Heat-resistant sealants: properties and scope

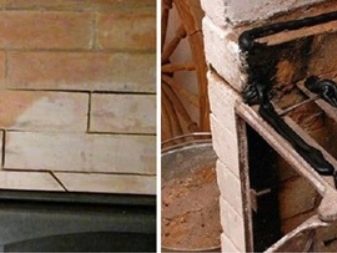

When heating systems are destroyed, it is not safe to use them. It is impossible to dismantle some structures and install new ones for a number of reasons, and it is not practical to make new laying of stoves. Therefore, it is easier to restore the integrity of the destroyed elements and repair cracks and seams.

Heat-resistant compositions will come to the rescue. The discovery of high-temperature sealants was a real discovery. With their help, you can not only carry out repairs, but also install new systems.

Features and benefits

A feature of any heat-resistant sealant is its ability to manifest its functions at high temperatures. Its purpose is to fill, fix and connect.With all the variety of types and brands of this product, their main advantages over conventional sealants are obvious. The component composition of thermo hermetics includes a special substance based on a polymer, which characterizes the specifics of their use.

This is a high molecular substance with a complex chemical formula that provides the adhesion of surface molecules and sealant. These or other features of sealants depend on the varieties on the consumer market. All of them are mainly produced in special tubes of various volume and quality. The format of their use can be different: from manual to application with a gun.

One of the leading places is occupied by hybrid mixtures. In addition to high reliability and durability, these new generation sealants are resistant to ultraviolet rays, chemical compounds and high temperatures. Hybrid sealants retain their inert properties for a long time, which significantly increases their shelf life. They are simple and convenient to use. Possessing a good binding structure, they cope with their functions perfectly when exposed to high temperatures.The good extrudability of these compounds provides a wide temperature and geographical range of their application.

MS polymers are safe and environmentally friendly to use, practically do not emit caustic chemical acetate odors. Due to the absence of solvent elements in the composition, they are safe for the environment and humans. Hybrid sealants have very good vulcanization. They have moisture resistant properties. Among their advantages is the ability to dye with various colors, any paints, even on a still wet surface without any effect on the solidification of the layer. However, in terms of heat resistance, their indicators do not exceed +120 degrees Celsius.

For the elimination of chimney leaks, as well as to protect the furnace from cracking, where special sealing compounds are required, special heat-resistant flame retardants are used. Their classification is based on the degree of heating of the elements.

Heat-resistant sealants are used when the surfaces do not heat up above +360 degrees Celsius. They fill the seams in brick and masonry, seal the joints of structures.Thanks to the waterproof components that make up the sealant, protection against weather conditions is provided.

Heat-resistant mixtures are designed for surface areas with a maximum temperature of up to +1500 degrees. They are used in the processing of joints of masonry with fire, in the chambers of stoves and fireplaces, on high-temperature pipes and other structural elements.

Modern compositions contain additives that affect heat resistance. For the treatment of the chimney apply sealant containing iron oxide, which significantly increases the temperature range of its use. There are also types of sealants with copper. Iron and copper give sealants qualities of particular strength. The shelf life of oven sealants is quite high and, subject to the conditions stated by the manufacturer, is 15 years. Some of them are able to withstand up to +4000 degrees Celsius.

Each type, along with positive qualities, has its own characteristics. So, the sealed silicone compound for the metal, with all its advantages, including water resistance and resistance to temperature extremes, has low vulcanization and is not subject tostaining.

Surfaces treated with silicate sealants become resistant to extremely high temperatures. They are durable and suitable for dyeing, but have weak adhesive properties with some smooth surfaces.

All sealants in this range comply with fire safety regulations. It is important to properly implement the operating conditions and follow the directions on the label.

Types and characteristics

High-temperature sealants are designed for temperature ranges +200 - + 300 degrees Celsius. They are suitable for sealing cracks and seams in chimneys and heating systems. The resistance of sealants to high temperatures depends on the polymer series used in their manufacture. On this basis of the polymer base, they are divided into silicone, silicate and bituminous.

The purpose of sealants can be changed in accordance with the specified characteristics. Bituminous sealants due to their inability to withstand high temperatures are limited. High-temperature sealants are divided into two groups: heat-resistant and heat-resistant.They are different in their properties and degree of resistance to temperature effects. Heat-resistant can heat up to +1500, and heat-resistant - up to +300 degrees Celsius.

The temperature-resistant silicone sealant contains synthetic rubber, which significantly expands the scope of its application and allows its use in outdoor applications. Silicone sealants are also used as glue - for bonding ceramics, glass, wood and other surfaces.

In terms of their composition, silicone sealants are divided into one-component and two-component.

Based on the name, heat-resistant one-component sealants are ready for use without any additional preparation. At room temperature, the composition seizes immediately. Hardening, sealants provide good adhesion to the surface, which completely eliminates the repeated application of the layer. The thickness of the sealed composition is from 2 to 12 millimeters.

Two-component sealant is quite rare. It is made of two parts: a polymer base and a catalyst. Combining, the elements enter into a chemical reaction and the composition hardens.In terms of functionality, it is in no way inferior to its one-component counterpart, but in terms of its application it has some difficulties: it must be fully used immediately after preparation. Within a few hours, it retains its properties, and then hardens and deteriorates.

According to the composition and method of application, heat-resistant sealants are divided into types. The most common of them are thiokol, sealants, pastes, sealants, gaskets, silicone, silicate (kiln), adhesive sealants and hybrid. Each type of sealant has special characteristics, has several advantages.

Thiokol high temperature sealant is one of the most durable sealants based on oligomers. It is resistant to solvents, oils and acids, non-flammable, oil-resistant, therefore it is used in gas stations and fuel stations. Due to its additional water and gas-proof properties, it is considered to be a universal means of waterproofing in the implementation of outdoor work. Thiokol sealants withstand temperatures from - 500 to +1300 degrees, keeping all their working qualities unchanged.

Heat-resistant silicate sealants-pastes of a heat-resistant group are used as a connecting element during installation and filling of joints and cracks in structures. They contain sodium silicate in their composition, which ensures their black color. The main scope of their application is directly related to the effects of fire. They are able to withstand maximum temperatures: +1000, +1200 and even +1500 degrees Celsius. Therefore, they are used directly in the furnaces and internal surfaces of fireplaces and stoves. Among their features is instability to deformation and movements. Such pastes have good thermal conductivity, but they are not recommended for outdoor use.

High-temperature sealants-gaskets are used in pump engineering, in carrying out repair work on an automobile, compressors — in a word, wherever deformation occurs and there is movement. The thickness of the gaskets is only six millimeters, but they perfectly withstand any mechanical stress, have increased strength and stability. The composition has a high heat resistance.

Silicone sealants are the most common universal type of high-quality sealant. Its working temperature range is from +300 to + 600 degrees Celsius. They are flexible and easy to apply. Silicone sealants are not painted, so the product line of this product has ready-made colors. While hardening, silicone sealants form a single unit with the surface. They are not re-applied, otherwise it is possible to nullify all the work and re-seal.

Silicone compounds are not used to fill deep surface crevices. The composition for vulcanization requires a special environment with high humidity, and it does not penetrate deep into the seams. The speed of hardening of the sealant depends on the external temperature: the higher it is, the faster the process.

Silicone sealants contain synthetic polymers and are of two types: acidic and neutral. Acidic high temperature sealant is applied as usual, but its feature is that during the oxidation process it releases acetic acid.

Narrow specialization of this type of sealant does not allow its use in combination with natural materials: stone, wood, iron and cement.In contact, it interacts and destroys the surfaces of structures on a natural basis. In this case, leaching or rust areas are formed.

Neutral sealant contains heat-resistant silicone without solvent. It has no aggressive substances in its composition, it is easy to use and, when interacting with various materials, it only releases water and butyl alcohol. The neutral ones include sodium silicate-based sealing compounds, so-called silicate (kiln) sealants.

Synthetic polymers included in the composition provide high thermal stability, which allows their use at temperatures of +1200 degrees, for a short time - up to +1500 degrees Celsius.

The area of their use is areas and surfaces that are in contact with fire. Silicate sealants seal up joints and defects in the heating system, boilers, hot water pipes, electric and gas stoves, fireplaces, chimneys. They are used as a cushioning material. These modern, innovative formulations completely eliminate asbestos from use. In contrast, they are safe and do not contain carcinogens.Absolute adhesion to the surface completely eliminates heat loss and all sorts of fuel leakage.

Unlike silicone, silicate sealants are afraid of vibrations. After their application any movements and fluctuations are undesirable. Otherwise, a depressurization of the system may occur.

Glue-sealant also belongs to sealing drugs. It also belongs to the group of synthetic polymers and, in addition to its sealing properties, has good adhesive qualities.

For repair and maintenance of furnace equipment and chimney, the adhesive composition is used to seal the foundations. It does not enter into chemical reactions with salts and acids, does not depend on environmental conditions, is oil-resistant, water-resistant and therefore can be used to repair gas heating systems, as well as water supply and drainage systems.

Hybrid sealants based on isocyanates and solvents are very relevant today. They withstand temperatures up to +1200 degrees. The main component of such sealants - MS-polymer is a polyester compound (polyurethane), which, in combination with the elements of the silicon group, reacts oxidation and creates some kind of organic cell, vulcanizing the polymer.The composition acquires intumescent properties and freezes.

These compounds are very resistant to precipitation, light and heat. Due to their resistance to alkalis and acids, they are indispensable in the chemical industry.

Self-made sealants are obtained by adding the necessary elements to the base to give the composition the necessary properties and qualities. For example, if fungicides are added to the sealant, then this product acquires the properties of anti-mildew. The structure treated with this composition, in addition to heat-resistant qualities, also acquires moisture-resistant.

Sealants are traditionally produced in vacuum packages-tubes with tips of 300-310 ml each. Packing of this type of product may differ slightly from each other in size and price. Special mounting guns are available to facilitate the extrusion of the composition. It is convenient to fill them with seams and cracks during the repair and installation of stoves, chimneys, fireplaces and other structures. The seams are smooth and neat. Consumption composition depends on the properties of the treated surface. Also commercially available thermo hermetic in tubes of 100 g, which are used on a small scale.

Colors

Silicone formulations are available in tubes with ready-made color solutions, since this type of formulations cannot be painted. The scope of their appointment varies from household to professional. The final color they take after drying the layer.

High-temperature sealants, in fact, white, but acquire a particular shade depending on the characteristics of its content. So, red color means that the main ingredient of the sealing compound is acetic acid.

Acidic acetic acid silicone sealants are distinguished by all shades of this palette: from brown to pink. The presence of special ingredients dictates the scope of each of them. For example, the high-temperature silicone sealant “Moment Germent”, which has a red-brown color, is used to join and seal iron surfaces.

Red sealants are used to replace various gaskets., gearbox, manifold, oil pumps and so on. Due to their high adhesion and strength, they successfully withstand deformations and are resistant to temperature shocks.The six-millimeter gasket formed by the sealant can withstand up to +400 degrees Celsius. The sealant from the heat-resistant group incorporates sodium silicate, which determines its black color.

Silicate sealants contain iron oxide, which gives them a gray color. Copper formulations have a distinctive reddish tint. High temperature transparent colorless silicone has good elastic properties. It cures well, forming a solid, rapidly hardening mass-sealant. The composition withstands high temperatures, has high technical characteristics, including excellent adhesion with smooth surfaces.

The scope of its application is different: from sealing heat transfer devices to sealing glass joints of a car. Colorless sealants are used in optical devices. They glue the glass and metal surfaces, as well as plastic and rubber. Sealants quickly set at room temperature, used without additional gaskets. Completely hardened in a day after application.

Manufacturers

Today, manufacturers of high-temperature compounds represent an extensive selection of sealants. Each type of this product has its own characteristics and advantages, which allows them to be used in industry, construction and in everyday life.

- Estonian products are in high demand among consumers. brand penosil. Among the advantages of this manufacturer is ease of use, as well as a good balance of price and quality of this type of high-temperature sealing means.

- Among the leaders of manufacturers of this type of product is also the Belgian Soudal company. High-temperature compositions of this brand are characterized by high indicators of quality, parameter of operation and shelf life. Prices for products of this group of this manufacturer in the market are somewhat higher than its analogues.

- Among the brands of domestic products - innovative development "Siloterm", created specifically for fire protection of metal, building and other structures. This high-temperature fire-resistant coating - the paint has all the functions of fire protection, resistant to chemical attack and corrosive environments. Fire-resistant paint produced by domestic technology.Designed for use in industry, but its scope of application is much wider. This type of refractory coating can be used to protect various structures in the construction and domestic sphere. It does an excellent job with the insulation functions of gas, water, smoke and fire. Among the producers of this product - CJSC "Elox-Prom". The company is represented on the Russian market by the line of products “Siloterm” for various purposes and properties.

Some brands of this type of product are especially popular. In the number of such as "Methylan", "Macroflex" and "Tangit" is included and "Moment" with an impeccable reputation. The quality of these brands is confirmed by many large industrial enterprises that have been using their products for several decades.

A wide range of temperature resistant sealants is represented by a high quality heat resistant grade sealant. "Moment Germent"designed to protect compounds exposed to high temperatures in heating systems for the repair of automotive engines. Possesses heat resistance up to +260 degrees.

It is also used in the form of gaskets and for bonding metal structures.

Scope of application

The special properties of high-temperature sealants are widely used in industry and construction. Heat-resistant sealants are widely used in professional and domestic fields. The difference is that the compositions for the implementation of professional work have properties that can withstand higher temperatures.

High-temperature silicate sealants are used in the construction and repair of furnace equipment., for sealing smoke pipes, filling any damage, cracks and joints in concrete and other structures. They are used in electrical and installation work.

They perform a protective function and are indispensable for sealing furnace chimneys on the roof, for repairing stainless steel chimney.

For sealing stainless steel chimneys used silicone sealants with good water and thermal insulation properties.

Sealants for the exhaust manifold of a car based on sodium silicate contain clay substances, fiber optic and metal shavings.They are ceramic and are designed to protect the engine from the products of combustion. Used for installation and repair of the motor system, reducing the level of exhaust, which eliminates the penetration of toxic substances into the car body.

Composition for fixing bearings is particularly durable, designed for couplings and bolts and other equipment. Its field of application is shipbuilding, automotive and other branches of mechanical engineering.

Special types of sanitary sealants are used to seal threaded joints of plastic and metal pipes in water supply systems. In addition to heat resistance, they have properties that provide good adhesion to the bonded surface of metal and plastic. Anaerobic sealant for fixing threads has advantages over fum-tape and sanitary thread - it quickly seizes and reliably interlocks the elements: applied, attached, and can be used.

Special heat-resistant silicone sealant is used to install and seal cooking panels in domestic and industrial premises. Cooktops are gas or electric.Their metal or stainless case is provided with glass and ceramic elements, therefore the material for sealing should have adhesive properties and good thermal insulation. In industrial panels there are structures made of metal and cast iron, therefore the requirements for adhesion when sealing these surfaces are different. Using silicone sealants, they glue and fix the panels, providing maximum protection against fire and gas leaks.

When sealing the oven, it is necessary to correctly calculate the temperature of exposure. It is also necessary to take into account the factor of mechanical damage, as the ovens are subject to frequent movements, which leads to abrasion of the insulating composition and, over time, requires new sealing. In contrast, bread makers are fixed, as they say, “tightly”, and do not need frequent sealing.

Silicone temperature-resistant sealants are also used to seal, install and repair a water heating boiler, steam rooms and baths. Differences mixtures for glass and water - in the hydro and thermal insulation of aquarium surfaces and pools.

For the implementation of outdoor work, when gluing sandwich panels, waterproof types of heat sealants are used that provide moisture resistance and heat resistance.In everyday life, heat-resistant sealants are used to repair irons and kettles.

Thiocol sealants are used wherever it is necessary to eliminate exposure to chemical fluids. The scope of their application is industry. They are in demand at gas stations and fuel stations and gas stations.

Thiokol and hybrid sealants are used in the aerospace industry, in aviation and mechanical engineering. Due to the high resistance to environmental influences are widely used in the field of construction and electrical engineering. Because of its moisture permeability and adhesion, they are used during installation and repair of metal structures of roofs and ceilings.

In the industrial field, these types of sealants are used in the manufacture of railway and other types of transport that carry out road transport. Their properties significantly affect the weight of any product, facilitating it, which leads to energy savings. It also speeds up assembly and installation. Sealant replaces welding, and bolts, nuts and screw connections are simply unnecessary. This cost savings provides the main advantage of this type of sealing.This is not the whole range of use of heat-resistant sealants.

How long does it dry?

High temperature sealants dry out differently after application. Some species take 24 hours to dry completely. It all depends on certain properties and types of compositions. Some freeze in a few minutes, others need more time to grip. The quality of the bonded surface as well as the ambient temperature are also important factors in the drying speed.

Each sealant tube is provided with detailed instructions indicating the time of complete drying. For successful application, it is important to follow instructions carefully.

In the next video you will find a presentation of heat-resistant Penosil sealants.