MDF moisture resistant panels: features and benefits

The bathroom is considered one of the most difficult premises, judging from the point of view of operation. In this part of the house, high humidity is often preserved and constant temperature drops are observed. The finishing materials used in the repair of sanitary facilities are subjected to such loads.

Recently, the shower room decoration with waterproof MDF panels is rapidly gaining popularity. This type of lining is used for decoration not only residential, but also industrial and commercial premises.

Specifications

Finishing the bathroom should have excellent technical characteristics compared to other similar options.A significant advantage in this case is the ability to carry out the installation process independently.

As a rule, ceramic tiles are used to design the above location. However, this option requires considerable expenses. It takes into account not only the cost of production, but also the price for its installation.

At the expense of modern equipment and innovative techniques on the shelves of stores there are new materials for wall decoration. Practical MDF panels designed for bathrooms, have excellent moisture resistance. The product has many advantages that we will look at later in the article. Currently, this option is considered a profitable alternative to standard tile.

Moisture-resistant products differ from conventional panels in their increased resistance to moisture and frequent changes in temperature.

Advantages and disadvantages

For many buyers, price is the deciding factor when choosing. Most materials used in the bathroom are expensive. Stylish MDF panels are distinguished by low cost, affordable to most buyers.The price depends on the manufacturer, quality and mark-up store, so before you buy, evaluate the market.

Quality product has a long service life. The average is 10 years. At the same time, the material retains its shape, texture, strength, and visual appeal. With proper operation, this period increases significantly.

The panels described are an environmentally friendly product, completely harmless to the environment, humans and animals. In production, ordinary sawdust and other wood components are used. Raw materials are carefully processed.

MDF panels can boast of high durability and reliability. Finishing is designed in such a way that from year to year it carries long-term temperature loads, humidity and other external effects.

Manufacturing companies have taken care not only about the technical, but also about the aesthetic side of the issue. The choice of consumers - a huge selection of colors. Given such a rich variety, it is not difficult to choose a model suitable for a specific style.

The process of mounting panels is easy and simple.The work can be done by hand, without spending money on the services of specialists. Professionals assure that even beginners who have no experience will cope with this. It is also an easy-to-handle material.

One of the main differences of wall panels is the ability to combine with other finishing materials. Facing can be placed on the surface under the tile, stone and other coatings. This feature allows you to translate into reality the original design ideas.

The dimensions of the panels make it possible to use them even on the basis of compact rooms. The wide dimensional grid of production includes a set of options as for spacious, and small rooms.

In the bathroom it is very important to maintain the required temperature. This is a prerequisite for a comfortable stay in it. High-quality MDF-finish has good thermal insulation, allowing you to create comfortable conditions in the bathroom.

Despite numerous advantages, this finishing material has its drawbacks.

After analyzing the products and reviews from real buyers and experts, the following disadvantages were identified:

- Low impact resistance.A sharp and heavy load can break the panel.

- Fire hazard Products are flammable.

- Low scratch resistance. During the installation process, take care not to damage the panels.

As you can see, the above disadvantages are insignificant, and given the numerous advantages, moisture-proof panels are a profitable acquisition.

Installation

To secure the panel, regardless of its size, you do not need special skills and experience. The work uses a standard set of tools. Despite the fact that the laying work is a simple and uncomplicated process, it has certain nuances.

To further facilitate the process of laying the finishing material, the sheets can be mounted on the sheathing. So under the construction you will be able to conduct various communications. This is the best option for rooms with uneven walls. If necessary, you can remove the casing from the batten and reuse it.

Work can be done without prior leveling of the walls, but only if the walls in the room are smooth and free from defects (chips, large cracks, etc.).

If there are flaws on the ground, you must get rid of them.The process of priming and plastering.

Plasterboard blocks can also be used. This option is the most reliable and efficient. As soon as the preparatory work has come to an end, it is necessary to take measurements of the room.

Styling tips

- Before you attach the finishing material to the wall, you need to give him a little time to acclimatize. It is advisable to leave the panel in the bathroom for a few days. This will allow products to adapt to the new conditions. During the lining will get used to the new level of moisture, as well as temperature conditions.

- It is necessary to carry out installation from a corner of a product. When making holes, remember that the smaller they are, the more profitable from the point of view of operation.

- The framework for laying the panels can be made of either metal or any other material.

- For fixing products used wall screws, nails, clips, as well as special brackets.

One of the options for fixing the lining - glue. It is a fast, simple and convenient way, but it is suitable only for flat bases. For work, special formulations are used that securely fasten the sheets to the walls.The advantage of the method is the saving of free space (ideal for compact rooms). The disadvantage is a complicated dismantling process.

Features of gluing panels:

- The layer of adhesive on which the sheets are laid should be no more than 5 millimeters.

- For the application of the composition is recommended to use a notched trowel for a more reliable grip between the finish and the base.

- Competent installation begins at the bottom corner of the product. Further, the process of fastening MDF continues in the direction until it stops. The following rows are stacked in the same way.

- Glue, which stands for the edges, must be removed, and not smeared on the wall.

- The maximum allowable gap between the elements is 1.5 millimeters.

- To improve the efficiency and reliability of fasteners, experts advise the use of silicone based sealant. It will also increase the resistance of the coating to moisture.

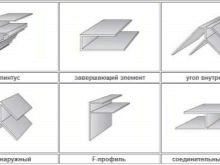

Beautifully arrange the gaps between the panels, you can use special moldings. This method will not only overlap the joints, but also make the coating more accurate and stylish.

How to make the right choice?

MDF panels are considered a relative novelty in the segment of finishing products.The product manufactured by the method of pressing sawdust is produced using special equipment. Due to the special treatment at the output of the product is obtained from the tree, which has excellent resistance to moisture.

Given the growing popularity of the product, more and more manufacturers offer their products to customers. On the one hand, a rich assortment gives more choices, on the other - it can simply confuse. Specialists have made a number of recommendations with which it is desirable to become familiar before purchasing panels.

To make the right choice, you need to figure out how different products of different types are different.

Dimensions and types

The durable finishing MDF material is different in size, shape and thickness of the panels. These characteristics are related.

Depending on the form, there are three groups of goods:

- Rack. The maximum width of the product is 28 centimeters. Thickness varies from 8 to 14 meters. The length of the rail reaches 38 meters. These are quite large panels.

- Tiled. Facing material is produced in the form of squares. Product length ranges from 30 to 98 centimeters.Combining various colors and textures, you can design an original and stylish design. The material is actively used for zoning rooms.

- Sheet. These are large and durable panels that differ in dimensions of 1.25 * 2.5 m. This option is preferably chosen for the design of large bathrooms.

The thickness of the cladding is related to their reliability and maximum sustained load. On thick panels, you can mount small cabinets, shelves and other structures.

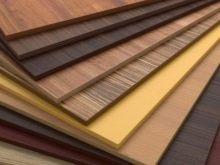

MDF products are divided into laminated, painted and veneered. For finishing the bathroom and bathroom most often use the first two options. The latter type is not so popular because of the need for careful pretreatment.

When buying a finishing material, you need to purchase components that will be needed during the installation process, as well as when decorating the corners and gaps between the sheets. Moldings are also different, and they are selected, given the size of the room, the type of cladding and other parameters.

How to mount MDF panels, see the following video.