How to make a compartment door with your own hands?

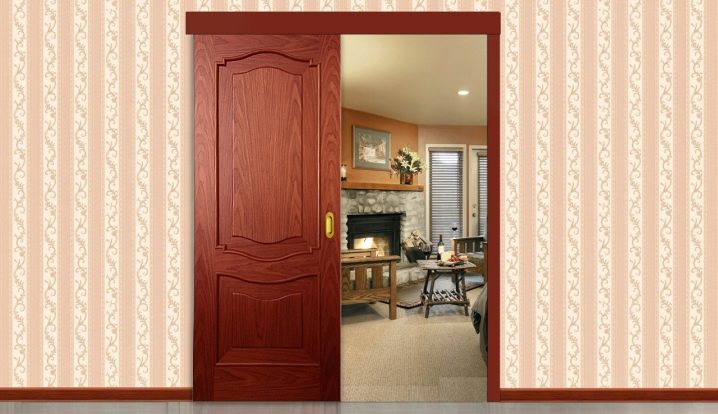

In modern houses and apartments, more and more often lately, coupe doors are being installed instead of not very comfortable hinged structures. They allow you to efficiently use the space of the room, enliven the interior, as well as being the most suitable option for people with disabilities. In addition, you can install them not only in the doorway, but any niche. This can be done with your own hands, thus saving a significant amount, the main thing is to find time, materials and tools for such a useful and fascinating process.

Required components

The compartment door, like any other design, consists of special elements. In order to install it, you must purchase components. The choice of necessary parts depends on the type of sliding system and the type of door leaf. Door leaf can be solid and consist of one material, and may consist of several materials. Regardless of the materials used, any composite fabric (sash) consists of profiles of different size and purpose. The frame has top, bottom, two side and intermediate (the number depends on the component parts) profiles.

The upper horizontal profile consists of two slots. The lower part of the groove holds the material, and the upper with a circular groove is designed to screw in the screw that holds the vertical profile of the door. The lower horizontal profile, like the upper one, consists of two grooves, but its lower part has longer side walls designed to hide the rollers.

The horizontal intermediate profile consists of two identical grooves. It is used as a link between the materials.Vertical profiles perform not only a supporting function and have a special groove to support the material, but also needed to set the sash in motion. This element is made in the shape of a pen and has various modifications.

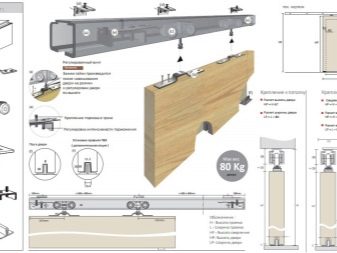

To drive the sash need a set of guides and rollers. To maintain the direction of movement of the sash, a pair of asymmetric rollers are used, which are installed in the upper part of the sash and located at different ends of the frame. In the lower part, a pair of rollers is installed in the same way. They are the main driving force, it is they who bear the weight of all the materials used.

Without guides, the movement of the valves is impossible. They are usually bundled in two pieces: upper and lower. They differ in form and purpose. The structure of the upper profile depends on the type of system. If an upper sliding support system is used, then a closed profile consisting of one groove is used. But most often for installation of a door of a compartment it is used lower support system and therefore the shape of the profile has a slightly different look.

It consists of two grooves of the same shape and depth.Thanks to him, the door moves in a given direction. The lower guide is designed to move the rollers and is a profile consisting of 3 slots. For each pair of rollers is designed its own groove (narrow). The middle wide groove performs a separation function.

In order to prevent the door from moving out of use, stoppers are used. Their shape depends on the type of sliding system. These elements are installed in the guides.

Materials

There are various types of materials used in the manufacture of compartment doors. For panel types of doors consisting of a whole sheet, one material is used. For composite (filleted) is used, as a rule, several types of materials that fit into the frame of a certain form. The most cheap and affordable material is chipboard. From it can be made as a whole canvas, and a frame for other materials.

Doors with parts made of chipboard are not very suitable for installation in the nursery, as in the composition there are resins that can, due to their volatility, harm the health. You should not also forget that chipboard is in fact pressed sawdust, therefore the edge of this material needs to be closed. Most often, chipboard is veneered with PVC film or veneer.

Safer material is MDF, since no resin is used in its production, wood particles are combined due to paraffin or lignin. It is possible to make canvases with curly contours from it. Due to this property, it can be used both as a whole canvas and as a constituent element of a figured frame.

Often the door leaf is made of solid wood. This material is expensive and requires special skill in work. It is used as a whole canvas, and it can also be used as a frame or as separate panels with shaped edges.

A good alternative to an array of wood can be such material as plywood. It is obtained by gluing sheets of veneer, and for bonding strength, they are laid in a special way, the fibers of one sheet lie perpendicular to the fibers of another sheet. The surface of the door panels of plywood is often laminated, giving the desired color and structure of natural wood.

Unlike wood, plywood is simpler to use and costs much less than a solid array. Recently, a material such as polycarbonate has been used as a door leaf.Lightweight and durable polycarbonate sheets can be used as an insert in combination with other materials and as a separate canvas. This material, in order to avoid the disappearance of transparency, it is recommended to close profiles on all sides. It is a good alternative to glass.

Very often a mirror and glass is used as a door leaf. The mirror surface of the door helps to visually expand the space of the room.

It perfectly reflects both natural and artificial light, so that the darkest corners of the room are always lit. Mirror and glass, as a rule, is fixed on all sides by profiles. Both materials are well combined with each other.

How to independently calculate the size?

In order to make coupe doors with their own hands, it will be necessary to make measurements. The width and height of the doors depends on the size of the opening, in which they will be installed. The size of the optimal width of the door is in the range of 60-90 cm. You can make doors with different widths, there is a small variation in the range of 50-110 cm.

In the manufacture of door leaf is better to adhere to the specified limit, and this has its own reasons. Width less than 50 cm will have a bad effect on the door leaf movement.possible misalignment and even falling out of the slots. The interior door with a width of 110 cm and more is very difficult to move, so this width is not used.

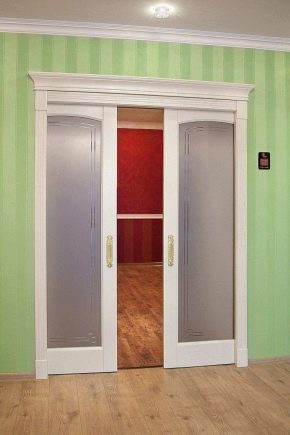

To calculate the required width of the sash, if you plan to install two doors, you need to measure the opening and add the width of the profile to the resulting value, and then divide this number by the number of doors, that is, 2. For a specific example, it looks like this. The width of the opening is 1800 mm, and the width of the profile to be used as a handle is 24mm. We count: 1800 + 24/2 = 912 mm.

The width of the profile and aperture is chosen arbitrarily; in calculations, you should rely on your measurements and the width of the profile you have chosen. If you plan to install in the opening of the three wings, then the calculation of the width is a little different. To the width of the opening you need to add the width of the profile multiplied by 2 and divide the resulting value by 3. As a concrete example, we take the same width of the aperture and profile: 1800 + 24 * 2/3 = 616 mm.

The height of the sash can be calculated as follows. Measure the height of the aperture and subtract 40-45 mm from the obtained value. The length of the side profiles is equal to the height of the valves. The length of the horizontal profiles depends on the acquired handles, located on each side of the sash, or rather on their width.To calculate the length of the profiles, subtract twice the width of the handle from the width of the leaf; the value obtained is the length of the horizontal profile.

Now you can begin to calculate the width of the filling. In order to make the calculations clearer, you can use the obtained values. The correct fill width is calculated as follows: 912 (616) -24 * 2 = 864 (568) mm. From the width of the leaf subtract twice the width of the profile (handles set on both sides of the leaf).

We consider the height of the sash in a similar way, namely, from the height, subtract the width of the upper and then the lower profile and as a result we get the desired number. This height calculation is suitable if the canvas is whole, not requiring seals. If seals are used, then the doubled width of the sealer is subtracted from the obtained value, as it is located both at the top and bottom of the canvas.

As a rule, silicone rubber is used as a sealant, its thickness is 1 mm, and the double value is 2 mm, respectively. Clearly, this calculation can be represented as follows: height 2500-10-38-2 = 2450 mm. Where 10 is the width of the upper profile, and 38 is the width of the lower profile.

If the door is made of component parts, it is necessary to take into account the thickness of the intermediate profile. How many profiles - so many values will have to take into account.

How to make yourself at home?

Making doors with your own hands is a rather time-consuming process, but nothing is possible, the main thing is to take into account some details.

.

Rectangular sliding doors

First of all, you need to decide on the filling of the door. The easiest way to work with chipboard panels and plywood, but you can choose a wooden array, MDF slab (preferably with an untreated surface). It's easier to buy ready-made canvas of the right size, but you can make it with your own hands. To do this, you need to prepare the tools that will be needed in the future when installing the assembled structure and some additional materials.

It will take: a drill, a face saw, a sanding machine or sandpaper, a special film for covering the surface and a varnish (for wooden cloth).

First, the prepared material is cut to the desired size, and the ends are ground. Coating in the form of a film or veneer is applied on the MDF board.Then in it holes for handles are cut, and also fastening points for the roller mechanism are prepared. The surface is cleared of dust pollution. The wooden cloth is treated with impregnation, preventing rotting, and then covered with a layer of varnish.

To facilitate the door leaf can be cut into the workpiece holes in the shape of a rectangle or square. Insert the appropriate size of the workpiece from glass, mirror or lighter plywood. First, a figure is drawn on the canvas, and then the middle is cut out with the help of a jigsaw. This should be done carefully, starting with the angle of the marked-up figure.

The ends of the formed hole are processed with a special tape, which is fixed on the material with the help of an iron. Selected inserts are held with a bead. It is possible to assemble a door leaf from profiles and different materials. It is necessary to purchase ready-made profiles and materials for insertion, which are collected in a specific order.

All profiles are cut to pre-calculated sizes strictly at an angle of 90 °.

In the vertical profiles, handles need to make through holes.In the upper part, for fixing the upper roller, 7 mm holes are drilled from the edge, 2 holes, the diameter of one is larger than the diameter of the other.

This is done so that the screw easily passes through the larger hole and is fixed at the bottom. Then 4 holes are drilled. The first pair of holes is made after the indent of 7 mm, and the second after the indent from the edge of 42 mm. Now you can proceed to the assembly of all the contents. On the glass and mirror inserts around the perimeter is worn silicone seal without overlap. On the mirror for safety on the back side you need to stick a film. The prepared components are inserted into the profiles.

For durable fit of the material when connecting inserts with profiles use a rubber mallet. We attach vertical profiles-handles to the assembled canvas and fasten the structure with fasteners. First we twist in the upper part, for this we take a roller and fix it with a screw in a vertical profile.

In the lower part, we fix the profile first through the far hole, tightening it all the way, and then attach the lower rollers to the profile. To do this, insert the plate with the roller inside the lower profile and move it to the vertical stand.

There is a hole in the plate of the roller, it needs to be aligned with the hole in the vertical profile and tighten with a hexagon, while pressing the roller. Door leaf is ready for installation.

Radial sliding doors

Making radial sliding doors is much more difficult than regular rectangular doors. Unlike conventional doors, they have smoothed corners. The canvas can be of various shapes and curvatures. For movement on the surface is used aluminum profile. Door leaves can be made of tempered glass, plastic and other materials. To make such a canvas at home will not work, so it is better to order ready-made doors and all the accessories to them.

Step-by-step instruction

You can install compartment doors anywhere. Most often with their help equip wardrobe. It must be remembered that the installation of the structure should be carried out after repair. After collecting the door leaves, you can install guides. Need to start with the top rail. It, as a rule, is fixed on a mortgage bar or directly on the ceiling. The guide must be located at a distance of at least 10 cm from the shelves.

To install the lower guide requires a laser level or plumb, but you can do without them. We put the lower profile on the surface without fastening and start the door leaf first in the upper guide, and then in the lower profile, having previously installed stoppers in it. Fixing the canvas in a strictly vertical position, you can fasten the bottom profile. Now you can insert the second canvas. On both the sash sticking in the side parts of the strip, softening the blows. The doors are ready to go.

In the partition

Coupe doors are a versatile option and therefore you can even install them in a plasterboard wall, but you must first carry out the preparatory work. First you need to install a frame made of metal, having calculated all the dimensions. The metal structure must be from double vertical racks. Then set the guides. Attach the top rail to the timber, and fasten it to the structure above the opening. The lower compartment rail is attached to the floor.

After you need to sheathe the frame with sheets of plasterboard and lay the flooring, only after that you should install the doors. The compartment doors are often installed in homemade cabinets that are built into the niche. Such cabinets - a real find for small apartments.In addition, the internal content of such a cabinet can be equipped at your discretion.

Beautiful interiors

Coupe doors are the perfect solution not only for living rooms and built-in wardrobes, but also for the bathroom. With their help, you can without a loss for the space to separate the bathroom from other rooms. In the bathroom, combined with a bathroom, with their help separate one zone from another. In addition, these doors are used instead of curtains. As a rule, frosted glass is used as a material.

Coupe doors are in demand in studio apartments, as they do an excellent job of separating one zone from another. Very often they are installed for the kitchen. With their help, you can easily hide kitchen utensils when guests arrive. It is possible to install both furniture options, and cloths of glass, mirrors and plastic.

How to make interior doors with their own hands, see the following video.