Carpet underlay

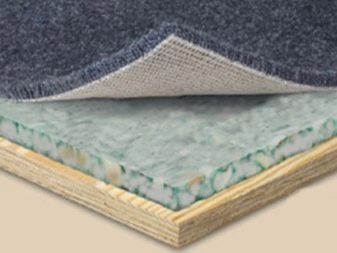

If you correctly approach the laying of the flooring, it will last much longer. Competently is to use certain tricks that prolong its service life and allow you to save on repairs. For example, when laying carpet this trick is to use a backing. Its presence allows the use of thinner coatings that are easier to maintain and are cheaper. The substrate enhances noise insulation, prevents moisture on the reverse side of the carpet, enhances the spring properties of the coating, adds softness to it.

Walking on this floor is more convenient and comfortable.

Special features

A feature of any type of substrate is that it extends the service life of the coating and, depending on the material, increases it by two or even three times. This is achieved due to the high damping properties of the substrate, which takes the bulk of the load, and the remaining evenly distributes over the area of carpet about 1 m2 from the human foot. Without a substrate, the entire load of friction is taken over by the carpet and abrades faster. With it, on the carpet there are no traces of furniture, the nap rises faster and more fully.

The second feature - giving flooring extra softness. The gasket, laid between the floor and thin carpet, compares it in softness with a long pile carpet.

There is no need to even say that it is much easier to care for short-haired or looped carpet than for a fluffy carpet.

If the substrate thickness is not less than 0.5 cm, then it is not necessary to level the surface additionally (put a new tie over the old one). If the floors are wooden, then the substrate prevents the effect of a "floating" floor, does not allow the floor covering to swell and fall.

Another characteristic is a high level of noise insulation, improving the thermal properties of carpet and most importantly, increasing hygroscopicity. Thanks to the interlayer, the coating will not mold from accidental moisture, which often occurs on a concrete screed in the offseason, neighbors will not complain from below that elephants are running around your house, and in winter your feet will be warm even without socks.

Materials

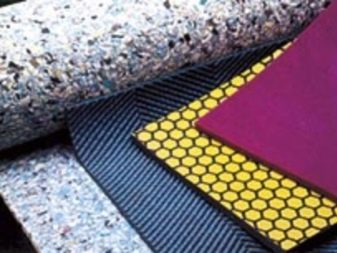

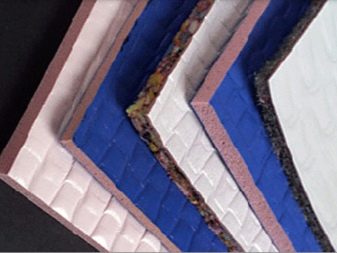

Substrates are made of synthetic and natural materials, while not always synthetic worse, just for each material its purpose. The consumer selects it based on their priorities and the base of the carpet: latex, jute, glue-based or synthetic felt. Let us consider in more detail each material:

- Polyurethane foam and polyurethane substrate based on PVC - This is the most popular type of interlayer. It is distinguished by low cost, affordability (available in every store), it conducts air well, protects the carpet from moisture and creates excellent sound insulation. Perfectly hides floor level drops of up to 3 mm.

- Fastening with the floor is carried out by adhesive method, for this it is better to use glue B-2. This material is placed only on dry and even floors, all air bubbles are removed immediately. If there are joints between the floor slabs, they must be leveled. It is imperative to check the fresh screed for hygroscopicity, and if it is not completely dry, it is better to give it another week or two to do this. This type of substrate may have the base and the upper part of polyethylene, and may have a paper base and a felt top. Carpet on the substrate is laid using hooks by the method of stretching. Pozhozhka itself put the joint into the joint without gaps and overlaps. It is used for all types of carpet, including synthetic felt.

- Rubber substrates are made of rubber (rubber crumb), which is interconnected by hot pressing. This is an excellent cushioning material, they are often filled with gymnastic mats and sports tatami. It is also a good soundproofing room, is a strong and solid filler. Most often it is used where they are going to lay the flooring on a natural felt basis.

- Cork backing one of the most expensive, but the most environmentally friendly. Despite its low thickness, it perfectly absorbs even the thinnest carpet (therefore it is used in rooms with a high degree of load), perfectly warms the floor and is completely hypoallergenic, therefore it is suitable for allergy sufferers and children. Smoothes uneven floors up to 2 mm. The only limitation for stopping is the presence of a stable humidity level in the room.

If it fluctuates strongly, then it is better to choose a bitumen-cork substrate.

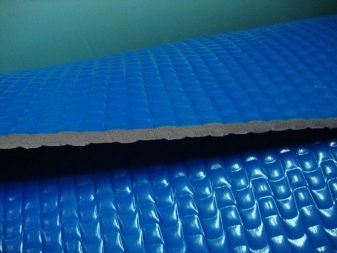

- For those who like to wash carpets with a washing vacuum cleaner, suitable PE foam backing (isolon, ponofol). It has a large variation in thickness - from 2 mm to 2 cm, it is completely hygroscopic and can be of two types - with and without foil. Foil substrate is an excellent insulator for water, steam and heat. It can be used in rooms with a high level of humidity. The disadvantage of this cheap material is its fragility and instability to UV rays. That is, over time, the substrate simply ceases to restore its original shape, and it also deteriorates from the regular impact on the floor covering in direct sunlight.

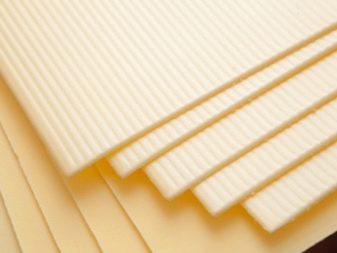

- Polystyrene substrates - A special kind of foam, they are durable and reliable. It is found in both rolls and sheets, the thickness is from 1 mm to 1 cm. It is divided into foiled (low thermal conductivity, suitable for a system of warm floors, low hygroscopicity, high wear resistance and thermal conductivity) and extruded polystyrene (not afraid of long-term exposure of heavy objects flooring in unheated rooms, more expensive than foil).

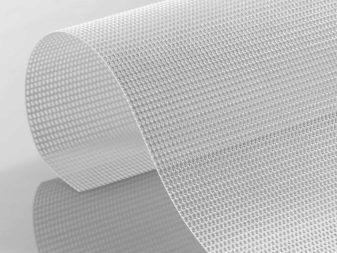

Polypropylene mesh is not used as a substrate, they only reinforce the floor under high pile or velor carpet.

Floor

Usually carpet spread on a concrete or wooden floor. Each of them requires preliminary preparation under the substrate.

The wooden floor in a private house or old apartments must first be sanded and each nail must be checked: whether its head protrudes, or if it is loose. If the nail is loose, it is better to remove it and score a new one next to it, so that the hat is flush with the level of the board. It is not necessary to level and grind plywood floors, but if there is a significant level bias, then in the place where the lowest point is located, it is recommended to lay a thicker substrate. Before laying the floor must be cleaned of grease stains and protruding stains of paint.

Concrete floor under the carpet, too, must be pre-treated. You need to start with determining the moisture content of the base. To do this, cut the plastic film 1x1 m, is attached to the concrete screed with adhesive tape around the perimeter and left for a day. If there is no condensation on the film, it means that the substrate can be laid.It is recommended to treat the floor with a chlorine compound to prevent the development of the fungus.

After that, a primer is applied to the concrete, which prevents it from crumbling and spoiling the substrate.

Which is better?

The substrate under the carpet is represented by certain manufacturers, reviews that say that the quality of the material fully complies with all the standards:

- For carpet no thicker than 2 mm, the substrate is suitable Napa. In addition to excellent elasticity, it has antimicrobial properties and allows you to fix the coating in two ways: by stretching and gluing.

- Substrate from Berbermax fits perfectly both on the concrete and on the wooden base, it has additional reinforced inserts, which makes it possible to lay it even under the baseless carpet (resistance to mechanical stress and fracture).

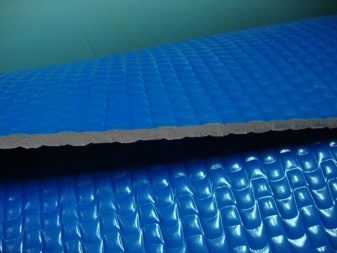

- Coverage from HC-Blue incorporates a reinforced mesh, antimicrobial impregnation and viscose yarn. It is suitable for any type of carpet, increasing its service life by 3-4 times.

- Tuplex suitable for floating floor, as it has the effect of self-leveling, hiding all the irregularities and without damaging the flooring.

How to choose?

First you need to decide on the type of carpet and understand how it combines with the type of base available, then determine the purpose of the room and the degree of load on the floor (high traffic, the presence of heavy furniture).

Whatever type of substrate for carpet you choose, you always need a personal inspection of the material in the store: the substrate must be dense, springy and not give the impression of loose.

It must necessarily restore its shape after pressing, while the restoration should occur instantly.

Familiarize yourself with the composition of the material not only on the price list, but also on the certificate offered to it. Do not be afraid to look stupid, your health depends on it. If you smell a strange smell when sniffing synthetic material, then immediately dismiss this option. A good substrate does not smell.

Buy the substrate only under the carpet. When the seller will assure that the substrate for different types of coating does not differ in anything, do not believe it. Each of them has its own density, thickness and certain properties.

Installation

Installation of substrates is carried out in two ways: adhesive and glueless.The glue method is the application of glue to the substrate (concrete or wood) and the laying of the substrate onto it as wallpaper sticking (with air bubbles from the center towards the edges). Special attention is paid to glue. Often used PVA base and the substrate shrinks. It is better to choose glue based on polymeric substances.

Also to the adhesive method is laying the substrate on a double-sided construction tape. The peculiarity of this method of fastening is that the base should be ideally cleaned of dust, therefore, it is more suitable for wooden pilaf.

When laying the substrate, it should be tightly stretched so that waves do not form.

The glue-free method involves laying the substrate on the floor without first glueing it with glue. But at the same time the carpet itself is glued to the substrate. Due to such a two-layer “cake”, the substrate firmly adheres to the floor and does not move.

You can find out how to lay the roll backing on the carpet in the next video.