Features metal collapsible garage

Collapsible garage is a convenient and practical facility for placing a vehicle and is very popular among car enthusiasts.

Our article is devoted to the features of this design.

Special features

Collapsible garage is a pre-fabricated temporary or permanent structure, the installation of which does not require the formation of a capital foundation, and installation does not cause any difficulties and can be done independently. Prefabricated garage produced in standard sizes with a minimum width of 2.9 m, a length of 4.6, and a height of 1 m 80 cm.

More dimensional models have a height of 3.5 m, a width of 4 m and a length of 6 m. Prefabricated garages are a designer, which consists of frame parts, facing panels and fasteners.

The framework of a construction is made of a steel galvanized profile of a U-shaped or square configuration, possessing good anticorrosive stability and providing a durability and rigidity of a design. Steel has the first class of galvanization and is characterized by a high indicator of strength C-350.

To give the garage more stability, diagonal stiffening ribs are often installed between the vertical frame elements, which help to withstand the wind load and guarantee the preservation of the original shape of the structure throughout the entire life cycle.

On the upper part of the frame is a truss system designed for dual or single pitch roofing.

To ensure the hydro-and thermal insulation of the building, the construction kit includes additional elements in the form of abutting slats, providing protection from wind and rain.

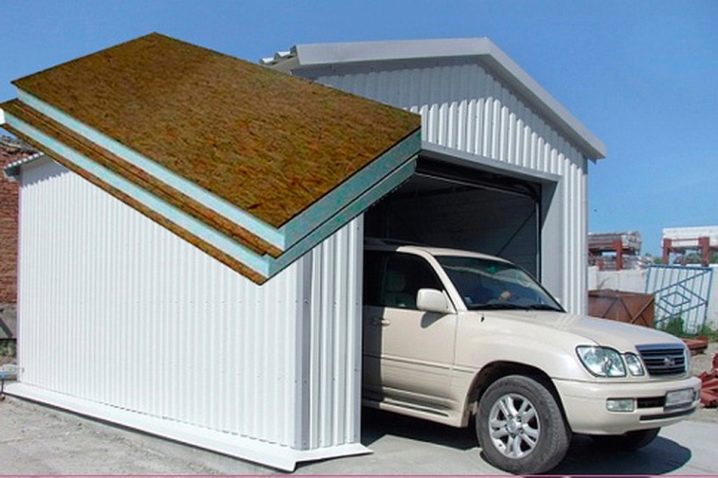

The roof can be made of sheet metal, galvanized profiled sheet, metal tile and sandwich panels with insulation. The simplicity of the roof design allows you to place a ventilation system of any type and perform ceiling insulation.

The design of the frame consists of an upper and lower frame, to which vertically arranged stands are screwed. The step length between two adjacent elements is 2 meters. Racks are placed around the perimeter of the buildingand the front side of the garage has two additional supports for installing the gate.

The walls of the building are made of corrugated with a thickness of 2 mm, attached to the frame with bolts and a metal corner.

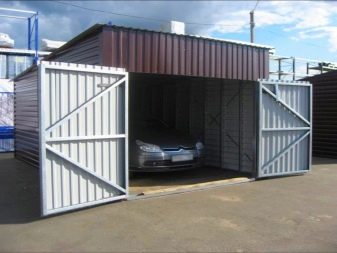

Garages are equipped with gates with lifting, sliding or hinged opening system. Swinging system is the most budgetary option, but has a significant drawback, which is the difficulty of access to the garage during heavy snowfall. Also swing system implies the presence of free space before the constructionnecessary for the free opening of the valves.

The cost of a collapsible garage depends on many factors. The presence of thermal insulation and an automatic door opening system, the number of shelves and racks, equipment by a ventilation system, the presence of additional windows and a fire alarm are taken into account.

Advantages and disadvantages

The high consumer demand of collapsible garages is due to a number of undeniable advantages of their design:

- Low cost in comparison with stationary capital buildings and underground parking places explains the growing popularity and demand for prefabricated systems.

- Quick and easy installation without the need for expensive equipment and the involvement of specialists allows you to install a full-fledged garage on your own and in a short time.

- Due to the fact that the collapsible garage does not apply to capital buildings, for its installation does not require special permits and conclusions.

- The high fire safety of the structure is due to the absence of highly inflammable and combustion-supporting materials in its construction.

- The small weight of the garage allows its installation without a foundation.

- High anti-vandal properties and resistance to mechanical stress contribute to the preservation of the original appearance throughout the entire service life.

- Good protective characteristics due to the fact that cutting the metal is not easy.This will require special equipment, and the process itself will make a lot of noise than it will attract the attention of others.

- The versatility of the design allows the use of a collapsible garage in any climate zone.

The disadvantages of prefabricated structures can be attributed to the possibility of theft of the garage with the help of a hydraulic crane and a car platform.

The installation of a strip or column foundation and the formation of a concrete floor 10 cm thick will help to avoid trouble. In addition, it is recommended to weld the walls of the garage to the concrete bars of the reinforcement in 50 cm steps.

The disadvantage is the appearance of condensate on the internal surfaces of the structure. In order to prevent this phenomenon, the ceiling and walls should be insulated with mineral wool or expanded polystyrene plates, followed by sheeting and fibreboard.

Another disadvantage of collapsible garages is their susceptibility to corrosion, to prevent which structures need to be painted regularly. Especially it concerns self-made structures.

Attention is drawn to the low temperatures inside the garage during the cold season.Part of this problem can be solved by installing a heating system and pre-warming the floor, ceiling and walls.

Kinds

Structurally collapsible garages are presented in three types:

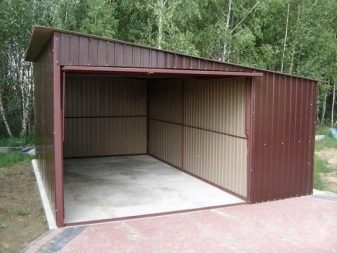

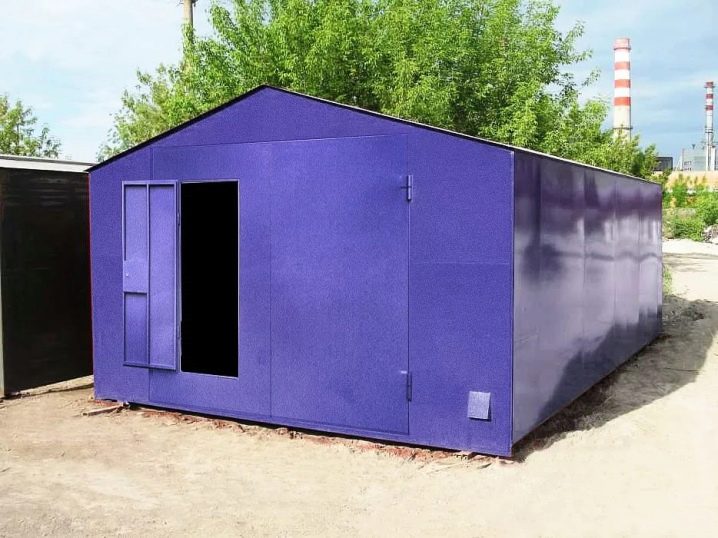

- Metal frame. This is the most common type of collapsible structures, which is considered the most versatile. It is characterized by ease of assembly and low cost. The steel profile is usually used as a frame, but sometimes a wooden bar or board is used. The metal structure is sheathed with iron sheets with a thickness of 2 mm and, if necessary, painted.

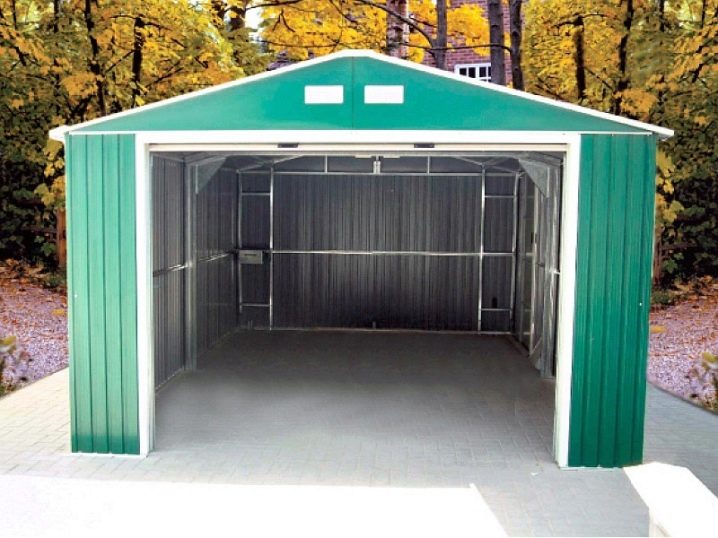

- Sandwich panels. Models are made on the basis of a metal frame and are distinguished by high heat-saving characteristics. The sandwich panel is a construction of two layers of sheet metal with a heater laid between them and is characterized by fire resistance and aesthetic appearance. This allows you not to perform decorative trim inside the garage and not to use additional insulation.

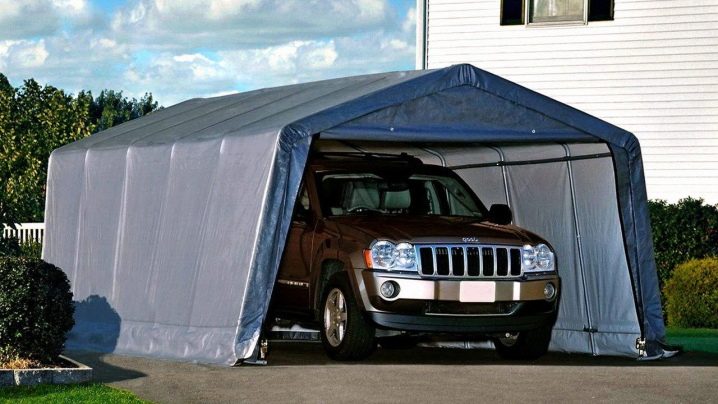

- Awning. The structures are characterized by high installation speed and low cost. Formed shelter is a temporary structure and allows you to store a car in it at the cottage in the warm period.The garage has a frame basis, and a strong thick fabric acts as a protective material. In order to install an awning garage, it is necessary to dig in and concrete four pillars, and then stretch the awning on them.

Materials

On the modern construction market there is a huge amount of materials, so it is easy to assemble a garage on your own. Initially, you should determine their list, and calculate the required number. According to the accessories materials can be divided into three groups: for the foundation, frame and sheathing.

If you plan to design a metal frame, then you need to stock up on the corners, galvanized profile and pipes. If the frame is planned to be made of wood, then you will need a board, plywood and timber.

Next you need to decide on the material for the formation of the foundation.

If a car garage is being built as a permanent structure, it is recommended to use a concrete foundation that will serve as a reliable basis for the entire structure.

Reinforced concrete slabs are well suited for the floor, repeatedly increasing its strength.

However, it should be borne in mind that Gravel should be covered under the floor of concrete goods. It creates a “cushion” necessary to raise the garage above the ground and does not allow rain and melt water to flow under the garage.

For the formation of a concrete floor and screed device, cement M-200, crushed stone, sand and reinforcement bars with a thickness of 6 to 8 mm will be required.

For the interior of the finished garage will need sheets of drywall, plywood and wall paneling. If you plan to use the garage to store the car in the winter, it is additionally recommended to buy insulation. For exterior trim homemade garage will need primer and paint.

How to collect?

Unlike capital panel structures, the quick-assembly metal garage can be built independently.

Conventionally, the assembly is divided into several stages:

- Foundation formation Begin with the removal of the fertile layer and thorough tamping of the soil. Then, exactly repeating the size of the frame, a trench is dug, the depth of which should not exceed 50, and the width - 60 cm. The bottom of the trench is covered with sand and carefully tamped. The thickness of the layer is usually 20 cm. Next, a plywood formwork is installed with a height of 20 cm above ground level.

The distance between the sheets of plywood should be 40 cm, and the bottom is required to cover with polyethylene.Then you need to install the reinforcement rods, tie them up with wire and fix them with transverse rods, the distance between which should not exceed 50 cm. Next, a cement mortar consisting of one part of cement, two parts of sand and two parts of gravel is prepared and poured. After the concrete has completely set, the formwork is removed.

- Screed device. Initially, the floor should be covered with sand. The thickness of the layer must be at least 10 cm. After that, the sand is carefully tamped. Then a reinforcing mesh made of reinforcement from 8 to 12 mm thick is laid on top of the sand layer, and lighthouses are inserted. Next, pour a layer of solution thickness of 10 cm.

- Frame installation. The first step on the completely dried foundation is set and firmly fixed the lower frame. It is very important to carefully align the structure with a building level. Then a vertical profile is installed at the corners of the frame and at the place of fastening the doors.

Then the roof truss is mounted and the roof is laid. The fastening of the frame elements is made with the help of bolts, nuts and metal screws.

- Gate installation. For collapsible improvised garages, it is more rational to use a double-wing swing system. The first step is to assemble the frame for each half, and drill holes in it for the bolts. Then the canvases are fixed in the frames, and the resulting flaps are hung on the inner loops, which should be pre-fastened to the vertical posts.

- Sheet metal sheeting. For the formation of the walls of the garage is usually used sheet steel or steel sheet. The material should be fastened with metal screws, laying rubber washers under them. After installation, the surface is primed and painted.

For painting, you can use alkyd or acrylic enamel. Alkyd paint dries very quickly, but is characterized by increased flammability. Acrylic has a long service life, does not fade in the sun, non-toxic and fireproof.

- Installation of locks. The most suitable option are mortise and overhead models. The use of padlocks is not recommended due to their low resistance to burglary. On the inner part of one of the valves should be installed vertical latch, necessary for better fixation of the gate.

- Electrical installation, ventilation and insulation is made at the request of the owner of the garage. Temporary and seasonal designs are not usually equipped with additional systems.

Tips and tricks

Strict compliance with installation technology and the advice of experienced professionals will help build a reliable and durable car storage facility.

- To connect the details of the construction should be used only galvanized fasteners. This will help to avoid damage to metal by corrosion and prolong the life of the structure.

- When assembling the frame, it is recommended to constantly check the readings of the building level. On how smoothly the installation of the bottom trim will be performed, the correctness of the construction of the structure as a whole depends.

- The slope of the roof should be 20 degrees or more. With a lower incline rate, water will accumulate on the roof surface and adversely affect the metal.

- Sheathing of the frame sheet metal should be made from the bottom up.

- The most budget and effective insulation is foam. To fix it on the inner surface of the walls of the garage, you can use foam and galvanized anchors.

- Fasteners in the installation process should be carefully lubricated. This will help to quickly unscrew them if necessary dismantling.

Collapsible garage is easy, but at the same time durable construction, and allows to solve the problem of temporary and permanent placement of vehicles, significantly saving money at the same time.

How to assemble a collapsible garage with your hands, see the next video.