The advantages of priming walls: types of soil and features of its use

No repairs can be done without the process of priming the walls. The primer is one of the components of the preparatory part of the repair or construction work. It depends on it how well the finishing coatings will form.

Purpose

Primer material is a composition having an ancient origin. He appeared about 2 thousand years ago in Egypt. Previously, it was used to process sarcophagi, so that they remain in good condition for many millennia. And the Egyptians succeeded - the sarcophagi were really well preserved when using such material.

After the secret to preserving the durability of materials was discovered, the primer began to be applied in many other areas - even artists specializing in wall painting became interested in it. For example, in ancient Rome, artists used to create frescoes and other images, as well as to preserve their integrity, using a primer with marble chips incorporated into it.

Representatives of each country created more and more new primer recipes, including a variety of compositions. For example, Tibetan experts used glue and milky vodka with this mixture. Domestic artists also used this material in the field of painting. He was especially popular among icon painters - for the first time, they created, on the basis of the primer's composition, specialized mixtures designed to cover the boards with them before applying drawings to them.

Also earlier in the primer included linseed oil and oil. Some masters added there whitewash. Only after the ideal composition was created, it was widely used in the construction industry: domes were treated with primer during the construction of churches.

But modern specialists, who are professionals in the field of construction and decoration, were able to adopt the methods of manufacturing and using this building material. Currently it is used to prepare walls for painting or for applying other coatings.

Many have noticed that if you paint on the raw wall, you can only draw attention to all its flaws, roughness and irregularities.But if you treat the surface with a primer, as noted earlier, the painted wall later became better and more attractive. Then they began to use it before applying other topcoats.

That is why Currently, the primer is an integral element of construction and finishing works. Many even create such material on their own at home from the ingredients at hand.

Soil for walls is a building material that is required for any decoration. It allows you to transform not only the decorative quality of the room in which it is used, but also improves the operating conditions of any coatings.

The primer determines how professional the repair will be. It depends on its composition and quality of carrying how long the finishing material will last.

Features of this composition:

- Each type of polymer used for finishing requires the use of certain protective compounds. Primer performs the function of adhesion, protection and insulation.

- It is a building material that is used in the initial stages of finishing.

- Allows you to perfectly align the surface and make the coating more decorative.

- It creates additional warming, as it affects the sealing of the room.

- It plays the role of a binder of building material, which well connects insulation and finishing material, due to which the quality of both of them improves.

- Allows you to combine plaster and putty in the repair process - thanks to it, many incompatible finishing materials are combined.

- Protects surfaces from many mechanical influences and strengthens them.

- Many formulations in which manufacturers add special ingredients have bactericidal properties. Thus, this coating prevents the spread of fungus and the appearance of mold, as well as other bacterial effects on the decorative coating.

- Many primers also have a moisture resistance quality - thus they prevent the floors and walls from penetrating deep into the moisture. Each composition performs certain functions and is necessary for a specific result.

- Manufacturers also represent compositions that differ in their elements.That is why the specific purpose of the primer determines its appearance, as well as the basis on which it is applied.

- Can protect surfaces from corrosion if working with metal.

- Material protects against rotting wood surfaces. Thus, regardless of which primer to choose, it will fulfill its protective function and improve the operating conditions of a particular material.

- Reducing the possibility of formation of cracks on the coating, as well as the exfoliation of the top finishing materials.

- If you paint the walls, the primer will prevent it from shedding and peeling.

- When installing the tile primer will not allow it to disperse, and subsequently will not have to restore the surface.

- Due to its properties, the wallpaper does not spoil and does not stick off.

Benefits of priming

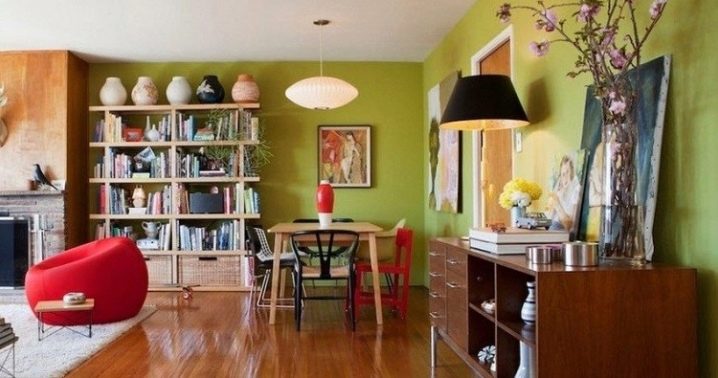

The many advantages of priming the surface are noted by those who are going to use paint as a decorative coating.

- First of all, a big advantage is the reduction of paint consumption due to the use of soil. On average, it is used about one and a half times less than this finishing material than it would have spent without soil.

- The primer allows to apply any paintwork material with higher quality. It fits well on the surface not only of the walls, but also of the ceiling or floor. In addition, the paint adheres well to the surface and does not split off.

- A great advantage of a primer during painting is also the fact that it allows to ensure a uniform painting of surfaces. In the process of applying finishing finishing material on the walls there will be no gaps, the color will be as smooth and uniform as possible, the coating will look monolithic. The primer protects the walls covered with paint from cracking. Thus, a person will not have to do additional repairs to eliminate them.

- The primer makes painted surfaces smoother and more uniform. In addition, the applied primer changes the odor that appears during the dyeing process to less harsh. Thus, the premises can be quickly returned to the residential destination.

If you plan to apply glossy paint, the primer will provide them with a brighter and more luxurious shine.

- Another advantage of this building material is that it prevents stains on many coatings, including paint.After all, it is often because of the incompatibility of the paintwork and the base spots are formed on the surface. Primer completely eliminates this problem.

- An important advantage of the primer is that it simplifies the possibility of repainting the walls. For example, if you need to repaint the surface from a dark to a lighter shade, in some cases you will have to dismantle. And thanks to the use of a primer, old coatings will not have to be removed - you can only apply a layer of soil and paint the walls again with the required color. Therefore, we can conclude that the primer several times simplifies and speeds up repairs.

The advantages of the primer can be assessed not only when using paint as a veneering material.

- If there is rust on the walls of wet rooms, then the primer modifies it into a protective layer.

- Good primer blends allow you to create waterproof film on any surface, thereby preventing the walls from getting wet.

- If you plan to use wallpaper as a decorative coating, then the primer will also ensure the uniformity of their gluing.They will not move away, and with such a finish the joints will become less noticeable.

- If a tile is used for finishing, the primer adheres it to the surface of the walls or the floor much better. Thus, it will not break away and crumble, because it is a rather heavy finishing material that not every adhesive will hold.

- The primer can increase the adhesion and adhesive properties of any material.

- The soil strengthens the microparticles of bonded surfaces.

- The material does not collect dust on itself and, thus, provides a perfectly smooth base on which any glue and finishing materials, including paint, can be applied.

- There are compounds that are deeply absorbed and fill the micropores of any material due to the fine particles that make up their composition. Thus, the advantage of these compositions can be considered the fact that they strengthen any working surface with the help of special impregnation - special liquid compositions.

- Thicker formulations usually have a white tint, are not absorbed, but, on the contrary, create a flat surface on which dirt forms. Primer aligns the walls.Its big advantage is that all materials are better placed on it.

- Another advantage is the universality of the soil as a finishing material. It must be used when finishing floors, walls, ceilings, metal structures, if you plan to plaster or putty them. Any materials for painting and tile laying surfaces are suitable for it. It is necessary for almost all finishing work.

- Primer also provide masking functions. If there are stains or other visual defects on the walls, then it allows them to be hidden in such a way that such defects do not affect the external surface.

- The primer also saves glue consumption during the finishing process - it does not allow this compound to be absorbed into the base surface, and thus, the fixing and adhesion of the finishing material is improved.

- The material does not allow the surface to collapse and mold. Many compounds protect walls well from moisture, which can adversely affect the foundations.

Types and properties

Each type of primer has its own properties, which depend on its composition. Below are some varieties of primers.

- Acrylic Primer. This composition has a water-based basis. It is suitable for many surfaces, including brick, concrete, plywood, foam blocks, plaster, drywall. Acrylic primer is easy to use - almost everyone can apply such a mixture. In addition, it almost does not emit odor in the application process and dries in no more than 4 hours. Acrylic compositions are both surface, that is, protective, and soils of deep penetration.

- Alkyd Primer. This type of soil is most often used for the preparation of wooden substrates for painting. As a rule, this type of soil dries up to 16 hours. It allows loosening wood and improve adhesion between the paint layer and the wooden surface. The paint on an alkyd primer lasts several times longer than without it. Alkyd primers are also often used to treat iron surfaces. But they are absolutely not adapted for the finishing of mineral bases.

- Epoxy or polyurethane primer. Externally, this primer resembles a paint, in the process of using it is diluted with a solvent.Usually, the manufacturer presents its own recipe for the preparation of this composition and offers separately to purchase a suitable solvent. As a rule, polyurethane primers are usually used for treating concrete substrates.

They are ideal for subsequent application to the surface of enamel paints.

- Polystyrene primer. These compounds are used to treat plastered and smooth wooden surfaces. But they are usually used for outdoor work, as they are considered toxic and release harmful substances during the drying process.

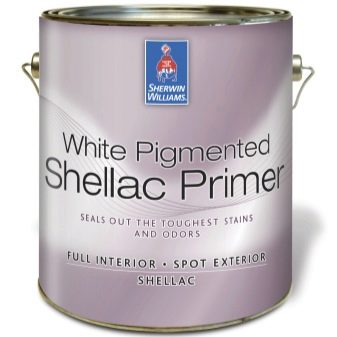

- Shellacous. This type of soil is used in the processing of coniferous wood cuts, as well as to cover the cut knots. This primer prevents the release of tar. It is ideally combined with water-soluble stain.

Specialty Soils for Metal

This type of primer is of several types:

- insulating;

- tread;

- phosphating.

In the composition of the insulating soil are zinc white, and iron oxide.They do not undergo a chemical reaction when interacting with the metal and protect it from moisture penetration, creating a mechanical protective layer.

Among the insulating soils, manufacturers also represent glyptal and phenol-formaldehyde compounds. Such mixtures dry much longer. Sometimes the period of complete drying is about two days.

Protective and passivating primer for metal is much more reliable than insulating, so its cost is several times higher. These soils are used only to cover ferrous and non-ferrous metals. Most of the composition is zinc. That is why they can be used even in the most aggressive environmental conditions.

Phosphating primer for metal increases the level of adhesion of metal and paint. However, it fights with the formation of rust. Soil has a special technology of preparation.

Before using it, the manufacturer recommends the use of an acid diluent. Phosphate primer is applied in several layers. As a rule, subsequently it is painted only with permanent enamel paints.

Also, all priming mixtures are divided into types according to theirpurpose:

- anti-corrosion;

- waterproofing;

- moisture resistant;

- quick-drying;

- electrically conductive;

- frost-resistant;

- deep penetrating;

- firming;

- harboring;

- silicone;

- silicate;

- latex;

- specialized;

- magnetic;

- concrete contact and many others.

For interior work

Primer for interior work performs one important function - it increases the adhesion of the base with other finishing materials. As a rule, acrylic soils are mainly used for interior decoration. They can also include in their composition, in addition to acrylic, also latex.

Each such composition for interior decoration has a basis in the form of a water dispersion, a film former, components that accelerate drying, pigments, as well as other auxiliary components.

Manufacturers can add special substances in order to improve the functional characteristics of the compositions for interior decoration. For example, if you finish the bathroom or kitchen, as well as other wet rooms, then the important point will be the acquisition of a model with fungicidal and water-repellent components.

As a rule, there are no organic solvents in the composition of mixtures for interior decoration - that is why they do not have an unpleasant smell. In addition, the compositions for the interior can dry much faster than coatings for facades.

For exterior finish

In this case, usually use specialized compositions intended for outdoor use. They include solvents and differ in some properties.

These are mainly coatings that increase the durability of surfaces. They are excellent for application to concrete, plaster and brick.

Weatherproof primers are used for exterior finishes. They are well tolerated by the effects of any precipitation and temperature changes. They can be used even in the most aggressive conditions, including at low temperatures. In addition, this ground is not afraid of exposure to direct solar people. It is also worth noting that mixtures do not spoil from a large number of defrost and freeze cycles.

Primer mixtures intended for exterior use, have in their composition a higher content of film former and adhesive components.This is due to the peculiarities of their operating conditions, which imply the need for a more reliable strengthening of the base.

Universal

This type of primer is characterized by the fact that it is compatible with almost any type of base and coating. Its main purpose is to protect against dust and bond two surfaces. As a rule, a universal primer is presented in the form of deep penetration compounds.

This type of primer is made on the basis of alkyd or epoxy resins in the form of an aqueous solution. It permeates the walls and increases the grip.

Manufacturers

Today, the primer from the brand is especially popular. Lacra. These are anti-corrosion water-dispersion formulations, as well as specialized primers from this brand. Customer reviews show that the latter are well suited for structural, textured and decorative plaster. Among the brand primers "Tex" buyers like most universal impregnating mixtures, as well as waterproofing latex compounds.

Brand brands Volma Volma-Interior and Volma-Universal are popular compositions.They are characterized by excellent value for money and good adhesion.

Scope of application

Primer is needed for any reason in the room for interior decoration. It is ideal for wet rooms. In terms of their application, primer compositions are divided into several groups.

Primer for mineral surfaces

This composition is used to cover bricks, cinder block, concrete, aerated concrete, plaster, as well as other materials that are the foundation of walls and ceilings. In this case, use a deep penetration primer. It impregnates the base with the highest quality. Thus, the polymer components of building materials are well connected with the structural elements of the base.

The surface to be treated remains porous. That is why the soil penetrates much better into the mineral composition, and the finishing finish is better placed on the material. In addition, deep-penetration impregnating mixtures often contain fungicidal additives that protect walls and other surfaces from fungus and mold.

But if the mineral surface is too loose and it has large pores, then their strength arises in doubt. In this case, reinforcing primers are usually used.Their composition includes adhesives that penetrate into wide pores and fill them, thereby strengthening the spatter surface. But in this case the consumption of this type of primer mixture increases.

Strengthening compounds are most often used in the decoration of the walls of old buildings, which consist of poor-quality plaster. But even such protective materials will not save the crumbling material.

Anti-alkaline primer

It is used only if it is planned to apply organic paints on mineral bases, and the surfaces contain alkali in their composition. Typically, this mixture is used in the processing of concrete, cement screed, as well as surfaces that have been treated with fire protection equipment.

Primer concrete contact

With its help, treated hard surfaces, characterized by smoothness. It is excellent for finishing concrete slabs, plasterboard foundations, as well as walls and other surfaces that were previously painted with oil paint. The composition of concrete-contact primer mix according to GOST includes sand and cementing elements.Thus, due to its composition, the surface becomes rougher and its adhesive properties are improved.

It is no secret that on a smooth surface putty, plaster, and ceramic tile falls bad. It is thanks to concrete contact that you can use all these materials instead of specialized compounds for the finishing of any bases.

Wood primers

Wood processing requires some subtleties, including the use of certain primer mixtures. All of them allow you to protect wooden bases from rotting, fungus, algae, mosses, as well as from the effects of some insects and rodents. As a rule, primers are used for this, including antiseptic, fungicidal, pesticidal, insecticidal and other types of soil.

This type of impregnation is applied on wooden surfaces in several layers. Conventional types of primers are applied to wooden surfaces before painting. They allow you to make the surface smoother and remove some irregularities and roughness.

There are also wood blends that, on the contrary, make the base more embossed.But in both cases, the paint on the tree falls much better and smoother, it is less absorbed into the surface and, thus, the number of applied layers will be less, as is the flow of funds.

Special primer mixtures are also used for the treatment of coniferous wood. They perform a de-oiling function, qualitatively preparing surfaces. But after using such a primer, it is necessary to additionally process wooden surfaces with tools in order to completely remove all the resins.

Priming mixtures for metal surfaces

If the work is done with metal, then there is always a problem - its corrosion. This is especially true of ferrous metals, where rust traces are most noticeable. In this case, the primer is a necessary element of the finish. As a rule, rust converters are chosen for the mixture and then the surfaces are machined.

After that, the metal surfaces are again treated with other types of primer. Thus, you can restore the original appearance of any metal surface and make it more presentable.That is why manufacturers represent individual mixtures intended for both ferrous and non-ferrous metals. Many of them include phosphoric acid, which protects them from rust.

Priming mixes for other surfaces

Since the purpose of the primer is very wide, it is used for painting many materials. After all, paint and varnish compositions do not always fit well on the surface, in some cases, even corrode finishing materials. This is especially true of coatings such as tiles, glass, plastic surfaces. In this case, manufacturers recommend the use of compounds with a high level of adhesion.

Also for many such surfaces, a primer is used, the main purpose of which is to block the appearance of stains and other manifestations, such as grease or soot. Thus, it reliably masks all these defects and does not allow them to manifest themselves even after a long time.

How to choose?

Since the primer affects the microrelief of the surface, it is selected depending on the materials being fastened. For wood, metal, plaster and other materials choose different types of primer.It is important to consider the purpose of the composition, which is often indicated on the packaging.

It is believed that The most versatile is the acrylic primer. It is the most popular and is often used for home use. It is suitable for almost all materials, with the exception of metal. Acrylic formulations simplify work and penetrate the material to a depth of 1 cm.

If the bases on which it is planned to apply the primer are made of wood, as well as when using fiberglass, tile, PVC, or any type of tile, then it is better to give preference to the alkyd primer composition. It holds these finishing materials better.

If there is a finishing of metal surfaces, then for them it is necessary to acquire only specialized types of soil. Conventional primer formulations of a universal type will not work for this.

If concrete is processed during repair, then it is necessary to pay attention to the penetrating ability of the mixture. This is especially true when self-leveling compounds are used for finishing.

When choosing a soil for wood or gypsum, experts recommend paying attention to its water repellent properties.These materials are capable of being destroyed by moisture, they quickly lose their quality characteristics and presentability - that is why It is important to use water repellents that create a protective film.

Special attention is paid to the processing of smooth surfaces, because any, even the most securely fixed finishing materials, quickly fall away from them. When purchasing a primer for smooth surfaces, it is better to look at products with special additives, for example, quartz sand. They keep the finishing material and make the surface is not so smooth.

The primer is also chosen depending on the condition of the surface. If the walls are in a positive state and no additional reinforcement is required, then reinforcing soil can be used for the treatment. It allows you to remove dust from the surface and fix the finishing layer well. In addition, this composition forms a protective film.

If additional strengthening of walls is required, then it is recommended to acquire a primer of deep penetration. It permeates the walls to a layer of up to 10 cm, which cannot be said about the reinforcing type of soil.But this composition has a rather high cost, so it should be used only in case of emergency.

If paints and varnishes are used for finishing, the primer should be chosen depending on its type and the components included in its composition. For example, water-dispersion paint requires the use of water-soluble acrylic primers, and if oil paints are used, it is better to buy the same type of soil - thus you can increase the adhesion of the surface.

When choosing, it is also necessary to take into account the amount of primer in advance, so that it is enough to cover the walls. If the materials are porous, then it will take several times more soil, because in order to increase the adhesion of these materials, it is necessary to cover the walls with several layers of soil.

For a medium-porous surface, a universal primer is ideal, as it lays well on the surface and is consumed in moderate quantities. When buying a primer is recommended to study the instructions for use of this building material, as well as its specific purpose.All manufacturers indicate on the label with the soil the components included in its composition, as well as detailed instructions for applying it. It is also better to look at the part of the characteristics on the label that describes its compatibility with a particular material.

When choosing, it is also recommended to pay attention to the primer density. If the soil is thick, it will not be able to penetrate deep into the walls. But such compositions have a good level of sealing. In addition, when buying a thick primer easier to calculate its consumption.

If you need to save on the purchase of soil, you can purchase this composition in a dry bulk form. But because of its consistency, you will have to prepare the composition yourself at home. But in bulk form the composition will be stored for quite a long time, and it costs much less than ready-made mixtures. Basically, such compositions are sold in large bags, and even in this volume they are cheaper than ready-made primer mixtures.

If you need to protect the surface as much as possible during finishing, then it is better to acquire both a thick and liquid primer. Thus, it is possible to ensure the strengthening of the base, and then, waiting for it to dry out, you should apply a thick type of overlap to level the surface.

If you want to buy primer mixtures for painting, then you should pay attention to the compositions of the shade, similar to paint. They should be closest in color, not in exact shade. Some surfaces require additional waterproofing - for this it is better to buy a bituminous primer.

Also, a passivating primer can protect against the harmful effects of water. Especially it concerns those cases when with its help it is planned to process metal surfaces. To protect the base from electrolyte, it is better to use a tread compound. When buying should take into account all factors. In addition to the type of base and finishing material, it is necessary to take into account the operating conditions, as well as the age of the base material.

It is recommended to weigh all the advantages and disadvantages of each type of primer in order to determine which one is the most suitable, because the durability of the repair will depend on the quality of the primer.

Application Tips

Before applying the primer to prepare and acquire all the tools and materials. In addition, it is important to comply with all safety requirements.First of all, it is recommended to protect the eyes with the help of special building glasses, and hands - with the help of gloves.

You should ensure that there are no allergic reactions to the components of the primer and all its components. Otherwise, it is better to abandon self-finishing and resort to the help of specialists. When applying the primer should try to avoid it falling on the body. This rule is due to the fact that it will be rather difficult to wash it off yourself without using specialized tools.

In order to thoroughly prime the walls, it is necessary to acquire the following tools:

- tassel;

- roller on a long handle;

- sandpaper with fine grain or grinding machine;

- spatula;

- scraper;

- putty;

- bath for primer;

- chemical wash;

- protective elements (glasses, gloves).

Of course, it is also necessary to purchase a primer suitable for finishing work.

Even an inexperienced builder, who first encountered this, can cope with wall priming. Before proceeding to this process, you need to thoroughly clean the surface from dirt, dust and debris.If there are cracks on the surface, then they need to be cleaned with sandpaper and putty. In no case should the so-called breathing areas be left on the walls.

If the primer is applied to wooden surfaces, then you need to get rid of all the roughness and irregularities. All rusty areas are cut from metal surfaces.

Before priming, first of all, it is necessary to polish the working surfaces. To do this, it is better to use a grinding machine or sandpaper. But the original surface is cleaned from old finishing materials, such as paint, wallpaper, as well as a layer of rust. Spools, if any, are removed from the surfaces. You can use a scraper or trowel, as well as a scraper.

If there are irregularities on the walls with a thickness of no more than 2 cm, then it is necessary to use a putty or a primer with a thick texture to align them. Thus, coatings in the form of a primer can be applied only after a week, when the previous finishing layer dries out completely.

To use the primer can go in the case when the old coating will be completely polished.

Ready primer composition must be poured into a special jar to the desired level. Do not pour the full capacity, otherwise there will be a chance to spill it. Stir the mixture thoroughly before priming, even if it appears homogeneous. In this container, you should evenly moisten the brush or roller so that the soft elements of the tools are well soaked.

It is important to evenly distribute the primer over the entire surface - do not leave gaps. The roller should be slowly and carefully rolled over the entire surface in order to completely saturate it with a primer. It will be noticeable how it is saturated with soil. That is why the priming process must be thorough and accurate. This procedure will take quite a lot of time.

Work usually starts from the window of the room. It is better to divide the room into areas of approximately one and a half square meters and apply the mixture in stages.

To apply the primer, you can use the spray gun - it allows you to paint the walls more evenly and leave no gaps. But not everyone can handle such a tool. In addition, if it is decided to use the spray gun, it is recommended to wear a respirator on the face, since the composition will saturate the air.

Particular attention should be paid to the joints of the walls, as well as the surfaces around the batteries and other difficult areas. The primer is usually applied in several layers. The exact amount depends on the friability of the base. If it consists of no foam concrete, then it must be covered with soil at least three times - only after that a reliable film is formed on it, which improves adhesion.

Each applied layer must be completely dried before applying the next one. It is enough to dry the first layer within an hour until the wall absorbs moisture. Then you can proceed to applying the next layer. But if the moisture absorption at the surface is bad, then you need to wait a little longer.

The final drying time of the primer depends on the temperature conditions in the room. If the room is colder and the air humidity is higher, then the primer will dry much longer than in normal conditions. If the air temperature is below 10 degrees, then it will take about four days to dry the primer. But if the indoor temperature is about 20-25 degrees, then the primer will dry out in less than a day. After the primer is dry, it is important to quickly proceed to applying decorative coatings.

If it is necessary to prime the walls before applying the plaster, then it is better to use a concrete contact primer - it protects the surfaces from dampness and moisture and better impregnates concrete walls. For fine surfaces, it is better to use a polyurethane or epoxy primer mixture. They are able to level and strengthen practically any standard basic basis.

Storage conditions

The primer must be stored in a tightly closed container. Moreover, it is necessary to place it in a dark and not too wet room, excluding direct sunlight on the container with the composition. It is necessary to provide good ventilation in order to prolong the shelf life of this material. Its location is not allowed near sources of open fire, as well as heating appliances. It is better to exclude the presence of a number of operating electrical equipment.

It is important to pay attention to the shelf life of such a composition. If suddenly the primer is expired, then it must be replaced with a new one. Otherwise, this may lead to delamination of the material and lowering its properties. The primer is best kept at standard room temperature.If you place it in an unheated room, then large lumps will appear in it and the composition will become not so uniform, which will affect the quality of the finish of many surfaces.

An untight composition will be subject to the formation of a thick film on the surface and damage, therefore it is important to close the composition tightly with a single use of the mixture.

Most manufacturers specify a shelf life of 12 months. But subject to the necessary rules and conditions of storage, the period may be extended for another six months.

If the soil has not been used for a long time, then it can stagnate and become a little thicker. In order to avoid difficulties during application, it is recommended to bring it to the desired consistency with solvents.

From the following video you will learn all about primers and priming.