How to make the front door with your own hands?

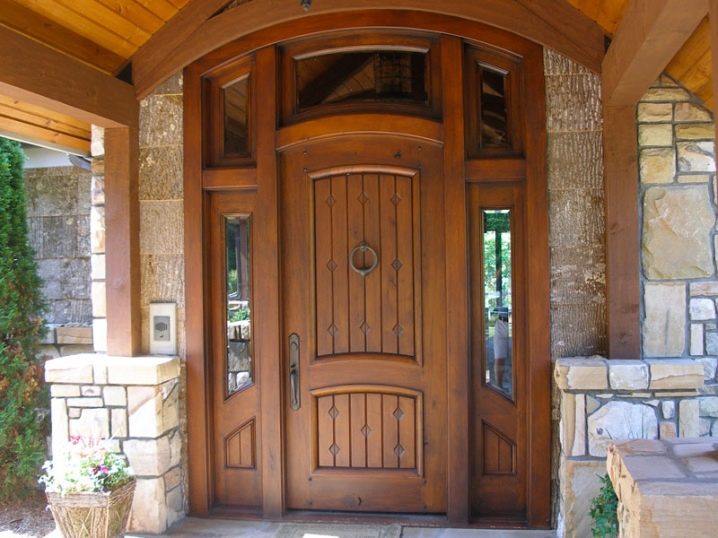

The front door is the hallmark of any home. Therefore, it should not only look beautiful, but also provide good thermal insulation, harmoniously approach the design and architecture of the building. Safety of property directly depends on the strength and reliability of this design, as well as protection of housing from the penetration of cold air, precipitation and noise from the street.

To date, the choice of doors provided in a wide range, with each model is distinguished by its configuration and external forms. The entrance structure can be bought off-the-shelf, made to order or manufactured by yourself. It may surprise many people, but there is nothing difficult in this, it’s just necessary to make the right measurements, find the right model version and be patient.

It should be noted that the self-made design will be different original design and in a special way will emphasize the entrance to the room.

Features and models

Entrance doors are installed both in the apartment and in a private house. Regardless of the location of this structure, its direct purpose is to protect the housing from cold, noise and burglary. Therefore, choosing a particular model of the entrance door must take into account many nuances. Recently, self-made metal and wood constructions have become very popular, while metal doors are distinguished by their functionality and design features; they are resistant to explosions, burglaries, fireproof and bulletproof.

As for the wooden versions, they are characterized by an original aesthetic appearance, doors with sliding systems also deserve special attention.

To date, there are many types of entrance doors. According to their purpose, they are:

- Fire and bulletproof. Such products are made from metal of increased strength. In addition, these types of doors are additionally treated with strengthening compositions.

- Shockproof Are the most reliable option to protect housing.

- Soundproofing. Interfere with the penetration into the house of noise and sounds.

- Hermetic. Often installed in farm buildings.

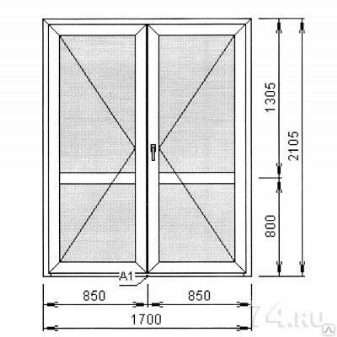

Entrance doors can be opened in different ways. There are hinged and sliding models of structures. In addition, the doors are classified according to the number of leaves and are:

- Single doors. Made of solid canvas.

- One and a half. Represent a design consisting of two parts, where only one opens.

- Bicuspid. Large doors with two opening doors.

All entrance doors differ in appearance and form, so they distinguish between rectangular and arched products. Also designs with a deaf transom are popular.

Recently, manufacturers are trying to make the entrance to the house unusual, so they often decorate doors with glass.

Materials

Entrance doors are made from different raw materials, with metal and natural wood being used most often for independent production. It should be noted that the functional properties of the structure will depend on the chosen material,as a good and high-quality door should not let in cold air and completely isolates the house from extraneous sounds.

Despite the fact that metal products are very popular, yet wood does not lose its advantages and is often used in the manufacture of doors. Such models are found both in modern apartments and in country houses. As a rule, such wooden structures are made of solid oak, as well as birch and pine. Wood doors do an excellent insulation and retain heat well.

Due to the unique features of wood, products made of boards protect housing from the penetration of cold air.

To ensure that such products are not rotten and not covered with mold during operation, they are additionally treated with special solutions that reliably protect the web from wood pests and increase the service life. In addition, the tree is easy to process and decorate with various inserts or carvings. The only disadvantage of this raw material is the high cost, so plywood panels are often used as an alternative.

Unlike wood, metal structures have more advantages.They are strong and durable, and in order for such products to provide optimal insulation, they are covered with a protective layer. Metal doors are also painted with enamels and varnish, this protects their surface from rust and allows installation to be performed both indoors and outdoors in country houses.

For independent production of entrance structures, as a rule, steel sheets are chosen.

Recently, you can also meet plastic or metal doors. They are intended for buildings where there is a possibility of chain heating, because plastic does not retain heat. In addition, for such products will require additional protection in the form of alarms or gratings. Although plastic is easy to install, it is still not suitable for homes.

A huge choice of colors, the presence of decorative inserts and ease of care allows you to use plastic doors to enter various organizations and offices.

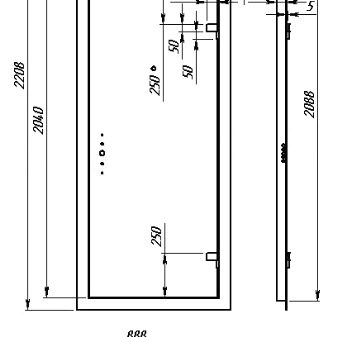

Dimensions

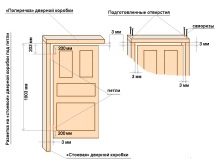

Before you start work on the fabrication of the entrance structure, it is necessary to pre-determine the dimensions of the future product and correctly measure out the doorway.It is worth paying attention to the fact that in each apartment or house the dimensions of the openings may vary. If you plan to install a standard single door, then it will need cloths of 860 × 2050 mm or 960 × 2050 mm. If necessary, you can make custom panels. For simple double doors, 1200x2050 mm or 1400x2050 mm canvases are used, but for office premises and private houses it is best to choose more designs - 1500x2100 mm or even 1600x2100 mm.

Often when installing the entrance doors one has to face such a problem as non-standard dimensions of the openings. The best solution in this situation will be the expansion or tab of the opening itself.

Step-by-step instruction

Home repair takes a lot of time and money, so often many owners decide on a desperate step and carry out finishing work with the installation of entrance doors on their own. Of course, the design can be purchased in finished form, but if you want to save money, then it is quite possible to make it yourself. Before you start to make the door, you need to decide on the external forms and the load that will be on the product.

You will also need to prepare the following tools:

- Roulette;

- Pencil;

- Hacksaw;

- Hammer;

- Self-tapping screws;

- Screwdriver;

- Jigsaw;

- Glue.

In addition, upon completion of the work, the doors should be beautifully decorated, so it is important to measure the doors correctly, place the box, and decorate the doorways with platbands or additional elements.

Various materials can be selected for such work., but the most affordable is natural wood. To make a quality product, you should give preference to a timber with a width of 5 mm and a thickness of not more than 4 mm. Such cloths will provide excellent sound insulation. In addition, in wooden doors easier to set the threshold and put the stairs. As for the installation technology, they are based on the correct measurements of the door frame, the maximum connection of the timber with the frame will depend on them. And for street construction you will also need to weld the hinges and make the surface painting.

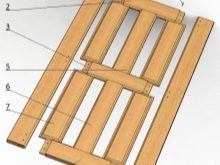

For the manufacture of standard doors going to the canvas with a length of 205 cm, while its width may be different. First, the frame is made, which will have the form of a frame.Then, according to the size of the frame, a sheet of hardboard is cut out and secured with screws. After assembling such a design, the fiberboard is coated. It is desirable to strengthen the bars not only with screws, but also with glue.

The finished door is carefully dried, and then the hinges are screwed and the lock is inserted. In order for the product to get an attractive look, it is recommended to additionally trim it with dermantine on the gasket. Thus the door will turn out beautiful and warmed.

Particular attention in the installation of construction should be given as a lock inset. Its thickness should correspond to the thickness of the canvas. In addition, the lock is a thin mechanism, so when installing it is not allowed to skew even 1 mm.

As for the painting, this is the final stage of work, and it is carried out only after the box is installed.

How to warm?

One of the purposes of the entrance structure is considered to be good thermal insulation, so the fabric should be well insulated. To do this, use different technologies. If the box is made of metal, then first of all it is necessary to fill its internal unused cavity.In this case, it is filled with special insulating material in the form of mineral wool or foam. Also, to keep the door warm, it can be sheathed with wooden beams. The only drawback of this technology is the formation of cold bridges.

Well insulated front door and dermantin. With this technology, the door leaf is upholstered on one side only, and a thin layer of insulation is applied on two openings. The insulation is glued directly on the door, and then it is decorated with dermantine or natural leather.

Equally important is to protect the structure from drafts. To do this, use two methods:

- Warming of gaps between a box and a cloth. As a thermal insulation, a rubber or foam seal is well suited. It is attached using a self-adhesive base and is applied both to the box itself and to the canvas.

- Opening the door frame. The upholstery of the outer and inner sides of the slopes is carried out, and the gaps between the opening and the structure are filled with insulating material.

In the event that none of the types of thermal insulation are suitable, the installation of a second entrance door can be an alternative solution.

How to weld canopies?

Before you put the entrance door, you need to weld hinges (sheds). As a rule, to keep the standard construction, two loops will be needed; the distance between them should not exceed 20 cm. Before starting work, canopies are thoroughly cleaned and treated with a special solution. Welding hinges is desirable to perform horizontal with respect to the door frame. In the event that the opening is already installed, then the welding seam is carried out vertically.

Loops are welded as follows:

- Prepared blanks are divided into two components, one of which will be welded to the canvas, and the second to the box.

- First, attach the bottom loop, it is bolted by welding in several places.

- A check is made on the location of the loop with a building level.

- A final check is being carried out.

As for the upper loop, the installation work is carried out similarly, the only thing worth considering is the location of both sheds in the same plane. They should be placed clearly above each other. At the end of the work, it is important to clean the seams from plaque well, then weld the fittings themselves.

Examples and options

No matter how wonderful the country house or apartment is, the exterior design of the housing must be complemented by a beautiful and reliable entrance door. Today, the construction market is represented by a wide choice of these structures, they all differ in the material of production, design and safety class.

For cozy houses in the countryside, you can choose both wooden and metal doors. It all depends on the exterior of the building. If, for example, a house is built of natural timber, then the door must be made of natural material. Metal structures are best suited for brick buildings. As for the apartments, for them the best choice is considered to be durable metal doors that can not only protect the home from robbers, but also provide excellent sound and heat insulation.

How to make a metal front door with your own hands, see the following video.