Hammer paint: what is it and how is it used?

Today the range of paint coatings is more rich than ever. The ideal product can be selected for finishing any surface.

Today we will talk about unusual hammer paints, as well as look at their pros and cons.

What it is?

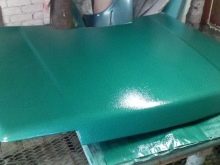

Hammer paint is a reliable and durable paint coating, characterized by durability. This painting mixture got its name for resemblance to the imprint of a blacksmith's hammer on metal. Previously, it was used for processing factory and laboratory equipment, various equipment and other structural elements for which ordinary paint is not suitable.

Over time, hammer paint has become more common. Designers paid attention to the spectacular “shagreen” surface of this finishing material, which made these coloring compositions more popular and in demand.

Currently, hammer paint can be seen in many home interiors.

Special features

Today, hammer paint is very popular because it has anti-corrosion properties. In addition, she is not afraid of negative external factors. Hammer paint is not afraid of rain and snowfall, so it is often used to finish the facades of buildings.

Under the influence of temperature changes such wear-resistant paint does not crack and does not lose color saturation. That is why it is used not only to decorate certain bases, but also to protect them from various external influences.

The secret of such resistance to wear lies in the composition of the hammer paint. It contains special polymer resins, which are particularly high quality set with metal surfaces. Moreover, they protect them from the formation of corrosion and prolong their lifespan. In addition to polymer resins, acrylic and alkyd constituents are present in such wear-resistant ink mixture.

In addition, hammer paints are often mixed with silicone oil, epoxy resins and complex fillers, such as aluminum powder or glass fines. These components make the coating not only high quality and durable, but also provide him with increased adhesiontherefore, the hammer paint smoothly rests on virtually any surface.

Hammer paint has a high density. This parameter of the mixture is provided by metal powder, which is in its composition.

However, due to the excessive density of such paint spray is unlikely to succeed. Initially, such dye mixtures were produced only in gray. When they began to be used for decorating various bases, manufacturers added pigments of different colors to their composition. Today, in stores you can find reliable hammer paint of any color.

This paint looks on those or other surfaces is very unusual. It not only differs in interesting brilliance and unusual texture, but also forms small ruts, due to which it is very often confused with a powder mixture applied in special thermocameras. Real and high-quality paint with a hammer effect is sold in ordinary banks and it does not need to be diluted., as it is initially ready for finishing work.Working with hammer paint is pretty easy. Even an inexperienced home master can cope with this without problems.

Unfortunately, today in shops there are a lot of fake hammer inks, which are not of high quality. They are often present branded stickers that are trusted by many consumers.

In order not to stumble upon a low-quality and fake mixture, experts recommend contacting verified retail outlets and not looking for too cheap trains.

Advantages and disadvantages

In search of high-quality and attractive paint, each consumer strives to find the perfect option, which will delight him with its durability and durability. The original hammer mixture meets these requirements.

In addition, similar coloring compositions have many other advantages that make them popular and in demand:

- Hammer paint is not afraid of temperature extremes. Neither hot summer, nor frosty winter, nor rainy autumn will affect its appearance and performance.

- Hammer-effect enamel can be applied to rusty surfaces.And for this it is not necessary to prepare the bases and treat them with a primer.

- Hammer blends dry quickly enough.

- So the paintwork is not afraid of dampness and moisture.

- High-quality hammer paint protects metal substrates from the appearance of rust in the open air up to 8 years. Far from any enamel boasts such a characteristic.

- Such enamel can be bought for both interior and exterior decorating.

- Paint with hammer effect is not subject to mechanical damage. Due to this characteristic, it will be very difficult to leave a scratch or other damage on a similar coating.

- This paint composition is safe for health. It does not emit hazardous substances either during application or after drying.

- It should be noted decorative properties of such paint. It is presented in a very rich color palette. Over time, the hammer mixture does not fade under the action of sunlight.

- Hammer paint does not have an unpleasant smell.

- The dried hammer surface has an interesting ability - it repels water, dirt and dust.That is why the objects on which it is applied, look well-groomed.

- Due to the characteristic texture, the hammer paint is able to hide minor defects of the base. If there is a noticeable chip on it, then it can be painted over locally. In this case, the tinted place will not be noticeable.

As you can see, the hammer paint has a considerable list of positive qualities.

However, she has her own weaknesses:

- Removing such a paint coating from any surface is not easy. For this it is necessary to use aggressive solvents and abrasive tools. However, even with such devices to remove a layer of paint will be difficult.

- If you paint a metal base with hammer paint, then you need to make sure that no area remains unpainted. Otherwise, corrosion will quickly appear on the unfinished area, which will eventually spread to the coating itself.

- It is very difficult to apply such paint using an airbrush (or using a spray can) because it is characterized by high density and density.

- Many consumers cite the high cost of a hammerpaints. Moreover, it is distinguished by high consumption, therefore it is not necessary to speak about its availability.

What is it for?

As mentioned above, hammer paint was originally used for the finishing of various structures and their components. In addition, it is often used to design forged and cast iron products. Now with this blacksmith's paint cover various bases, not only from metal.

- This ink mixture can be finished and interior and garden furniture. She is also often covered with large office cabinets, high metal shelving (found in many organizations), safes, indoor chairs, and benches for parks and squares.

- Without such a paint can not do in automotive parts and mechanisms. For example, these may be electrical switchboard enclosures, machine covers and various parts belonging to motor vehicles.

- Hammer paint can be safely used in the finishing of such constructions as gates, fences, any fences, doors and gates. Constantly being on the street, these details will not lose their color and saturation.

- Quality blacksmith paint is very often used. for finishing steel building structures. These include support columns, beams, fasteners and drain pipes.

- Hammer paint also covers small details, for example, frames, shelves, decorations with forging elements, garden tools, various tools and accessories from metal.

Many consumers familiar with such wear-resistant paint, believe that it can finish only metal structures. In fact, it is not.

It fits nicely on wood, plastic (solid), glass and ceramic surfaces.

If you decide to decorate an object with such a dye composition, then you It should be borne in mind that it is better placed on the base in a horizontal position. From a vertical plane, the paint will drain, forming ugly smudges.

In addition, with this option of finishing a beautiful shagreen effect will not be achieved. If the object can not be placed horizontally, then this means that you should stock up on quick-drying blacksmith paint. This mixture dries so quickly that it does not have time to spread on the base.

Kinds

There are several types of forge paintwork. Each of them has its own abbreviation and composition:

- ML-165 - it is an enamel having an alkyd-styrene base. It has high heat resistance (up to 130 degrees) and excellent adhesion with various base materials.

- VC-123 ME - this painting mixture is epoxy. It combines both paint and primer mixture. It is this composition that is used when painting cranes, cars, loaders, fences, doors and gates. Such paint can be applied even to rust without special preparation of the base.

- NTs-221 This is a relatively inexpensive Hammer Nitro Enamel that performs a more decorative than protective function. It is not allowed to be applied on a rusty base, and in matters of resistance to high temperatures, it is no better than simple coloring mixtures. This enamel can be used for both interior and exterior finishing.

- Hammerite - This enamel from the English manufacturer is quite expensive. It is recognized as one of the most popular blends of foreign production. It can also be applied on rusty bases.

Solvents

Hammer paint is a special nitro enamel with polymers in its composition. It can be diluted with almost any chemical solvents.

Most often in such coloring compositions are added:

- special solvent 646, as well as other brands;

- xylene;

- solvent;

- petrol.

In many cases, the quality of the solvent affects the hammer enamel as a whole. That is why it is recommended to use special components of the same company as the paint itself when working with similar finishing materials.

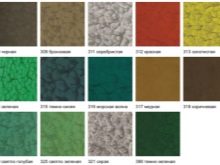

Color spectrum

If earlier hammer paints were produced exclusively in gray color, then today in the stores you can find mixtures of the most different colors. For example, an expensive and wear-resistant mix for Hammerite rust is available in the following colors:

- whites;

- brown;

- light green;

- blue;

- golden;

- copper;

- reds;

- dark blue;

- gray;

- black;

- dark green;

- silver gray.

All of these colors look very attractive. Originality and additional brilliance of them adds characteristic for the hammer mixture mixture texture. In addition, the paint can be matte or glossy.

Application details

Applying hammer coating is quite simple. However, it should be borne in mind that it is possible to trim surfaces only at a temperature range from +10 to +25 degrees. At the same time, the humidity level should not exceed 83%.

When you paint this or that basis with a similar composition, you should pay attention to the thickness of the applied layer. It should not exceed 100 microns.. This thickness is suitable for proper formation of a high-quality anti-corrosion formation.

In order to distribute the dye mixture on the base, you need to use the tools provided for this:

- Brush. This method of applying the coloring composition is the most popular. Thus it is possible to trim the bases of small size and simple configuration. As a rule, for a greater protective effect, it is recommended to apply 2-3 (maximum 4) layers of paint. Special attention should be paid to edges and corners. If you plan to carry out more serious decorative work, then you should stock up on a high-quality brush with natural bristles.

- Roller. Hammer paint can be applied with the help of a popular tool - roller.This method of application is recommended to apply if you plan to process sufficiently large and flat surfaces. Before applying the blacksmith paint must be diluted in proportions of 9 to 1, using a special solvent. Then the mixture should be carefully applied to the surface of the base. For this ideal roller with a short fur or wool pile.

- Spray can. It is very convenient and simple to apply the coloring composition with an aerosol. Moreover, it takes quite a bit of time and effort. This type of treatment is most often addressed when there is a need to tint minor defects on small surfaces. Base painting should be carried out in accordance with the instructions, which, as a rule, are indicated on the spray can. Apply blacksmith paint spray should be in 3-4 thin layers. After applying the first layer, it should be kept for 2-3 minutes, and then the surface should be treated again. With each new layer, the interval between application should be increased to 15-20 minutes.

- Pneumatic sprayer. For finishing more large-scale and impressive areas ideal pneumatic spray.However, for such devices it is necessary to select colors of a suitable consistency. In accordance with the instructions, the hammer paint in the powder is diluted in a ratio of 2 to 1. To achieve the proper decorative effect, experts recommend applying a “zero” layer on the substrate. It is a very thin coating that should be kept for 1-2 minutes. With the further formation of subsequent layers, the starting layer will become thicker.

- Airless Sprayer. For finishing large surfaces, airless spraying can be used. For such design options, it is necessary to dilute the dye mixture in the ratio of 1: 9. In order for the mixture to acquire an optimal consistency, the sprayer must be thoroughly shaken.

For details on how to paint metal with hammer paint, see the following video.

Manufacturers and reviews

Today in the market of finishing materials there are many different manufacturers producing hammer paint. See the list of the most popular companies:

- Hammerite. This English manufacturer is a leader in the production of high quality hammer paint.Its range is incredibly rich. The composition of a suitable shade can be chosen for any situation. Moreover, the brand offers not only textured, but also smooth paint over rust. Judging by the feedback from consumers, Hammerite products are very thick, have no unpleasant odor and perfectly paint over rust. However, many buyers were upset by the too high price for the hammer paint of this brand. Moreover, some people were faced with the fact that the paintwork from Hammerite did not protect the painted metal surfaces from the appearance of corrosion. Of course, dissatisfied customers could easily encounter fake enamel. In order not to run into such products, it is recommended to buy hammer paints in reliable stores of building materials.

- Dali. This large brand offers customers high-quality hammer paint with high adhesion. It fits perfectly on a variety of bases (not only on metal). In addition, Dali products are durable and easy to apply. Most consumers leave positive feedback on the products of this brand.They were impressed by the beautiful decorative effect of Dali brand paints, as well as their ability to perfectly hide various defects. Buyers do not have serious complaints about the colors of this brand, however many people consider the prices for branded mixtures to be too high.

- "Prestige". Prestige Holding produces inexpensive hammer enamel that can be applied to rusty surfaces. The assortment of this manufacturer contains paints of golden, brown, silver, silver-blue, silver-green and silver-red colors. Based on consumer feedback, we can conclude that cheap paint from the company "Prestige" is not of excellent quality. Some customers were satisfied with it, noticing only a slight unpleasant smell, while others were deeply disappointed in this product. Some people claim that the prestige hammer paint does not quickly fade the sun and has a rather weak hammer effect.

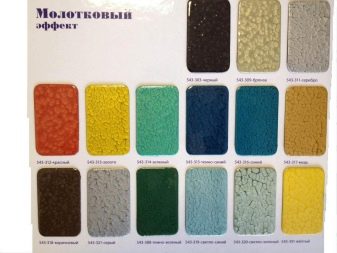

- "Moloteks". Firm Molotex produces paints with a hammer effect, having different colors. One of the most popular are the compositions of brown, gray, dark green, dark brown, dark blue and black colors.They can be applied not only on galvanized, aluminum or copper, but also on rusty surfaces. As a rule, consumers are satisfied with the use of Molotex hammer paint. They like not only the aesthetic appearance of branded coloring mixtures, but also their performance characteristics. In addition, the range of this manufacturer can be found relatively inexpensive paints.