The scope of application of refractory tiles

The most common way to use ceramics in interior design, apart from dishes, is to cladding various heating devices - fireplaces or stoves. In the era of centralized and gas heating of apartments and houses, the need for furnaces for heating residential premises has decreased, but such alternative heating devices do not lose their relevance, being a colorful and useful object in the interior of residential premises.

Special features

Variants when the furnace in the room is not only an element of the general style of the dwelling, but also serves for heating, suggest its competent finishing and facing. However, not all tiles can be used for these purposes. The lining process of a stove or fireplace assumes that the material will meet certain requirements.Tile for stoves and fireplaces is a special material, since the conditions of its use are directly related to the exposure of the product to high temperatures.

Basic material requirements:

- attractive appearance is a prerequisite due to the fact that the heating device, whether it is a fireplace located in the center of the living room or a stove in the kitchen, is the main subject in the room, setting the direction for the whole design idea;

- environmental friendliness, ensuring the safety of operation of fireplaces and stoves, because when heated, harmful and toxic substances that may be in its composition tile, will begin to evaporate;

- heat-resistant properties of the material, suggesting that it will be resistant to heat up to 1000 degrees. Manufacturers put special designations on the packaging - the letter "T" indicates that the products are intended for facing fireplaces, the presence of a number of numbers indicates the number of tiles firing. The larger the number, the better;

- High rates of thermal conductivity and heat capacity are responsible for the ability to provide room heating;

- the level of thermal expansion of the product should be no more than 8%;

- good moisture resistance tiles - water absorption level of 3%. Manufacturers designate this characteristic with the letter “E”, next to which the corresponding percentage is written;

- product thickness must be at least 8 mm;

- anti-static;

- resistance to fading and temperature fluctuations;

- resistance to mechanical stress, which provides fine porosity of the material. This indicator is referred to as “PEI” with roman numerals next to it. The less pores a tile has, the stronger it will be. For facing fireplaces, you must purchase material with the figure IV or V.

The range of tiles that manufacturers now offer is very diverse, even with such high demands on the material. Design and color are selected taking into account the overall style in the room, the color design of the walls in the room.

The fireplace will occupy a central place and attract attention to itself, which is why its decoration is always performed in bright colors, very often adhering to the design of ethnic trends. For example, the traditional Russian stove has always occupied a central place in the house, it was called "Mother" and decorated in accordance with the traditions and functional features.

Functions

Furnace lining performs a number of specific functions:

- reducing the time required to heat the room;

- providing convenience in the care of the device - washing the tile is much easier than, for example, plastered surface;

- attractive decor;

- increase in heat transfer and heat capacity of the furnace;

- psychological aspect - according to most psychologists, the presence of a traditional stove in the house has a good effect on the general atmosphere in the home, as well as the mood of others.

Kinds

Refractory tiles for facing stoves and fireplaces are very diverse. Most often for such works, these types of ceramic tiles are used:

- tile;

- tiles;

- clinker;

- chamotte;

- majolica;

- terracotta;

- ceramic granite;

- fake diamond;

- natural marble.

A tile (ceramic plate) is very susceptible to extreme temperature fluctuations, despite the fact that the material has good heat resistance properties. Lining furnaces with such tiles is best done with small matte elements.

Ceramic tiles should not be used in rooms where the air temperature may have negative values. The technology of laying this material involves the use of special heat-resistant glue or mastic.The tile has a zero water absorption value, therefore it is impossible to use cement or clay solutions for facing works.

Sometimes laying tile perform without adhesive composition - in a metal frame.

Tiles are box-shaped with a relief or smooth surface, covered with enamel. The specific structure of the tile, due to which an air gap is formed between the kiln brick and the tile, increases the ability of the tile to retain heat. The tile is made and painted manually, which is why it has a sufficiently high cost. This material is the most environmentally friendly among the entire range of tiles. In addition, the tiles have good heat dissipation.

The heat-resistant tile is fastened to the steel wire installed in the seams of the masonry or it is lined with a ready-made furnace, but this process is very laborious. This type is considered the most beautiful material for decorating heating devices.

Clinker tiles It is made by mixing a number of shale clay, chamotte powder and various dyes.The color range varies from red to orange, from yellow to brown, or from white to beige. The surface of the product is not glazed. This oven stove has a good frost resistance due to the density of the material. That is why it can be laid in rooms where there is a sharp drop in temperature.

However, this kind of tile can not be used for devices whose inner walls are made of kiln bricks. This limitation is associated with a large difference in the structure of both materials, as well as in terms of thermal expansion. Fireclay or acid resistant stove is an expensive material that is made by hand. Refractory clay and stone flour are the main components used in production.

The technology of production of this finishing tile requires roasting of the material at a temperature of 1300 degrees. The high cost of tile justifies several of its advantages:

- absolute refractoriness;

- does not crack and is not erased;

- low slip rate;

- resistant to static loads and extremely low and high temperatures;

- does not react with aggressive media.

It is produced in single or paired form and does not require additional surface insulation. Majolica is a tile made of baked clay with a decorative pattern and a surface covered with glaze. Each element is made by hand, so the material is sold at a high cost. Majolica perfectly accumulates heat.

Terracotta tiles very often used for cladding. It is affordable, heat-resistant and finely porous, imitating the finish under natural stone. Differs in the big service life, and also the natural color characteristic of clay with a rough surface. Terracotta does not have a shiny surface, it is very much in demand for decorating heating devices in private houses in the Provence style.

This variety is used for indoor and outdoor use. It is often used in baths and saunas, it is faced with both the stove itself and the walls near it.

For facing the fireplace also buy stoneware tiles. The material is made of several types of clays - a mixture of quartz sand and marble or granite chips. Salts and oxides of metals work in the role of dyes.The tile has a dense structure and excellent resistance to low and high temperatures. The surface of the material may be different, for example, matte, polished or embossed. This variety gives the finish spectacularity and naturalness.

Porcelain tile does not fade in the sun and perfectly imitates the finish under natural stone, so it is very popular. Laying tiles produced by hot melt glue. For ovens that are in the yard, a frost glue compound is used. Porcelain does not have a high heat capacity.

Another excellent option for stoves and fireplaces is fake diamond. This material does not require a high level of professionalism and experience from the handler. The stone is of various sizes, so it perfectly hides all the irregularities of the stove. In the process of laying stone, it is necessary to clean off the excess solution from the reverse side.

Marble is a natural and very beautiful material for expensive interior decoration. In addition to its high cost, additional costs will be required for the services of the designer, as well as precise cutting of the material and the services of the master-handler.

Where is it used?

Refractory tiles for fireplaces and stoves are used primarily as an element of the decor surfaces of heating devices. Thanks to the tile, these objects can be turned into a real work of art, giving the stove or fireplace an individual style or finishing, adhering to certain cultural traditions. A great example is the Russian stove, which is still used in homes directly for its intended purpose or as a bright element of the decor of a room.

The tile is not used for finishing the space around the stove, working and internal surfaces.

All types of refractory tiles must necessarily be with a certificate of quality. Only with supporting documentation can we say that the material will meet the stated characteristics.

Design

The decoration and decoration of the oven’s fronts is a long-standing tradition that has not lost its relevance today, when fireplaces and stoves in houses most often perform only a decorative function. The fireplace is a symbol of the family hearth, which will decorate and complement the interior of the living room or kitchen, and lining the device with ceramic tiles will provide an opportunity to harmoniously fit it into the overall style of the room.

To implement these ideas, manufacturers offer a variety of tile, products that mimic natural materials, as well as exclusive options for decoration. For example, the tile of blue-white color in the style of Gzhel will be a bright element of the decor, which will emphasize individuality and complement the style of the room. Gzhel fits perfectly in both English and Russian interior design.

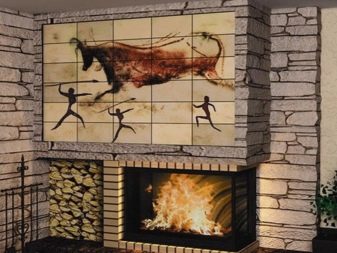

Small household fireplaces are often veneered with patterned tiles, but large-sized stoves, which are entirely covered with handmade paintings or handmade tiles, can be seen much less frequently, since pleasure is not cheap. An excellent option for facing large devices for heating is a combination of finishing materials, for example, painted tiles and beige-colored tiles.

Alternating tiles or creating a certain image allows you to create a distinctive decor on the surface of the fireplace or stove.

The uniqueness of the tiles has always attracted attention, because even a small-sized multi-colored or embossed panel will give a unique appearance to the device.Many designers use tiles with glaze applied to them with small cracks, which creates the effect of antiquity.

Bright embossed inserts on the sides of the furnace, strict horizontal or vertical stripes, made with the help of tiles, give freedom for the realization of the most daring fantasies.

Tips for choosing

Before buying a tile, you need to decide on the type of furnace on which to lay it. There are many designs of these devices, and each has its own characteristics regarding the specifics of the materials used in its manufacturing process, the shape and other equally important parameters. A very important indicator that allows to classify the furnace is their degree of heating. It can be high, medium and low.

Masters specializing in the surface finishing of such heating devices give several recommendations regarding the proper selection of kiln material for lining:

- There should be no geometric defects on the tile. To verify this, it is necessary to compare the samples with each other;

- The thickness of the product should be 6-8 mm;

- All products must have the same shade;

- A tile with any defects cannot be taken into work;

- It is better to purchase square products, they have good rigidity and strength, and it is also convenient to coat the surface with them;

- Material needs to be bought with a small margin;

- Any damage should be absent on the reverse side of the products.

Even the elite types of tiles can be made in violation of technology, so before buying you need to make sure that there are no different chips, scratches and other flaws.

Beautiful examples in the interior

Ceramic clinker tiles are an excellent "simulator". Through the use of this material, you can get almost any type of finish, for example, under a brick, wood or natural stone. Fireplace decoration, imitating stone, will give the interior austerity, luxury and grandeur, like old fireplaces in the castles of the Middle Ages.

Tiling with tiles is considered to be the most sophisticated and striking example of finishing stoves. In creating a decor of such material there are no boundaries for imagination. The huge choice of the most various patterns, colors and shades equates furnish of the furnace with tiles to high art.Such devices will delight and delight with their appearance for years, whether it is a small fireplace in the living room or lobby of the apartment or a Russian stove in a country house.

In Russia, stoves lined with tiles were very popular during the reign of Peter I. Now these devices are experiencing their second birth. To revet a fireplace with blue-white tiles, brick material or luxurious marble - all this was made possible thanks to the variety of types of refractory tiles. Now modern technical capabilities are easily combined with nostalgic images of the past era.

An overview of the chamotte tile in the design of the fireplace, see the following video.