Warm floor under the laminate: recommendations for choice

The choice of a warm floor under the laminate is fraught with many "surprises" and subtleties. To correctly answer all the questions that arise, you need to know more about the types of underfloor heating, about its application in various conditions. And then you will not face any problems in principle.

Types and features of coverage

Heated floors are divided into three main groups: with circulating water, with heating cable and with infrared heating. Regardless of the specific type, all these solutions are different:

- Uniform supply of heat.

- High energy efficiency.

- Aesthetic appeal (no heating blocks needed)mask or beat on purpose).

- The exclusion of the movement of dust (inevitable even when using the best radiators).

Laminate, laying on top of a warm floor, always contains formaldehyde, and as soon as the material warms up to 26 degrees, they begin to pollute the atmosphere in the house. Conclusion: always get acquainted with the accompanying documentation and look in it for information about the admissibility of laying a heated floor under a particular batch of coverage.

Is it possible to put: all pros and cons

Installing a laminate over a warm floor is quite possible if waterproofing and optimum temperature conditions are provided. When in doubt, is it permissible to lay such flooring, or is it better to use another, when you do not know what exactly and how best to do, consult a specialist.

If you compare the laminate with other flooring, it becomes clear - it is ideal in the sense that allows easy access to preheating devices. Heating allows you to safely walk on the floor, even in the most severe winter, without fear of hypothermia and discomfort. Install underfloor heating should be at every opportunity, they are quite practical.Carpets will not be allowed, because they will block air circulation and may cause overheating.

Selection conditions

The maximum temperature of a warm floor mounted under the laminate is 25 degrees. It is necessary to increase it by two degrees, and fibreboard will begin to deform, stratify into individual fibers. But even earlier, at 26 degrees, dangerous compounds will evaporate into the air.

To lay on top of a warm floor can only such a laminate, which is labeled accordingly. Moreover, the tolerance refers to either electric or water heating methods, be careful! At all It is not necessary to use heaters over the entire floor surface, it is enough if they are located only in the recreation area and on the usual ways of moving around the house. For laying under the laminate can only be used heating blocks no more than 110 watts per square meter.

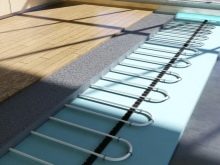

When warming the floor, it is desirable to use high-strength substrates based on XPS-polystyrene; their grooved surfaces significantly improve convection. Be sure to include the interval from laminate to the wall, so that it is less subjected to thermal deformation.

Water-heated floor should be placed on the substrate, providing both water absorption and heat saving. Fiberboard almost does not let in heat, that is, it cannot crack, but it is difficult to warm it up. The substrate placed above the heater should ideally have perforation for the passage of heated air to the floor covering.

If you need, first of all, high power, developed by the most thin warm floor, you should opt for infrared film. Specific power is most often 150 or 220 watts per square meter, occasionally you can find a film that gives 440 watts.

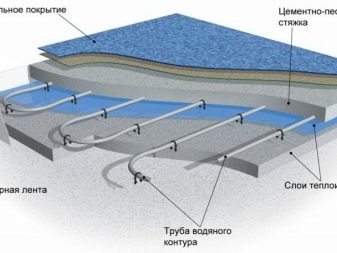

Water heating

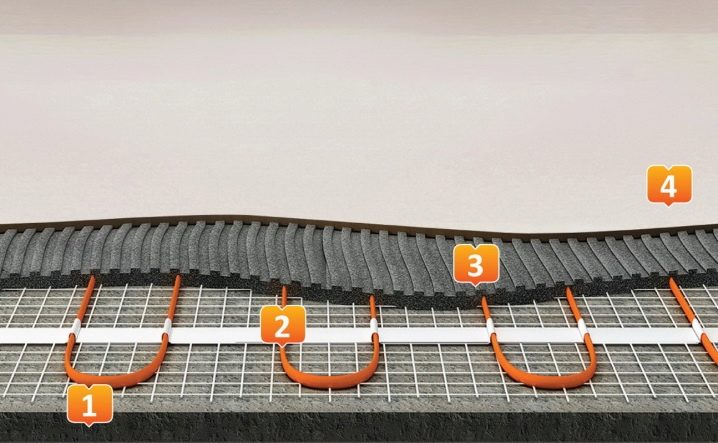

Water heating systems are always multi-layered. The base is made waterproofing, then there is thermal insulation (it does not allow heat to go down). Later, pipes of small diameter, covered with a base layer - a concrete screed, occasionally with gypsum fiber, are being installed. And only then comes the turn of the actual flooring. The type of overlap determines the thickness of the whole structure, ranging from 5 to 15 centimeters.

Advantages and disadvantages

The advantage of a water heated floor is its safety and stability of use, effective work in the mode of natural circulation, even in the absence of current in the network.It should take into account the complexity of the installation, lowering the height of the room. If the pipe leaks, it will be quite difficult to repair the defect. The designers, however, take into account this fact, and the pipes are now made from such reliable materials as polyethylene and metal-plastic. The additional protection of their cement-sand screed also reduces the risk of damage to a minimum.

Installation Features

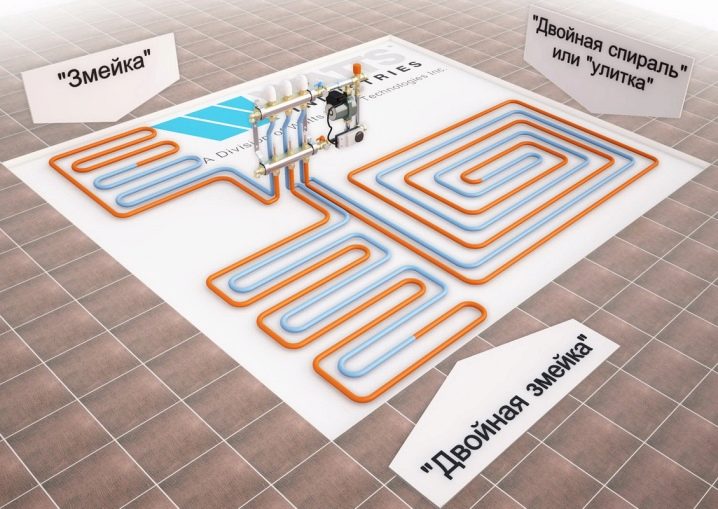

The optimal installation scheme is “the snail”: its laboriousness, the need for careful fitting is justified by a completely uniform and uniform heating of the entire floor surface.

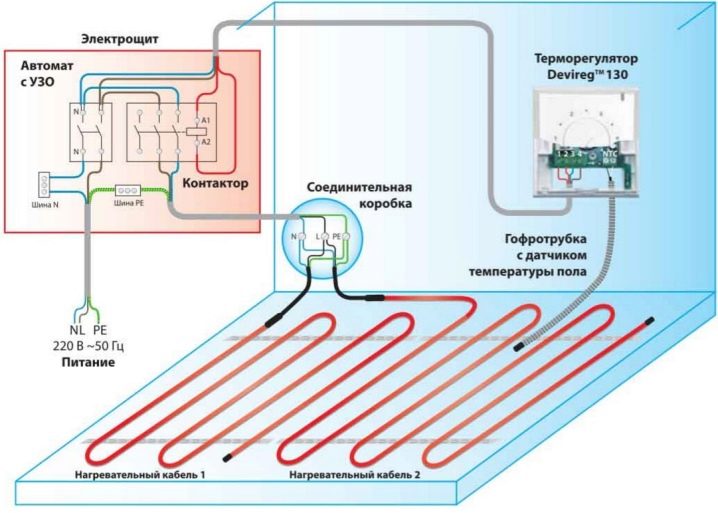

Electric heating

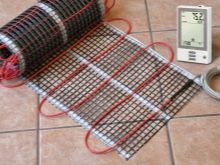

The essence of the device is already clear from its name - the cable element generates heat when current flows through it. The cable can be with two conductors or with one. The first option is more appropriate in any residential building or apartment, because less level of electromagnetic field. Laying a two-core wire with your own hands is also easier.

But it will be necessary to work carefully not to damage the contact of the cable - if it is broken, the floor will overheat. It is advisable to use a self-regulating heater that automatically stops the temperature rise after a certain value.

Recommended repeatedly (in the most difficult cases 5 times) warm the screedThis will form a grid of small thermal cracks. Such a "training" will allow you to avoid further the appearance of deformations that can damage the laminate. When all installation work is finished, you will need to drill the plinth and remove the cable from them. According to experts, it is best to put foiled foam under electric heaters to isolate from rough floors.

What is the benefit?

Electric heating is much easier to use (the system is mounted and adjusted much easier than water), its service life exceeds 20 years. The undoubted advantage will be the ability to adjust the temperature in the room, set its value as accurately as possible. But electricity consumption is quite significant, and you will have to pay for it.

The economy of all three systems causes fierce disputes, because the heating cable is cheaper to operate, and it is more profitable to install water devices. But if you take all the costs when using it, infrared film is immediately out of competition. Consider, however, not only financial indicators, but all the parameters at once - how big the room is, whether the heated floor will be a key means of heating or just an auxiliary one.

Laying technology

To install an electric floor heating is necessary only after careful preparation of surfaces. The base of the floor is cleaned, if necessary, then leveled and insulated. The choice of materials for leveling and thermal insulation depends on your personal preferences. On top of it is a thin screed, into which a reinforcing mesh is inserted, the screed must dry at least 48 hours. After that, fix the mounting tape.

Work will be significantly simplified if you use heating mats. First, determine where the thermostat will be, and lay the cable in accordance with the manufacturers instructions. When the sensor is fixed, the thermostat is set, a test run of the system is carried out. If everything is in order, you can pour the coupler from 3 to 10 centimeters thick. After pouring it is required to wait a month, and only then the screed will be strong enough for laying the laminate.

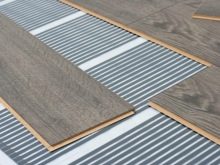

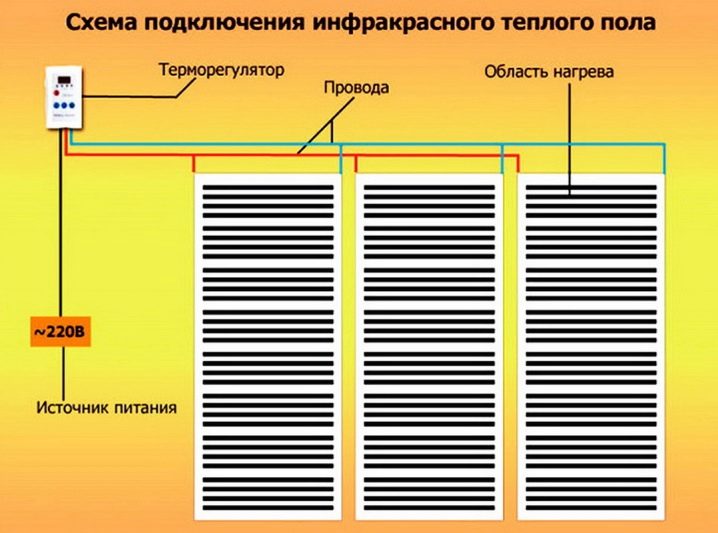

Infrared film

Infrared film is the most advanced development in the field of floor heating. Very little will have to be done: the heating block itself is placed on the heat-reflecting material and covered with polyethylene. Everything after this will only lay the front cover.Even the screed, mandatory for electric and water warm floors, is unnecessary. But grounding, since we are still talking about a current-consuming device, is an absolutely necessary thing.

Advantages and disadvantages

If you install the infrared film, you will not encounter a decrease in the height of the room, and at the same time such a heater consumes less current than the most effective cables. But on the other hand, infrared film is quite expensive it cannot be used wherever there is high humidity. And be sure to need a flat base, otherwise there is a risk of breaking the device.

It is not allowed to put films under the furniture, only on the free part of the floor. Consider that the “phase” is in the infrared film itself, and it is necessary to install the most reliable protective cutout devices.

Tools and materials

First of all, you need to thoroughly calculate how much thermal film and how much volume of reflective material you need. Be sure to come in handy when working, except for the installed set:

- thermostat;

- temperature sensor;

- protective films;

- scissors and screwdrivers;

- construction knife;

- pliers;

- adhesive tape to connect parts of the canvas.

How to mount?

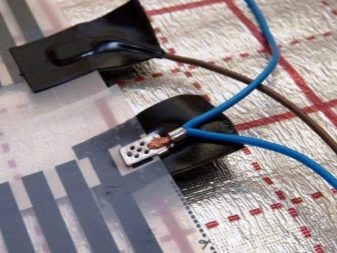

Be sure to check not only the flatness of the floor, but also that it is clean and dry. 100% of the surface is covered with heat-reflecting material having a dense layer. The use of aluminum foil in any form is unacceptable. Using adhesive tape fasten parts of the substrate. Once it is ready, you can choose a place to connect the thermostat. The built-in regulator and the wires through which current flows to it must be placed in the gate.

If the width of the strip of film is 50 centimeters, its length cannot exceed 13 meters. With a width of 80 cm, the allowable length is reduced to 10 meters, and meter strips should be made no more than 7 meters in length. To cut and connect less, lay the strip along. At least a centimeter should be left between them, and the gap to the walls should be at least 5 centimeters.

Direct the strips with contacts to the side where the thermostat will stand, and in no case do not overlap one thermal film with others! Since it is required to connect the wires in parallel, it is possible to assemble them in one side and disguise them with a plinth. The film at the time of installation is glued to the substrate with tape, otherwise you can tear it.

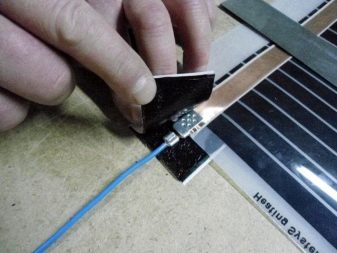

One end of the contact clip is introduced into the cavity separating the film from the silver strips, the other is fixed on a copper base and pressed with pliers. Successively moving, all contacts are processed in this way. Do not forget to isolate the connection points! The temperature sensor should be attached to the bottom side of the black strip, it is held by bitumen insulation. remember, that Thermal bands must be at least 10-50 centimeters from any heating devices, depending on the heating power.

The outer surface on which the laminate will fall should be as even as possible. To meet this condition, for wires, the sensor and clips it is necessary to make cuts in the substrate. The wires hold the tape so that they do not budge. Note that if the total power of the heating unit is 2 kW or more, it is necessary to connect it to the mains only through a separate protective shutdown device!

Which is better to choose?

Warm floor of any kind can be successfully combined with the laminate. It is only necessary to select it as carefully as possible, otherwise the coating will be deformed with the slightest violation of the temperature regime.Or the result of the work will not satisfy you.

Putting an infrared warm floor is the easiest, but not only so it’s worth choosing. Due to the design features, the rays will not penetrate the base, and you will not needlessly heat the concrete or other base; This circumstance is especially important for balconies.

If the dwelling is connected to the central heating system, then you will have to abandon the use of underfloor heating in any case. Laminate over a warm floor in any case should be of high strength, its thickness is at least 8 millimeters. Evaluate the thermal resistance of the flooring.

Use on the balcony cable warm floor or not - it's up to you. The fact that the screed first warms up and then the floor can be considered both a disadvantage and an advantage. You will have to wait about half an hour for the effect to be achieved, but the heated cement layer gives off heat even for some time after shutdown. But the fact that you will need to do the coupler itself is a very serious minus.

The point is not even labor and additional costs. The design of the balcony is much heavier, sometimes carrying parts can not withstand it.We'll have to forget about the installation of voluminous furniture (wherever she stood up, there will be spots from overheating, not at all decorating the appearance of the laminate).

An alternative solution is electric mats, and on the loggias the simplicity of their installation is very relevant. But be prepared for the fact that the cost of construction, heating the same area, will rise by 50%.

Make a warm floor in the country - it is a reasonable idea. Such a technical tool will definitely help to increase the comfort of staying in the home, if you take into account all the nuances.

With all the strength of wooden rough floors, it is undesirable to overload them and if this consideration is important for you, it is appropriate to prefer the infrared option. When there is a well-equipped, established system of independent heating, you can also use it to supply hot water to a water-heated floor. Film designs are good when you want to insulate a country wooden house:

- it is easy to mount them;

- no need for connection to heating facilities;

- can always be removed and moved to another place;

- current consumption is minimal.

Assessing the energy efficiency of the system, you should not give unduly great importance to the indicators declared by the manufacturers.In reality, it is necessary to take into account how the installation was carried out, the device for thermal insulation, the quality of the reflector, the climatic conditions, and many other points.

Both in the summer cottage and in an ordinary private house, laying a heated floor under the laminate helps to simultaneously make life more comfortable and improve the space. In terms of visual appeal, reliability and ease of use, laminate bypasses the old, cracked floors. A wide variety of its textures allows you to reproduce the look of natural wood.

Set such a "layer cake" will only in the case if the general condition of the original floor is satisfactory or can be fixed by redecorating. In very old buildings it is often necessary to change the foundation. When using a water heated floor, the former wooden base will need to be precisely removed and a screed instead. The works are quite complicated and time consuming, because, for example, it is necessary to prepare a concrete solution.

It is undesirable to use "dry" technology of installation of a water heat-insulated floor on heat-exchange plates. Yes, the wooden base is preserved.But the efficiency of use of the heater becomes less, in addition, it is necessary to mill or adjust parts to make the channels for the installation of pipes. In addition to laying circuits, connecting them to the direct and reverse heating pipes, you will have to install equipment that supports the necessary heating and circulation. With your own hands there is little that can be done Inevitably need the help of specialists.

Electric cable floors and even mats require the use of a screed, again - again it will not be possible to preserve the wooden base. As in the case of tubular structures, alternatives can be found, but they are all just as simple and less effective. The conclusion is absolutely obvious: it is better to find nothing better than infrared floor heating and for a private house (not only for an apartment). This solution eliminates any “wet” installation work and can be put into operation in a few days.

Reviews

To make the right choice, it is not enough to pay attention to the manufacturer’s technical documentation. It is also necessary to take into account the experience of using heated floors by different people. Judging by the reviews, polypropylene pipes in water systems are significantly better than metal-plastic ones, and even significant thermal inertia does not prevent them from warming floor surface as it should.

Users of infrared floor heating note that it allows you to vary the temperature not only for individual rooms, but even for certain segments, however, you will need to purchase expensive automation and properly configure it. Electric underfloor marks "Heatlux" cause a very different attitude: someone enthusiastic, someone sharply negative. It is hardly worth acquiring them, it is quite a risky move.

Products Warmstad It is made in Russia and fully meets even the most stringent quality requirements. Those who bought it say that a well-designed polymer cable sheath allows him to work confidently for at least one and a half decades without interruption. The system can flexibly adapt to different climatic conditions.

Warm floor Devi are perceived by the majority of consumers as a completely worthy and well-made solution, rarely giving failures. Among other manufacturers, high praise deserved goods Thermo, Ensto, Energy Cable, Caleo. All these brands are known on the market for many years and are quite diverse in their characteristics.

How to lay a heat-insulated floor under a laminate, look in the following video.