Rocking chairs do it yourself

Rocking chair - a symbol of comfort, harmony and peace of mind. Unfortunately, buying this product is not a cheap idea. Prices start at 5,000 rubles and up. However, it is quite possible to make their own hands. In this case, you can think of your design project and design.

How to design?

The network has a large selection of ready-made drawings. However, using them, keep in mind that they can be developed for certain people and are not intended for a wide range of people. To make the chair comfortable and meet individual needs, learn the kinematics. Briefly, stability and comfort of a rocker depends on the location of the center of gravity of a person relative to the center of the circle. Remember eIf these two points coincide, then there is a so-called dead balancein which the chair does not swing. Such a coincidence is rare, but it happens.If the center of gravity is higher than the center of the circle, then the structure will be unstable. To avoid such a scenario, the rocking chair is designed for the tallest and heaviest person in the family.

Remember that too much wiggle can always be softened with a pillow under the back and on the seat.

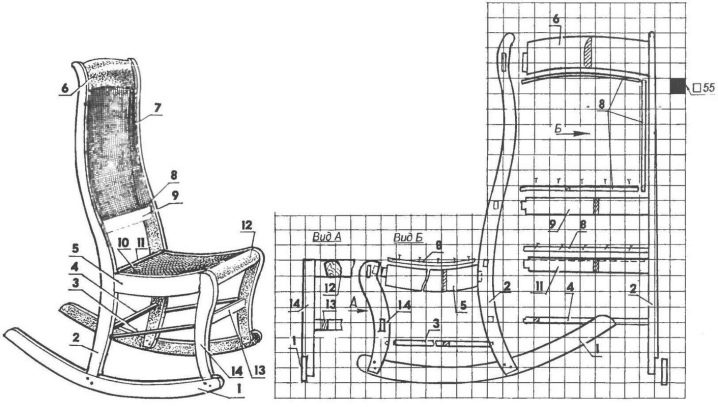

Making skis

It depends on the runners comfort and smoothness of the swing. Consider two ways to make them:

- The first option is simple and does not require much time.. Skis made from plywood with a thickness of 1.5 cm, no less. With the help of patterns and drawings cut two blanks. Grind them. In the legs of the chair we cut the slots under the runners with a depth of 7-10 cm. Install the skis. At installation it is necessary to achieve full symmetry. Having achieved harmony, we perform through holes in the place of their contact with the legs of the chair. We process them with glue and insert a wooden spike. Runners ready.

- The second option. Runners are made from a square meter bar with a side of 4.5 cm. Cut the grooves under the legs of the chair. Prepare the legs of the chair for their landing in the slots on skis. Bars soak in hot water. When the tree becomes pliable, we arch the runners into the desired shape and leave to dry.We process joints with glue and install dry runners on the legs. Skis are ready.

If there is no ready drawing at hand, you can make it yourself. Building a profile of variable curvature runners is done in several steps:

- Select the point of the center of the circle.

- Choose a fixed angle, it is usually equal to 10 degrees.

- Draw a line exceeding the radius of the center of the circle by 2-3% and mark the point.

- Next, increase the radius at each turn according to the law of geometric progression. The indicator is taken equal to 1.02 or 1.03. We also raise the center of the circle after each turn according to the same law.

- Connect the obtained points with the help of a smooth line.

- Profile runner ready. The scale is better to take 1 to 5 or more.

The rocking chair is unlikely to be perfect the first time, so the resulting product must be balanced. A badly rocking chair requires weighting the rear overhang. This problem can be solved by a U-shaped beam connecting the ends of the runners. In the beam you need to put the goods. It also happens that the rocking chair falls back. In this case, it is required to weight it in front. A step or load attached to its underside will help in achieving balance. In some cases, it may be necessary to change the shape of the runners.

Most popular options

Before you take up the project chair and do it yourself, you need to examine the existing types. There are several product concepts depending on the needs of consumers:

- With radius runners. The first version of the rocking chair, which arose in everyday life. Received its popularity due to the simplicity of design and technology. In most cases, has a low landing, associated unstable equilibrium when swinging. On large amplitudes, tipping is possible. To avoid it, runners do with a closing horizontal arc.

- With runners of variable curvature. Their main advantage is the impossibility of overturning. Suitable for creating rocking cradles, as they guarantee safety and comfort.

- Chair Nirvana. There are two types: spring and ellipse. Rolling is smooth in both cases. However, there is a big difference in manufacturing and use. Spring models require special materials: high-quality wood or spring steel. In addition, they are unsafe and inconvenient to use. The gap between the skid and spring is clogged with dirt and you can pinch your fingers in it.Options on ellipses do not guarantee tilting, but have a very easy and pleasant wiggle. You can solve the problem by installing bump stops. Ellipse rockers with an awning never topple over.

- Rocking chair 3 in 1. The name speaks for itself. The chair includes a rocking chair, and a chair, and lounger. The main advantage is multifunctionality. The disadvantage is large dimensions, which are not always possible in the conditions of an apartment. In addition, the transition from one regime to another may be accompanied by unpleasant shocks.

- Pendulum bearing. An improved version of the classic chair. The difference is in a fixed base and completely silent operation. As well as rocking horses with runners of variable curvature, they are suitable for rocking small children.

Materials for the manufacture of rocking chairs are varied and sometimes surprising:

- Metallic. The excellent decision for the street thanks to high wear resistance, durability and resistance to adverse external conditions. However, forged rocking chairs require special equipment and skills, in addition, finished products are heavy.You can consider the option of manufacturing a profile pipe, it is better if there is an ellipse in its section. To reduce the weight of the structure, and therefore, reduce the moment of inertia, the seat is made of another material.

- From plywood. Suitable for joiners with the presence of a little experience. The main advantages of plywood are that it allows you to make precise connections, is lightweight and, due to its flexibility, is suitable for implementing non-standard ideas and solutions. Plywood products must be impregnated with any protecting compound, be it acrylic lacquer or polymer emulsion. In this case, the product will last longer.

- From wood. Traditional material for the manufacture of any furniture. Affordable, natural, eco-friendly and simple. Wood has high strength characteristics, has a long service life, and also has a pleasant appearance. However, in conditions of high humidity, the tree begins to rot. Solve this problem with a variety of paints. Fortunately, there are many on sale.

- From proftruby. Immunity to moisture, pleasant color and ease of assembly contributed to its spread.Plastic pipes do not require glue, they are easily painted in any color, but there are also disadvantages. The main disadvantage is low strength. During operation, parts of the furniture are deformed, lose their aesthetic appearance, and sometimes break.

- From polypropylene pipes. Affordable, lightweight and durable. The flight of design ideas will easily support a wide range of pipes presented in stores. The set of tools necessary for making furniture is minimal and includes a hacksaw, a marker and a tape measure. Suitable for fans of unusual interiors.

- From plastic bottles. Ecological movement is gaining momentum. In this vein, they are increasingly offering to recycle waste. Plastic bottles are no exception. The main thing is to have a lot of them and they look aesthetically pleasing.

Sketches of simple options

The easiest, fastest, and cheapest way to make a rocking chair is to make it from an old regular chair, attached skis to it. We will need:

- a chair with legs (if not, you will have to do it);

- runners;

- screwdriver;

- screws;

- drill;

- sandpaper;

- paint and brush.

Production takes place in several steps:

- Preparation of skis. You can cut them yourself or order from the joiner. The distance between the legs of the chair should be 20-30 cm less than the length of the runners. In the place of attachment with legs we drill holes. Try on - the skis should "sit down" on the legs. If all went well, then you can start painting. Grind the surface of the runners with sandpaper and paint it. To achieve a deeper color it is better to paint in several layers.

- Installing runners. We put on the runners on the legs. To fix them, we drill holes for screws in the legs of the chair, insert them and twist them. Turn over. Rocking chair ready!

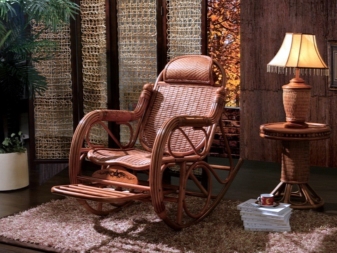

How to weave?

The highlight of the interior can be wicker furniture. It will add an atmosphere of comfort and harmony. The advantages of wicker furniture in comparison with the usual:

- environmental friendliness;

- ease;

- ease of use;

- ability to withstand heavy weight;

- beauty.

Among the shortcomings include the following: the cost and complexity of manufacturing.

Rattan and willow are most commonly used for weaving. Rattan is a plant from the palm family. The furniture of it is well tolerated by moisture, so it is preferred to be installed under the open sky.It is eco-friendly and has an excellent appearance. However, the repair of such furniture will cost a lot of money due to the cost of the material. A cheap option is willow. It is less flexible and unstable to moisture, like rattan, but more accessible and therefore common. Perfect for home furnishings.

Wicker chair made of willow, wicker or rattan is not so easy to do. Before you begin work, you need to prepare the material. Vines are harvested during the cold seasons. The raw materials collected at this time are easier to process. Harvested vines stand in the open air in a vertical position for 70-120 hours. Raw materials are sorted according to destination. For the framework, thick branches with a diameter of 5 cm are selected. For the braid, 1 cm thick rods will fit.

Raw materials before weaving must be processed as follows:

- Soak sorted rods in hot water for 10-12 hours.

- We remove the bark.

- We make taverns - we trim the length of the bars into lengths and cut them into 3-4 pieces.

- Pull each tire through the press. The result should be tapes of the same length.

- Thick branches are bent over the cylinders of the templates, fastened and allowed to dry.We make templates according to the drawing as follows. Drawing the frame put on the tree, we attach to it wooden cylinders.

- We are waiting for complete drying. Most often it is 3 days.

We proceed to the assembly of the frame:

- Attach to the frame support. For reliability, fasten them with cross-slats.

- Install armrests and other parts.

- Fix all the screws and remove the temporary mount.

Braid construction occurs only on the assembled frame in the following order:

- Before weaving the shank we knead, pulling them through any cylindrical object.

- Lubricate the places of the braid with glue.

- Weave. For structural strength, the frame should be wrapped in three rods.

- Inside weaving can be different options - openwork, single.

Having finished with weaving, we install runners, supports and overlays:

- Turn the product upside down.

- Heat the set pad with a hairdryer.

- We install it on the ski and put it on with a tape.

- From the cooled lining remove the tape and glue them to the skid, fasten with nails.

- After the glue has completely dried, we replace the nails with screws.

Before use, the chair must be treated with liquids protecting against fungus and wood pests, and also coated with varnish.In case you need to give the chair any shade, then before you varnish it you should soak it with linseed oil or paint.

From wood

Rocking chair made of wood, perhaps the easiest and easiest option after using the old chair. Special popularity gained garden benches. Their peculiarity is that they collapse 90 degrees if you lean back. Sitting will be in position on his back with his feet in the sky. If you pull them forward, the bench will stand in the usual position. However, the manufacture of runners for such a bench is somewhat more complicated. Amateurism they will not tolerate.

For a smooth and comfortable shaking, it is better to use a proven drawing and transfer it precisely to the material.

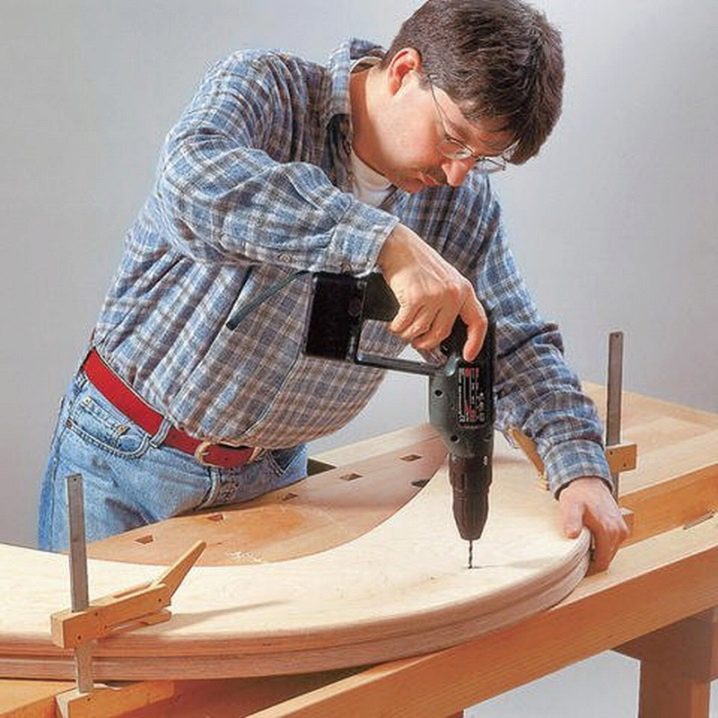

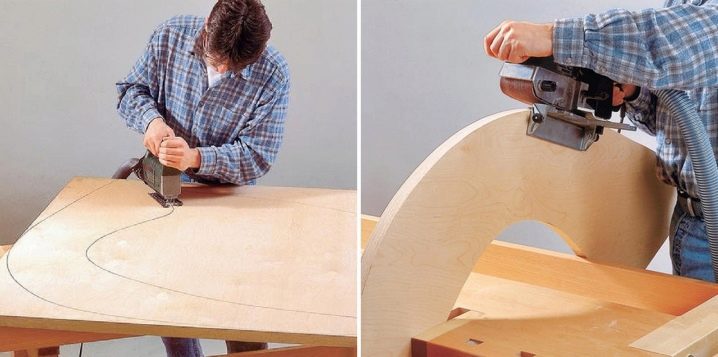

Consider the manufacture of bench-tumblers. We will need a jigsaw or hacksaw, sandpaper or sander, tape measure, construction angle, level, screwdriver with a set of drills, hammer, putty, pencil and paint brushes. The choice of materials is important for the characteristics of the finished product. We will make the side parts of plywood, and the slats of any elastic wood.

Getting Started:

- Cut out the side elements of plywood with a jigsaw or hacksaw. We get a semicircular base with grooves under the flannel.

- Cooking slats. They can also be made of plywood, if it exceeds 30 mm in thickness and has sufficient flexibility.

- With the help of three bars of 30x50x600 mm we connect the side parts together.

- Attach the rail to the frame.

- It remains to give the product an external gloss. We grease the place of attachment of the rails to the sidewalls to hide the grooves under the screws. We are waiting for the complete drying of the filler.

- Cover the bench with varnish on wood and leave to dry.

- Bench tumbler for the garden is ready.

If desired, you can make the seat soft, for this you can use foam rubber. Another solution would be a removable soft case. It will last longer, as it can be removed during bad weather.

Of metal

Metal rocking chairs make more difficult. It will require special equipment and knowledge. However, they are perfect for the garden due to its high strength and wear-resistant characteristics. What can we say, your grandchildren will also be in a metal rocking chair. There are various options for manufacturing, but we consider the most simple. For him, we need the following set of items:

- steel rods and angles;

- galvanization;

- Bulgarian;

- welding machine;

- drill and drill bits for metal.

Getting Started:

- We study the drawing.

- We cut steel strip 1 meter from the metal profile.

- It is necessary to weld the frame and weld the rods to it, the distance between which is 1 cm.

- We make the seat of galvanized and attach with bolts. Holes are made by a drill.

- We sand potentially dangerous places.

- We paint

The main disadvantage of metal furniture is its weight. Therefore, it is worth considering how to reduce it. In case the metal rocking chair will be used at home, you should stick a strip of rubber on the runners to protect the floor from scratches.

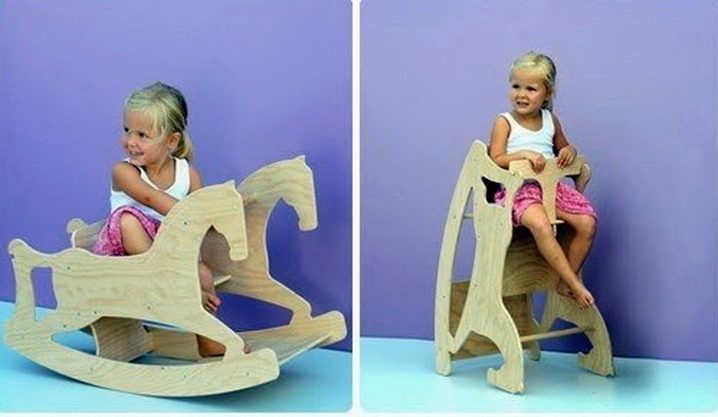

For a child

Memories of a homemade rocking chair will warm the soul of grown children for a long time. Making a rocking chair for a child does not have any radical differences from making a regular chair. The only thing that should be considered is the size and proportions, as well as the presence of pens. Rocking chair for children often makes in the form of a horse, but this is no longer furniture, but a toy. Consider the easiest option.Necessary equipment: circular and miter saws, Bulgarian, router, jigsaw and a set of hexagons. Required materials: 18 mm plywood, cardboard, 2 threaded rods 50-60 cm long, 4 nuts for hairpins and paint. We start making with sidewalls. Cut them to the plywood drawing. Cut out the grooves. The thickness of the plywood determines the thickness of the groove. Drill holes.

Cut out the seat. The width is determined individually. To the edges of the seats entered the grooves, tightly narrow them to the edges. When cutting back, keep in mind that its width should be equal to the width of the back side of the seat. We collect all the details and measure the resulting size of the spacer. Cutting, consider the size of the grooves. We process the edges of sandpaper and set the studs under the seat. Sticking studs saw off grinder. We tighten sidewalls, tightening nuts on hairpins. We start painting. Fine, if the child will take part in creating the design of a new piece of furniture.

Restoration

Favorite things sometimes easier to update than to tear off from the heart and just throw out. Often they are reminiscent of long-time kinship or pleasant events. It also happens that the old furniture has not lost its remarkable properties, but its external leaves much to be desired. Restoration will help in this and other cases.Suppose you have a battered rocking chair with a wooden frame. Faded wood and shabby upholstery are striking. We will restore it at home. We need: a grinder or sandpaper (the first one is faster, the second one is more interesting):

- screwdriver;

- acrylic paints;

- new fabric for upholstery;

- furniture foam rubber.

The procedure is as follows:

- First you need to disassemble the chair with a screwdriver. Screws clean up, we still need them.

- Remove the old layer of paint with sandpaper or a typewriter. Sandpaper should be fine grain. In the case of silt pollution remove a larger layer.

- We cover the wooden parts with acrylic paints, linseed oil or varnish. Here you can use different methods of painting. The scuff effect is very popular right now.

Replacing seat mats

We proceed to the waist of the soft part of the chair:

- We remove the old upholstery and soft layer.

- We are preparing a new soft layer of furniture foam rubber sheet. We cut a new upholstery with allowances of 5-6 cm. From the fabrics you can choose shenill, tapestry, corduroy.

- We collect the chair. Please note that there should be no play in the screw connections.

- The updated chair is ready.

Convenient and comfortable rocking chair is guaranteed to become one of the favorite interior items. He will be appreciated by every member of the family.

To learn how to make a rocking chair with your own hands, see the next video.