Primer for concrete: types and characteristics

Before starting to finish the concrete surface it is necessary to apply a primer composition to the concrete. Primer - an important building material that improves the adhesion of the finishing coating to concrete, the structure of the structure, reducing the consumption of the applied compositions. In the modern building materials market there are many varieties of such products, it has very different characteristics. If you take into account the technology of application and the rules for choosing primers, the work will be carried out quickly and efficiently.

Features and benefits

Primer composition for concrete - a versatile material. It includes modifiers, polymers and substances that destroy toxic microorganisms or prevent their development. Acrylic and latex are the main components of such a material.

Deep penetration mortars allow you to:

- improve the adhesion of the concrete base and coating;

- make the most effective use of finishing material;

- prevent mold and fungi;

- eliminate surface defects.

Deep penetration primer for concrete is a popular material for consumers, with an affordable price and many advantages. Such material is in demand among beginners and professional builders, it is suitable for both internal and external works.

The main advantages of this coating:

- improves grip;

- minimizes the consumption of finishing materials;

- penetrates the base and makes the surface more durable;

- slows the evaporation of moisture;

- circulates the air flow;

- absorbs dust;

- eliminates microcracks;

- does not have an unpleasant odor;

- has antiseptic properties;

- different acceptable price.

Such materials can be used for surfaces with different porosities. They expand small pores, large - narrow. Such coatings are easy to use.

What is it for?

Concrete is a very durable building material, characterized by a long service life, but it is not resistant to external influences.

Such surface easily collapses under the influence of wind, moisture, vibrations:

- frozen water in the pores will lead to stratification of the material and the appearance of cracks;

- the iron frame under the influence of water and salts will be covered with corrosive deposits and will begin to break down;

- fragile top layer of the concrete floor during the destruction of the dust forms harmful to human health.

Cracks, chips, mold and fungi will appear on the untreated surface of the concrete structure.

To protect the surface will help primer solutions that have the necessary properties and perform very important functions:

- polishing and filling all cracks and pores in the rough concrete surface;

- binding of all dust particles and minimizing contamination;

- improved adhesion between the wall and the material;

- increase the period of operation of the structure;

- increasing the strength of a concrete structure with a porous and free-flowing structure;

- compaction of the top layer of concrete and increase of resistance to mechanical loads;

- protection from the negative effects of external factors (rain, wind, vibrations, and so on);

- minimization of consumption of paints and coating solutions;

- reduction in the percentage of surface drying.

In modern construction, lightweight cellular concrete - aerated concrete has found wide application. Such building material consists of cement, water solution, lime, quartz sand and additives (crumb from aluminum).

The gas block has many advantages:

- strength;

- ease;

- refractoriness;

- thermal insulation;

- low price;

- environmental Safety;

- wide range of.

This material has many positive qualities, but it is necessary to highlight and drawbacks:

- susceptibility to moisture and hygroscopicity (before laying finishing materials it is necessary to provide high-quality waterproofing, so you can avoid problems in the future);

- insufficient resistance to mechanical damage.

To reduce vapor permeability under the plaster it is necessary to apply a deep penetration primer. Then you need to paint the surface.

Types and characteristics

Manufacturers produce several types of primers for mineral surfaces, differing from each other in composition and quality characteristics.

- Polystyrene. Suitable for technical premises and facade work. The composition of such materials includes a toxic solvent. This coating improves adhesion between the surface and specific paints.

- Polyurethane - waterproofing, frost-resistant polymer primer. Used for industrial facilities.

- Polyvinyl acetate - dries quickly (approximately 60 minutes). This significantly reduces the time of work.

- Epoxy resin primer - water-repellent mixture, used for self-leveling floors, tiles, paint and metal work. Increases the strength of the base, has a pungent odor, diluted with a special solvent. At the time of the work it is necessary to remove flowers and animals from the room.

- Alkyd - colored primer, suitable for interior work. Provides protection of facades of buildings. Drying time - up to 20 hours. Such material is used for processing wooden surfaces, not applicable for metal.

- Acrylic - a demanded type of finishing materials for works in rooms. Basis - acrylic and polymer components. Advantages - the lack of odor, sharp and harmful to human health.

This coating reliably protects the structure, it is quickly applied and dries in the shortest possible time. This material has an affordable price. The disadvantages of such a primer for painting - not suitable for outdoor use, is incompatible with polyurethane coloring compounds.

- Zinc - can be primed metal surfaces, protects against corrosion. The main component is zinc.

- Soil enamel - consists of a paintwork material and a special primer composition. The components of the system form a uniform coating with high adhesive properties and excellent performance characteristics.

- Deep penetration primer - suitable for different types of concrete. Ideal option for porous foam concrete. Advantages - the ability to use for surfaces with high porosity, penetrates 10 mm inside the base. Significantly improves adhesion. Particles of synthetic latex are transformed into glue under the influence of a special solvent. They penetrate into the depth of the porous surface and increase its density.

- Impregnating - well suited for loose surfaces. Such coatings strengthen the upper layer of the base. The components of the primer penetrate the surface and solidify at a depth of 5 cm, fill the pores and microcracks, increasing the strength of the structure.

Priming compositions are divided into different types in accordance with the place of work.

- For external use. This material strengthens the upper layer of the base and provides protection from the negative effects of external factors. This coating has a number of advantages: it retains surface characteristics, increases the life of the base, prevents contact with incompatible material. This material improves adhesion. It consists of antioxidants.

- For interior work. For high-quality performance of work it is required to select a material carefully, considering all its properties. Quartz sand, which is part of the mixtures - the key to a great result of work, good adhesion and wear resistance.

Depending on the type of base being processed, the following types of materials are distinguished:

- for old or new coating;

- for smooth or porous material.

According to the method of influence of the primer composition, such coatings are distinguished:

- firming;

- textured;

- insulating;

- antiseptic.

How to choose?

The main criterion when choosing a primer is the presence of an antiseptic with a broad spectrum of action, which will protect the room from toxic mold and fungi. The presence of dangerous microorganisms in the room can lead to asthma, allergies and dizziness among homeowners.

When buying a product, you must check the date of manufacture, manufacturer, markings and logos. So you can avoid buying low-quality, fake goods. Quality goods do not always have a high price.

When choosing a primer composition is necessary:

- select a solution in accordance with the type of base (primer for the gas block is suitable for porous surfaces) and the place of work;

- apply to dense concrete with a durable epoxy primer;

- take into account environmental conditions during the work (temperature, humidity), which may affect the efficiency, quality and properties of the mixture;

- take into account the level of load;

- Take into account ultraviolet radiation, temperature drops, moisture and chemical exposure to the surface.

You need to know whether the primer and the substrate are combined.It is necessary to dry the coating as much as indicated in the instructions. When choosing a suitable material, consider the chemical composition, vibration load.

Tips and recommendations for use

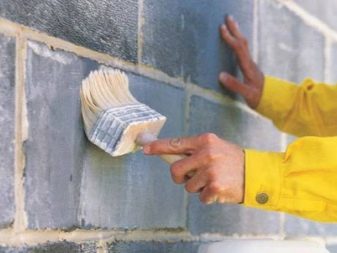

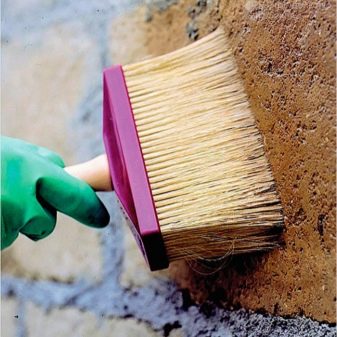

The process of applying a primer is very simple:

- clean the surface from debris, dust and other contaminants;

- remove all cracks and defects on the surface using a putty;

- apply a deep penetration primer that will strengthen damaged areas;

- grind the treated areas;

- evenly apply the primer to the concrete using brushes and rollers;

- dry the surface, if necessary - apply another layer of material;

- allow the required time to dry completely.

For a good result of finishing work it is necessary to take into account the experience and professional skills of craftsmen.

Pay attention to the following nuances:

- multiple damage to the old base indicates that priming was not carried out;

- to protect the structure from microorganisms in rooms with high humidity, it is necessary to use a primer with antiseptic properties;

- when preparing the composition, it is necessary to strictly follow the recommendations indicated by the manufacturer on the package (if there is too much material, you simply will not have time to use everything and the remains will dry out);

- before applying the primer must complete all construction work;

- Do not add a primer to the concrete solution; the task of the composition is to strengthen the surface of the structure.

Manufacturers

Among a large number of manufacturers of primers for concrete, buyers distinguish the domestic company "Betonit". This is a young company that produces dry building mixes. The assortment includes both simple and rather complex building structures. Affordable price, modern technology, quality control at all stages of production - the key to the success of this manufacturer.

Products TM "Betonit" has a number of undeniable advantages:

- profitability;

- environmental Safety;

- ease of use;

- modern packaging;

- production according to all standards and hygienic requirements.

The company uses when creating products raw materials of famous manufacturers.

She cooperates with many construction organizations and various enterprises, offering them:

- flexible discount system;

- advice and recommendations for use;

- product samples.

You can find out how to primer a concrete floor in front of a self-leveling mixture from the following video.