Features of the manufacture of metal doors

Metal doors are popular for reliability and safety. But industrial enterprises charge a significant fee for the manufacture of such structures. In the meantime, doing all the work with your own hands is not difficult - there would be a desire and basic technical knowledge.

The advantages of homemade products

Creating metal structures by hand is more difficult than using professional equipment. But there are no restrictions imposed by specific models and specifications. There is no risk that substandard materials can be used for the sake of economy.than even large suppliers of finished products often do. Design and execution perfectly meet the expectations of the owner of the house, garage or holiday cottage.

It is also important considerations of economy, especially now, when every ruble gets harder over the years.

Design

There is no point in taking on the manufacture of steel doors without drawings and diagrams. First of all, measure the height and width of the openings. The collected data is rewritten and an exact scheme is drawn on it, showing how wide and high the canvas will be. In most cases, you can do with a door block 90x200 cm, if the dimensions are larger than this bar, an auxiliary fragment is placed on top.

The following options can be used to close the frame:

- Sheet steel;

- lattice steel construction;

- glass detail;

- deaf fragment;

- swing open block.

It is impossible to bypass any element in the project. If it is not specified or is specified incorrectly, great difficulties will inevitably arise.

The number of loops to be laid in the project is determined by the massiveness of the product. In almost every case, 2-4 hinges are enough; more complex doors are rarely used for domestic purposes. Be sure to specify the size of individual structures, and the thickness of the frame sheet, and the type of exterior door. It is also important to immediately deal with the desired type of metal.

Tools and necessary materials

It is the metal that accounts for the main costs of both large producers and private craftsmen. Almost all other materials are significantly less, with the exception of finishing coatings. Nevertheless, it is quite possible to make a steel entrance structure within the range of 15 thousand rubles with our own hands. For this amount, it is unlikely that it will be possible to purchase even low-quality crafts from Asian countries.

Most often, do-it-yourself door designs are made of a professional pipe with a section of 2x4 cm. 18–22 meters of such a pipe allows you to perform a door block of typical dimensions - 100 cm in width and 200 cm in length.

If misunderstandings arise, it is worth starting from the sketch, it is not difficult to find already calculated product drawings for all occasions. The minimum thickness of metal sheets is 0.25 cm, and the remaining dimensions must match the size of the opening.

When choosing loops, experienced craftsmen give preference to those in which there is a bearing.

Given the considerable weight of the structure, the three loops obviously work better and more reliably than two.

And metal profile corners, fittings, thermal protection and decorative coatings may be required. During the work abrasive circles and drills, electrodes spend a resource. In addition to the welding machine and a special table for working with it, it will not be possible to do without an angle grinder, a high-quality drill and an electric jigsaw.

If necessary, dismantle the old design will help the hammer, nail puller and sharply sharpened ax. Hardware is sometimes more convenient to fix with a wrench or a screwdriver.

We make measurements

Custom sizes of homemade doors are an important advantage over serial designs. Professionals in factories charge extra for deviations from the most common dimensions. But first of all it is necessary to estimate the actual size of the doorway and the door unit, which should be placed in it. Measurements are made with a tape measure and must be fixed on paper: do not rely on memory in this case. In addition to the size of the canvas, they also take into account the fact that along its perimeter there will be a box, which usually has a thickness of 20-30 mm.

Since in the area of the loops the width is larger, and for the rest of the perimeter of the web - less, you will need to always lay in the project the use of additional parts. They take into account the widest size, since only this condition allows attaching the casing sufficiently tightly. The height of the openings is measured on the side slopes on both sides. With a very high cavity, it is necessary to reduce the opening or prepare large platbands.

When the height of the hole is small, it is better to cut the wall with a special tool than to make adjustments to the door under construction.

How to make an iron front door?

Having finished all measurements and selecting material, tools, you can immediately get to work. Technology implies mandatory verification of walls. They must be from strong block materials or solid concrete.

It is recommended to put prefabricated boxes in the opening with dimensions over 150x200 cm, the top or sidewall of which is covered with an additional strip of metal.Wide notches are equipped with a pair of auxiliary modules with glass. They will help make the door stronger and decorate it.

The door should open to the outside, not to the inside, in order to facilitate care in the event of an emergency.

They begin work by laying out the key parts of the box on a steel workbench and cutting them according to the marking. The accuracy of the cuts is verified by test assembly and evaluation using joinery corners.

Much attention should be paid to the exact connection of all the diagonals with the corners. The seams left after welding are refined using angle grinders.

Now you want to make the workpiece on the frame, they use steel corners. When working with templates, rectangular constructions of a strictly specified thickness are used. The main gaps from the frame to the duct in the area of the castle are approximately 0.5 cm, and on the other three sides of the structure they are taken by 0.3 cm. They mark and cut the profile, put it in the duct and check the accuracy of the diagonal. Side profiles are provided with slots for locks.

In order to weld the door itself from metal, it is necessary to begin work by fixing the corners of the frames and welding the frames at several points along the perimeter.Then a strip metal is welded onto the frame to hold the casing, and a stiffener is welded in the frame. Immediately after that, you need to clean the resulting seams, mark the canvas.

The recommended overlaps on the box are 1–1.5 cm, and in the area of the loops - 0.5 cm.

Now it is possible to cut sheets with the grinder and weld them to the frame. After that it is required to insert and weld additional stiffening ribs.

Space for mounting the lock is marked directly on the canvas; there they drill a well and bring it to the desired condition with the help of a file. Then prepare the holes for the lock, cut the thread.

As soon as the installation of the lock is completed, you can tackle the hinges, welding them to the web frame and to the door frame. It is worth noting that the box is required to open and secure the hinge parts inside with the help of a welding machine.

Often this does not end the work and builds a door with a window.

It is recommended to cut an aperture in the middle of a cloth, for this purpose use mainly the Bulgarian.

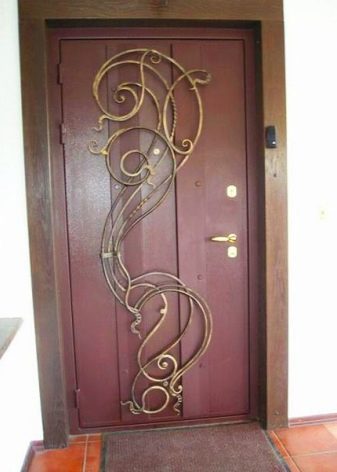

Not only glass, but also a decorative steel lattice made in the technique of cold forging can be put into the prepared recess.As practice shows, by the ability to transmit light, such a solution is no worse, and in terms of design characteristics it is even better than a simple glazed opening. If you want to preserve heat in the room as much as possible, however, the grille can be combined with a double-glazed window. If you wish, you can try other design solutions.

The process of making the box

In addition to the door itself, no matter how comfortable and high-quality it is, a box is sure to be needed. It is easiest to create it with the help of a woodworking machine; the initial component is a planed board. It is worth checking the wood, whether it is well dried, otherwise the whole structure can quickly twist.

The necessary elements will also be the following:

- saws;

- hammers;

- reiki;

- screwdrivers;

- self-tapping screws;

- nails;

- other metal fasteners.

At the entrance door the main part of the box is mainly made of metal, which is welded. But the tree has its advantage - it is easy to handle. But the fibreboard is not long enough, and very soon it will be necessary to change the box. When choosing wood worth paying attention to the dark spots. If they are, then this indicates a violation of the drying technology. Such defects can not be disguised even with several layers of high-quality paint.

The markup is first produced at the top, then at the bottom. To avoid mistakes, you need to add respectively the crossbar and the threshold. After completing the blanks for the notches made, they are adjusted to the dimensions of the door.

As soon as the hinges are hung and the door is put in place, it is corrected again to eliminate the appearance of gaps. For your information: if at some point in the work it inspires fear, there are doubts that not everything can be done, then you need to turn to professional craftsmen.

Installation of double doors

Double-leaf doors are set slightly differently than single-leaf construction. Moreover, they have their own division within, which must be taken into account. So, one door with a pair of wings open, and others - moving apart. If the door is already installed, it is dismantled as carefully as possible.

To save the old boxes, do this:

- remove the trim;

- remove cement and foam;

- unscrew the screws or cut the nails.

After removing the box, remove the remaining leveling layers, for this use a punch. If the old shell is made according to the rules and is well preserved, it is left intact, only by removing the mounting foam. As in the case of a single door, you will need to measure the opening. But in addition, adjacent planes are also measured. Box timber is cut at a 45 degree angle.

The most practical tool is a face saw, but in the absence of it you can also use a hacksaw with a small tooth. Then they cut into the vertical parts of the loop opening, for this purpose a milling cutter is used. Replace it in a pinch will help chisel and hammer; and it will be even easier to use superimposed insect-type loops. Stringing together the design is done with screws. To keep the box intact, before inserting the fastener, holes are prepared 1 mm smaller than the diameter of the screws.

The box in the doorway is set exactly, and you need to follow not only the verticals, but also to ensure that the design does not leave even the small contour of the notch.Having attached the rollers to the canvases, marking out the height of the guides for them, they draw a line along the level and fasten a 4–5 cm thick bar to the wall. The guides are mounted on the bar and the door is suspended from it. It is always required to reserve a technological gap from the flaps to the box.

So that he would not let the cold air and precipitation into the room, this gap is filled with foam.

How to make a warm door at home?

But even the hermetically sealed door design cannot by itself become a reliable barrier to frost. To avoid the associated negative phenomena, it is necessary to warm it. Most often, foam polystyrene and polystyrene are used for this, which in production are converted into slabs of various thicknesses. Such materials are not destroyed by moisture, so they are allowed to be used for insulation of all rooms, regardless of climatic conditions. The framework is made of a dry bar which should not damage sheets of metal.

Materials are placed in the gaps between the bars or put in a window. Attaching them can occur both mechanically and on glue.

It is necessary to try that the gaps separating a heater from a framework were minimum.

After finishing work, they wait for some time and check if gaps have arisen.A layer of facial material is placed on top of the insulation. It is very important that it is not only durable, but also the most elegant.

Decoration and decor

To decorate the doors, even made independently, numerous teams of builders and designers are ready. But the fee for their services is often excessive, calculated on an arbitrary basis. And at the same time all the same work can be done by hand in the shortest possible time.

Door openings may be covered with the following materials:

- laminate flooring;

- decorative stone;

- clapboard (plastic or wooden);

- siding

Siding and laminate flooring compare favorably with other materials, since this is the recommended upholstery for steel doors. It allows you to create a really interesting and original appearance.

The advantage of the lining is that it is mechanically strong and lasts a long time. Wood should be properly dried, and it will have to be impregnated with antiseptics and fire retardants, if this has not been done in production. Application of a lacquer coat outside helps to reduce the risk of drying out the material.

Decor patterns both monochrome and painted in a variety of bright colors can create a very attractive look.The application of paint implies an ideal preparation of the surface, it must be extremely smooth. Painting works are from the top left, gradually moving down and to the right. When there is a desire to make a drawing, the door is initially primed, only then the background is prepared. Which option to choose will tell your own taste.

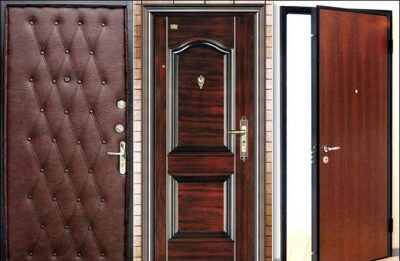

Self-made models in the interior of the house or apartment

If there is not even a rough idea of how exactly a metal door should look like, how it should be decorated, you can focus on the experience of others.great people. MDF panels can be used for upholstery, which mill or complement the panels. A more expensive, but also more aesthetic option is the use of wood panels made from natural materials. Thanks to the ornaments and carved details of the wooden array, you can make the design truly original. Noble wood from light and slightly darker fragments, covering the entire perimeter of the door - this is one of the best ways to decorate.

The door painted in dark red tones causes no less delight among connoisseurs of modern aesthetics.Imitation of noble wood looks attractive in combination with the black edging of the canvas, and with shiny metal details. The light handle of the classic look elegantly complements the composition.

Some people tend to do something more old-fashioned, then they come to the aid of forged items. The photo clearly shows how attractive the combination of straight bands and a single round element (ring) is.

This is what the front door covered with MDF looks like. It is intentionally made a little lighter than the surrounding elements of the interior. It also shows how attractive the box can be, which is dotted with small specks. But the PVC film is able to transform the type of metal so strongly that it is difficult to believe in its presence.

The choice is truly enormous. The main thing is to make the right decision, weighing all the alternatives both in design and in the design of the door unit.

The nuances of making metal doors with their own hands - in the next video.