Description and properties of "cold welding"

In the process of repair or other economic needs, it is sometimes not possible to use conventional welding due to some of the reasons. A good alternative can be “cold welding”, which is not complete, but can temporarily replace the first option. In order to properly use and select it, it is important to know what it is and what the principle of action is.

Special features

Cold welding glue is a substance that can help join two pieces of metal without involving a thermal reaction. The composition can be deformed in such a way that it is possible to reliably cover the parts by gluing them together. It is most often used in the process of repairing sanitary equipment and shows excellent results in working with machines. The great advantage of this glue is the ability to glue the elements that were not prepared in advance for this procedure, which speeds up the process and makes it more convenient.

"Cold welding" is a mixture of a substance with polymers and obtaining the final result. The quality characteristics of the substance will depend on the quality of the ingredients in the composition, as well as on the correctness of its manufacture. If the repair process creates conditions that are close to ideal, then the glue can become stronger than the metal itself, but in reality this can almost never be done, because the use of glue can be useful for temporary needs and a short-term exit from the problem situation.

Using "cold welding", you can work with metals such as copper, lead, aluminum, nickel, iron, cadmium and silver.

It is especially convenient to use this composition where it is impossible to use elevated temperatures, and the parts must be reliably soldered. The convenience lies in the fact that in the process of soldering it is not necessary to work with homogeneous metals, you can connect several options that will be well attached to each other with the help of glue.

If we talk about a number of advantages, then they should include:

- no deformation of the metal surface due to the absence of temperature effects;

- the seam is neat and quite strong;

- for a number of metals, only the use of “cold welding” is possible, these include aluminum and copper, which are not connected by other options;

- after work there is no metal waste;

- no need to use electricity;

- environmental friendliness of the procedure;

- no need to have training for the procedure;

- no need for specialized equipment.

The use of such glue can save in some situations, and in some cases it is the only possible type of connection of two metal parts. That knowledge of the properties of this glue will help to use it properly.

Kinds

If we talk about the composition of "cold welding", then it is not very complex, it has:

- epoxy resin, which helps to impart properties of uniformity and plasticity, which is the basis of the substance;

- a metal component that serves as a filler;

- sulfur and other components that are additives.

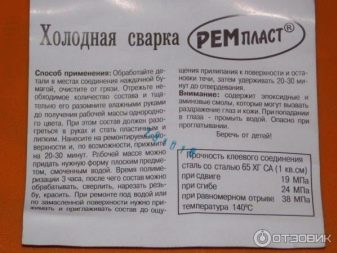

The composition of the weld affects the level of temperature that the object can hold. On the packaging, you can always read these values, because choosing the right option is not so difficult. It is important to apply the product correctly to the surface, following the instructions exactly, which will give a good result: beautiful, smooth seam and reliably welded parts, even if the work is done on pipes with hot water.

The structure of the adhesive can be one- and two-component.The first type is important to use in the shortest possible time, otherwise the adhesives will lose their properties. The second option can be stored for quite some time and use as needed.

In addition, there are options for glue on the material for which it is used:

- For metal objects, it is used both in everyday life and in professional activities, as well as machine repairs. The term of use is small, but if a significant load does not affect the parts with welding, this substance will reliably serve for quite a long time. It helps very well in the quick repair of plumbing, but do not leave it there for a long time, soon replacing it with a hot welding option.

- For plastic products, it is less popular, but it is used both at large industrial facilities and at home. Scope - plastic pipes and similar structures, it is a universal version that fits any product made of the desired material.

- For gluing linoleum - the composition is able to combine dense rubber, and therefore is ideal for working with flooring. The use of adhesives and double-sided tape gives a much worse result than “cold welding”.

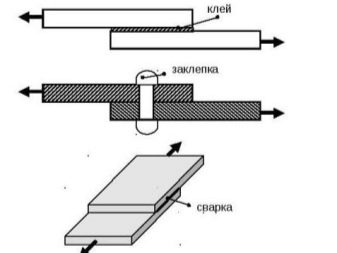

If we talk about the types of this glue, there are several among them.

- Point type - is actively used in the auto industry for working with tires. Handles are well glued to aluminum pans. You can apply copper to the end of the aluminum wire so that it is better attached and so on.

- Suture variety - suitable for creating various hull variations that should be sealed, for vessels of considerable size, as well as for vessels with thin walls.

- Butt version - recommended so that you can easily connect the two ends of the wire, in addition, you can actively use for the production of rings.

- There is also a T-type and welding with a shift.

Considering the “cold welding” according to its consistency, it would be reasonable to divide it into two types:

- liquid - two-component, the use of which is reduced to the fact that there is a mixture of glue and hardener before use;

- plasticine (resembling clay), which should be well kneaded before use.

Having the necessary knowledge, it is possible to easily choose the right version of the adhesive in the store for its intended use, which will make the process of minor repairs convenient,and in some cases “cold welding” will be a real helper and for a long time, firmly gluing parts together.

Temperature characteristics

"Cold welding" is a compound that has good resistance to high temperatures, which makes it possible to use it for different surfaces. The standard mark that is indicated on glue packages is 260 degrees Celsius or some similar indicator, but this is far from the limit. It should be said separately that those compositions where the temperature indicator is specified within these limits should not be operated at such indicators for a long time. A normal environment with temporary and irregular temperature rises will give a normal effect, while other conditions will not allow welding to last for a long time, and soon it will be necessary to carry out repairs again.

If there is a need to find a substance that fixes places with a temperature that has high rates, then the maximum should be figures at 1326 degrees. Such a type is called high-temperature welding, which is often used where it is difficult to reach by conventional welding, or it will be ineffective.

Application area

The use of "cold welding" becomes possible for products made of aluminum, cast iron, copper and other options. It is actively used in the process of eliminating the problems of plumbing equipment and heating pipes. For batteries it is not always convenient to use a hot welding variant, and a properly selected glue applied in the correct way can completely replace it. In addition, the composition successfully copes with the repair of metal tanks and radiators for cars, because in this case its application is particularly welcome.

For polypropylene and plastic pipes this glue is considered the best assistant., because the option with the use of the welding machine will be impossible. In addition, building accessories, garden tools, stainless steel products, all this is an opportunity to correct or correct it with the help of the desired composition. Equally important is the use of glue for working with copper wires, on which it is not easy to weld aluminum tips, but if there is a welding compound, the process is easy.

A special type of welding glue makes it possible to glue parts from rubber, ceramics, wood and not only, for which an appropriate adhesive is needed that can hold parts of the products.Having decided on the material and its application, you need to choose the right glue.

If the work is done with automotive parts: radiator, gas tank, muffler, then use the composition with a metal filling. For those options, when the operation is carried out under the influence of temperature, and these are some parts, as well as machine components, it is important to choose a heat-resistant type. Choosing the right type, it is worth understanding that the use of “cold welding” for those parts that are operated under pressure cannot be, this composition will not stand and burst. The exception is the heat-resistant varieties, which are several times stronger, which means they are more tightly seated.

The scope is quite wide: from simple domestic needs, gluing and welding small problem areas to use in the automotive business.

User's manual

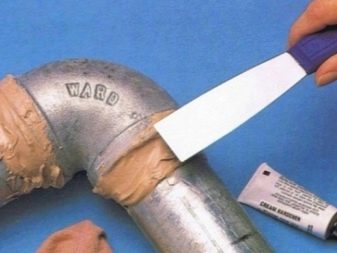

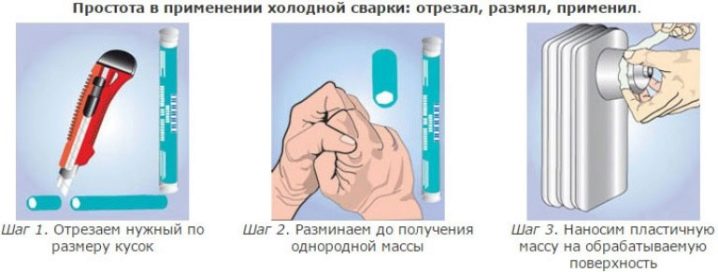

To glue together any parts using welding glue, a number of preparatory actions are required. To ensure the best result, it is worth preparing the surface, pre-stripping and alcohol treatment.When everything is ready, you need to remove a piece of welding, knead it and put in place of the spikes. If the glue has become soft and pliable, acquired a brown tint, it means that it is completely ready for use.

After applying you need to fix the composition of the clamp, you need to wrap it with a harness. For partial solidification, you need to wait about an hour, after this time it is possible to drill the holes, if they are needed, to make threading and carry out any other actions. The glue dries to full hardening for at least one day. If the work needs to be done on a pipe that is leaking and the water cannot be closed, the composition is applied to the problem area and pressed tightly until it starts to harden, after which it is rewound with a harness for at least an hour to prevent the separation of welding.

In the process of repairing any object with the help of “cold welding”, one should not take into account the humidity indicators, they do not fundamentally affect anything, but the air temperature should be above five degrees, otherwise one should not expect a good result. All work with glue should be carried out in a spacious room, or well ventilate the room where the spike is carried out.The components themselves are harmless, but when combined with each other, they not only weld surfaces securely, but can also affect the integrity of human mucous membranes.

Making any actions with welding glue is not too difficult., but it is important to follow the instructions clearly, therefore, mix the components of the adhesive in a specialized container and mix until the composition is uniform and plastic. "Dry welding" freezes quite quickly, because the time to use the finished solution is quite small, it can be from 10 minutes to an hour, after which the content freezes and is more unsuitable for use.

When applying glue to the surface that will be welded, it is important to ensure that there is no excess material left on the product; they should be removed after the pieces have been joined. Each brand and type of "dry welding" works in different ways, which is why the time of hardening varies. In some cases, just five minutes is enough for the composition to clutch, and for some options it will take an hour. To completely brew a problem place, and to be able to use the object,You need to wait for the maximum drying time of the glue. The fastest will be ready in two hours, and the slower will be dry within 24 hours.

It is possible to carry out work with the help of "dry welding" on a variety of surfaces., but it is important to choose the right kind of glue, read the instructions for it to know about the time of hardening and not be late with the application, and also not get ahead of the moment of full readiness of the object to be able to fully use them. In addition, it is useful to choose a product of a quality and proven manufacturer who uses the necessary ingredients, thanks to which the best result is achieved.

Manufacturers and reviews

There are quite a few manufacturers of any products, and it differs radically. There are options for domestic firms, and there are also foreign options. To choose which of the presented options is better, a qualified employee can, therefore it is worth contacting him in the process of selecting the right composition. Not always a foreign brand or the high cost of the goods speaks about its quality.

Choosing welding, you need to read its composition and operating conditions. If they do not cause questions, then the glue is suitable for use. It is also worth paying attention to the date of manufacture of the sample, because after its expiration the main qualities may be violated. Those who wish to choose the best option, should look to several leading manufacturers.

"Ermak"

You can buy the product both in stores and on the Internet. Glue composition: 100% plastic, red color. This is a Russian brand, and the manufacturing process takes place in the DPRK. With the help of "Ermak" you can achieve a quick connection of parts, which will be quite durable due to its tightness. Such glue can be used in a wet environment without loss of quality of adhesions. Most often used for the repair of plumbing. Available in tubes of 55 grams.

"Amethyst"

This is a novelty on the market, but has already gained considerable popularity. Its composition: polymer matrix and discrete filler. The adhesion process takes place at the molecular level due to the interaction of the polymer matrix with the surface to be repaired. You can buy such glue throughout Russia. It is possible to use it in almost all areas of human life, it is well manifested in the soldering plumbing. Such welding in tubes of 58 grams is on sale.

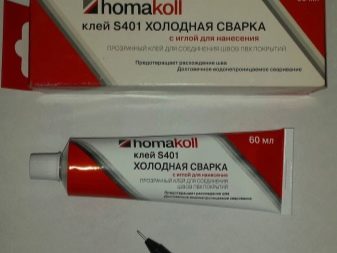

Homakoll s401

Used to prevent seam divergences, it is a good alternative to linoleum formulations. This variety is in great demand among users who note its effectiveness, ease of use and reliability of the result. In all respects, except for design, consumers give Homakoll very high marks, confirming them with their positive comments.

Among the shortcomings can be identified: an unpleasant smell the next day after use, it is difficult to remove from the surface of the skin, if the composition got on it. An important advantage of this adhesive is its water resistance, which is of great importance for working with flooring and determines the service life of the adhesive. Externally, the welding is presented in the form of a tube of metal and nozzles for more convenient application. Sold in a package of 60 grams.

Hi-gear

Country of manufacture America. The popularity of glue due to the fact that in the line there are several varieties that are aimed at a specific type of material for bonding. The universal option can be used in almost any situation, connecting products even of different compositions.With Hi-Gear, it is possible to seal holes of small diameter. The process is similar to the use of conventional clay. Most often, this glue is used where it is not possible to apply hot welding. Parts that have been connected in such a composition can withstand strong vibrations and temperatures up to 150 degrees.

Using glue is quite simple, you only need to read the instructions and follow it. Such welding dries pretty quickly, which is its undoubted advantage. Almost all consumers note the high quality of the spikes of parts, which is not inferior even to traditional welding.

There are, however, its own drawbacks, which include: the fragility of compounds for breaks and shifts, the high cost of a number of similar substances, the need to ensure the composition of certain conditions so that it retains its properties for the next use. You can buy this glue in tubes of 57 grams.

These are just a few of the most popular brands that are represented on the domestic market and are trusted by people who do not have much experience in repair and construction, as well as experienced workers who know exactly what, when and where to use.

Tips and tricks

The process of repairing any equipment is not an easy task, and it is important to know what needs to be used in order not to spoil it. "Cold welding" is most often used for the repair of plumbing, auto and other appliances. If we are talking about cars, then it is most convenient to use such a glue for the gas tank, it helps to seal holes and problem areas without forcing the driver to purchase a new part.

To work quickly and efficiently, it is best to ensure the convenience of its implementation. To seal the hole, the easiest way is to fit it with a screwdriver and screw in a bolt that will fit. "Cold welding" all this is fixed and held very securely.

If it is necessary to deal with a radiator, then it is blown with a compressor with the help of water and places with damage are determined. Sealing with cold welding in this case is a temporary solution to the problem, and more serious steps must be taken. If there is a problem in the silencer, then glue can be used only if it passes by the temperature index. It is best to initially acquire a composition capable of withstanding maximum temperatures.

The repair process is carried out using surface cleaning and degreasing.that helps the device to serve for quite some time. Depending on the magnitude of the problem, welding either completely removes the problem or becomes a temporary solution. In cases of serious damage, an inverter or semi-automatic machine is used for welding.

With the help of "cold welding" it is possible to carry out repair work with metal objects, but a firm belief is needed that the product will not be subjected to strong pressure and tension, otherwise the repair will not withstand a long time. If during the operation of some parts there are vibrations that can tear the parts apart, then the use of glue is impractical, since it is practically powerless in this case, it is best to use hot welding and securely fix all moving parts.

The use of "cold welding" is very popular because of its versatile use and ease of use. Due to its properties, it is convenient to apply glue to any surface, and the strength of the result does not cause questions. Due to the availability of this composition, anyone can purchase it.who needs a quick solution for household chores or with a car, but it is worth remembering that the possibility of welding is not endless, and in some cases it is worth replacing it with a traditional option.

For more on cold welding, see the following video.