the Internet, you can find instructions in which everything is described. Professionals will talk in detail about where to start, what you need. They will show the manufacturing process itself.

A detailed course on making a sofa do it yourself in the next video.