Grout for mosaic: how to choose and how to use?

The mosaic is one of the most popular finishing materials. She is highly valued for her beauty and practicality, inspiring the most creative ideas to come true. The integrity and integrity of the mosaic composition largely depends on the choice of grout. Its properties, color and quality of application largely determine the appearance and usability of the future coating.

Species: how to choose?

On the market of modern finishing materials are such types of data compositions, such as:

- cement;

- epoxy.

Grout cement based differ in the low price and are simpler in drawing and removal. These materials do not tolerate a humid environment, and are also easily subject to mechanical and chemical effects, but they are also an excellent prophylactic against fungi and mold.

On sale cement grout produced in the form of bulk materials that need to be diluted with water or liquid latex to a certain consistency.

The composition of some grout sand or Portland cement, making them more durable.

Cement composition in its pure form can be used for grouting joints with a width of no more than 0.5 cm. For wider joints, the material is mixed with sand, but such grouting is not suitable for every material. For example, they cannot be used together with enamelled tiles, as small grains of sand can scratch the coating. In addition, cement formulations differ scanty colors.

More common grouting are epoxy compositions based on cement and resin. Epoxy nicknamed them in the people for the speed of setting with the base. A more correct name is two-component. As a result of mixing epoxy resin and silicon filler with a special hardener, a plastic grout is obtained, which is easy to work with. A grout of this type does not tarnish over time, as colored chemical sand, not chemical additives, is used as a dye.He also plays the role of mass filler.

The color scheme is quite diverse. If desired, you can get any shade, sparkling grout or finish in gold or silver.

Although latex is included in the composition of cement mortars, it is impossible to call them two-component, since latex in it is an optional element. Unlike epoxy, in which both components play an important role. At first glance, the differences between the two types of grout are insignificant. But professionals know that over time, the cement composition loses its original appearance, and the lining will look stale. Two-component counterparts preserve the beauty and whiteness for much longer.

Mosaic can be used for cladding the external and external walls of the house. When choosing a grout for a mosaic, it is important to know some nuances that will simplify the further operation of facing materials. This applies to the place of use of the tile, the environment, the effects of chemicals on the coating, air temperature and the width of the seams.

To avoid mistakes in the choice of a particular grout, you should pay attention to the following factors:

- abrasion ability;

- resistance to sunlight;

- high percentage of adhesion;

- moisture resistance.

Special quality requirements are put forward for compositions used in the lining of pools.

In this case, only epoxy compounds, known for their fast setting, are suitable for mashing the tile joints. In addition, they are resistant to chemicals, which is no less important when facing not only the pool, but also the shower, kitchen walls and surfaces in the bathroom.

There are several basic requirements for grouting.

- Elasticity. The composition should be of a consistency, so that during application there will be no stains. But with too thick grout will be difficult to work. Most modern materials retain elasticity even after solidification, so that the suture layer does not crack even after displacement of tiled masonry.

- Strength. Grout should not crumble and crumble. To avoid this result, it is better to use only proven means and carefully observe the proportions when mixing the components.

- Water resistant. Tile joints should be well protected from the harmful effects of moisture, mold and dirt.Therefore, it is best to give preference to moisture-resistant compositions.

Colors

Until recently, the color of the wipe compositions could be selected only from two options: white or gray. Today the color range is practically unlimited. But, despite this diversity, the white grout is the most requested. But the correctly chosen color allows you to hide irregularities and surface roughness.

Experts recommend choosing a grout to match the mosaic itself, or to a tone that is darker. Bright seams will merge with the general appearance, the mosaic will lose its appeal.

Mosaic properties are an equally important aspect when selecting colors. Glass, mirror mosaic or photo collage requires delicate handling, so the grout is better to choose transparent. It is important to know that after complete drying the grout can change color, so when choosing a color it is better to consult with professionals. It is better to choose and acquire formulations immediately with the tile - this will allow to achieve one hundred percent similarity of tones.

If you have doubts about the choice of color, you can give preference to a white shade or transparent formulations.

In some cases, contrast colors such as black or red look beautiful. It should be noted that the use of rich colors requires a certain combination with the design of the room. Otherwise, the coating will visually disintegrate into fragments.

The rules for choosing the color of grout are as follows:

- compositions of light tones visually merge with the mosaic, and the surface seems to be cast. This is a great way to hide the not perfect tile;

- dark grout is the best option for zoning;

- for grouting floor tiles most often used compositions of gray and brown colors;

- when making a panel or a bright mosaic using a contrast grout is inappropriate. Formulations of similar colors are more suitable for ideal surfaces;

- for grouting mosaic laid out in the form of a pattern or ornament, it is recommended to use compositions of neutral colors.

When choosing the color of the grout, it is worth considering in advance how it will be combined with the tile, whether it will be appropriate in the overall design of the room, because only a well-designed interior can please the eye for a long time.

Consumption per 1 m?

Grout consumption is directly related to the width, thickness and dimensions of the mosaic tile. The amount of material spent is also influenced by the professionalism of the master and the grouting method used.

It is recommended to consider the parameters taken into account in more detail.

- Tile parameters. If it is shallow, then there will be more joints per square meter than usual, respectively, the composition will be more. The same can be said about the thickness of ceramics - the thicker the coating, the greater the consumption of grout.

- The width of the seams. This parameter is directly influenced by the parameters of the tile. Small mosaic will look beautiful in the frame of narrow joints. For a wide tile, 2 mm is left for the seams, and 3 mm for the floor.

- The depth of the interlayer stitch. This indicator is measured by the distance from the wall to the tile itself, created by a layer of applied adhesive. Grout should tightly fill all empty space.

- Grout density. Different manufacturers offer formulations that are completely different in their consistency.

- The quality of work. Even if the process is managed by a real master, the consumption of material may be large due to unforeseen circumstances.It is necessary to take into account the need to hide flaws, chips, uneven coverage.

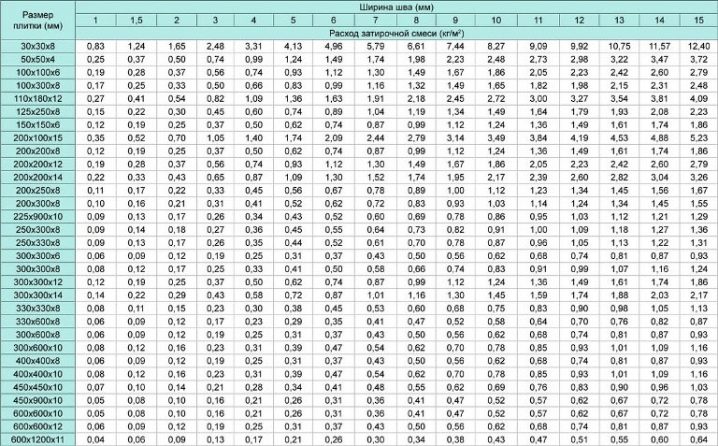

This table shows the calculation of the material consumption per 1 m² for grouting interdental joints. If the size of the mosaic is non-standard, you can calculate the approximate consumption of material yourself using the following formula:

Consumption (kg / m²) = (k + d) / (k * d) * z * m * n, where:

- k is the length of the mosaic tile (mm);

- d is the width of the mosaic tile (mm);

- z is the thickness of the mosaic tile (mm);

- m is the width of the seam between the plates (mm);

- n is the density of the composition (kg / dm³), usually a figure from 1.5 to 1.8.

For example, the size of a mosaic tile is 20x20 mm, and the thickness is 4 mm. The thickness of the seam should be 2 mm. It is necessary to divide the sum of length and width (40 mm) by the product of length and width (400 mm). In this case, this indicator is 0.1 mm. Next, you need to multiply the resulting number by the tile thickness (4 mm), then - by the width of the seam (2 mm) and by the coefficient (1.6 mm) - it turned out 1.28. In the table, all values are rounded, and our number turns into 1.3 kg, which confirms our calculations.

Similarly, you can calculate the consumption of grout, not only to the mosaic, but also to the usual tile. If you do not want to bother with the calculations, you can use the standards of the manufacturers indicated on the packaging of each trowel.

Application: process description

The process of grouting mosaic tiles requires certain skills to work with materials and tools. Much depends on the knowledge of the process technology, the nuances of the work, the quality of the selected materials.

The grouting process involves several steps.

- Before you begin grouting the surface must be thoroughly cleaned from dirt and dust. It is possible to begin work only 24 hours after tile laying. This is necessary so that the mosaic is properly frozen, and the troweling cannot harm the coating, otherwise moisture can affect the color of the joints.

- Remove glue residue along with dirt.so that the surface can dry out. Wash the glue to help special acid cleaners. After their application, the surface of the mosaic should be washed with plenty of water.

- If you will use lightweight grout, the recesses between the tiles must be completely clean. The decorative mosaic can be cleaned several times, letting it dry out after each cleaning. To prevent the grout from cracking after drying, it is recommended to wet the tile with a sponge, which will remove excess moisture.

- Mixing means must be strictly in certain proportions.by following the manufacturer's instructions. As a rule, they indicate all the important aspects of working with grout: the width of the joint, preparation, application. To achieve a homogeneous mass, you can use a drill, using a special nozzle on the drill for kneading.

- To make the grout go better and not lose moisture, and the seams are smooth and neat, the edges of the mosaic can be slightly wet. If there are concerns that during the work the tile may be damaged, it is recommended to treat the surface with a special protective compound. If the applied mixture begins to dry, you can wet the surface with a damp sponge or slightly sprinkle with a spray bottle.

- The finished mixture should be rubbed with a rubber spatula diagonally from top to bottom. All holes must be filled immediately, after which excess material is removed. You can begin to wash the tiles within 30 minutes after the completion of the troweling works. It is impossible to wait for complete drying, since it will be quite difficult to remove the hardened mass from the tile surface. The drying time of the grout depends on the type of composition and the manufacturer. Some materials are already dry after 15 minutes.

- Use soft circular motions to remove excess grout from the mosaic. It is better to wash the tile with a soft cloth or sponge, regularly washing it in clean water. You should not press down hard on the tile in order not to damage the integrity of the coating. After the grout has completely dried, the entire coating should be wiped with a dry cloth or a hydro-sponge.

- Two-component grout washed off much harder. In addition, it will take about an hour to dry, and the seams will have to be washed down with warm water. If time does not wash off the excess epoxy grout, then get rid of the dried mixture can only be mechanically.

- The time of complete drying of the grout is approximately several days. Before the surface is ready for use, it should be protected from direct sunlight, temperature extremes, drafts and wetting.

- To simplify the process of mashing the joints will help the grout. This special device consists of sheets of glass fiber with perforations, on the surface of which crushed silicon carbide is applied. But you should not resort to using this tool without experience, as there is a risk of scratching the coating.

Recommendations

Professionals in the construction industry are advised to follow a few tips when working with grout for mosaic.

- Before you begin to apply grout, it is recommended to check it on an inconspicuous area, waiting for complete drying.

- If you choose a certain color is not possible, white grout is equally well in harmony with any color mosaic.

- The grout area at a time should not exceed two square meters.

- It is better to wash the mosaic several times, taking breaks to dry. Acidic cleaners can be used, but they should also be rinsed with water.

- In the process of troweling mosaic tiles can move out. To get them back in place, you need to gently fix the edge with a smooth part of the spatula. It is worth bearing in mind that it is possible to adjust the tile locations only within the next half hour, then the glue will harden and the mosaic will firmly “grab”. And if the grout is carried out in the hot season, the drying time is reduced.

- Epoxy compositions are more suitable for grouting wooden mosaics, since wood easily changes its size under the influence of temperature and humidity. Therefore, mineral compounds that can quickly crack, are not suitable.

- Grout glass mosaic is better to do a colorless composition, the color of which will not stand out against the general background. This will give the coating integrity.

For more information on epoxy grout for mosaic, see below.