Installation of metal doors

Metal doors are considered to be the most reliable protection of the house from the outside world. Due to the design features, many buyers prefer them. It is necessary to note the appearance, which may look the way the buyer wants, due to the huge number of design variations.

Iron doors are great for private buildings, apartments, offices and utility rooms. Their cost varies considerably, and the installation is often equal to half the cost of the metal protector itself.

To the careful owners, we’ll reveal the secret: if you do the installation yourself, then with the money saved you can get a sample of increased safety and comfort to which you can relate noise and heat insulation and the absence of odors (in case of fire at the site, a good door will prevent the penetration of carbon monoxide into the apartment).

Tools and materials

For self-installation, you need tools to work. The approximate list includes:

- Puncher or electric hammer drill;

- Building level;

- Lomik;

- Convector with electrodes;

- Hammer;

- Grinding machine with a cutting disc;

- Screwdriver (cross and slotted) and wrench;

- Roulette at 5 m;

- A simple pencil marker.

Materials and components include:

- Anchor bolts (anchor), the size of which is not less than 100x150mm.

- Set of hexagons;

- Metal fittings with a cross section of 10-12 mm (if the door will be fixed by welding);

- Foam for installation - to fill the voids between the door frame and the ends of the opening;

- Spacer bars, they are a set of wooden wedges of different cross-section and are needed for temporary fixation in the doorframe aperture, with their help they also check the correctness of verticality and horizontal position of the structure;

- The solution will be needed if the increase in the doorway was done carelessly, and the gap between the opening and the box is more than 25 mm;

- Solid oil for locking mechanisms of the hinges and the door itself;

- Large bags for waste;

- Broom and dustpan;

- Dense cardboard to protect the floor from mechanical stress;

- Covering material on the furniture, if it is located next to the door. It will protect from construction dust and dirt.

How to make the measurements yourself?

For high-quality installation to make accurate calculations of parameters is one of the most important operations. If for some reason an inaccuracy sneaks into the calculations, it is necessary to re-measure and re-install the door.

There are standard sizes of entrance metal doors (box and cloth) of premises. Sizes of embedded units:

- 860 * 2050 mm - it needs a width of the opening from 880 to 960 mm, height from 2070 to 2100 mm;

- 960 * 2050 mm - width should be from 980 to 1060 mm, height from 2070 to 2100 mm;

- 880 * 2050 mm - from 900 to 980 mm wide and from 2070 to 2100 mm high;

- 980 * 2050 mm - from 1000 to 1080 mm in width and from 2070 to 2100 mm in height.

For non-residential entrance groups - non-standard and individual parameters. The fact is that GOSTs are a huge amount, exact criteria and definitions,in order to somehow systematize the concept of non-residential openings, no.

Measurements are taken in several stages:

- It is necessary to calculate the width of the opening from wall to wall and the height from the top edge to the bottom. If there are platbands from the old door, they must be removed and afterwards be engaged in calculations;

- In case the aperture differs from standard parameters, then it needs to be narrowed or expanded. The choice is made on the basis of considerations that are faster and more economical;

- Unforeseen circumstances, in the form of poorly fortified or crumbling walls, should be eliminated, then measured.

Dismantling the exterior iron models

To dismantle the old door you need to be treated with all responsibility, since the wrong actions can lead to the deformation of the opening and even injury. Metal samples, including those made from steel, are not as difficult to dismantle as they might seem at first glance. However, it is necessary to strictly carry out the sequence of actions and be careful.

The action plan is as follows:

- Preparation of the necessary tools (nail puller, crowbar, hammer, stationery knife, screwdriver, pliers).

- Remove the canvas (door).If the design is fixed with universal hinges, then you will need to unscrew the self-tapping screws when there are card or detachable hinges - in this case, you will remove the canvas rather quickly.

- It is necessary to remove the trim.

- Remove the door frame. It is necessary to find a place in the wall where the box is fastened (most often it is located next to the hinged or locking connection). Once the fasteners are loosened - dismantling is completed.

Important points:

- if you can not remove fasteners, you can use the grinder and carefully cut them off. It is necessary to note the safety rules - use gloves, special glasses. It is also recommended to use a new circle, in order for it to provide the correct pruning, and the device should not rest against the door frame;

- in case the cutting wheel does not pass between the box and the opening, it is required to increase the gap by gouging the plaster with the help of a spike, which is inserted into the cartridge of the perforator;

- pruning is done strictly according to the rule (box threshold - sidewall - upper part), if the order is disturbed - the box will fall with all the ensuing consequences;

- in the presence of old foam - it can be removed with a sharp stationery knife, and the plaster can be removed with a hammer.

Preparation of the opening

Preparing the opening is an important part of replacing the door. It does not always work out that it fully complies with the parameters of the embedded input group. Consider several options for changing the dimensions of the doorway.

Increase (expansion)

Make it possible in two ways:

- The most common method of expansion is felling, since it does not require significant cash outlay. After cutting, the finished opening can already be leveled and plastered. You can hack both on the one hand and on the two.

- Cutting. The method is a little expensive, its advantage lies in the use of load-bearing walls, of any level of strength. To perform this procedure, you need specialized equipment with a diamond disc.

Narrowing of the opening

Reducing the size, you need to produce with the expectation of preserving the strength of the structure, as well as its reliability. In any case, it is necessary to bind to the main wall with steel reinforcement. There are 2 possible ways to reduce the parameters:

- brickwork.Production is carried out both in one brick, and in several, up to the necessary size. In 3 days after work with a brick, plastering is carried out. And install the door leaf can be no earlier than 10-14 days;

- concreting.

It is worth noting another alternative version of the narrowing of the doorway - this is the installation of a double door, where you do not need to open the small sash every time. Plus it is that it can be opened by expanding the opening, when you need to bring a large object.

Mounting options

At the moment, there are three methods for fixing the entrance metal door to the box:

- Directly in the wall, retractable way. The wall thickness must be at least 200 mm, otherwise any intruder will be able to break such a door. Anchoring bolts are used as fasteners; for them, holes must be made in advance, taking into account technological gaps. When work is finished, the ears of the bolts are masked with special plugs in the color of the box itself.

- On mounting plates. Installation is made on the plates that protrude from the door unit, their number is usually 3 or 4.They have special holes for mortgages. After proper placement of the door frame around the perimeter, there should be a gap of about 10–20 mm. Then steel guides are installed in the holes, the remaining ends are welded or unclasped. Anchor bolts or reinforcement can be used as a replacement guide.

- Combined, which involves the combination of the first and second methods.

DIY installation rules

Self-insert both metal doors into an apartment is a difficult task, but doable. The whole process is divided into several stages:

- Installing the door frame. It is fixed with wooden bars, their thickness should slightly exceed the technological gaps. Wedges need to drive between the box and the opening, then check the level of the correct position.

The top corner of the loopback side is the beginning of the box installation. Next, you need to drill holes through the plates, with the diameter of the holes will be 15 mm, depth - 100 mm. In them we hammer pins or bolts that are welded to the plates. Then check the box level.

- Verifying hanging door leaf.As soon as the fixation of the box is completed, it is necessary to hang the door itself to check its progress. The door stroke should not require any effort. Then remove the canvas

- Install fasteners. We fix the fasteners from the feigned side, blow the indents with the mounting foam, remove the excess. After doing the installation dobori and cashing.

- Hanging the canvas. The final moment - we hang the door leaf, lubricate the hinges, install the lining.

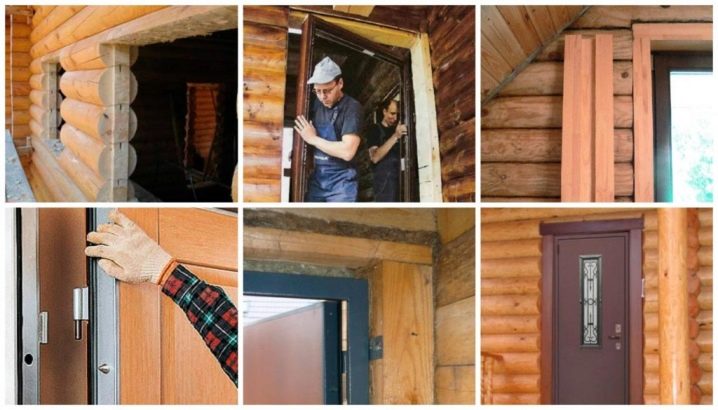

Consider several technologies for installing metal doors. The first technology - installation in a wooden box. To fix the metal to the tree in modern conditions is a very real task. We note a few nuances:

- the wooden structure (log frame of solid wood, as well as private wooden buildings, of minibus or log house) have their own shrinkage (8-12 cm). If the structure is more than 5 years old, you should not worry about changing the parameters of the structure;

- For mounting in a tree, a semi-rigid fastening of the leaf in the box is used, and the hinges only use external ones.

If the building is made of foam block, gas silicate blocks in aerated concrete block walls, polystyrene concrete slabs, then due to the low strength of the compositions, the installation of doors in such houses is an additional reinforcement. Perhaps this is in several ways:

- embedded item;

- metal construction;

- wood construction.

In frame and panel houses, for structural strength, doorways can be reinforced with additional spacers and struts, for greater reliability and rigidity, they are made of timber.

In the Khrushchev panel it is recommended to install metal doors with additional sound and thermal insulation, as such houses, unfortunately, do not have sufficient tightness.

How to put a turn signal?

Pivot or handle the valve is also called the night watchman, as this is an additional protection of the door from the penetration of unwanted "guests." This mechanism drives the valve, it is installed on the inside of the door, as a result of opening it from the outside is absolutely impossible. Install this device in several stages:

- First, a so-called “seat” for the body of the valve itself is drilled in the necessary place on the end of the door;

- form a special pocket on the counterpart of the door unit;

- mounted locking bolt;

- drill a hole with a suitable diameter to the rod on the inside of the door and install a turn signal.

The nuances of installing the chain door on the landing

The tambour door serves as additional protection against intruders in the apartment. Installing such a door allows you to carve out the space for personal items, for example, a baby carriage or a bicycle, without worrying about their safety and freeing up space in the apartment.

“Corridor doors” are divided into several types according to their design characteristics:

- door with one leaf in the center and solid side parts. Such blocks are installed in rooms with wide and low openings;

- a metal door with two opening doors, one of them is the main one, the other opens, if necessary, and is locked mainly on the latch;

- combined models. Due to the transoms, which can be movable, you can extend the passage. In the case of deaf transoms, parts of the door unit will be fixed. These samples are installed in rooms with high ceilings and wide openings.

The installation process of the chain door is quite similar to the installation of the entrance door. Moments specific to the installation of a common door on the landing:

- if the door has already been, then it is advisable to fit the lock holes and attachment points in the new door;

- strict observance of the correct installation of the vertical and horizontal lines;

- after completion of the installation, you must wait, do not use the door immediately. It is necessary for the foam to be applied to dry.

How to check the installation?

In order for the metal door to serve for a long time, its proper installation is necessary. Refine the presence of deviations from the norm in several ways:

- Open and close the door. This checks the accuracy of the level and the presence of distortions. It should not open spontaneously. Only by applying effort from the outside you can act on the canvas.

- The interval between the box and the door. It should be kept to a minimum, as the seal will compensate for it. The compactor performs another very important function - isolates sounds and heat.

- The presence of the interval between the doorway and the box. It should not be big, but its presence is necessary. In many respects, it depends on the correctness of the choice of the size of the door itself.

- The weight of the front door. It depends on the material and technical characteristics of the unit (profile, corner, combined). The most weighty is a combined metal structure, due to the fact that in its manufacture a curved profile was used, which means that it is the most stable and reliable. Once the installation of the door is complete - try to work on it, the force you apply should not be too great. But even if you are not completely comfortable because of the severity, this question is solved with the help of a suitable platband.

- Door handle and lock. The handle should not hang out and be flimsy, as well as tightly pressed. Balance is important here. Any fittings, including those for the door, should show themselves perfectly in use from the first day of installation and for a very long time. The lock after assembly in the door should also show itself. Modern models are developed initially without any defects, so it is not worth giving a chance to develop a new castle. It should be used easily without effort.

- Door hinges. For full operation, they must be lubricated during installation.Otherwise, the opening mechanism will be broken.

- The appearance of the door. On the canvas should not be scratches and even more dents. If they appeared during transportation and installation (that is, with minimal impact on the surface), then there is no need to talk about its anti-vandal protection functions, immediately abandon a sample of such quality. The same can be attributed to the decorative elements on the door. If the door unit with additional elements is intact, you can be sure that you have a quality model.

Finishing work

To begin work on the decoration and improvement of the door space should be from the slopes. The slopes are divided into internal (which you see) and external (which see everyone else). In addition to the decorative function, they protect from drafts. There are 3 basic rules for finishing work slopes for metal entrance doors:

- To create a flat plane you need to accurately measure the dimensions of the doorway.

- The distance between the slopes on the inside should be less than their distance from the outside.

- They must be placed 15 to 20 mm below the level of the box.

Materials use a variety of:

- Decorative rock.Stone finishing is done with a mortar, using or without texture materials, slate or pebbles.

- PFH panels. The budget option, due to color solutions and textures is very popular among buyers. The principle of operation is similar to MDF panels, the only drawback is the fragility of the plastic.

- Plaster or cement screed. The easiest type of finish. The prepared solution is applied with a spatula on the surface, leveled, if necessary, remove excess. With the help of beacons mixture will fall correctly. After completing the work with the material, you can paint the facade paint.

- Drywall This finish looks interesting, the decor variations are huge.

MDF panels

This finishing material for use in the decoration of doors is of two types. Laminated - moisture resistant, having great strength, it has proven itself well. It has the widest range of colors, including imitating wood. Veneered - it is resistant to wear and has a long service life; it is the most suitable option for finishing openings.

Finishing processes:

- Treat the slopes. If you need to seal the gap, remove the excess of old cement.

- Apply a primer to the treated surface.

- Smooth out the slopes with putty or sand-cement mixture using beacons.

- Secure the outside corners tightly.

- From MDF panels cut 3 parts (2 side and 1 top parts) of the required parameters.

- They fix the panels with the help of a specialized glue, first they put it in the middle layer, then put the panel and wait for it to set. It is advisable to use spacers.

- Cover the remaining gaps with liquid nails.

- Treat the outer edge with a decorative corner.

- Make a cash out.

As you can see from the article, install and improve the entrance metal door with your own hands is a task that is doable and very interesting. In this way, you can not only save a decent amount, but also create a special business card for your home - the front door.

How to install a metal entrance door, see the following video.