Porcelain tiles: varieties and nuances of choice

Porcelain tile is a high-quality facing material. It is often used in the decoration of floors and walls, as well as for exterior cladding of buildings. But for each type of finish it is necessary to select a certain type of such coverage.

What it is?

Porcelain tile is a finishing material, which consists of press powder. This component includes clay, kaolin, quartz sand, feldspar, as well as water and pigments. All these components are pressed at high pressure, then burned at a temperature of about 1,300 degrees - the highest quality durable material is obtained.

At first, porcelain stoneware was considered a material for household premises.where the floors have a huge load.For example, it was most often placed in public, most passable places or in warehouses, where there is a lot of equipment, as well as freight transport.

But now in the manufacture of porcelain tiles use dyes that make this coating beautiful. That is why it is used in decorative decoration: laid on the floor or on the walls. Moreover, this material is used for both interior and exterior decoration - it looks elegant on the facades and is perfect for decorating the interior.

Such a product is laid only with the help of a special adhesive that allows it to stick to surfaces, which means that the facing material will be securely attached to the plane of decoration.

According to the characteristics, you can choose different models, taking into account the marking on the packaging: the wall tile is marked with a palm sign, and the floor tile is marked with a foot sign.

Advantages and disadvantages

Porcelain tile has a number of advantages:

- Durability. It is believed that his life may be more than a hundred years. This applies only to high-quality models, made in compliance with the requirements of GOST.

- High-quality porcelain sturdance endures various scratches, it does not leave marks from damage and bumps.

- The big advantage is that it is almost impossible to destroy porcelain stoneware.

- Differs in resistance to moisture, frost and temperature drops.

- Versatility. It can be used almost everywhere: on the street, at home, for production purposes at business and industrial enterprises.

- Separately, it should be noted aesthetic appeal of such material. It looks very beautiful, especially for some varieties that have undergone additional processing.

- Now a wide variety of such models is presented, a number of them can imitate other materials and textures. You can also choose any color.

- The coating does not fade and does not fade.

- Security. It is caused by environmental friendliness and fire resistance.

- Consists of natural materials and therefore safe for human health. The material does not emit harmful and toxic substances, which allows it to be used in residential premises.

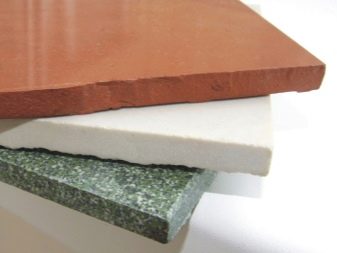

- An important advantage in comparison with many other materials, for example, with ceramic tiles, is that dyes are included in the composition of this material during production before it is pressed.That is why they are evenly distributed throughout the mixture.

But other finishing materials have a different composition. Dye pigments are applied to them already after the creation of the material and only on the top layer, so the drawing and paint can fade. Thus, porcelain is painted completely, so its color is deep and resistant.

In addition, even the patterns are applied very high quality and do not wear out at all during operation. If over time, the strong effects of porcelain will be slightly erased, or if a small element breaks away, the color of the coating will remain the same, and the chip will be invisible. This can not be said about other coatings, which differ in color inside and outside, as can be seen when chipping.

But besides all these advantages, the material has some drawbacks:

- He is very fragile. It is easy to break during transportation. Dropping or hitting plates, they can be easily broken off or damaged. In addition, porcelain is difficult to cut and handle in the process of laying.

- This material also has a large weight, which greatly complicates the installation. This is especially inconvenient when they need to trim a vertical surface, for example, a wall or a facade of a building.

- In addition, we can note the high cost of this material.It costs significantly more than other veneer options, such as ceramic tiles.

- In addition, it cannot be said that it is ahead of other materials in a variety of colors, textures and patterns. On the contrary, it is in last place in terms of color, although its quality is better.

- It is a cold material, so laying it in a residential area is not accepted. But this disadvantage can be easily compensated by installing underfloor heating in the room. Porcelain tile has a high thermal conductivity. Thus, the surface can be made a little warmer.

- Low water absorption. If it is required to lay this material on cement located outside the building, then it will be stratified during frost. That is why it is customary to lay ceramic granite on cement only in residential premises where the temperature does not drop to low. On the street, only special adhesives are used for its installation in order to avoid delamination of the coating.

- Another disadvantage that many people call this coating is that it slides badly if water is poured on it. But this disadvantage can be avoided by buying material with a pronounced relief.

- Over time, porcelain stoneware, although not abraded, loses its glossy shine and deteriorates from the effects of sand and dust, as well as from anti-slip agents that are sprinkled on the streets.

- The coating is quite traumatic for children: falling on such a durable and hard coating, you can easily break the knee.

Before you buy this material, you should weigh all its advantages and disadvantages in order to determine where you can lay it yourself and whether this cover will be suitable for a given room.

Specifications

Porcelain tile is great for both household and for industrial use. Models produced according to GOST have the best quality characteristics:

- The material has a low level of water absorption. This figure is less than 0.05% of the total mass. Thus, the material practically does not absorb moisture and therefore is frost resistant. Thanks to this, it can be laid on the street.

- It is believed that porcelain is able to withstand more than 50 complete cycles of thawing and defrosting. Other coatings are not able to tolerate such conditions, and therefore they quickly lose their external and qualitative properties.

- Impact resistance coating. On a scale of impact resistance, porcelain is second only to diamond.The coating is much stronger than marble, and is not damaged by external mechanical effects.

- The material is resistant to chemicals. It is not affected by detergents and a number of abrasive compounds. It is believed that only hydrofluoric acid can damage it.

- Hardness. It is 7 out of 10 points according to the generally accepted classification. Thus, the coating has a high density and hardness. That is why it serves for many decades.

- Abrasion resistance. Now porcelain tile is used mainly as a finishing material for the decoration of floor surfaces. That is why it is so important that this material retains its original appearance for a long time. Moreover, it practically does not wear out, even under heavy loads.

- The coating has a bending strength that is 55 MPa, which is considered to be quite high compared with other materials. It also has a high resistance to stress: more than 2000 N. Such a material is tested for strength.

- Another important characteristic is the coefficient of friction of the surface. It is important that he was high.

- Most varieties of porcelain stoneware do not change color from the effects of external factors, including from direct sunlight. This determines the depth of color and visual appeal over the years.

Kinds

Porcelain tile differs by type depending on its external and qualitative characteristics:

- Technical granite. This coating, which looks like the most common granite of natural origin. It is rather nondescript in appearance, but it is of high quality. In its production, the emphasis is not on decorative properties, but on strength and high resistance. It is immune to even very long exposure and high loads. Thus, the coating is not erased over several decades.

- Glazed. This coating is a glazed porcelain stoneware. She covered the material, and then burned under the influence of high temperatures, so that the glaze is fixed on the surface. Glazed porcelain tiles are durable and reliable models and at the same time look very presentable.

But with high traffic or mechanical damage, the coating can lose its durability and original appearance. That is why glazed porcelain is more often used for finishing walls or rooms with low traffic. As a rule, it is often laid at home. For intensive and high loads, this coating is not suitable.

- Polished. This type is distinguished by the fact that in the manufacture of this material is polished to a mirror finish. As a rule, in the process of polishing the coating loses the top layer and loses some quality characteristics. It gets coarser, but gets shine.

In addition, during the polishing process, the pores of this material open, so it has a higher percentage of water absorption. Thus, open pores can provoke damage to porcelain tiles: dirt gets clogged up in them, and the coating darkens with time and loses its aesthetics.

Even the grouting process can penetrate these pores. That is why after installation it is important to process such a coating with a special compound. Polished stoneware looks presentable, but during operation the polishing wears out and it becomes dull and coarse.

- Matt. This is a standard type of porcelain stoneware that does not undergo a polishing procedure. It is quite inexpensive because its production process is simple. As a rule, such material undergoes high-temperature firing and standard processing, while decorative coatings are not applied to it. It is often used in industrial premises, for example, in garages or in warehouses. It has a long service life and unpretentious care.

- Structured. This kind of porcelain stoneware has a pronounced relief surface. Such models are very popular because they are able to imitate the texture of some natural materials, for example, parquet. Structured porcelain stoneware is also called ceramic parquet.

In addition, structured porcelain can even repeat the texture of a natural stone or a model of fabric or leather. They look very stylish and elegant. Also, by your own order you can make a structured parquet for any embossed pattern. Gold leaf is even applied to more refined coatings.

- Satin finish. Before such a ceramic granite is roasted, mineral salts are applied to it. Due to this, the surface gets a light soft gloss that makes the material look like a waxed surface. Thus, this coating is not machined, so it is anti-slip. This material is suitable exclusively for the decoration of residential premises, as it does not tolerate high loads.

- Lapped. Such material is differently called "rubbed". It has a non-uniform texture, which is partially matte and partially polished. Thus, the combination of different types of textures looks very elegant and unusual. In the manufacture of the material is ground to obtain a semi-polished coating.

This production technology came to us from Italy and is now very widely used in the manufacture of porcelain stoneware. To create it, special stones are used, which grind the surface.

By itself, the grinding is not as long as in the manufacture of polished material. Such a surface will have shine, but not bright. Thus, the front side will be an interesting combination of gloss and roughness.This material is more durable than polished porcelain, because polishing is only partially.

Lappatirovanny porcelain tile is suitable for walls and floors. On the floors of this material is placed in rooms with high traffic. Suitable for offices and shopping centers.

- Double faced granite. This material is very different from previous versions, as it is a coating created by a special technology. On the top layer of the tile there is a filling of the required color, and the main part is made of the same, but unpainted material. Thus, this production technology reduces the stability and versatility of the product, since when the chip is cleared, the main color of the material will be visible.

From the outside, such a surface can be covered with an interesting and bright shade, which cannot be said about models made using standard technology. Materials covered with red, orange, blue, green, yellow pigments. Due to this production technology, the cost is reduced, since the material is partially painted. At the same time, wear resistance remains the same, and the upper layer is practically not erased even after many years.

Models with double filling are very popular and are most often used for home decorative floor and wall decoration.

Wear resistance classes

Stoneware coatings are divided into classes of wear resistance depending on their abrasion. Thus, models of different classes of wear resistance differ in their quality characteristics, as well as in thickness and some other indicators. In addition, porcelain tiles of different classes has a different purpose.

Wear resistance class assigned by the method of PEI. It characterizes the possibility and degree of damage to a particular type of porcelain stoneware. To do this, it is tested using special machines. During testing, the coating is subjected to abrasion. According to this principle, porcelain tile is divided into wear resistance classes.

Models that are not abrasively abraded, have a high wear resistance class - 4 or 5, and the most unstable models belong to class 1. It is also believed that this indicator depends on the specific type of porcelain stoneware.

Models of the polished, glazed type, and also some types of material,past decorative processing, have a low level of wear resistance, therefore, they most often belong to the 1st or 2nd class:

- Models of the first class of wear resistance are mainly used for wall decoration and decoration of some surfaces. As a rule, they are not laid on the floor.

- Models of the second class are mounted both on the walls and on the floor. As for outdoor models, this is an excellent solution for rooms with low traffic, where they mostly move in soft shoes. Thus, this coating is great for home use. Second class porcelain tiles are laid in the bathroom and in the toilet.

- Porcelain tiles of the third class of wear resistance are laid in passable rooms of non-street type, and also where there is no direct entrance from the street. Most often, such coatings are mounted on the balcony and in the kitchen. This is a good material for home use, which has high quality characteristics. They are also used to finish the facades of buildings and exterior cladding.

- Models of the fourth wear class are more durable. They are often laid on the floor in public spaces.Here, the passability criterion is measured by quantitative indicators. Such porcelain tile is suitable if the permeability is a little more than a few hundred people per hour.

- Models of the fifth class of wear resistance can be laid practically in any premises with the most intensive movement. It is perfect for railway stations and airports, as well as for hospitals and squares.

If you need to choose a model for your home, then you should give preference to third-class porcelain stoneware. This is the best option, which has low porosity and high strength. In addition, it is resistant to abrasive and chemical influences.

The only exception is the floor in the hallway and in the hallway. For finishing of these zones it is better to select models of the fourth class. More fragile models of the first and second class are better to buy for the walls of the house - they can decorate the walls in the bathroom, the kitchen apron and some other surfaces.

Dimensions

Models are divided into types depending on the size. Now manufacturers are the most diverse in size and thickness of the product, but still there are average indicators that are the most versatile.Standard porcelain stoneware is most convenient to lay yourself, many models do not even require cutting. That is why it is important to choose the size of porcelain, so that you do not have to cut it yourself when laying.

Standard are models with dimensions of 30x30, 45x45, and 60x60 cm. But there are other popular sizes of ceramic granite slabs. For decoration of corridors often use rectangular models: 15x30, 30x45 and 30x60 cm.

For finishing small hallways and kitchens, they usually acquire porcelain stoneware 15x15 or 20x20 cm. For larger premises, large porcelain tiles are used: 120x40, 120x15 or 120x30 cm. These models are suitable for both wall and floor finishes. It is most convenient for them to veneer large areas of the premises.

Manufacturers represent the largest modifications of products so that they can be made facing the facade of the building. So, the parameters of such plates are usually 120x360 cm. But this porcelain stoneware is rather thin and is completely unsuitable for the floor.

Outdoor porcelain tiles can be laid mosaic. That is why manufacturers present models 5x5 cm.

It is important to make all the calculations correctly. If the choice of the size of porcelain stoneware seems difficult, then you can use the method of water-jet cutting.So you can pick this material under the format of a room of any size, even for a narrow corridor or a small room of irregular shape.

Good porcelain tile is rectified. This process is a trimming of the edges of a tile using special technical equipment. Rectified porcelain stoneware is always a smooth and fitted material. Indeed, after the porcelain tile is fired, its edges are deformed and become uneven.

That is why some models are sold without processing. They are cheaper, but differ in size.

In addition to the parameters characterizing the size, manufacturers indicate and caliber. It characterizes the possible discrepancies of tile dimensions in the same batch. As a rule, this figure does not exceed 0.5 cm, but still it is noticeable, so you may have to cut the tile yourself.

Products that have undergone rectification have a more regular shape and precise dimensions, which are indicated on the package. The size of the tile also characterizes its thickness. Although it has almost no effect on its quality characteristics, it is still an important indicator.

The smallest thickness of porcelain is considered to be 3 mm.But at the same time it is as strong as the model with a thickness of 3 cm. It is this indicator of porcelain stoneware that is considered the maximum in thickness.

The average is 9 mm. This material is able to withstand a load of more than 200 kg per square meter. However, thickness is important only in order to well join the porcelain stoneware with other finishing materials. For the walls, as a rule, thin products are used, and for the floor - models are not thicker than 8 mm.

Colors

Now you can find almost any color solutions that are manufacturers. In modern interiors it is popular to use black glossy porcelain stoneware. It is great for high-tech or techno. It can look exquisitely both in the kitchen and in the room. They even finish the working area of the kitchen: an apron and countertop, designed for cooking.

For more recent interiors use bright porcelain green, blue or yellow. It is also used for finishing the kitchen, but, as a rule, only for accent finishing. Colored porcelain can be laid in mosaic or patchwork. Such a bright decor will surprise any guest, and rich colors will not let you get bored.The kitchen apron area can be decorated with mirror granite using the panel technique and the same plinth.

The interior is a popular light-colored granite or marbled beige matte floor. Such colors are typical for Provence style. Such tiles can be both with a pattern and without it. Natural patterns of the ornament are often used as patterns, including flowers, branches of plants, silhouettes of trees and other elements of vegetation.

For finishing of a bathroom blue, blue and white porcelain tile enjoys special popularity. But the specific color solution for the surface finish depends on the color scheme of the interior and on its stylistic design. It should also be borne in mind that if you give preference to bright coatings, they should overlap with other details that are available in the interior.

Styles and design

It is now customary to purchase porcelain tiles that can imitate other surfaces.

Porcelain stoneware

Since natural wood is quite expensive and does not tolerate moisture, it has a lower lifespan, and many prefer ceramic granite,imitating wood material. So, porcelain tile can imitate a wooden floor, parquet tiles and even small piece parquet. Moreover, the material will be completely indistinguishable from the original coating. When walking on it will be noticeable that such a floor is colder. In order to eliminate this disadvantage, porcelain stoneware is often laid on heated floors.

Porcelain tiles can imitate almost any tree species. Manufacturers also present models with embossed wood texture with a unique and natural pattern. You can even choose the type of sawing wood: tangential or radial.

In the classical interiors are often used porcelain, having artificially aged textures. Outwardly, it is almost indistinguishable from the tree, including by touch. Moreover, manufacturers are and rough and polished models.

Porcelain stoneware tiles are a unique and versatile solution.which is suitable for many interiors. With it, you can finish the floors in the style of Provence, classic or country. In combination with warm floors, it is ideal for finishing all the rooms in the house.

In more modern interiors are often laid porcelain, imitating parquet. As a rule, rectangular elongated plates are used for this. On large tiles there is an imitation of several parquet plates. Such coatings are able to imitate different types of parquet masonry, but depending on the type of such pattern, its price varies. More sophisticated models are quite expensive, but outwardly they look presentable.

There are models that mimic the laying of "Christmas tree". They can be laid independently, placing the tile at a right angle to each other, and you can buy ready-made square plates on which the pattern will be applied. In this case, you will not have to do the joining - the installation will be quite simple.

The next version of woodgrain coating is porcelain stoneware with “Vietnamese” design. It is a floor made up of squares of several porcelain tiles. Each adjacent square differs from the nearest one in another direction.

A more complicated way is a ceramic granite tile for wood with “wicker” laying. To do this, use tiles of different colors and textures.In this case, the material is laid in such a way that it constitutes a pattern similar to basket weaving. It is very difficult to lay porcelain stoneware in this way by yourself - for this, they hire craftsmen. However, the result is worthwhile.

Popular also "deck" laying of porcelain. Rectangular samples are placed diagonally with a slight shift of the joints of all subsequent rows. This interesting variant of laying under a tree is very popular in modern interiors.

Stoneware brick

For the interior in the style of a loft perfectly suited for ceramic brick. It is created using double firing technology. The floor becomes resistant to fading, stronger and more durable. Such material can be used for decorative decoration of the interior in some modern directions.

So-called bricks can be large or very small, they can also be laid with Christmas tree, brickwork or other means. On the street, such material is used for laying on the paths in landscape design, as well as for finishing pedestrian areas.

Porcelain stoneware under the laminate

In the modern interior is very fashionable looks porcelain with a design under the laminate. This is an excellent solution if you want to arrange wood floors in the bathroom, but there is no possibility to use them, because they do not meet the quality requirements. That is why you can choose the so-called lamellas of porcelain, imitating laminate. The floor will also look modern and presentable, and the characteristics of low water absorption and high durability of porcelain stoneware will be preserved. It will completely imitate laminate in both color and design, and in texture, and even to the touch. But this cover is quite expensive. The difference will be only in the surface temperature of such a floor.

Such floors are also often laid in the kitchen. or in case the kitchen is combined with the living room. This solution is also suitable for a studio apartment. At the same time, ceramic granite tiles are used under the laminate and are combined with natural laminate: the kitchen area is usually finished with ceramic granite, and the living room and dining area is covered with a conventional laminate coating.

Thus, the workspace will be decorated more safely and without risk of damaging the floors, but in the dining area there will be a more comfortable warm floor, which also costs much less.With the help of such a coating, you can practically arrange the floors in the room, as well as produce a competent zoning due to the interesting design of this material. It is only important to carry out the correct joining of porcelain tiles and laminate.

To carry out a pronounced zoning, you can make a threshold - onn will allow you to hide the joint between these two coatings and divide the room into zones. But if there is no desire to make zoning, and you only need to conditionally divide the room into zones, then you can use the dock without the threshold.

Stoneware under concrete

In modern interiors in the style of hi-tech, minimalism or loft, laying ceramic granite under concrete is popular. Basically, this interesting design solution is presented in gray and beige shades, which in color and texture completely imitate this coating. Externally, it looks stylish and original.

How to choose?

When choosing a ceramic granite tile, you should think about the room in which you plan to use it. It is also important to determine for which surfaces you will need to use this coating. If you need to finish the walls with ceramic granite in the room for technical purposes,it is better to buy the simplest porcelain without decorative elements - you should not overpay for the structured or satined porcelain tiles for finishing such rooms.

When choosing a material for a particular zone or room, you need to take into account the specifics of this room. So, when purchasing porcelain tiles to finish the floor in the hallway or on the street, you need to give preference to models with medium-sized relief. Otherwise, dirt, sand and dust will be clogged in the relief elements. Therefore, it will be much more difficult to care for this coating.

Choosing a porcelain tile for your home, you should buy only high-quality models. It is better to overpay for such coverage than to buy Chinese and low-quality stoneware. Be sure to purchase models with calibration. Otherwise, you have to spend a lot of time cutting the tiles.

You should also purchase tiles that are included in one batch. Even if the models belong to the same collection, but were released in different batches, the number of color pigments and their saturation in ceramic granite may differ by one or two tones.Therefore, models from different packages should be checked for batch consistency.

Before buying, it is necessary to measure the total surface area, which is planned to be covered with ceramic granite tiles. Then you need to decide on the most suitable size of porcelain.

If the choice fell on the standard model size, then before purchasing the desired format, you must perform the calculation: you need to divide the floor space by the square of one tile. In this way, it is possible to calculate the number of tiles required for finishing. But it is better to round up the result obtained so that the facing material is probably enough for work.

When purchasing such a finishing material for a house or street, it is necessary to take into account the class of wear resistance, since it will be clearly different for different purposes of models. For example, porcelain tiles for a bathroom must meet the requirements of tolerance to the effects of chemicals. It is necessary to take into account the fact that you have to clean it with a special tool, as well as stains from cosmetics and personal care products will fall on it.Any porcelain stoneware should have good acid resistance so that it can last for a long time.

For exterior work, it is better to purchase large panels of small thickness - they will simplify finishing work, but at the same time, the coating will be no worse than other models in terms of quality characteristics.

For the hallway is better to buy anti-slip stoneware. The same requirement must be considered when buying a bath model.

This characteristic of porcelain stoneware is also important for the entrance hall as the floor will slide in wet weather. Therefore, the coating must have a matte and rough texture.

For the living room you can buy beautiful seamless porcelain stoneware. As a rule, such floors look whole and beautiful. The tile is trimmed at the plants on the ideal parameters. Thus, when laying the joints will not be visible. Monolithic stoneware in the living room will look very stylish and organic.

Care Tips

In general, the care of porcelain is an easy process. But depending on the specific type of coating, the peculiarities of care may differ. So, first of all, after laying such a coating, it is necessary to treat it with a water-repellent agent.Although porcelain stoneware itself has a low level of water absorption, moisture can penetrate into the seams between the tiles, which will destroy the coating from the inside.

In addition, water-repellent compositions must necessarily handle polished porcelain. This is due to the fact that after removing the top layer and grinding on porcelain stoneware micropores are formed, which reduce its hydroprotective properties.

If the work on laying porcelain stoneware is completed quite recently, it will be necessary to clean the grout for joints, which remains on the surface of the material. To do this, use an acid-based solution. And in order to remove the grout, it is necessary to apply special tools on the surface of the plates, leave for about an hour, and then remove with a brush. After installation, it is also important to wipe the floors and walls with a damp cloth and then wipe dry.

Polished porcelain stoneware after laying also must be necessarily treated with a sealant that will clog the pores on the surface of this coating. So, a special sealant is applied with a wide brush and is left to be completely absorbed.This procedure needs to be done one-time, but ongoing care is a simpler process.

You can purchase a product for the care of granite coatings and remove stains from the tile surface with their help. You should not clean the floor with metal brushes and sponges - it is better to use a damp cloth.

You should also perform regular dry cleaning with a vacuum cleaner or a regular rag. Dry cleaning should always be done before a wet one, since the remaining sand particles can serve as an abrasive and contribute to the loss of gloss and the appearance of micro-scratches on the surface.

As for the matte porcelain, it is the most unpretentious in the care: after laying it almost does not need to process. In this case, for the removal of dirt, the use of special chemical compounds is allowed, and it is also possible to clean it with an ordinary damp cloth.

Famous manufacturers and reviews

Now is popular ceramic Italian tiles Alaplana Fresno. These coatings are designed to finish the floor. The tile from the Fresno collection is decorated in marble with a matte texture. Models have parameters 45x45 cm.The surfaces are decorated with various patterns and ornaments using high resolution digital printing.

In Russia, porcelain is made Kerranova, Lasselsberger, and Keramin brandwhich produces tiles in many countries of the world. All these three companies are in great demand because they represent interesting tile collections that embody the perfect combination of price and quality.

Now the brand collection is especially relevant. Atlas Concorde Supernova Onyx. It combines classic and elegant models with modern and bright solutions. All of them repeat the exquisite texture of onyx stone.

In Spain, famous tiles are produced from KERAMA MARAZZI. This brand represents exquisite high quality models. Especially in demand Venetian stoneware tiles.

Porcelain stoneware tiles from brand atem has a lot of positive feedback. The manufacturer offers to purchase models for both walls and floor. Especially praise the modern design of such tiles, which is perfect for the design of current interiors. You can choose one of one hundred collections and choose the desired size of the facing material.

Examples of use in the interior

Porcelain tile is used not only for finishing the floor, but also for the walls. So, they can lay out all the free space on the balcony, using any technique. They can also beautifully arrange the kitchen. Especially popular is the combination of a kitchen apron made of glossy porcelain stoneware with similar tiles on the floor. With porcelain stoneware, worktops in the working area of the kitchen are trimmed and the apron area is faced in the same way. This harmonious combination looks both stylish and practical.

Ceramic granite can be laid out and the floors in the bedroom, but for this you need to use a heated structure. So, in this room is better to use stoneware parquet. It looks stylish and aesthetic. This is especially true of light models, for example, tiles in the color of bleached oak. It perfectly repeats the wood texture and has a delicate shade with beige notes.

How to choose porcelain stoneware, see the next video.