Types and nuances of the choice of acrylic sealant

One of the stages of construction or repair work is the sealing of joints or slots. As a rule, this is done with the help of special compounds - sealants. A universal sealant with high technical characteristics and environmental friendliness is an acrylic-based compound.

What it is?

Acrylic, or rather, polymethylacrylate in the composition of the aqueous dispersion is considered one of the simplest plastics and acts as the basis of acrylic sealant. In addition, thickeners are present here (provide the desired consistency of the composition), fillers and plasticizers (due to their presence, the specified characteristics of the sealant are achieved). When a combination of some of them is formed abundant foam, to eliminate which manufacturers are forced to add defoamers. In addition, the composition contains surface-active substances (surfactants) and antiseptics, as well as ammonia solution.

A feature of acrylic sealant is its water content, which begins to evaporate after application. After the evaporation process is complete, the seam is polymerized and hardens.

Acrylic based sealant is designed to fill small cracks and gaps. However, most acrylic aggregates are intended for use in ambient conditions. Inherent to the premises, slight changes in temperature and humidity are not terrible for the sealant, which is not the case with the effects of negative temperatures. The seam in this case becomes excessively hard, loses elasticity, which, in turn, leads to cracking. However, today in the construction market you can find modifications that can be operated at a temperature of -20 ... +70 degrees.

Formed seam is characterized by elasticity, resistance to vibration and mechanical loads. The standard composition is available in white or transparent version, after hardening the surface can be plastered or painted. Some brands produce colored sealants, including those imitating various types of wood.Such compositions are indispensable in those cases when you want to create an inconspicuous seam, indistinguishable in shade from those surfaces that it joins.

Composition form - small tubes (it is convenient to use them with a small amount of work, for small cracks, the sealant is squeezed out directly from the tube into the gap), tubes or cartridges (using an assembly gun) or a plastic bucket (it is profitable to buy it for large areas, the seams are filled with a spatula).

Advantages and disadvantages

Advantages of acrylic sealant:

- Versatility. Ability to use on different types of surface.

- Good adhesion performance. In many ways, precisely because of this, the universality of the composition is achieved - sealants adhere securely to both porous and smooth surfaces.

- Environmental friendliness, due to the fact that the composition of water-based does not contain toxins, in this regard, the tool does not emit a sharp unpleasant smell in the process of application or drying.

- Fireproof. Due to the absence of solvents in the composition, acrylic sealants are of class NG, that is, non-flammable.

- Ease of application.Due to the convenient form of release, the material is easily applied, it is easy to remove the liquid in a liquid form, and in a frozen form it can be cut off with a knife.

- High vapor permeability, so that the tool can be used for sealing seams in the frames, between the elements of window openings - excess water vapor will be removed from the room.

- Resistant to UV rays.

Acrylic-based sealants do not turn yellow or crack when exposed to sunlight.

- The ability to paint the seam, as well as the variety of color modifications of the composition, thereby achieving a high aesthetic appeal of the treated surfaces.

- Ease of application - this can be done directly from the tube or using a gun for sealants.

- Durability.

- Price availability of the composition. Compared with silicone sealant, acrylic is much cheaper.

One of the most noticeable disadvantages of a sealant is its inability to withstand moisture., due to its water-dispersion composition. At the same time, some packages have a “moisture resistant” mark. Is there no contradiction here?

The fact is that the stiffened seam is not afraid of a slight exposure to moisture (the amount of water vapor that is present indoors with normal moisture levels). But with prolonged contact with moisture or its increased content in the air, adhesion, and then other characteristics of the composition begin to decline. Thus, it turns out that the composition is not suitable for sealing joints in the bathroom, in the kitchen, washing, pools; It is not intended for outdoor use and is not suitable for gluing objects and surfaces that contain water.

Kinds

Acrylic sealant is divided into 2 large groups - one-component and two-component composition. The first is a mass ready for application. The second includes 2 components, which before use must be mixed to a uniform consistency.

One-component composition is universal, while it is afraid of exposure to moisture, cracks at low temperatures. It is better to use it for sealing seams only indoors with normal humidity values. Such seams are optimal for painting, the coloring composition lays down in an even layer, without changing the shade during the drying process.

To obtain a composition with higher technical properties allows the addition of other components, primarily silicone or latex, as well as water-repellent compounds. For example, to obtain a frost-resistant product allows the presence of latex in the composition of acrylic sealant. This allows it to be used for outdoor work.

Siliconized two-component sealant is characterized by increased adhesion. Silicone in the composition allows to glue surfaces with smooth, sliding surfaces. First of all, it is plastic.

However, this composition is indispensable for sealing gaps on excessively porous surfaces.

The advantage of acrylic-silicone compositions is also their increased resistance to the effects of precipitation, temperature changes. The presence of silicone increases the elasticity of the sealant by about 20–25%, so it tolerates lower temperatures better. In this regard, this composition is also suitable for outdoor use.

Preventing excess viscosity with silicone allows the addition of organic extenders., and increase the resistance of the sealant to the aggressive effects of the environment allows the introduction of fungicides.The result is a more durable joint, resistant not only to atmospheric effects, but also chemically inert. In this regard, such a sealant is called "professional."

Other types of two-component sealants are considered professional.featuring improved technical specifications. As a rule, they are more difficult to apply, have a higher cost, so for domestic purposes their use is irrational.

They demonstrate good adhesion to surfaces made of concrete, brick, plastic, glass, as well as on plastered surfaces, and are suitable for repairing window and door frames. After curing can be painted with latex or oil paints.

In addition, they emit waterproof and non-waterproof acrylic sealants. The latter are absolutely safe from the point of view of environmental friendliness, but are suitable only for dry rooms. They cannot be used in joints subject to thermal expansion and deformation.

The waterproof composition has special additives, which is why it cannot be called 100% natural (however, it is suitable for use in residential buildings).Demonstrates high adhesion to most building materials, including textures of different composition, as well as in sedentary structures. Can be used in conditions of high humidity, but not in direct contact with the liquid.

Typically, the composition of moisture-resistant acrylic sealants contains antiseptic additives that prevent the appearance of mold and microorganisms on the surface of the seams.

Another criterion for dividing acrylic sealants into groups is the presence or absence of pigment in them. The standard composition is clear or white. If a certain pigment is added, then the shade can be anything. Such a paint sealant allows you to quickly eliminate small cracks, without using other compounds.

A separate group consists of compounds that imitate noble wooden surfaces.

Acrylic rubber sealant is used to fill seams on wooden surfaces., and also is suitable for use in mezhventsovy seams of log houses. He allows to receive a warm and reliable seam, is not afraid of temperature change of geometry of wood. As a rule, such a sealant is placed on top of the inter-coat insulator.Its shade is selected in the tone of the log house.

When adding flame retardants and other components to the composition, it is possible to obtain a fire sealant. As is known, the acrylic one-component composition itself is non-combustible, but the presence of certain additives in its two-component analogue can change the situation. A feature of the fire (both one and two component) composition is its ability to localize the spread of the flame.

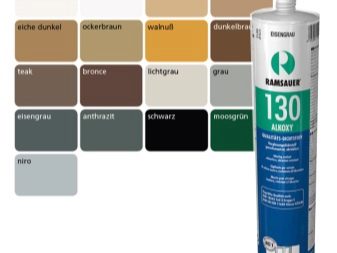

Colors

The standard shade of acrylic sealant is white or transparent. But it is sometimes necessary to get a seam of a certain shade that will fit the rest of the surfaces.

In this case, two solutions are to get colored sealant or paint a frozen seam with paint of a suitable color. The palette of most manufacturers includes the most common pure colors - gray, beige, green, blue, brown and even black.

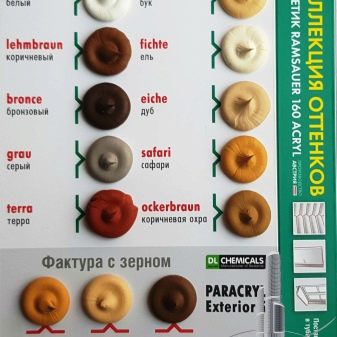

If the seam is laid in wooden surfaces, it is better to choose a composition for one or another type of wood. Today sealants in a shade of oak, cherry, birch, wenge are produced.At the same time, a quality product guarantees maximum closeness with a natural shade.

If you want to get a complex shade or color, rolling over one another, it is better to paint the seam after it is completely set. To do this, you should choose a water-based paint. If the finished form is not for sale, you can use white paint, tinting it with special compounds.

The second method of obtaining a seam of a certain shade is more laborious and costly, however, this is the only way to obtain complex or unusual shades, as well as graduated dyeing.

It is possible to make painting, as already mentioned, only after the seam has been polymerized, otherwise the liquid that is part of the acrylic paint will erode the seam.

For a better, smoother coating, before painting, the surface of the seam should be lightly treated with fine sandpaper.

Famous manufacturers and reviews

Today, among the reputable manufacturers whose products have won positive customer reviews, there are several.

- Novbythim. This St. Petersburg company has more than 15 years of history and specializes in the production of paints and varnishes, mastics and sealants, including acrylic.

The high quality of the compositions is due to the application of the latest scientific developments in the production process.

Respect for customers is also achieved due to the price loyalty of the manufacturer - its products are available to the general population. For example, the price of universal white acrylic sealant, produced in a 50-mg tube, is 30-50 rubles.

- Zigger The composition of the German manufacturer, characterized by high quality and average price. Production is carried out exclusively within Germany, which eliminates the risk of lower quality and low-grade products entering the market.

A single component composition for laminate has become widespread, which is supplied in a 310 mg cartridge and is available in a gray tint, and imitates the colors of natural wood (oak, cherry, beech, birch). The average cost is in the range of 150-180 rubles per tube.

To seal the seams on the surface of the walls, it is better to use a special white or transparent composition, on the package of which there is a litter “for building structures”. Its price is within 100 rubles per tube in 310 ml.

- Henkel. Another part of the German production, which is produced in factories in Germany, as well as in many countries around the world, including in Russia.The most famous silicone sealants are “Moment” and “Moment Germent”. Both are produced in Russia, they are frost resistant, have a low cost (90-120 rubles for 420 g). The first modification is recommended for filling the seams of inactive structures, the second - for sealing and joining the surfaces of walls, walls and window, door openings, repairing the floor.

- Belinka. A brand from Slovenia, whose products meet European quality and safety standards. There is a composition of universal action for fixed building structures, as well as a tool for parquet. Both compositions are available in 300 ml tubes, floor sealant is available in several shades.

The average cost is from 100 to 150 rubles.

- Loctite A well-known Russian manufacturer, under the brand of which are produced sealants, including acrylic-based - PL S50. It is a frost-resistant mass for application to the gaps and joints of concrete, brick, wooden surfaces and other fixed (slow-moving) building structures. Available in a bucket of 420 g, for which you have to pay about 90-100 rubles.

- Makroflex. Finnish brand. The two-component composition (acrylic-latex) is suitable not only for indoor use, but also for outdoor use. Refers to the average price range - 90-100 rubles for a container of 300 ml.

- Penosil. Russian product with several modifications. Thus, the Cosmofen ca 1 single component sealant is distinguished by its versatility of application, and due to its improved adhesion it can also be used as an adhesive. Available in small (20 and 50 g) tubes.

For fixation of plastic elements, the manufacturer offers the option “Cosmofen plus hv”, which is also notable for its increased resistance to temperature changes. Available in tubes or tubes of 200 ml.

For coating on PVC and foam surfaces, Cosmofen plus-s can be purchased in 200 ml containers.

- "Accent". The product of domestic production, also having several options depending on the scope of application. Thus, the single-component “Accent 117” is distinguished by its versatility of application and is even suitable for application to external surfaces. The modification, marked with the number 124, is siliconized, therefore it is used both inside and outside the object, suitable for expansion joints, and withstands increased loads and vibration. It can be used on household and industrial facilities.

Option 128 is characterized by high vapor permeability, which makes it optimal for application on wood, as well as in places with high humidity. For wooden coatings, there are also special modifications - these are “Accent 136”, 140 and 125. The latter is intended solely for professional use, the rest can be used both in household and industrial needs. For wide joints on wooden surfaces it is better to use a more flexible sealant 136. And the best moisture resistant and antiseptic properties characterized sealant "Accent 140".

Unlike the others, it is applied with a brush over the entire surface and protects its exposure to moisture and the environment.

- Ramsauer 160 Acryl. Composition from the German manufacturer of premium class. Differs in universality of application, higher polymerization rate, richness of color palette.

Selection and scope

The main sphere of use is the filling of seams on the surface, as well as the joining of various moving and stationary surfaces. A one-component composition is used to eliminate cracks on the surface of the walls, as well as in the joints between the walls and the window sill, window and door openings.Often the composition is purchased for sealing joints between concrete or stone surfaces, plastic bases, wooden coatings.

Restore furniture, parquet, fill the voids between the elements of the laminate - with all of this can handle a universal sealant on acrylic. It is also suitable for PVC panels and tiles, providing a sealing surface and making imperceptible joints of elements.

The advantage of the composition is its ability to fill the seams between dissimilar materials. So, the sealant is often used to eliminate the joint between the tile and the pipe.

Acrylic sealant is used not only as a means of sealing and eliminating gaps. It can also act as a construction adhesive, for example, for fixing ceiling moldings, as well as a baguette. To do this, the composition is applied directly to the back side of the decorative element, and the surface of the wall is slightly moistened with water. After that, the plinth or baguette is enough to attach to the wall and press a little.

If foam polystyrene tiles are used to finish the ceiling, the sealant is useful for sealing joints between them.Unlike silicone sealant, which can also be used for these purposes, the acrylic analog is eco-friendly and can be painted.

If you use a composition with enhanced moisture-resistant properties (they contain a small amount of silicone), then it can be used in rooms with high humidity, where the seam is not in contact with water, for example, in the bath rest room or changing rooms adjacent to the pool or shower.

The advantage of acrylic sealant when used in such places is the presence of antifungal and antiseptic components in the composition, which prevent the appearance of mold and fungus on the surface of the seam.

When choosing a sealant, like any building compound, it is important to consider the scope of its application.

Only with this approach, the composition will reveal all its qualities and will be durable.

So, for plastic substrates that usually have smooth surfaces, you should purchase a sealant with high adhesion. You can do and universal modification, but pre-treat the working base primer.

If you plan to use sealant in an aggressive environment (primarily with high humidity), then its composition should contain fungicides.This product is suitable for filling joints in the pool, bathroom, shower, but from its use in the kitchen (especially in places of contact with food) should be abandoned.

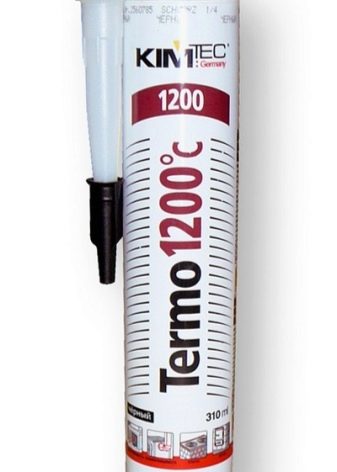

For sealing joints in conditions of elevated temperatures (for example, in the waiting room), you should choose compositions that can withstand temperatures of up to +300 degrees. Today, there are even fire-resistant sealants with heat resistance values up to +1500 degrees. Undoubtedly, such compositions are suitable for sealing cracks on the surface of stoves, fireplaces and various heating devices.

It is important to check the shelf life of the composition and the integrity of its packaging. Verify the originality of the purchased goods and its quality will allow the study of certificates of conformity. Before buying them you should definitely ask the seller.

If the sealant will be used on surfaces accessible to the eye, it is important to make sure that it does not disturb the aesthetic appeal of the surfaces. To do this, make sure that the stiffened seam can be painted. Otherwise, you can choose a colored sealant. When applied, it usually looks darker than the manufacturer promised.However, as the seam is drying, it slightly brightens.

Tips

For applying the composition does not need to have professional skills. It is important to pre-clean and dry the surface of the seam, then fill it with sealant, squeezing the last of the gun or immediately from the tube.

Too deep seams require more of the composition, which entails additional costs and increases the hardening time of the seam. This can be avoided by placing an elastic seal in the form of a polyethylene cord at the bottom of a deep gap.

Achieving an optimal positive result will allow following certain recommendations when applying the composition:

- Work can be carried out at a temperature of -40 ... +120 degrees, while the temperature of the working surfaces should be within + 4 ... +32 degrees.

- The sealant is suitable for application in gaps 6 mm wide - 5 cm.

For wider gaps, it is better to pre-use a sealing cord.

- When applying sealant in conditions of high humidity at the time of hardening of the composition, it is better to cover the working surface of polyethylene.

- When applying the composition in a humid environment, the room can be used only after the seam has hardened.At the time of solidification, the moisture on the seam is unacceptable - the liquid will just blur it.

- For dyeing the seam latex formulations should be selected; the dyeing procedure can be performed 21-30 days after the use of a sealant. Pre-recommended sanding surface. It is possible to sand only completely dried seam.

- It is better to use the opened packaging completely. It is permissible to keep the composition in closed form in case of violation of the original packaging for 2-4 days. After this time, the properties of the sealant deteriorate.

- In the acrylic sealant does not need to add a solvent or other components, if this is not provided instruction. The two-component composition is kneaded from 2 components, and in most cases it is necessary to mix the two compositions completely, leaving no part for later use. Violation of proportions in this case leads to a deterioration or complete loss of its properties by the sealant.

The shelf life of the composition in a sealed original package is one year at a storage temperature of 20-22 degrees. Do not freeze the product and its subsequent use.

If the product comes into contact with neighboring surfaces, it can be immediately washed off with a damp cloth. If you have not done so and the sealant remains, you can use a blade or a clerical knife. Attach the tip parallel to the traces of the sealant and carefully cut it off. No need to drive a tip on the surface - scratches will appear. The remains of the composition are washed with a damp cloth.

In addition, it is possible to dissolve the stains with special products for acrylic compositions. Manufacturers advise to use a mask and gloves while working. As a rule, the solvent is applied on dried spots and left for 30 minutes. After a specified time, the stain is removed with a damp cloth.

Before using the solvent, make sure that it does not damage the material on which it is applied.

To do this, apply a small amount of solvent to the sample or in an inconspicuous place. If after half an hour no negative effect is detected, the composition can be used on the main area.

For information on how to use acrylic sealant, see the following video.