Silicone transparent sealant: features of choice

Practically any construction and repair work requires reliable sealing of joints of various materials, since it is this task that largely determines the result and reliability of the structure and system. On the modern market there are products that can cope with such work, they should include silicone sealant.

Special features

Before such products became widely used, various kinds of putty were used as precursors of the material, which were made by craftsmen themselves. However, the effectiveness of their use remained rather low. Colorless silicone glue at times exceeds home-made materials in its technical characteristics, which explains the relevance of this product today.

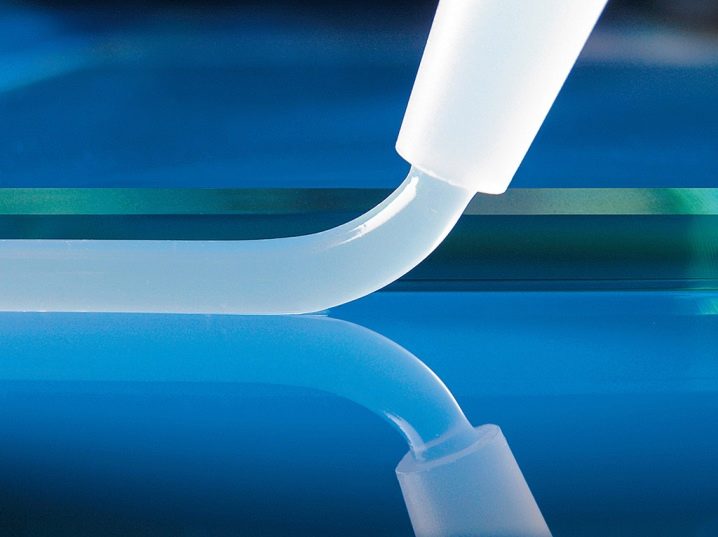

The composition is a viscous transparent substance, which is inherent in a good density. As for the field of application, in this case it is worth noting the sealing of joints and cracks on most materials, sealing the joints of elements, bonding between the components of a structure.

In addition, the composition acts as a protective agent against water and other factors, most of which have a destructive effect on the working surface.

It should highlight the main positive properties possessed by silicone sealant.

- Resistance to atmospheric phenomena, so that products are allowed for outdoor use.

- Resistance to contact with chemical media.

- The composition does not lose its qualities from exposure to ultraviolet radiation.

- Products have good adhesion to most building materials.

- Accommodation accommodates at least 20%.

- Sealant resistant to negative temperatures. In addition, the material is thermally stable.

- The temperature range of use of the substance varies between -30C - + 60C.

In addition to the advantages described above, the products have some drawbacks.Among them it is worth noting the inability to perform their functional tasks with the composition when applied to a wet base. In addition, in the light of the absence of natural components in the composition of the sealant, it is rather difficult to be colored.

Taking into account the specifics of silicone sealant, it should be noted that it is a rather complex chemical composition.

Products include the following components:

- Silicone rubber acts as the basis of the product;

- the strength component is the booster;

- color and volume of the composition governs the filler;

- for elasticity and viscosity, the vulcanizer and the plasticizer are included in the composition of the sealant;

- For high adhesion rates, a special primer is used.

Its characteristics as well as the effectiveness of the substance depend on the presence of one or another component in the composition of the material.

Given the area of use of the product, silicone sealant stands out for its versatility, which allows the composition to be used for exterior and interior applications. It is in demand for the installation of sanitary partitions, repair of plumbing, the material handles the joints of shower cabins and baths with a wall.Applying sealant reduces the risk of leaks and, importantly, the development of mold and other microorganisms on the surfaces.

In the course of installation work related to the arrangement of kitchen premises, sealant is an indispensable material, since it is treated with the ends of tabletops in places with high humidity, in particular, near kitchen sinks.

The composition has found its application in the process of installing window blocks made of wood, thanks to it, it is possible to fix the glass in the window frame as tightly as possible, thus avoiding drafts in the future. Such processing is performed with a cold-resistant sealant, which is completely invisible on the surface of the window.

If you need to use a substance with a certain color, you can find colored silicone products on sale. Among the presented diversity can be found black, white or red compositions.

In the assortment of such products, heat-resistant sealant stands out, it does not lose its qualities in the temperature range from -50С to + 300С. Such products are in demand when carrying out electrical work, assembly of industrial equipment, heating systems, chimneys, and so on.

For arranging roofs, where slate or tile acts as a roofing material, it is possible to seal cracks and other defects in the coating. In addition, silicone compound seals cracks in the basement and the foundation of buildings.

During the work there are situations that require removal of the sealant from the surface. In such cases, resort to the use of a solvent, but with the condition that the surface on which the composition is applied, will be resistant to such effects.

In addition, special washings for silicone products should be highlighted, presented on the market by domestic and foreign manufacturers.

Kinds

Product classification is based on its composition. There are two-component and one-component silicone sealants. They also vary in their field of application.

The first group is used in the industrial sphere, with regard to single-component compositions, in which case products can be divided into types based on its basis.

- Alkaline Sealants - Amines are used in the material manufacturing process. Such products can be attributed to special-purpose substances.

- Acid materials - produced on the basis of acetic acid, the smell of this substance will be present in the process of solidification of the composition on the base. The main disadvantage of acid silicone sealants is their incompatibility with certain types of metal. As a result of its contact, corrosion processes begin to occur on the surface; in addition, there is a limitation regarding the treatment of such compositions with cement surfaces that have an alkali in the list of components.

- Neutral Products - remarkable for its effectiveness when applied to any type of base, due to which such substances are classified as universal materials. These compounds are based on alcohol or ketoxime.

Based on the scope of application, silicone sealants can be divided into several types.

- Substances for special purposes - they are designed to operate at elevated levels of humidity. In addition, the products are characterized by excellent adhesion to surfaces that have a heterogeneous and porous base; in contact with aggressive chemicals, sealants do not lose their properties.

- Building compounds - are resistant to UV light, except for work requiring the treatment of various joints. The products are used as an adhesive for fixing indoor decorative moldings and moldings in the rooms, in addition, building sealants are good seals for automotive lighting devices.

- Automotive sealants are needed during the fastening of automotive gaskets. Products are resistant to contact with antifreeze, can withstand high temperature heat.

Consumption per 1 m

In order not to be mistaken in the course of calculating the required amount of the composition for sealing, one should take into account the specifics of the work, due to which it will be possible to determine how much it will be needed for surface treatment. In this case we are talking about the size of the gap being processed - depth and width.

Material consumption is calculated by the following formula: the width of the seam is multiplied by the depth. If the junction has the shape of a triangle, the result is divided into two. Based on existing consumer reviews, it can be noted that a 0.3 kg bottle of sealant is enough to handle ten meters of a working base measuring 5x5 cm.

Manufacturers

On the shelves of building supermarkets you can find a large range of silicone sealants. Products are manufactured by Russian and foreign companies.

Among the products that are popular today, it is worth highlighting a number of brands presented below.

- Makroflex - a company with extensive experience in the production of various sealing compounds. The list of goods sold can be noted universal composition, which has a high level of technical characteristics, thanks to which from the positive side has proved itself in use.

- Soudal - Polish brand, which is engaged in the manufacture and sale of adhesive and sealing compounds. Products comply with European quality standards, but have a high price compared with similar compositions of domestic companies.

- Among the Russian goods leader in the production of sealants acts brand "Moment". All products are manufactured in Russia, combining high quality features and affordable cost. Among the proposed range of distinguished composition "Germent" 280 ml, which is a universal product,recommended for use during construction and repair work both inside and outside the premises. The composition is easy to paint.

- Atol Spheraflex 300, 310 - is a representative of the group of one-component sealants, which has a high level of adhesion to glass, wood, metal and ceramics. This composition should be used for processing joints between parts with moving parts. Products are easy to operate due to the possibility of working with a gun.

- Flex Plus Silicone Silicone Compound designed for work with bases where there is a high level of humidity, often used for sealing joints in bathrooms, in the kitchen, and so on.

Tips

The described products have a huge amount of low-quality counterparts made from cheap raw materials of organic origin, they should include oil or kerosene, which reduce the strength of the substance, resistance to humidity and resistance to different temperatures. Such products have a short lifetime, and the quality of the work performed will leave much to be desired.

To avoid all sorts of problems,associated with the use of low-quality compounds, preference should be given to products of proven manufacturers of building materials, which have positively proven themselves on the market today.

As for the work on the sealing of seams, which have already been subjected to the processing of any compounds, before applying the silicone sealant, it is necessary to pre-clean the working area from the old substance. To perform such a task on sale are various specialized tools.

Sealing places where development of microorganisms is possible, be it a bathroom or other room with a high level of humidity, requires a fungicide treatment before applying the material, after which it is necessary to thoroughly dry the surface.

In the process of performing work, where special attention is paid to the smooth edges of the formed layer, it is useful to use masking tape. In order for seams to be distinguished by a high level of quality and reliability, it is necessary to let the products dry completely.

As a rule, manufacturers indicate the period of complete curing of the sealant on the package - usually it is about a day. But this value is rather advisory and averaged, since the time of complete solidification will depend on the thickness of the applied layer of the substance, temperature, including the level of humidity, which in each case will be individual.

High-quality silicone products should be 90% rubber, the remaining 10% will be made up of various fillers.

On sale there are products, marking which includes the presence of the letter "A". This designation is assigned to sealants, which will emit a specific smell of vinegar. When working with them, it is necessary to secure the respiratory tract, therefore, the application of the compound should be carried out in a respirator, as well as protected from contact with the eyes and hands.

To remove excess material, you can use construction tools, such as a trowel. They will help remove the sealant from concrete or wood. However, work should be done as carefully as possible to avoid damage to the surface. Until the product is dry, excess volume can be removed with a damp cloth. The composition of the skin is well washed off with soap.

How to choose a sealant, see the video below.