How to install suspended ceilings without heating their own hands?

More recently, the ceiling finish assumed his whitewashing or just plaster. Then ceilings and suspended ceilings began to appear. Nowadays, when choosing the best way to finish the ceiling, many people prefer the stretch ceiling, which can be made using PVC or from a special fabric treated with protective agents.

Special features

PVC film is distinguished by its ability to reflect light. She can hold a large amount of water, take care of her quite simply. A serious lack of stretch ceilings is a complicated installation. At installation of a design it is necessary to heat the room to high temperature. There are several reasons for unwanted heating of the room.

- The room should be completely freed from the decoration and furniture, as at high temperatures they will become unusable.

- The use of a heat gun is quite expensive and requires special skills.

- There is a risk of contact with unscrupulous employees, which can lead to an accident. For example, the equipment may be faulty or the worker will not be sufficiently qualified.

- It is impossible to independently install the tensioning structure with the help of a gun, since the specialists working in this field must undergo special training.

Fabrics do not need to be heated, as they can become narrowed and deformed when exposed to high temperatures. When installed, such a cloth is loaded into a pre-assembled profile under normal temperature conditions. That is why the installation of a stretch ceiling without heating is becoming more and more common among people who are self-repairing their apartment or house.

There are some factors that affect the cost of work.

- Material itself. For example, the most expensive canvases are from German and French manufacturers, and the cheapest ones include ceilings made in Russia or China. Also, plain canvases are cheaper than those that have different prints and designs.

- Room shape. The harder it is, the more difficult the installation process will be.

- Additional decorative elements (relief, bends and so on).

- Type of lighting. For example, the illumination can be single or multi-level, with diodes around the perimeter, with a lot of point halogen lamps over the entire area, and the like.

- Professionalism the master himself is the fifth and main factor in determining the cost of work.

Kinds

There are several main types of stretch ceiling coverings.

Glossy

This is the most common type of ceiling. Such canvases are presented in an extensive color palette and can even be in two or more colors. With the help of a glossy ceiling (even a dark shade) you can visually expand the room, as it has a smooth surface. The disadvantages include the visible seam, which is formed when welding two parts.

Matte

Such a ceiling is a classic option when installed in the home. Because of the non-shiny surface, the shade of the material is clearly transmitted, and you can focus on the interior itself, since the ceiling will not be the main detail of the room.

Satin

In appearance, satin canvases look like matte, have a perfectly smooth surface that allows you to focus on the deep saturation of the hue. In contrast to the matte surface, satin canvas reflects light well, but worse than gloss. Also advantages include stealth welds.

Fabric

It cloth fabrics do not require heating the room. They are also used if necessary for the material to “breathe”. Externally, the fabric structure is not much different from matte - it all depends on the tension. So, the surface can be made not only flat, but also with a relief (for example, a corrugation or plis is often used).

It is worth knowing that such ceilings can be made of polyester or of ordinary material. Depends on the degree of transmission of air.

Merits

Like any material, the fabric has many advantages.

- Fabric ceilings have no seams.Since PVC films are manufactured in certain sizes, it is often necessary to sew two (or even more) pieces when installing in large rooms. This is done using high frequency current. Of course, the seam will not be very noticeable, but this may affect the strength, because the solid material will be much more reliable.

- Fabric material for suspended ceilings in the manufacture passes the stage of impregnation with various polyesters. Due to this, the product will have high strength and reliability. Unlike film, fabric piercing or tearing will be very difficult.

- The composition of the material does not contain toxic substances. Often a sharp smell of chemistry remains from the PVC film. The fabric ceiling will smell like fresh linen.

- Natural ventilation of the room will not suffer, as the fabric is well breathable due to the porous structure. This quality will help to avoid creating a greenhouse effect and the formation of mold and fungi.

- Excellent tolerate temperature extremes. Often these ceilings are installed in rooms without heating due to good resistance to frost.

- There is no need to use a heat gun during installation.

- You can install various hidden light sources.

- It has good fire resistance, that is, in the event of a fire, the material does not ignite.

- Long term use. Fabric stretch ceilings with proper installation and good care can last more than twenty years.

- Few people know that fabric stretch ceilings can be painted (and not even once).

When painting it is necessary to use acrylic enamel, which is represented in the widest range of colors. Thanks to this, you can embody any design ideas, and the fabric ceiling can safely be painted 8-10 times.

disadvantages

Fabric stretch ceiling has some drawbacks.

- The rather high cost of a fabric web (more expensive than a film), but this is offset by an inexpensive installation and functionality.

- The fabric cloth will not save from a large amount of water in case of flooding from above, unlike a PVC film. If water gets on the canvas, it can change the color that will look unaesthetic. For this reason, they can not be installed in rooms with high humidity (for example, in the bathroom or kitchen).

- It is better not to use in rooms with low ceilings, since during installation more free space between the stretch and main ceilings is required, and the height of the room will be even smaller.

Mounting methods

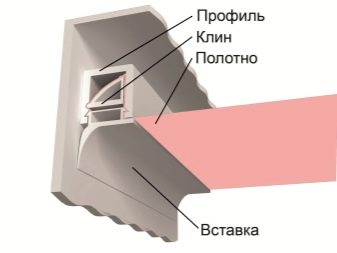

Wedge

This method greatly simplifies the installation process, especially if it is done by hand, since the material does not need to be tailored to fit the room. The cloth is required to be tightly fixed in the baguette, using the expansion bar. After that it is necessary to cover the distance between the walls and the ceiling with a decorative plinth.

After completing the wedging step, excess material is cut off using a construction knife.

Cam

It is mainly used if it is necessary to make inserts when the area does not exceed 20 square meters. With a larger area of vinyl can sag or stretch.

When using this method, as well as with a wedge, you do not need to cut out the material in advance. It is fixed between the movable and fixed cam baguette.

Harpoon

This method of fastening is the most reliable and practical, as it provides the possibility of complete disassembly and then assembly of the same design.This is especially useful if there is a high probability of leakage from above. The downside is a great investment of time, since it requires a preliminary pattern of the web with the help of equipment specially designed for this, as well as the fact that the harpoon is welded in production at the manufacturing stage.

Installation

Installing stretch ceilings without using heat, it is easy if you have basic skills in repair. Most likely, one person will not be able to install a stretch ceiling, so you need to assemble a company of two or three people.

To begin with, it is necessary to remove the previous finish from the main ceiling so that it does not subsequently fall on the stretched material. In addition, the walls must also be cleaned of old finishes and plastered with cracks and defects. Then you need to apply on the surface of the ceiling and walls (about 10-15 centimeters from the ceiling) antiseptic and waterproof primer. This is done in order to avoid the formation of mold, fungi and other microorganisms.

The next step is to create a markup of the places where the lighting devices will be installed,and conducting electrical wiring (it is recommended to hide in corrugated pipes and only then fix it on the ceiling). Further, it is necessary to outline the attachment points of the supporting profiles. To do this, use the level and cord.

Fastening profiles made in increments of 20-25 centimeters. After that, you can proceed to the tension of the fabric. Since the canvas will be spread on the floor, it must be washed well.

After unpacking the canvas, it is necessary to moisten a little with the help of a spray gun and pick up its edges to the profile frame using a crocodile. Along the edges, it is necessary to leave the material allowances and fill it with a profile using a round spatula. To achieve a uniform tension, allowances need to be filled together on opposite sides.

The final stage is cutting off excess material and closing the junction of the walls and the ceiling with a baguette. After the fabric dries, the tension against the material will become stronger. The correct installation technology must always be maintained, as it has the most positive reviews.

In the video below you can clearly see the installation of a stretch ceiling.