How to make a tree chair with your own hands?

In furniture stores a wide range of various pieces of furniture. All of them have different shapes and designs, but it is much more interesting to make a product with your own hands. To personally make a wooden chair, you need the ability to own tools and a desire to work. And to facilitate the task, there are many detailed drawings and lessons on the manufacture of furniture.

Model selection

To make a wooden chair is a laborious task, but anyone can cope with it. Having found the best option and some free time, you can get to work. The process itself consists of the development of detailed drawings and blank parts, which then need to be combined into one. All instructions have a standard algorithm of actions, in which the parts are first prepared,make holes for fasteners, fasten parts with screws and glue, and at the end paint the product or cover it with varnish.

Assembling the chair should take into account the established plan, so as not to make a single mistake.

The job of making a wooden chair begins with determining its type. After all, not every type of chair can be made by hand, some of them require either mechanized actions or professional skills. After examining all the possible options you need to choose the one that will be right for you. It is unreasonable to take on a complex drawing at once, since in the end nothing will work out.

Chairs that really do it yourself:

- Soft - here the main frame and upholstery. Properly assembled product and neat upholstery - the key to success. Such a product can be put in any place convenient for you to create a cozy corner for relaxation.

- Folding - This is a more complex option, but more functional. The frame of the product is made so that it can be folded and folded with some pressure. This chair is the perfect subject for a country trip.

- Kentucky - a simple version of the product, but very original in appearance.To create it will need only bars and wire.

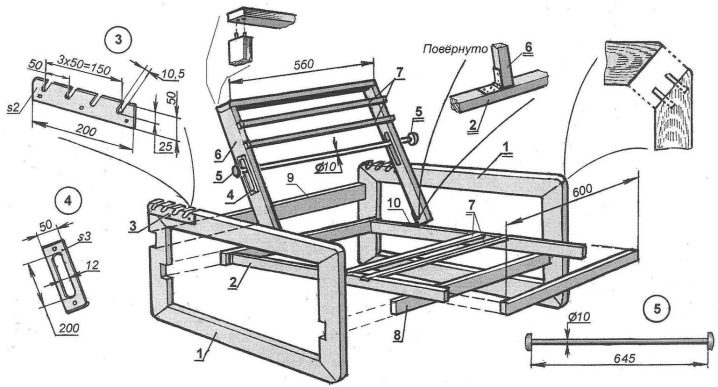

- Sliding - their design is more complicated than a regular chair, but a beginner can easily cope with it. A sliding product will help save space in a small room and will be able to replace a full bed.

- On wheels - in their construction the main thing is to install stable wheels that will be able to move both an empty chair and a chair with a person sitting in it. This is a pragmatic option for the disabled or the elderly.

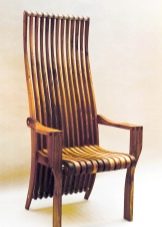

- High back - these products can be hard or soft, the main thing is that they have a comfortable high back. Make it no more difficult than a regular chair.

- Rocking chair - these products are not suitable for beginners, but for experienced craftsmen it is quite a doable task. The main thing in the design of the seats is the arc-shaped bases, due to which they will swing.

Wood as the main material

Make a wooden chair can be quite easy if you choose the appropriate method. You can use the old chair or chair, if you can not buy individual parts. Even from the stool can make a small chair that will appeal to any child.To create a classic chair usually use boards, bars, logs. The product from the massif has a number of advantages over other pieces of furniture, because wood is an environmentally friendly material that is completely harmless to health.

Natural wood is not a cheap material, but it is - a pledge of quality home-made chair. Making sure the quality of the tree, you can start creating a work of art. There should be no knots and cracks in the solid wood or in the bars. All parts must be carefully polished, and only then proceed to the assembly. A special coating will protect the material from insect attack and desiccation.

For the manufacture of chairs it is better to use oak, birch, ash or alder, because they have a unique beauty. These materials allow the product to serve for a long time, not to creak or crack. The beauty of the product can emphasize high-quality textiles, which will be used when upholstering it.

The main advantage of wood is its environmental friendliness. This is what makes it different from other materials. It is widely distributed in construction because it is relatively easy to mine and its cost is less than many other materials.

Wood is very durable and can even compete with metal. It is not amenable to plastic deformation and tolerates shocks and loads well. It is easy to work with it, and therefore a wood chair can be made independently. The disadvantages of this material include intolerance to moisture and high temperatures. Under the influence of water, wood swells and crumbles, so you need to pre-varnish it.

Manufacturing workshops

The step-by-step instruction will help to shorten the operating time and save material consumption. The most popular step-by-step instructions for making chairs:

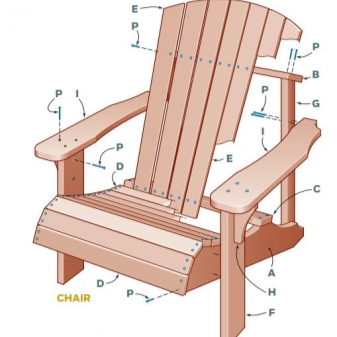

Chair for giving

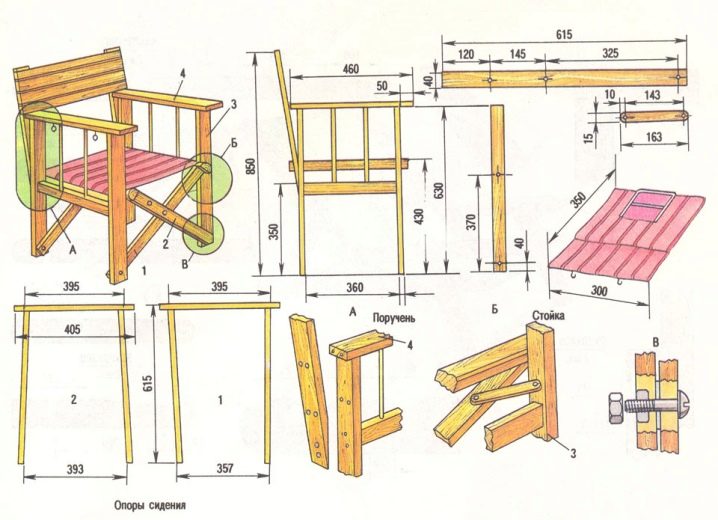

First you need to prepare the necessary tools and materials: electric saw, plane, manual mill, hacksaw, screwdriver, drill, centimeter, self-tapping screws, glue and boards. Procedure:

- From the boards you need to cut four legs (2 pieces 2 / 2.5 / 7 cm, 2 pieces 2 / 7.6 / 5 cm). Then you need to make the back size 2 / 2.7 / 9 cm two supports for armrests 2 / 1.2 / 4 cm and back support 2 / 7.6 / 6 cm. For the work you will need a jumper (2 / 5.1 / 5 cm) and slats (1.2 / 2/2 cm).

- Based on the drawings, need to prepare basic details. The most difficult is the manufacture of side supports. Therefore, before cutting, you need to print a full-size template of this element or draw it yourself on a large sheet of paper.

- To cut straight parts need a power saw and in order to cut curly elements, you need to use a jigsaw.

- First need make wedge-shaped support for armrestsand then using glue and screws to attach them to the front legs.

- Next stage - cutting out the armrests and rear support.

- To smooth out all the bumps in the part, they are sanded with sandpaper. Then you need to cut off the ends of the support, press the back part to the back to support and go through milling along the edge of the surfaces.

- The assembly process for parts must start after how they will all be treated with antiseptic.

- Rear legs you need to install perpendicular to the bevel support, and after that the side parts of the backrest and the first strap of the seat are connected. To fasten parts, need to make holes for the bolts.

- Installing the props, you need fix them with clamps. It is necessary to fasten the upper part of the back with screws, aligning it with respect to the lower transverse part. The slats need to be cut by marking, having previously made a radius of curvature.

Having finished the work, you need to sand all surfaces and hide the screw caps with wooden stoppers. Process finished wooden chair can be oil impregnated.

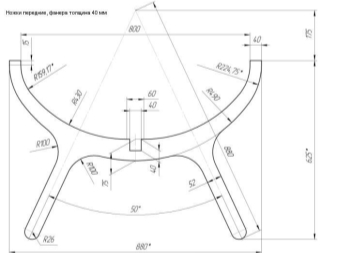

Shell

This unusual chair can be made by hand with the help of drawings and diagrams that it is desirable to create in a computer application and then print. This is necessary in order to obtain the exact dimensions and contours of all complex geometric parts. Procedure:

- All parts need to cut electric jigsaw. Movement should be smooth, so that no bumps remain. It is desirable to work with bent plywood after the master has previously practiced on a piece of waste wood.

- It is important to cover all the elements with varnish so that they look aesthetically pleasing and not exposed to external influences. But before that, it is necessary to polish all irregularities and chips and clean the surface from dirt and dust. The varnish should be of good quality and should be applied in at least two layers.

The assembly of the chair takes place with the help of wood glue, which fix all the details. In order for this process to proceed without incident, it is necessary to fix the places of gluing with clamps.Instead of the adhesive method, you can use screws, but you need to twist them deeply so that their caps are not visible.

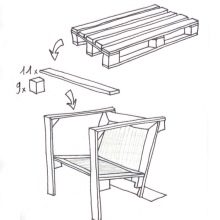

From pallets

For the manufacture of this product will not need drawings and preparation of additional elements. The self-made chair from pallets can be made in only a couple of hours:

- First you need to disassemble the pallets and remove old nails. They have an ugly look and can cause injury.

- To give the pallets a decent look, they need to be sandedafter which all parts must be reassembled.

- The assembly of the chair is done by joining several pallets. Seat height can be any, it depends on personal preferences. Usually this distance is 50-60 cm from the ground to the seat. For children, this distance should be an order of magnitude shorter so that they can comfortably sit on it.

- Armrests and backrest also need to be made from pallets, but for this they need to be partially disassembled. The height of the back is set by the master himself.

- It is advisable to varnish or paint all parts before assembly. And in order for the product to get an unusual look, you can put a foam cushion in a colorful case on it.

The chair of the pallets is not intended to decorate the apartment, but it will look good on the garden plot.

Manufacturing your own furniture is always an exciting process.. The desire to do something on their own arises from many creative people, because the furniture with their own hands is the saving of money. Making a chair of wood, the master is completely confident in the quality of materials, and most importantly, he controls his strength. For the manufacture of a wooden chair can even be useful old chair or a battered chair. By adding a few new parts and picking up a new upholstery, even the most unsightly product will acquire a new life.

How simple and tasteful to make a chair out of pallets, see the following video.