How long does silicone sealant dry?

In the process of carrying out repair work in houses or apartments, the question always arises as to how and how it is possible to combine various materials and products. For example, how to glue when installing plumbing pipes, how to insulate electrical wires and much more. Silicone sealant comes to the rescue in all these cases. All of its types, characteristics and drying time will be described in detail in this article.

Special features

The best way to seal a particular surface in a bathroom or in any other place with high humidity is to use silicone sealant. This is a very convenient building material, which allows you to firmly connect the surface of different textures and is considered a quality waterproofing.

Before proceeding to the consideration of the main question of the freezing of the composition, we will determine what is so good silicone sealant and why it is often chosen for installation work.

The positive properties of this composition include:

- high adhesion rates;

- long service life;

- not exposed to chemicals;

- moisture resistance and heat resistance;

- resistance to various weather conditions, so that the composition can be safely used not only for internal but also for outdoor work;

- ability to stretch, as a result of which it can be used to repair mobile areas;

- health safety.

By cons include:

- the impossibility of painting the applied layer of sealant (but you can buy in the store the composition of the desired shade);

- poor adhesion to the old layer of silicone sealant (it will have to be dismantled beforehand, which may cause some difficulties).

Kinds

The drying time of the sealant is different - it directly depends on its type.

For example, sanitary sealant. It is used directly during installation work in rooms with high humidity in the bathroom. In addition, sanitary glue is used for sealing window frames. From this it follows that the composition of this type of sealant is resistant to a moist environment, does not respond to UV rays, and is not affected by air temperature.

In turn, sanitary silicone boasts higher potential and performance. Use it directly when working with plumbing products. With it, you can connect and fix the surface of various textures, for example, non-porous and aluminum. With the subsequent use of finished plumbing sealant does not succumb to the effects of detergents of any type. In addition, it easily withstands a temperature pressure of +150 degrees. Service life - for decades.

Universal sealant is also waterproof. Its adhesive power allows you to connect surfaces in rooms with a moist environment. In addition, it is resistant to ultraviolet rays.

There are also many other sealants designed for different fields of activity.

- Automotive. Has black color, it is used for the works connected with automotive vehicles.

- Red. It is used when installing electrical wires. It can also be used to repair vehicle components. Dries as soon as it reacts with moist air.

- Bituminous. Used when installing the roofing surface.

- Aquarium. The name speaks for itself.It is characterized by high resistance to high humidity. After drying it has a clear color. The strength of this glue for centuries.

- Insulating. Used for surface insulation and sealing. With its help, electrical equipment is protected, whose work takes place in a humid environment.

What determines the drying time?

One of the main nuances of each silicone sealant is its composition, which subsequently affects the strength, the drying process and, of course, the adhesion of the surfaces to be joined. Sealants on this basis are divided into two types: neutral and acid. Neutral is a sanitary appearance. Because of its resistance to high temperatures, it is used when working with a heating system, when installing plumbing in the bathroom and in the kitchen. It contains alcohol and ketoxime, which counteract the appearance of a domestic fungus. Neutral sealant dries for about 24 hours, while the ambient temperature should be from +5 to + 40 ° С.

Acetic acid is present in the composition of acid sealants, which also combats fungal bacteria. The only problem is that they can not be applied on surfaces made of metal, marble and cement. But you should not worry about plastic coatings, wooden products or ceramics: when applied, the acid sealant gets into the structure of the product being glued and thereby creates an additional layer of strength. The drying time of the silicone sealant depends not only on its composition, but also on the surrounding external factors. For example, in a humid environment with a warm atmosphere, the sealant will dry much faster. In this case, the polymerization process will be accelerated due to the released steam.

Next is to consider a two-component sealant. In its composition there are special additives. Due to these additives, the time of hardening and drying becomes less.

But still it is worthwhile to familiarize yourself with the composition, as some sealants add additives and dyes in large quantities. And this factor affects drying in view of the increase in the desired time.

You should also pay attention to the density of silicone. It is worth noting the thickness of the applied layer: the thicker it is, the longer the composition will dry.So, 1 mm of sealant dries in less than a day.

Summing up, one can understand that acid sealants due to their composition and structure dry on average in 4–6 hours. Neutral sealant in about a day, but if the air temperature is above zero. Otherwise the process will take longer.

How to apply?

Working with a sealant in its features does not require a lot of work, but in some moments you should behave with restraint and care.

So that the bonding process was carried out qualitatively and lasted for a long time, Experts recommend sticking to a specific sequence of actions.

- First of all, be sure to change clothes. Working with silicone, of course, is easy, but getting dirty is even easier. But to get rid of the dried glue on the clothes will be impossible.

- To apply the compound to the base, you must use a special silicone gun. At the very sealant you will need to cut off the tip and put a dispenser on it. The cutter will also need to be cut, thus adjusting the flow of material.

- From the working surface it is necessary to remove all dirt and dust.Also, the silicone application area should be degreased. To do this, you can take pharmaceutical alcohol. After the degreased surface must dry, so that the silicone does not leave when applied.

- Apply a layer of sealing mass. It is necessary to apply carefully and smoothly so as not to stain the outer surface of the glued products.

- After application, any excess silicone that appears should be immediately removed with a damp cloth, preferably without lint. Rinse hands with soapy water.

Often in the modern world, many began to abandon the classic color of the bathroom. and make different shades of different colors, for example, red or black. In this case, use white sealant or a transparent color is simply unacceptable. But even here there is no problem, the main thing is to consult with a specialist who can choose a color solution for each bold and bright design.

As for white and transparent silicone, white sealant can be used in principle for any work: it can be plumbing and electrical work - mostly where it is practically invisible.If the sealant should be on the surface visible to the eye, then a transparent version is used. It can also be used when working with glass surfaces and ceramics.

Recently, aquariums have come into vogue, for which sealant manufacturers have developed a special composition technology. After all, it should not only firmly hold the glued parts of the glass, but also have 100% waterproof performance. The most important thing is that aquarium silicone should not release harmful and dangerous substances, since not only water but also the flora and fauna of the aquarium world interact with it. After applying sealant to the surface of the aquarium, it is imperative to remove all surplus, even the smallest. Otherwise, due to the incompleteness of the poured seam may begin to flow.

It is worth noting that the color solutions of aquarium silicone are also diverse.

Tips

Quite often in the repair process there is a problem with the drying time of the silicone sealant. Immediately there are questions, how to minimize this process and dry the glue faster? It is necessary to artificially increase the temperature of the air, preferably to 40-50 degrees,indoors where the silicone dries. The setting speed will increase significantly. And so wait until fully dried.

You can also use ventilation. To do this, it is necessary to open all the windows and doors, creating a high flow rate, which will speed up the process of solidification.

There is another way that should also help seal the sealant much faster: It is necessary to sprinkle with water initially hardened seams. It is advisable to make it out of the spray. Superimposed sealant seam dries instantly. Full curing of the glue increases 0.5-1 times.

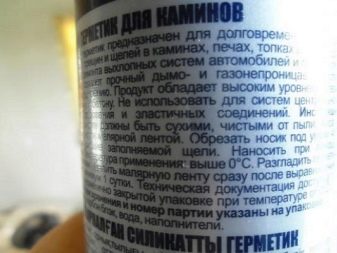

You can understand the quality of the sealant, its functions and capabilities by reading the summary, which is written on the package. From this you can understand the conditions in which silicone can be used, for which medium it is intended, for how long the glue hardens.

When choosing a silicone sealant is worth paying attention to some of the nuances.

- A good silicone sealant should be 90% silicone rubber and filler. Plasticizers, fungicidal additives, catalysts should be composed of not more than 10%.

- The presence of the letter “A” on the package means that the silicone is acid.When using it, you must wear personal protective equipment: a mask, gloves.

- High-quality sealant costs at least 150 rubles per pack, otherwise you face a fake.

About how much sanitary silicone sealant dries, see below.