Epoxy table - an unusual interior detail

The original wooden furniture, created using modern technology, will delight households and will certainly surprise guests. Such an interesting interior detail will be a table made of epoxy resin. This product will decorate any room, you only need to choose a good design.

Special features

Over the past few years, epoxy resin tables have become very popular. Initially, it was used for the manufacture of glue, insulating varnishes, plastics. Now epoxy resin is widely used by designers to create exclusive interior items. Very beautiful tables are made of such material.

Original furniture can be made independently.

Dried epoxy resin is able to maintain the original volume - this is one of its main advantages. Varnishes, for example, dry up because the liquid that enters them evaporates, and as a result the volume is lost. The resin hardens as a result of a chemical reaction. A table made of epoxy will not only be aesthetically appealing, but also durable. Such surfaces are resistant to temperature changes, humidity and mechanical damage. They are reliable and durable. With the help of epoxy resin, you can not only create new furniture yourself, but also transform old furniture.

Another important advantage of this material is low price It is available to all comers. Inexperienced craftsmen are pleased that working with epoxy is very easy. To do this, you do not need special knowledge and skills, you only need to do everything in a certain order and take into account the recommendations of the masters.

Kinds

Tables made of epoxy are striking in their diversity: there is furniture of various forms. Materials are hot or cold cured.If you create a wooden table made of epoxy resin at home, usually choose substances belonging to the second type. Design options for such furniture are very different. The table top can be completely made of epoxide and with a combination of materials, with different attachments, multicolor or one-color.

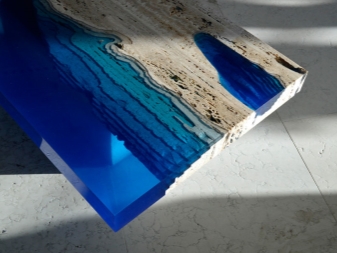

It all depends on your capabilities and imagination. A popular solution is the combination of natural wood and epoxy (for example, a "lightning" pattern). You can get the effects of a variety of landscapes - from sea to mountain.

Materials used

The following basic requirements for epoxy resin can be distinguished:

- The cost of epoxy should be low, because it will need a lot. Optics and jewelry materials will not work.

- The substance should differ in low viscosity, so that after mixing it does not remain bubbles.

- When curing the material should not lose volume.

- Suitable for furniture should harden slowly enough. So it will be possible to form various freakish distortions from epoxy until it is frozen. When the material is liquid, it needs to be poured, when it is very viscous (similar to rubber) - to form.

- To get almost any visual effects, you need to choose a transparent resin. You can add color to it.

Some illuminate this material from below using a phosphor or LED strip.

Epoxy freezes in several stages:

- Liquid. The substance flows freely from the sticks. In this state, it is just great to fill the hollows, fill forms.

- On a consistence similar to honey. This epoxy is a great adhesive, but it is not suitable for casting.

- Almost non-segregating. In this state, the resin is practically not used. It is necessary either not to bring it to such a stage, or to wait until it becomes even thicker.

- Rubber. Epoxy in this state can be compared with clay. Such material is used in order to obtain elements that differ in various fanciful forms.

- Hard material. This is the final stage. At this stage, the product is already completely ready.

Tables are made from solid wood. To create interesting products, you can use different elements: chips, round cuts, parts of plates.For the manufacture of furniture from epoxy some choose an old tree, shabby pieces with voids, corroded by bark beetles. Filling the hollows with resin, you can achieve very interesting effects. Focusing on the chosen style, complement the design using different decorative elements:

- Photo;

- Fir branches;

- River pebbles;

- Traffic jams;

- Cones;

- Coins;

- Seashells.

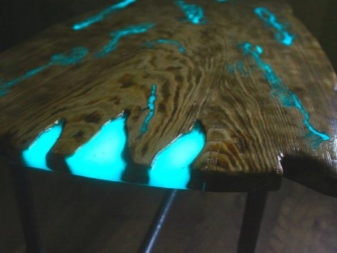

To achieve the effect of a beautiful glow of the surface, you can add fluorescent powder to the material. Epoxy is also suitable for modern motifs. Embed foil, semiprecious stones, metal elements, glitter. Putting on the open parts of the surface metallic paint, you can achieve a fantastic overflow.

Subtleties of manufacture

Careful preparation for the manufacture of epoxy countertops - a guarantee of excellent results. To make it as convenient as possible to mix the material, select the appropriate dishes for this. Its size will depend on how much epoxy you need. Prepare also measuring containers, a stick with which you will mix epoxy.Read the instructions: the proportions are different, they are determined by the manufacturer.

Prepare also the following:

- A room that is suitable for work. The temperature in it should be room temperature. Check if you have enough free space.

- Grout, separators (this, for example, petrolatum, paraffin). They will help ensure that the epoxy does not stick to the form. To be able to rub the gap, prepare the clay.

- Tools for grinding. The best option is a special grinder.

- Phosphors, pigments and so on.

- Elements of decor.

Measure the epoxy first and then the hardener. You will need to add it to the base.

Stir the material very carefully, it will affect the freezing. When the epoxy reaches a suitable consistency, it can be used.

Cracked wood

It looks very interesting wooden surface, corroded bark beetles or fungus. The “tracks” are filled with epoxy. In this way, you can get just fantastic pictures. You can make holes in the wood yourself.

To fill cracks and holes with resin, use a brush or spatula.When the material becomes hard, strip off the excess using a special grinding device; Epoxy should only be in the holes. Then apply a protective varnish on the countertop, it will protect the wooden surface from the effects of liquid and add brightness to the pattern.

Transparent or monochrome surface

First clean or degrease the workpiece. Wood is a material that absorbs moisture, so you will need to prime it using resin. So you can prevent the occurrence of bubbles. Then prepare the epoxy and place it in the mold.

If you want the surface to be colored, add the necessary colorant, while it is desirable that the pigment be from the same manufacturer as the resin. Dyes of different shades should be chosen in the event that you want to achieve interesting combinations of colors.

When the tabletop is filled, leave it for ten to fifteen minutes. If bubbles occur, remove them. After two days, sand and polish the surface. Seven days later, the furniture can already be used.

Filled Surfaces

The most interesting products of epoxy resin - options with various fillers.When creating such furniture are used a variety of items: bottle caps, beautiful pebbles and so on. If you are going to create such a product, you must first clean the surface, remove fat from it. If necessary, coat the blank with paint.

You can use small bumpers.

Put the fillers on the bottom of the workpiece. Make sure that they are completely dry. If the fillers are too light, stick them to the bottom, otherwise they will float. In cases where the elements used are small in height (up to 5 mm) and simple in shape, a single layer of resin will suffice. If there are indentations on the surface, protrusions or fillers are large enough, you will have to pour the epoxy in several stages (there should be up to two days between them).

Useful recommendations

The experts shared the following tips:

- Remember that the workplace must be covered with polyethylene. Other materials can be used to protect surfaces. Such precautions are necessary because otherwise epoxy may spill. The hardened substance will be very difficult to remove.

- If you are going to start working with epoxy, wipe the dust in the room.

- If liquid gets into the mixture, the tabletop may be damaged. Ensure that there is no water in the workplace.

- Note that if there is a lot of material, it will freeze faster. A layer of 1-2 cm will become hard in 24 hours, and 1 mm will not dry in a few days.

- Curing can be accelerated by increasing the temperature in the room. However, start heating only after the epoxy thickens at least a little.

- Do not forget to carry out grinding, polishing surfaces. To do without such work is obtained very rarely.

- Sunlight can damage the finished product. Using color will reduce the effects of UV radiation.

How to decorate the countertop using decor and epoxy resin, see the next video.

Beautiful options in the interior

For the manufacture of tables made of epoxy resin, you can use a variety of fillers. This original product catches the eye with a variety of color tones.

For decorating furniture from epoxy often use a variety of bright lids. You can collect a whole collection and perpetuate it in such an unusual way.

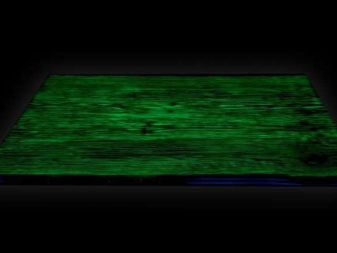

The green luminous table, created using photoluminescent paint, will make you feel like a real fairy tale.

A bright card on the table is an idea that is striking in its singularity. Such furniture is an ideal option for creative people, adventure seekers.