Sliding door guides

Today, zoning dwellings are increasingly used sliding structures. The growing popularity of such systems is due to their high functionality and variety of mounting options. For sliding doors, roller guides are an integral part, since they determine the principle of movement of door leafs.

Pros and cons of compartment systems

The compartment system is a device that makes it possible to open doors in a single plane. According to the designers, in comparison with the classic design of doorways with hinged doors, The use of sliding structures has a number of positive aspects:

- For the radius of opening of ordinary doors, a certain amount of unallocated space is required. Due to the mechanisms that ensure the movement of door panels in one plane, sliding doors contribute to more economical use of square meters of the dwelling.

- Sliding designs are more successful for a safe and ergonomic separation of the interior space. In contrast to the classic, the compartment models are not capable of causing injury or damage to the wall covering in case of accidental plowing up from a gust of draft.

- Doors, moving freely along a rail in the form of a long floor spike or rail, are successfully used for organizing storage systems in wardrobes and built-in mini wardrobe rooms. The use of such doors contributes to significant savings and rational use of space.

- Sliding planes are indispensable for temporary zoning of a single large space into several small rooms.

- Panoramic sliding doors carry not only a functional, but also an aesthetic load, allowing you to instantly turn your living room or bedroom into an outdoor terrace.

As a disadvantage of the compartment systems, a rather high cost can be identified. In addition, their installation requires the proper preparatory work of experienced specialists, since to ensure the beauty of the door and the durability of the guide mechanisms, ideally even horizontal surfaces of the floor and ceiling will be required. It should also be noted that some low-cost models of compartment doors lose swinging doors in terms of sound insulation.

What are the?

Depending on the method of installation, manufacturers offer options for rails such as overhead and embedded. Invoice system assumes that the moving door always remain in sight. The built-in version assumes a separation of door panels in a niche with hiding mechanisms.

Many experts recommend the use of the built-in design, as it reliably separates the space and absorbs noise well.

The number of canvases and the weight of working sashes determines which particular guide will be responsible for the strength of the entire system. Guide mechanisms are commercially available in the following types:

- For the device dividing the room, from a single door leaf.

- For a double-leaf design, which provides for the shift of cloths in one or in different directions.

- For a cascade structure made up of several webs that provide a multi-stage opening left-right or on opposite sides of the doorway.This design is very convenient for distinguishing spaces with different functional loads: a kitchen-living room, a bedroom-study, a dining-living room, etc. The multi-leaf system is also convenient in that it allows you to open the door fully or partially. For example, you can move one or two panels, hiding from the view the main space of the room or push all the doors at once.

- For partition, folding accordion, when the canvas is made up of several narrow sections.

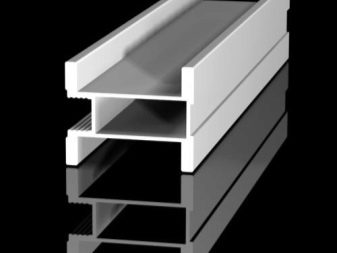

The compartment door can have an opening mechanism in which a single profile rail for one door or a telescopic construction for several doors is attached exclusively in the upper part to a wall or ceiling. In such relatively inexpensive systems, suspended doors move along rails using fixed roller carriages. Slide the pads gently prevent the planes from slipping into the final position. In the surface fastening method, a decorative strip is often used to mask the guide.

A more practical option is possible when the door leafs move along two monorail or telescopic rails mounted in the ceiling and in the floor.

Such installation ensures maximum smoothness of the course of webs due to uniform load distribution. Easy-to-operate doors move along guides by means of roller carriages fixed in the upper and lower parts of the door.

Both opening options have both advantages and disadvantages. Of course, the sliding interroom partition with one rail on top is mounted quickly and easily, but it vibrates more during operation, has less reliability and does not provide an adequate level of light and sound insulation. Two guides make the system much stronger and more stable, but the installation of such a door kit will require more effort, as it requires an exact fit of all parts. In the absence of mounting accuracy, there is a high probability that the product will soon jam and break. In addition, installing a system with two guides will be more expensive.

How to choose?

Guides together with rollers play a key role in the durability of sliding structures. Therefore, their proper selection provides compliance with such functional requirements for doors, such as:

- movement without distortions and jamming;

- unobstructed soft slip of the canvases;

- tight door closure;

- work without the spontaneous movement of cloths;

- warning of noisy door contact;

- the absence of factors leading to the deformation of components and parts.

The rollers should provide a quiet and smooth sliding cloths. Their surfaces can be rubber, teflon, plastic or metal. The strongest rollers are made of metal with a rubber coating, resistant to wear.

Modern high-quality rollers that can withstand loads of up to 100 kg have sealed bearings on the axle, protected from moisture, dust and not requiring lubrication. The quality of the roller, in addition to the mortise bearing, will also be indicated by the presence of a shock-absorbing spring, which will give the door a necessary softness.

When choosing a sliding mechanism, you need to take into account the weight of the structure. The greater the weight and width of the door, the more pairs of rollers it should have. For a door weighing from 40 to 75 kg, the upper rail can be used as a suspension with movement on two carriages.For a greater weight of cloths it is more reasonable to use a mechanism with four upper carriages.

The size and design of the upper wheels will depend on the type of guide. Asymmetrical rollers are placed on the open, symmetrical - on a closed profile.

A door kit weighing about 120 kg should be mounted on a pair of guides with floor and sub ceiling fixings. And on each canvas will fall on two carriages with four wheels on each. The bottom carriages together with the guide will take over part of the load, the rollers will allow you to adjust the position of the sash, compensating for small unevenness of the floor. At the bottom can be installed a pair of rollers with a rubber rim. This will not only eliminate the noise from the contact of the valves, ensure smooth sliding along the profile, but also give the system greater security.

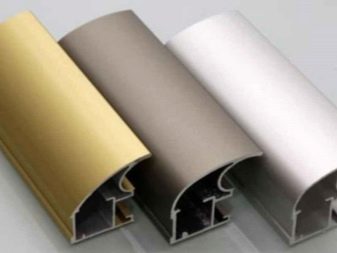

It is necessary to decide from which material the guides should be purchased - from plastic, steel or aluminum. After all, the quality and price of the material falls into the price of the entire system. Plastic products have a low price, but, most often do not differ sufficient strength. Therefore, their use is not recommended in the case when the doors are made of glass sheets.

Serious manufacturers of components for sliding systems offer aluminum rails, which have a number of advantages. With a small weight guides have durability, resistance to deformation and corrosion, as well as democratic price. However, according to some experts, massive sash of natural wood, decorated with glass, they will not stand and after some time are deformed. One of the most reliable materials for guides, despite the relatively high cost, is today considered steel.

Manufacturers

Today, a large number of manufacturers are engaged in the production of components for sliding doors. Polish and German brands are very popular. Polish companies Indeco and Komandor They supply the Russian market with interior door systems and components made of steel, characterized by excellent smoothness and quiet operation, traditionally high quality, confirmed by numerous tests.

Thousands of apartments and offices in our time are supplied with door partitions, sliding on aluminum profiles, from German manufacturers Braun and Raumplus. Companies specialize in producing high-quality profiles of various colors.

Permanently developing non-threshold sliding systems of these brands meet the most stringent requirements for reliability and safety.

For more information about the lower and upper guide for a sliding door, see the following video.