Criteria for choosing paint for concrete

Due to its stability, concrete is widely used in the construction and decoration of various objects. This is typical for walls as well as for floor coverings and ceilings, and can be used for interior and exterior use. The paint used in such cases varies significantly - the facade is much more resistant to aggressive environment, and the floor - to abrasion and other mechanical stress.

Special features

Considering the fact that concrete is used in almost any conditions, the effects on it, and accordingly, the requirements for the protective properties of paint, are the most extensive. To effectively cope with the tasks, the dye must have certain qualities.

It must have a strong adhesion. A strong connection to the surface is the basis for a long service life of the coating.

To increase this figure before dyeing, it is desirable to use a primer, because it not only enhances the adhesion of the dye and the surface, but also reduces its consumption.

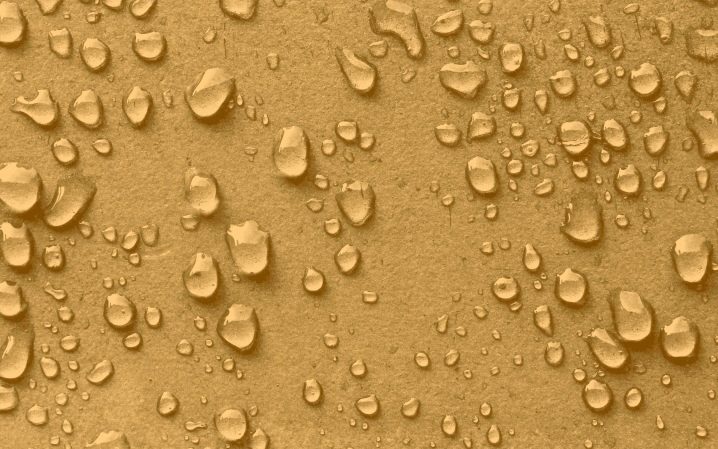

Moisture resistance is one of the important qualities. The property of concrete to soak up moisture is often inappropriate, as it contributes to damping the room. To counter this phenomenon, waterproofing additives are added to the paint to prevent water from passing through the surface layer of the coating.

Abrasion resistance should be present. The need for such quality arises when the concrete floor covering or the walls of institutions associated with human activity, for example, gyms, children's playrooms and other crowded places, are exposed to painting.

There must be resistance to sunlight. This property ensures the preservation of the original color of paint when painting facades and other objects that are directly exposed to the sun, and also helps to resist the destruction of the surface coating from the specific effect of ultraviolet radiation on the paint structure.This phenomenon is expressed in the peeling and cracking of the surface layer.

Vapor permeability is also an important indicator. The ability of the painted surface to pass the air mixture, and with it the evaporated moisture is very important for concrete, who loves to soak up the water. Despite the fact that the paint protects the finished surface from moisture, it can penetrate it from the other side. In this case, accumulated water will lead to dampening of the room and the appearance of mold fungus.

In addition, when cooled and heated, the water shrinks and expands, which leads to mechanical destruction of the concrete itself and the paint that covers it.

Also worth noting is the smoothness of the material. For the flooring, as well as for the walls of buildings facing the roadway, it is important to be painted with a substance that forms a smooth coating. In this case, the dirt and dust does not linger on the surface, becoming clogged in various folds and crevices. In addition, it is much easier to wash this coating. In general terms, this quality affects the appearance and is of secondary importance.

The rate of setting and full hardening is another distinctive feature of the coloring composition.This property is important for dyes intended for outdoor use, where a long drying period increases the chance of a freshly painted surface to be spoiled by rain. This quality also affects the overall finishing time.

Dye consumption should be minimal. Due to the fact that concrete coatings are usually used for finishing large areas, even a small difference in the consumption of interest by 10% results in a rather large amount.

It is necessary to choose the optimal ratio of price and quality. Paint properties are determined by its constituent components.

Therefore, choosing a paint, it is better to look at the composition of the brand, and not on its eminent name. If the components of the composition are equal, then there is no point in paying more.

There should also be manufacturability. In order for the finishing work to be carried out optimally, the dye must be able to be applied by any painting means: brushes, rollers, spray guns.

Color saturation should be maximized. The ability of paint to overlap the color of the base coat affects the appearance of the painted surface, which significantly affects paint consumption.Concrete in this regard is a complex material and is subjected to staining at least two times.

Types and characteristics

Concrete is amenable to painting with almost any kind of paint, however, it is not recommended to use oil paint due to its vapor-tight surface layer. Also, each type of paint has its strengths and weaknesses, so their use is appropriate under different conditions and needs. For example, silicate paints have a small choice of colors, but their resistance to atmospheric phenomena is well suited for painting unassuming street objects.

The following types of paints are represented on the paintwork market:

- epoxy;

- acrylic;

- polyurethane;

- silicate.

Epoxy

Epoxy - paint based on two main components: a dye and a hardener (epoxy resin), mixed before application. Characteristic features include the following qualities:

- it is applied to a covering of floors and ceilings, it is widely used when painting:

- garages, parking lots;

- warehouses and workshops;

- commercial premises, exhibition halls;

- refrigeration facilities;

- in the agro-industrial sector;

- easy lays down on concrete, forms a durable coating;

- high resistance to mechanical stress, abrasion;

- resistance to aggressive chemical compounds;

- good appearance;

- high waterproofing performance;

- any detergent may be used for cleaning;

- durability;

- narrow range of color performance;

- toxic and has an unpleasant odor;

- staining should be carried out in special protection and with good ventilation of the room.

Acrylic

Acrylic is paint and varnish products on a polymeric basis diluted with water. The main qualities of such dyes include the following positions:

- strong adhesion, adheres tightly to concrete at the molecular level;

- short period of setting and drying;

- resistance to mechanical stress and vibration;

- elasticity ensures no shrinkage and cracks in the finished coating;

- it can be applied to internal and front works;

- resistance to sunlight and destructive weather: snow, rain, strong wind and other phenomena;

- resistance to temperature extremes;

- high vapor permeability;

- good moisture resistance;

- resistance to alkaline compounds, easily cleaned with detergents and water;

- do not exude an unpleasant smell;

- non-toxic, paint microparticles do not cause poisoning and allergic reactions;

- paint composition is unsuitable environment for the growth of mold fungi and other microorganisms;

- a wide range of color performance, shade can be changed by the addition of tinting pigments;

- Excellent value for money and quality;

- invoice happens:

- glossy;

- matte;

- semi-matt.

Polyurethane

Polyurethane is a group of paints with four main subspecies.

On organic solvent

Her properties:

- durable wear-resistant coating, well resists all types of mechanical impact;

- powerful waterproofing properties;

- anti-corrosion effect;

- resistance to aggressive chemical compounds;

- toxicity;

- the application is complicated by the speed of curing from the contact of paint with air.

Water dispersion

Properties:

- does not exude odor;

- may be diluted with water;

- high moisture resistance and vapor permeability;

- go well on polyurethane;

- relatively low cost;

- weakly adheres to a smooth coating;

- relative to other polyurethane paints less wear-resistant and durable;

- cannot be stored at a negative temperature.

Alkyd urethane

Properties:

- White spirit is used as a solvent;

- good strength and elasticity;

- short drying period;

- affordable price;

- must be applied in a thin layer and at ambient temperature.

Two component

Properties:

- high strength and very wear-resistant, used for flooring in garages, parking lots, trading floors and warehouses;

- durable;

- fireproof;

- must be consumed within 6 hours after connecting the components;

- the temperature of the room when painting should be in the range from +5 to +30 С;

- relatively expensive.

Silicate

Silicate is dyes that use liquid glass as the main component. Their main qualities include:

- weak mechanical strength, does not apply to painting the flooring;

- very strong adhesion to the painted surface, removing paint is problematic;

- high resistance to weathering;

- good vapor permeability;

- excellent waterproofing;

- resistance to temperature extremes;

- refractoriness;

- durability;

- biological inertness - the paint material does not contribute to the reproduction of microorganisms, in particular, mold fungi;

- instability to fading, fading with time;

- inelasticity;

- when applying the composition should be used protective equipment: gloves, respirator, raincoat, goggles;

- small selection of colors;

- small consumption;

- affordable price.

Among the species also emit such paint:

- waterproofing;

- water repellent;

- plastic;

- acidic;

- pigment;

- dry;

- reflective.

Manufacturers: review and reviews

The paint and varnish products market is represented by a variety of paints for concrete from various brands. Here are some of them:

- Quality Technology Professionalism - epoxy paint from the Russian manufacturer. Among the positive qualities of good wear resistance and a variety of color dye. Approximate cost - 400 rubles per 1 kg.

- Dulux - English brand with a wide range of different types of paint. On average, the cost is about 400 rubles per 1 kg.

- Tikkurila - this is the famous Finnish paint, which is distinguished by its ease of use, high surface quality and a pleasant appearance. Price - about 700 rubles per 1 kg.

Among the manufacturers, you can also select "Tex", "Betoksil", "Aquapol", "Elakor". Their incombustible dyes are suitable for painting foundations, balconies, window sills and other surfaces.

It is desirable to first apply the soil of the same manufacturers.

Reviews

Most reviews of such a composition are positive. Here is what the users say about it:

- impeccable quality;

- in the ensemble with a primer you can save on the consumption of the coloring composition;

- a solid, durable coating is obtained;

- resistance to chemical reagents;

- Some formulations have anti-dust effect.

From the negative sides, users emit a high price of paint.

Tips for choosing

Depending on the place of work, the type of paint varies according to its intended purpose. For example, one and the same manufacturer produces two similar acrylic paints, but the one that is intended for facade work will have a significantly higher resistance to all kinds of influences.

In addition, for the exterior painting is not so important environmental composition, if, of course, painted object, not associated with children, for example, a playground.

Thus, choosing a paint, first of all, you need to look at the area of its application.

For exterior finish

For outdoor dyes, priority is given to Requirements related to the protection of coating in outdoor conditions:

- resistance to aggressive weather phenomena: rain, snow, wind;

- resistance to the sun;

- resistance to temperature extremes;

- if it is a floor covering, then it is necessary to acquire a composition with high wear resistance and resistance to mechanical loads and vibration.

For interior work

Choosing paint for indoor work, you should immediately determine whether the room is residential, adjacent to the residential, or it belongs to a technical structure. For a place associated with a person’s living, it is important to choose a non-toxic paint and no sharp odor.

If this is a wet room, for example, a bathroom, then moisture resistance and vapor permeability is required.

If it is a non-residential object, for example, a trading floor or warehouse, then here, first of all, strength is important,as well as resistance to mechanical stress and vibration. Abrasion resistance should also be present.

Today white and yellow paints are most popular - they are considered universal. Durable paint will help paint almost any surface.

Useful recommendations on the selection and application of paint, you will learn by watching the following video.