Enamel NTs-132: technical characteristics and scope

Enamel NTs-132 has not lost its popularity for 40 years and is one of the most popular paints and varnishes in the domestic market of household and construction chemicals. The material is successfully used for painting wood and metal surfaces, and can be used both for interior and exterior works.

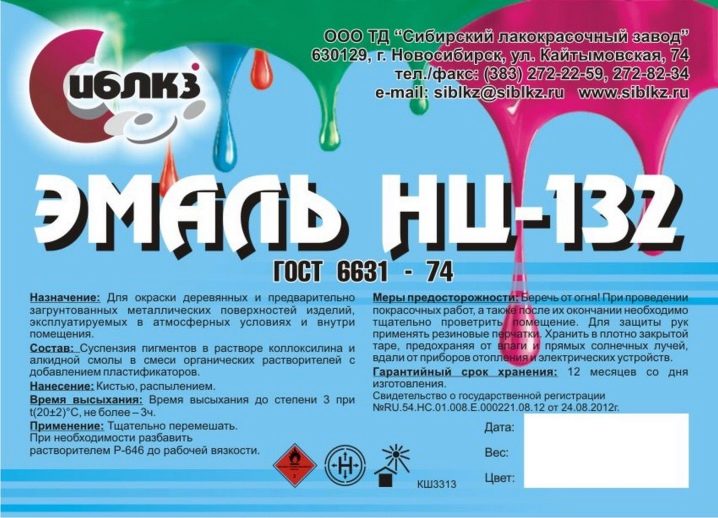

Specifications

According to its chemical composition, enamel is a mixture of colloxylin-nitrocellulose, containing from 10 to 12% nitrogen, alkyd resins, plasticizers and color pigments. In addition to the total share of volatile elements, enamel has in its composition non-volatile substances. These include toluene, butyl alcohol, high and low boiling solvents.

The number of such elements can vary and depends on the type of paint and its color. Thus, the proportion of dry residue of non-volatile elements in red enamel is 25–35%, while in the enamel of other colors, their proportion increases to 40%.To achieve the effect of a smooth and uniform application, an additive preventing flotation is added to the enamel. The material fully complies with strict international standards and is manufactured according to GOST 6631-74, which strictly regulates compliance with the formulation and manufacturing technology.

Enamel can be used at temperatures from –12 to +60 degrees. The setting time is determined by the lack of stickiness of the painted surface and is two hours. Full drying occurs only in a day.

The frozen layer has a hardness index of 0.3 units, which is a good indicator for enamels of this class. Indicator of the enamel layer resistance to the effects of industrial oils is 6 hours. You can remove the paint with a solvent for enamel №646. The average cost of one liter of NTs-132 enamel is 200 rubles for small containers and from 100 rubles for buckets from 10 liters.

Advantages and disadvantages

The high consumer demand for NTs-132 enamel is due to a number of indisputable advantages of the material, namely:

- the elasticity of the composition makes it possible to paint with enamel products of any geometric shapes and reliefs;

- the increased moisture resistance of paint provides ample opportunities for its use in damp rooms and on the street;

- good wear resistance values guarantee the preservation of the original appearance of the painted surface for two years;

- ease of care due to the resistance of the enamel layer to the effects of cleaning and detergent chemicals, including abrasives;

- resistance to ultraviolet rays. Enamel coating does not fade in the sun and does not crack;

- high resistance to extreme temperatures and their abrupt change allows the use of enamel in any aggressive environment;

- the optimal combination of price and quality makes it possible to significantly save money and get a good result;

- wide range of colors produced enamels greatly facilitates the choice and helps to implement bold design decisions. The painted surfaces get decorative glossy effect.

The disadvantages of the material include the high toxicity of the liquid composition, which is why in some countries the enamel NC-132 is implemented with restrictions.Therefore, when working with enamel, you must strictly observe the precautions and use personal protective equipment in the form of a respirator, goggles and gloves. The disadvantage is the high flammability of the enamel, which is why it should not be painted near the fire sources and heaters equipped with electric heaters.

Species

Enamel is available in two versions. Type NTs-132K designed for applying paint on the work surface with a brush. He has a rather thick texture. If necessary, the enamel can be diluted to the desired thickness, using the solvent. This species is produced in banks of 0.7, 1 and 1.7 kg.

For industrial use and dyeing large areas, large barrels with a volume of 17, 25 and more liters are provided. The shelf life of this type of enamel is one year.

The second type of paint is represented by a modification of NTs-132P and is intended for industrial painting of large areas with a spray gun. The composition has a more liquid consistency and is available in containers with a capacity of 0.8 and 1.5 liters, as well as in large barrels. Despite the fact that both types of enamel consist of the samecomponents, their compositions have different conditional viscosity and dry residue. The difference is the use of solvents.

For modification of NTs-132K, solution No. 649 should be used, and for NTs-132P enamel, according to GOST 18188, model No. 646 should be chosen.

Colors

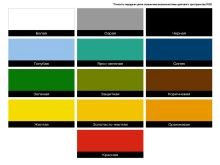

Enamel is produced in a wide, regulated by GOST, color range. This allows you to easily select the desired shade and buy paint for any type of finishing work. The light spectrum is represented by the colors of white, light gray, cream and light beige. The dark segment includes black, dark blue and dark green colors, as well as gray and brown shades.

Bright green, yellow, red and orange color look very nice. From natural flowers there are greenish-yellow, pistachio and light green.

Consumption

Enamel is sold in finished form and does not require additional dilution. Drawing can be made by means of a spray, the roller and a brush. In comparison with a brush, it is much faster and easier to work with a roller, but it should be borne in mind that its use significantly increases the consumption of enamel. Paint the surface with paints and varnishes recommended in two or three layers.

The paint consumption directly depends on the hiding power of the material.The higher this value, the less paint will be needed for dyeing.

The enamel consumption is also affected by the color of the material. Dark blue, black and dark brown are the most economical. The consumption of such enamel is only 30 g / m², while with white, yellow, blue and cream paints this figure corresponds to a value of 100 grams per 1 m².

A great influence on the consumption of enamel has the preparation of the working surface. If the metal base is painted, it must be thoroughly cleaned of rust, scale and dirt. Then the surface must be degreased and treated with a primer. Wooden foundations also require preliminary preparation, which consists in drying and subsequent grinding of the surface. Then it is necessary to prime the wood and wait until the auxiliary layer is completely dry.

Well proven primers AK-070, VL-02 and GF-021.

Instead of the finished primer, you can use the solution of the light enamel NTS-132 and the solvent, taken in a ratio of 5: 1. It must be remembered that wooden objects due to their high porosity have good absorbency and need double or triple staining. This property of wood should be taken into account when calculating the required number of cans and purchase material with a small margin.

Application rules

After the surface is thoroughly dust-free, degreased and primed, you can proceed to the installation. Initially, the enamel should be well mixed and the top film removed. Usually the paint has the desired consistency and does not require dilution. However, with increased density of the material it can be diluted with a solvent, the choice of which should take into account the modification of enamel.

Drawing is made by any available tool taking into account mission of paint, volume of work and a relief of the painted surface. After the first layer is formed, it is required to leave the surface to dry for two and a half hours, and only after that proceed to the application of the second layer.

If the surface is supposed to be polished, then you should wait until the material is completely dry.

Manufacturers

Among the enterprises producing NTs-132, the most famous are the Omsk association "Ladoga" and "Colorit" from Novosibirsk. Companies provide a bonus system of discounts to large wholesalers and offer a high-quality and inexpensive product.Belgorod "Belkolor" products are also popular among consumers, whose enamels are characterized by good hiding power and richness of shades. The line of enamels of the company “Tex”, which produces a large range of paints and varnishes at quite reasonable prices, is widely represented.

The largest enterprise for the production of NTs-132 enamel is the Lakra group of companies, whose production facilities are located in Canada, Poland, Russia and Switzerland. And Continental LLC is considered the youngest and fastest growing company, focusing on high European quality standards and producing a huge range of paints and varnishes.

The Crofor plant is also well known both in the domestic and Eastern European markets. The company's products are made strictly in accordance with GOST, has good quality and has many positive reviews.

Scope of application

NTs-132 enamels are intended for painting concrete, metal and wood surfaces. Excellent adhesion and plasticity indicators make it possible to apply the material on products with difficult terrain,and on substrates subject to vibration, deformation, and severe mechanical stress.

Due to its good covering ability, the material is used for finishing facades, painting large premises and metal fences. And excellent protective properties, comparable to the capabilities of the specialized enamel XC-5132, allow the use of enamel as an anti-corrosion agent for the treatment of metal surfaces. The paint has worked well in harsh climatic conditions with extreme temperature and high humidity.

In everyday life, enamels are used to paint the interior, furniture, metal doors and decorative items.

The enamel NTS-132 is a reliable and proven paintwork material, widely used in industry and everyday life. The paint has high performance, attractive appearance and durability. The use of this inexpensive and effective means will help to quickly and efficiently refresh the premises, update the facade and keep the production facilities clean.

Video review of the enamel NC-132, see below.