Roller for painting walls: types and features of use

The roller is an indispensable tool when carrying out painting work. Its use can significantly reduce the time of painting and get a well-painted surface.

Features and benefits

The paint roller appeared in the middle of the last century and firmly occupied its niche in the construction market. The popularity of the tool due to the simplicity of design, low cost, ease of use and high quality paint.

The principle of the roller is to imprint paint absorbed into a fur coat when the cylinder is rolled across a wall or ceiling.

Coloring is characterized by uniformity of application and the complete absence of stains, which in comparison with a brush makes the tool more attractive.

High consumer demand is due to the following indisputable advantages of the tool:

- Easy to use. Work with the roller does not cause difficulties even for inexperienced painters and allows to achieve a satisfactory result by spending a minimum amount of time. The tool is especially effective on flat and large areas: walls, floors, ceilings and facades.

- Economical consumption of material. Especially well felt when painting large areas and can significantly reduce costs.

- Even staining allows you to get the perfect surface, not inferior in quality to the surface painted with a spray gun.

- Using embossed rollers It gives wide spaces for creativity and helps in the implementation of bold design ideas. With their help, you can form relief patterns, apply ornament and imitate the texture of any finishing material. The roller is indispensable when working with stencils: it tightly presses the template to the wall and does not allow the paint to flow under it. As a result, it is possible to get a drawing with smooth borders and clear outlines of the silhouette.

- Versatility. The roller can be used for applying any kind of paint and varnish products, including fire retardant and conductive enamels.The design of the tool allows you to add an extension cord to the handle and work on the ceiling and other remote surfaces.

The disadvantages of the rollers include the impossibility of high-quality staining of hard-to-reach places and the complexity of working on uneven surfaces.

It is also necessary to control the rate of wetting of the tool in the paint - if the roller absorbs too much of the emulsion, then there is a chance of splashing and draining enamel from the handle.

Device

The design of the roller is a frame, curved in the form of sevens. The upper part is called a tube and serves as the basis for a rotating cylinder, which is called a "reel".

An absorbent fur coat is fixed on top of the bobbin, which can be either glued to it or fixed with the help of plugs. The bobbin itself can be attached to the frame in a frame or byugelny way. The first is characterized by the presence of a bearing, a lock, plastic caps and fixation of the fur coat with the help of stoppers. The second is characteristic of more expensive reusable designs and, if necessary, involves the complete replacement of the cylinder and fur coat.

Dimensions

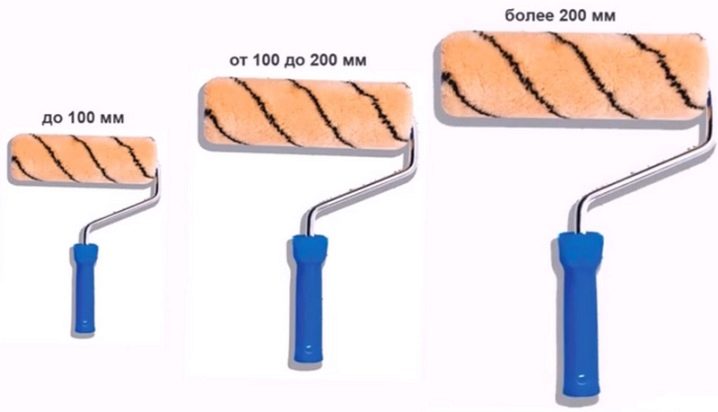

The rollers differ in the length of the cylinder, the handle and the diameter of the core. The smallest representatives of this tool are mini-rollers, the length of which does not exceed ten, and the section - one and a half centimeters. They are used to paint hard to reach places and corner joints.

Medium models are 15 centimeter cylinder with a diameter of 1.5 to 4 cm and are the most sought after species. Maxi rollers have a length of up to 27 cm and a diameter of 69 mm. Used for professional painting of large areas.

The roller handle can have a length of from 30 to 50 cm. When painting distant surfaces an extended one is used. telescopic tube, which is fixed on the handle and reaches a length of 4 meters.

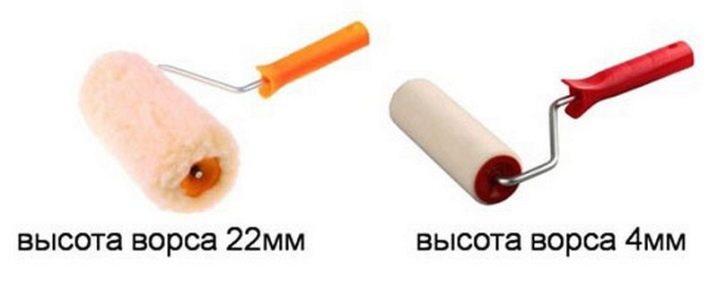

Also rollers differ in length of pile. The absorptive capacity of the fur coat and the ability to apply the tool to a certain type of surface depends on this parameter.

For example, a roller with a pile length from 1 to 1.2 cm is suitable for smooth bases, and for rough and problematic bases it is better to choose a pile of 2 cm.

Kinds

In the modern construction market, rollers are presented in a large assortment.Classification of models occurs according to the following characteristics: the material for manufacturing the fur coat, the method of supplying paint, the purpose of the tool, and compatibility with the paint.

Absorbent coats are represented by the following materials:

- Foam rubber. The advantage of this type is the rapid recovery of forms and good elasticity of the material. Polyurethane coat provides uniform coloring and prevents the appearance of bubbles on the surface of the wall. The disadvantage of foam rubber is incompatibility with some paints containing aggressive chemical components. Foam rollers are suitable for work with water-based emulsions.

- Polyamide. This is an artificial fiber, characterized by good retention properties and promotes uniform distribution of coloring matter on the surface of the substrate. Rollers have high wear resistance and are suitable for reuse. The length of the pile varies from 8 to 20 mm and is chosen independently depending on the surface to be painted and the type of paint. For enamels with a glossy shine, it is recommended to choose rollers with a thin pile,and for painting problem and rough walls, a long and thick pile will be required. Polyamide is suitable for all types of water-based paints.

- Velours. The fur coat is a velor fabric based on polyamide fiber and is used for final dyeing of smooth surfaces. Velor model is not prone to rolling and splashing enamel. Rag roller is used for water-dispersion, oil and alkyd formulations.

- Natural fur. For the manufacture of coats used sheepskin. It has excellent absorbency and contributes to the uniform distribution of coloring compositions on the working base. It is applied on any types of surfaces with use of all types of paints, except lime. The disadvantage is the probability of leaving the villi on the painted plane.

- Faux fur coat. Differs in high operational characteristics and a possibility of a reuse. Suitable for painting decorative surfaces, available in versions with different lengths and density of the pile.

- Felt. Universal material suitable for all types of enamels and surfaces.

According to the purpose rollers come in the following types:

- Models for decoration of walls and facades of a wide focus. Models are available in three dimensional versions and have a uniform fleecy surface. They are used for painting flat surfaces, decorating stencil patterns and rolling glued wallpapers.

- Textured narrow patterns. These are products with a relief surface, capable of creating three-dimensional patterns, a symmetrical ornament and perfectly imitate various textures. Used to create artistic images in the implementation of any interior solutions.

The cylinder can have rubber, plastic, polyethylene or foam rubber.

For the design of children's rooms are often used wooden models. They are distinguished by clear-cut relief, complete environmental safety and reusable use.

Structural roller can be made independently. For this it is enough to wind several ropes of different thickness on the cylinder. As a result of staining with such a roller, a pattern is obtained that is very similar to the texture of tree bark.

And to get a frosty pattern, just wind the roller with a damp cloth. With the help of a leather roller, you can apply Venetian plaster, create beautiful imitations of marble surfaces and achieve smooth transitions between the pattern relief and the wall.

Thanks to modern technology, the production of rollers with automatic paint supply. They are equipped with a spacious storage tank and dispenser. Products are equipped with a piston system that provides a constant supply of enamel. When using such mechanized devices, no additional pallets and containers for paint are required. The use of automatic models is very convenient when painting hard-to-reach and especially remote sections of the walls..

How to choose?

When choosing a roller for self-painting walls, you should not purchase wide models. They are designed for professional work, and without mastering certain painting skills, it will be difficult to handle them. Better priomedium sized roller for basic dyeing and a small model for painting joints of walls, niches and hard-to-reach areas. You should pay attention to the presence of seams: roughly decorated seams can leave marks and stains.

The color of the roller should not be dark. In case of loss, the dark villi will be too noticeable. on a light background. When painting the wall with two or more colors, for each shade you need to purchase your own roller. It will relieve from multi-colored stains on the painted surface in case of poor-quality washing of a fur coat.

Also, grasp the handle of the instrument and make sure that all the fingers on it fit. The use of a short handle will lead to excessive strain on the muscles of the hand and rapid fatigue.

Immediately before the start of painting work should be carried out with a roller on masking tape. This will collect poorly fixed and fallen villi and will help to prevent them from falling on the wall.

For a more uniform impregnation of the coat, you need to use special cuvettes and thoroughly blot the roller on a special pad. When painting high premises it is necessary to purchase an additional telescopic extension with a retainer.

For how to choose a roller for painting, see the following video.

How to wash?

In order to clear the roller of water-based latex paint, you need to pour warm water into a large bucket and add a glass of fabric softener. If the desired composition was not found, you can use dishwashing liquid. Then you need to carefully squeeze the roller and place it in the solution. When pressing, you can use the newspapers laid out on the floor. To remove excess paint you need to roll a roller in all directions.

Keep the tool in the solution should be within two to three minutes. After that, the roller is thoroughly rinsed and rinsed under running warm water. Rinse should continue until the water running off it becomes clear. Then the tool should be squeezed using paper towels and hang to dry.

To remove oil paint residues, blot the roller with old newspapers, and then place the tool in a container with alcohol. After dissolving the paint, it should be taken out, wiped dry and put to dry.

To wash the coat from acrylic paint should be under warm running water immediately after completion of the work.

If the remains of the enamel have time to dry, then clean the surface without the use of gasoline, acetone or white spirit will be impossible.

For high-quality washing of the roller from the remnants of two-component enamels, you can use a universal industrial tool, having in its composition gasoline and alcohol. This solution can remove any kind of paint.