Floor insulation with expanded clay: the pros and cons

An integral part of the repair is floor insulation. People who have started repairs often wonder: which material is better to use for installation.

The construction market has a wide range of raw materials that can be used for this task. One of the most popular and affordable insulation is expanded clay. Let's try to figure out what this product is.

Special features

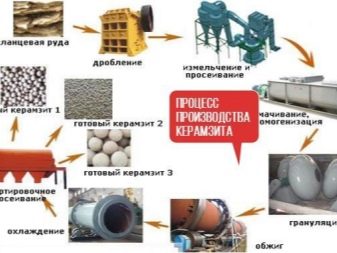

Expanded clay has several distinctive features from other materials. It consists of natural raw materials: clay and shale rock. Therefore, it is an environmentally friendly raw material, absolutely harmless to health. It is made in a cylindrical furnace under the influence of high temperature.

The rounded shape of the material due to the rotational movements in the stove.The material is lightweight: it has a porous structure, so it is most convenient to use in repair work.

Expanded clay can be used to warm the floor, walls and ceiling. It is also used in combination with other heaters (for example, with such as mineral wool).

Advantages and disadvantages

Each building material has its pros and cons. We will upset the advantages of using expanded clay, due to which it is particularly popular:

- it is an environmentally friendly material, it does not emit harmful substances in the air;

- excellent thermal insulation and sound insulation is formed due to the porous structure of the building material;

- durability and frost resistance are characterized by high strength of clay raw materials, as well as good resistance to high and low temperatures;

- The fire resistance of the material will ensure your fire safety: it will not catch fire.

- the lightness of the material is a huge plus for warming walls and ceilings;

- round shape facilitates the construction process;

- The low cost of raw materials is a nice bonus for repair costs.

Despite the large number of advantages, expanded clay has a number of disadvantages:

- Hygroscopicity: granules absorb water well. After that, the material becomes heavy, which leads to the deformation of the work done. It is not advisable to use expanded clay in the repair of wet rooms.

- Material fragility due to its porosity. It is necessary to carefully lay down the raw material: when damaged, the number of positive properties is reduced.

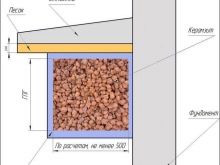

- Requires a large layer expanded clay for high-quality thermal insulation.

Species

Expanded clay is produced in the form of granules, which differ from each other in their size.

Depending on what size the initial granules are involved in the production, there are several varieties:

- expanded clay sand - fine fraction material;

- expanded clay crushed stone - medium fractional material;

- expanded clay gravel - large fractional material.

All of these types are made on the same technology, but they are used for different types of construction works. Expanded clay is made by grinding larger granules. Particle sizes range from 1 to 5 mm. It is used as a filler for cement mortar.It is also used in a mixture with gravel and rubble to fill in empty spaces.

Ceramsite crushed stone is not round, it is more angular. This material is formed by crushing large pieces. It does not have a certain size, rather it is the medium-sized granules between sand and gravel. Use it as a base layer of backfill.

Expanded clay gravel has dimensions from 5 to 50 mm, it is distinguished by an oval and rounded shape, is the most demanded material during construction work. Basically it is used for floor insulation.

Which is better?

Experienced builders recommend the use of a mixture of all types of expanded clay. Particles of different sizes are able to fill the empty space between the granules, which will further improve the quality of the work done.. Depending on the object of work (for example, in a house or apartment) choose which type of claydite is better to use.

Each fraction has an advantage in a particular use case. For dry screed it is best to use fine fraction expanded clay.. The sand will create a dense layer up to 5 cm thick.

For expanded clay screed used coarse-grained material (eg gravel).

Use cases

There are many options for the use of expanded clay, for example:

- It is possible to apply this construction raw material under a coupler. The presence of a porous structure characterizes a good insulating property of the floor. You can use it for warming the floor in a wooden, stone private house, in the warming of the loggia, attic and balcony.

- Expanded clay is used to fill the foundation of the house and finish the basement to insulate the first floor and form a blind area around the house.

- With the help of expanded clay fractions it is possible to isolate the stone basement, walls, chimney, floors of buildings, steam room.

- A mixture of expanded clay is used to create concrete blocks that are capable of holding on to screw piles. And also apply it to the timber frame overlap.

- This material is used as a cushion for the subfloor.

- To save heat, communication and water pipes are insulated with expanded clay raw materials.

- At the dacha the use of expanded clay is especially important. It is possible to form paths, to insulate a room built in a half-block, to decorate flowerbeds and lawns decoratively.

How to calculate?

For warming the floor often use a layer of expanded clay with a thickness of 15-20 cm. To calculate the amount of material needed, use the program "Tower". It helps to automatically perform accurate calculations in accordance with the rules and regulations, optimally easy to use. You only need to enter the parameters of the work object and the material that you will use.

How to warm?

There are several ways to warm the floor:

- dry insulation (with this method, the material is filled up in its original form);

- wet styling (characterized by mixing concrete and expanded clay);

- combined method (the first layer is filled with dry material, then a mixture of concrete and expanded clay is poured).

To warm a wooden floor, it is important to use the following sequence of actions:

- dismantling the flooring;

- surface preparation;

- waterproofing;

- installation of rails;

- expanded clay filling;

- installation of flooring.

To begin with, the dismantling of the upper layer to the level of the lag. Boards are removed and taken out of the room. After that, carefully inspect the lags and measure their level. Rotten, curved bars or deformed are replaced by new ones.. If possible, you can install new ones.

The next step is surface preparation. Clean it from debris and inspect.

If you find small cracks, it is recommended to rub them. If there are deep cracks, it is important to cover them with cement mortar or to seal them with building foam.

Inspect and work corners and joints. After that, for better adhesion to the surface of the waterproofing material you need to use soil. Next, the surface is covered with sand or treated with coating waterproofing materials (polymer waterproofing mastic, cement-bitumen composition, bitumen-polymer mixture, liquid rubber, roll materials).

To perform waterproofing, you will need a film that needs to be spread so that it covers the entire floor. It is important to fix lags with a construction stapler or scotch tape. With this it is important that the film fits snugly to the bars and grooves below. If you dismantled the bars, the next step is to install new rails. New logs are set to level and strengthened with the help of corners, which are screwed with screws.New slats are installed on the prepared surface.

Further, claydite is poured, mixing small granules with large ones. Backfilling is recommended to lay from the walls from right to left. It is important to fill the whole space so that there are no voids left..

The layer of raw materials should be smooth. To do this, set the beacons, which are oriented. After backfilling, the material is gently tamped down, leaving the particles intact.

A layer of expanded clay is covered with a waterproofing film, which is reinforced with a stapler and tape. The membrane can be diffusion, super diffusion, metallized, waterproofing. For floor insulation experienced builders advise to buy waterproofing film, as it compensates for the main disadvantage of expanded clay, similar to parchment.

On the protruding insulation stack the rough floor of plywood. After that make installation of a finishing floor covering. To warm the floor under the concrete base, the same algorithm is performed, but the following steps are added: reinforcement and screed.

Reinforcement - installation of metal mesh with large cells, which is placed on the insulation.It has important properties: increasing the strength of the screed, protection from the occurrence of cracks, increasing the service life, preventing subsidence. For the reinforcement of the screed, you can use metal mesh, polymer, fiberglass or fiberglass. The strongest of them is metal mesh.

By means of the coupler condense and level a surface. The solution consists of sifted sand, cement and water. Sand and cement are taken in a 3: 1 ratio, kneaded until a thick homogeneous mass is formed.

You can make lightweight aggregate. More often it is used in the event that it is necessary to raise the level of the floor or when the rough coating is uneven.

The mixture is prepared from sand, cement, expanded clay in a ratio of 1: 2: 4, and water is poured in to form the desired consistency of the solution. The screed should dry for about a month.

Reviews

According to reviews of Internet users, we can conclude that expanded clay is the No 1 material for warming and leveling the floor. Everyone notes only the positive properties of this building material, advised to use it in repair work.

About the unsuccessful experience tell only a few, which, most likely, did not comply with one important requirement - waterproofing.

For how to insulate the floor with expanded clay, see the next video.