Powder coating: technology and methods

There are many varieties of coloring compositions that can be applied in practice, but a special place among them is powder paint. This group of paint mixtures can not be applied at home - for work you will definitely need a special spray booth.

Principle of application

Powder coating is different from the application of the usual composition because it is a fine powder. Chemical analysis reveals in this powder a number of organic and inorganic components from a number of polymers. As the basis most often serves glass and metal. Chamber for polymerization - a furnace that can support heating up to 200 degrees heat. You will not be able to mix different varieties of paint, you will have to restrict to a monophonic plot.

Equipment and materials

Preparation for work begins with the choice of premises. In principle, you can do everything you need, even in an ordinary garage. The main condition for success is sufficient space for painting and placement of equipment to be applied. Characteristics of the painting installation are selected according to which base will be painted. The sprayer is installed inside the main chamber and injects powder paint into the oven.

Any work with powder paint is unthinkable, if you do not use a gun, more precisely, an electrostatic spray gun. An important function of such equipment is the connection of compressed air. An alternative is compressors with high pressure filters.

To apply powder paint, you also need to provide decent lighting (fluorescent lamps) and take care of the ventilation of the room. Only with the timely removal of the smallest suspension of dye outside and its neutralization can you be calm for your health. Professional work also includes the use of heat exchangers. Replace them in the home workshop with a vacuum cleaner cyclone group.An ordinary device will invariably get clogged with dirt in a very short time.

A number of electrical devices and a powerful network providing them may not help in solving the set task if they do not control the result of work with the help of thickness gauges. When you have to paint a large thing, it is desirable to use transport systems, and you will have to provide movement for every detail. With the help of trolleys, rolling on the rail, you can increase productivity and make work more comfortable.

A respiratory mask, although not needed for the job itself, is very helpful for greater convenience and also provides safety.. As the soil is usually used compounds that form high-quality phosphate film.

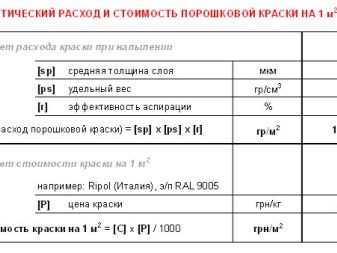

Consumption

The minimum thickness of a layer of powder paint is 100 microns. The use of sprayers helps to save dye. With these tools it is possible to reduce the consumption of the coloring composition. to 0.12 - 0.4 kg per 1 square meter.

The manufacturers instructions always refer to painting surfaces with a minimum level of porosity. However, in reality, it is necessary to put up with a very fast absorption of paint by the substrate, as a result of which it takes more per m2 than planned.This is the case with concrete and wooden planes.

The rate is also determined by how fully the mode prescribed by the technology is sustained.

What to dissolve?

Considering how exactly the powder paint is applied, the question of how to dilute it is completely meaningless. In the painting chamber is fed exactly the composition, which is produced in an industrial enterprise. No improvement is needed - it is a ready-to-use mixture.

Technology and methods

Training

Standard technology assumes that the dye is uniformly sprayed onto the plane. Quality work is always done without any haste. In preparation provided:

- elimination of the slightest pollution;

- release of surface from fat;

- applying a phosphate layer (primer).

To clear metal, concrete, apply chemical and mechanical techniques. Oxides, rust and scale remove bead blasting well.

Sand, granules from steel or cast iron are taken as working parts. A propelling instrument is either a stream of compressed air or centrifugal force. When etching, various acids are used, and this method is more productive and easier than the mechanical method.Restrictions are primarily caused by the need to wash the surface and lose extra time.

The temperature during processing in the spray booth is rather high, and therefore during the processing, they try to assess the quality of the products (blocks) in order to avoid their damage.

Coloring

All equipment (cameras) has cleaning facilities: bunkers, vibrating screens and suction tools. The cameras themselves are divided into end-to-end (they color large-sized products) and dead-end ones (they paint small things there). The color of metal in automatic painting chambers is very productive, and therefore the fee for them is fully justified, rational. In most cases, the process takes place by an electrostatic technique: an electrically charged powder sprayed in the air covers the part and adheres sufficiently strongly to its surface.

But just to put the powder is not enough, the base will have to be subjected to heat treatment. The heated layer melts, becomes fluid and turns into a monolithic coating. In any case, it is necessary to strictly follow the recommendations provided by the manufacturer.

At home

The surfaces of aluminum and other non-ferrous metals are painted very poorly, since they are invariably covered with a layer of oxides. In industrial plants, the surface is brought to perfect condition, removing salts and fatty layers. After heating, metal products are gently cooled, waiting for the complete polymerization of the coating.

Powder paint on stainless steel is applied because it:

- additionally increases corrosion protection;

- helps to avoid scratches;

- lays perfectly and smoothly;

- reliably protected from temperature changes and corrosive substances (which is very important when painting radiators).

Thermoplastic paint is not suitable for painting aluminum profiles; it is not suitable also for aluminum rolled products. It is recommended to use thermosetting coloring compositions.

By chemical nature, they can be quite diverse: epoxy, polyester, acrylic, combined, and so on. Accurate selection of the type of paint is carried out taking into account the appearance and method of use of the product, taking into account the conditions in which it will be.

To polish a layer of powder paint is not necessary at all - it only hurts her. It is impossible to paint MDF in a similar way, because this material is not electrified.

Plastics can be painted with a powder mixture, but for this to happen, it must first be made in a special way - using components that provide electrification. In addition, special primers and preheating of the material help to enhance the electrical characteristics of the plastic.

Also, when selecting materials for work, their ability to tolerate significant heat must be evaluated. Yes, paints have already been created, requiring relatively low temperatures or acquiring the necessary qualities under the influence of ultraviolet, but such coatings are not yet very common and quite expensive.

How long does it dry?

Duration of drying is a very important property for any coloring composition. And the powder paint is far ahead of all liquid mixtures: it dries in 30 minutes. Spray is discharged by the technology from 1 to 5 minutes, the polymerization occurs most often in 10 to 20 minutes, the exact figure is determined by the nuances of the formulation and the technological developments of the manufacturer.

On how to paint the door with powder paint, see the next video.