How to make a bed with your own hands?

Modern furniture stores never cease to amaze with the variety of bed models, as well as their functionality. But for various reasons it is not always possible to choose what you need. In this regard, there are a large number of options for how to make a convenient and practical place to sleep and relax with your own hands.

Model overview

At home you can make almost any kind of furniture. Before making a particular type of bed, you must decide on its model. Depending on the purpose, a drawing is designed and materials are selected. A regular in-house bed can be added with built-in drawers for storing bedding or seasonal clothing.This is very convenient, since the room is not cluttered with furniture to accommodate things, thus leaving free space for living.

Such beds are made easy, the main thing is that all the details should be finished and polished with high quality, otherwise the boxes will be stuck in special openings.

Consider the basic models:

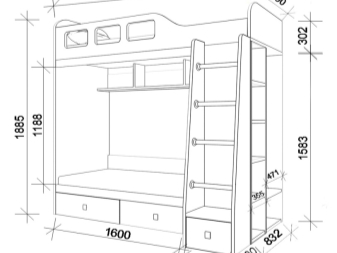

- One of the most common beds - bunk. This type of bed allows you to save space and place two people in comfort at once. As a rule, these beds are bought in the nursery. The body must be durable and of high quality in order to avoid accidents.

- If there is not enough space in the bedroom, then an excellent solution would be to make a bed transformer or wardrobe bed. In the daytime, this model can perform a functional load, and in the evening it can become a comfortable place to sleep and rest. These beds can be a different size and configuration. The most important thing in their independent production is to choose a reliable and correct lifting or folding mechanism so that there is no distortion and creaking of the furniture when it is used for its intended purpose.

- Another option to save space would be making the podium with pull out bed. The same place can combine several zones. At night, this is a place to sleep, and in the daytime - a working space.

- For rooms such as a loggia or living room, suitable chair bed. Such furniture is convenient because it can be used every day, it does not take up much space, and in the case of the arrival of guests, it can be easily transformed into a full-fledged sleeping place. It will be pleasant and the fact that the independent production will not take a lot of effort, time and money.

- A creative idea is to create hanging bed. The design itself consists of a frame and a frame with a slat. When installing it, you need to have enough free space, because during use it will swing, and if there is not enough space around, then there is a risk of waking up from a collision with a wall or furniture. For the manufacture should be preferred lightweight but durable materials.

Bring some magic and fairy tales into the bedroom will help "Flying" or "floating" bed. It is unique in that it has a cantilever attachment system, therefore the footboard is without support,thus visually it seems that the bed is frozen in the air. Very often, LED lights are attached to the bottom to support the idea of flying. In addition, a soft mattress is a place to relax for both children and adults.

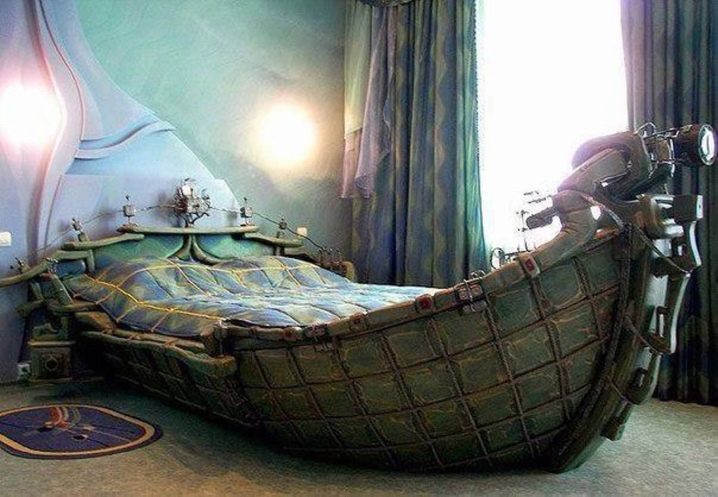

Interesting ideas

If it was decided to make the bed yourself, then it is better not to limit ourselves to the standards and come up with an unusual and creative model, saving a good amount on this.

Beds can be for both children and adults. Children can make sleeping places in the form of a car, house or outboard, it all depends on the imagination and means.

For babies up to 5 years old, it is better to make a bed with a limiter, as in a dream, many of them actively move and sometimes fall to the floor. The limiter can be mounted separately and with time it can be removed. As a rule, it is made of metal, wood or plastic. It is easy to sew a cover on it so that the child does not touch the “bare” metal or wood.

The dream of every child is to have their own little home where they can play and have fun, but it will be even more interesting to have your own home-bed. Such a bed has many options for designs and models:

- In the first case (and more simple) the usual bed box is made, and on top of the support rails 4 beams are attached to the roof hull without any additions. All parts are well processed and sanded if they are made of wood, so that the child does not splinter the surface of the skin. A light canopy is hung on top of this whole structure. The LED strip along the contour of the base of the roof of a sleeping house will look original as a night light. Thus it turns out a beautiful and cozy bed.

- In the second case the house is being made in more detail, namely with a full-fledged roof and facade, which will serve as the side of the bed. This option is suitable for double-decker beds, where there is a real staircase, on which children will go to each other "to visit".

When making beds for adults You can experiment with form and functionality. It will be very interesting to look round bed. However, it will be difficult to execute it personally, so if there is little experience in this business, it is better to order the parts from a professional carpenter or carpenter.

When you want to make a large bed, but not enough money, designers offer to use wooden pallets.For a double bed, you will need 6-8 pallets, which are fastened to each other in a rectangular shape, and a regular mattress is placed on top, and the bed is ready.

If the bedroom is small in size, then you can create an ergonomic and compact sleeping place with your own hands. Best of all, when the bed is with a sliding mechanism, which will allow to collect it in a small and compact sofa after sleep. Or equip the bed with drawers that can hold bed linen, seasonal items or other items rarely used.

It is often the case that a floating bed is made with wall panels embedded in the wall that serve as a table. They can accommodate night lamps or floor lamps of medium size.

Headrest deserves special attention. It can carry in itself both semantic, and decorative loading. In most cases, the head of the bed is used as an element of decor that complements the space with an unusual shape or ornament. In the second case, functional, it is better to make it soft and voluminous, so that it is convenient to rely on it when reading or watching a movie.

Dimensions

When self-manufacturing bed is better to adhere to certain standards. In this case, it is much easier to choose a mattress and bedding (sheet, blanket, duvet cover, etc.).

Berths are divided into three categories: single, double and one-and-a-half:

- Single beds designed for a comfortable sleep of one person. Its standard dimensions in width are 80-100 cm, and length is 180-190 cm. The parameters of length and width can be adjusted for your own height and body volume. The length should be 15-20 cm longer than the height of the sleeper, and the width is calculated from the average thickness of the person in the shoulders plus 25-30 cm on each side.

- Single bed is an intermediate option. It can fit 2 people with medium volumes or two children. The usual sizes: width - 120 cm, length - 200 cm. There are models “extra”, where the width is increased by 20-30 centimeters.

- Double bed - It is a large large bed, which provides a comfortable rest for two people at the same time. The width of the bed varies from 160 to 200 cm. The length is most often 200 cm. There is a type - a “king size” bed or, in a simple way, a three-bed. Its width is more than 200 cm.It is designed for the sleep of parents with a small child or for tall and large people.

To make a bed of optimal size, it is necessary to take into account the individual characteristics of the body. If a sleeping person is actively turning and turning over, then the width of the bed needs to be done more so that he does not fall on the floor during sleep.

Actual styles

For a comfortable stay is best to make the bed under the overall style of the room. Otherwise, a resonance in space will be created. Everything else should be selected depending on the size of the room itself. There are several current styles that can be divided into 3 large groups: for small bedrooms, medium and large.

Small bedrooms

For such premises suitable bed in the style of hi-tech, Minimalism, Loft, East Asian direction:

- Beds in style High tech They are distinguished by their originality and interesting design, which is most often supplemented by practicality and functionality. Such beds have unusual shapes and a modern look. Be sure to have the correct geometric shapes and shiny surfaces.The dominant colors are pure and life-affirming colors: white, yellow, red, green, etc.

- Sleeping in style Minimalism distinguished by their simplicity and concentration. A distinctive feature is ergonomics, simplicity of form and the absence of elaborate and unnecessary details. As a rule, the design implies light and solid colors: white, gray, milky.

- East Asian direction The bed style has many features. The most obvious is the earthiness, namely the small height of the bed relative to the floor. The form has clear lines, sometimes there is a canopy.

- Not so long ago, at the beginning of the twentieth century in the USA, an unusual interior style appeared, called Loft. Such a design appeared when the premises were not originally built for living space. It was specially altered under a living zone. Usually it is the upper floors of factories or workshops. Apartments are distinguished by their scale and simplicity of design.

Under the influence of such premises, designers began to create a whole series of furniture (armchairs, tables, beds, etc.) dedicated to this style. As for the beds, they stand out for their simplicity and neutrality in color. A distinctive feature is also the presence of "rough" elements.For example, on the headrest can be metal rivets or artificial worn.

Medium sized rooms

For mid-size bedrooms fit beds in the style of Provence, Country or Modern:

- Style Provence subconsciously perceived as something airy, light and unpretentious. These beds are suitable for lovers of the classics and the general refinement of the interior. Sleeping beds have impeccably regular and precise forms, which are combined with airiness and volume of bedspreads and pillows. The main highlight is the headboard (it should be beautiful and soft), as well as the quirkiness of the support legs (they can be curved, twisted or carved). The predominant colors are pastel shades.

- The most practical and convenient styles of beds include style. Country music. The bed is squat and has massive forms. Materials for its production are taken only natural, namely pine or oak. Sometimes there are decorative elements made of metal, for example, on the headboard or legs, or fabric covers are sewn in khaki, saffron, marshy or earthy.

- Direction called Modern differs in the roundness and smoothness of forms. Modern style involves the mixing of materials in harmonious proportions, such as wood and metal, plastic and textiles. Colors may be completely different.

Large spaces

A large room allows you to place beds of any style, but the most refined are the sleeping places in the Baroque, Empire style, Rococo and, of course, Classicism:

- Baroque sometimes called pretentious, as it implies an abundance of decorative elements, gilding, rich and dense materials for the upholstery of the bed. In most cases, the bed has a large and massive headboard, which can be supplemented with stucco. Color is also important. Usually these are shades of blue, silver, pistachio, gold, pink, red.

- Empire is one of the unique styles that combines luxury and aristocratic modesty. For the manufacture of beds in this way are taken only the highest quality and expensive materials such as mahogany wood, bog oak or walnut. The size of the bed is also impressive. Forms have straight and sharp silhouettes without flatulence, as in Baroque.For upholstery fabrics are used with deep and rich colors (indigo, pure gray, emerald green, purple, etc.).

- Style also boasts softness and comfort. Rococo. Forms at the bed smooth, without sharp corners. Decorative elements are presented in gilding, textured carvings and perfect smoothness of the lacquered elements of the main bed box. The colors of the style are soft, close to pastel colors.

- As the designers say, if there are no ideas on choosing a style, then there is nothing better. classics. Such furniture is distinguished by its reliability, durability and functionality.

The body is made without excesses, the correct form. Materials for the manufacture of beds are taken high quality and durable. It may be wood or metal. The color palette is very restrained, but may include bright, but not catchy decorative elements. There are white, black, gray and other pastel shades.

Currently, an increasing number of designers and craftsmen offer not to follow strictly one direction, but to competently combine them with each other, which will allow to combine simplicity of forms, elegance and convenience at the same time.

Selection of materials

Competent selection of materials for self-manufacturing bed is one of the main points in the creation of furniture. As a rule, his choice depends on the calculated amount and the chosen design:

- The most common material is wood. In order for the bed to serve for a long time and not to spoil health, it is better to give preference to pine, oak or ash. Yes, wood is expensive, but it will repay its durability and environmental friendliness. In addition, the frame will be strong enough and light. The only drawback of the tree is its susceptibility to air humidity. If the bars are not treated with a stain or varnish, then there is a risk that they will start to rot or become covered with mold. In the case when the bed is constantly in an unventilated room with dry air, the wooden product can crack and crack.

- If you do not have enough money for solid wood, you can replace it with plywood or fiberboard - MDF. Such a bed usually serves about 10 years. Thanks to the synthetic inclusions, chipboard does not grow moldy, and also pests do not start there.

Many people do not choose this material because of its unnatural appearance, the lack of beautiful texture and design. Also in plywood there is a small percentage of formaldehyde resin that evaporates when the material is heated or dampened. In this regard, you should not make a bed for a child from MDF panels or plywood.

- At present, fashion on beds with a metal body has begun to return. This material has long been valued for its distinctive characteristics, such as durability, reliability, resistance to temperature fluctuations and the ability to create original forms and patterns. The material itself is harmless and does not emit unpleasant and toxic odors. But at the same time, it has several drawbacks: a large weight of the structure, tactile discomfort and traumatic risk. In winter, the body of such a bed will be cold and uncomfortable if you touch it. Moreover, the metal is solid in its structure, and if you hit it, there will be a bruise or hematoma.

To facilitate the weight of the bed, you can make the body of a metal shaped tube. These are hollow iron tubes that are easily welded to each other.They are round, oval and square.

- In order to save and sell the remaining materials, an unusual bed can turn out. from the remains of PVC pipes or polypropylene (if for example, a bathroom repair was done). From such material it is better to make a bed for children, because under the large weight of the mattress and adults, the frame may crack or deform. If you still have a choice, then it is better to give preference to polypropylene pipes. They are more durable and tough in their characteristics. To assemble such a bed, it doesn’t take much time and effort, it’s just necessary to make the main box and transverse slats so that the weight of the sleeping person is properly distributed around the perimeter. Experimental designers advise to make each side of the main body of several rows of tubes, so the design will be more durable and reliable.

How to make measurements?

One of the important points in the manufacture of the bed is to measure the details and the space where it will be located. The scale of the future bed can be based on 2 parameters: the size of the room and the dimensions of the future mattress.The bed should be commensurate with the external space and concisely complement the room. Therefore, if the room is large, you can afford a large and bold size.

As for the dimensions of the mattress, it is better to proceed from a specific example. Standard double mattress has a length of 2 meters, width - 1.4-1.8 meters. Height depends on the weight of the sleeping person - the heavier it is, the thicker the coating should be.

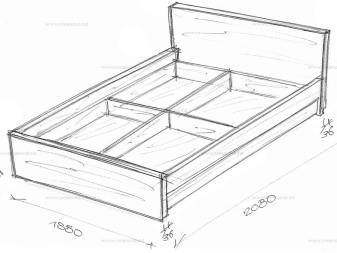

Once the measurements have been made "soft" component, you should proceed with the alignment of the dimensions of the body of the bed. The inner part should match the size of the mattress. If its width is 1.4 meters, then the width of the case should be 16 mm larger on each side, so that there is a small gap for comfortable placement of the mattress. Accordingly, the size of the head restraint will be calculated as follows: 1400 mm + 16 + 16 = 1432 mm. The length of the side parts is also calculated: 2000 + 16 + 16 = 2032 mm.

The height of the bed is calculated from the individual parameters of the person according to the standard that the bed from the floor should end at about the height of the knees. The mattress should “peek out” by about 10 cm in order to protect the feet from strikes against the body of the sofa.The height of the head can be taken arbitrarily, but it must also be commensurate with the common part of the bed. For example, if the bed level is 600 mm, then the total height of the headboard will be 1 meter, i.e. + 400 mm.

Based on the above examples, you can set the following dimensions of the bed and the number of parts for its body:

- Headboard: length - 1432 mm, height - 1000 mm (1 part);

- Opposite wall: length 1432 mm, height - 600 mm (1 part);

- Side parts: length - 2032 mm (2 parts). The height of these parts depends on the material used and the model of the bed. As a rule, the height is 200-150 mm.

It is very important not to forget to calculate the inner lining of the rails, on which the lamella or the whole sheet of chipboard will be laid. Long side parts should rest against the top short. The upper and lower slats should be equal to the dimensions of the mattress, namely 1400 mm in length and 50 mm in width, the side panels - 1968 mm by 50 mm, since you also need to subtract the width of the small slats against which they rest (32 mm). Each item is required in duplicate.

Thus, the main body of the bed is calculated. Next, you need to calculate the length and height of the internal racks, which will additionally support the laid lamella and mattress.It is very simple to make, they will be equal to the main height of the bed (600 mm), and in length they should correspond to the inner upper or lower support rail (1400 mm).

After all measurements and calculations, you can proceed to the implementation of the resulting drawing.

Step by Step instructions

In order to make a quality bed by yourself at home, it is necessary to withstand a certain phasing and consistency. Next will be described the phased construction of a standard double bed. For its basis will require high-quality wood, for example, pine.

To work with wood, you will need a tape measure, a construction pencil, 65 and 40 millimeter self-tapping screws, metal corners for fastening 45–50 mm wide, a Phillips screwdriver, a hammer, a small saw, sandpaper, carpenter glue or PVA.

Before buying wooden bars, it is necessary to draw up an accurate drawing with an indication of the scale and future holes for fasteners.

How to develop a drawing?

In order to draw in detail the future bed, you need a sheet of paper (you can take it with a millimeter ruler for convenience), a pencil and a ruler.The first thing you need when developing is to decide on the model of the bed and the mattress under which the frame will be assembled. If you wish to create a non-standard and unusual bed, you can also make a mattress yourself. A simple model of a rectangular bedroom bed is designed easily.

The drawing should be executed in triplicate: top, side and front view.

In the top view, the width and length of the body along the inner walls are usually marked. The data is directly dependent on the dimensions of the selected mattress. The figure should immediately note the intended thickness of the wooden bars, as well as their number. It is better to calculate in millimeters, since the more accurate the calculations, the better the furniture will be. For convenience, the wizard marks the place where the fastening corners will be located or the screws will be screwed in.

The side panels, as a rule, consist of two boards interconnected by means of dowels - these are rounded cylindrical rods about 1.5 cm in height and not more than 0.5 cm in diameter. Next comes a stubborn transverse bar, and on the sides are 2 bars with holes for screws or bolts for connecting to the front panels.It is necessary to designate the places of gluing and fastening. On the front view, namely the headboard, you need to specify its height, width and number of boards required for its construction.

With the help of a clear and correctly executed drawing, it is possible to calculate the number of required boards and fasteners for them, from here you will immediately see the necessary amount for the project.

If the drawing fails, then there is always the opportunity to contact the furniture salon or workshop where they can tell and show how to do it.

For a double bed you will need: for the main box and legs - a bar 50 by 50 mm with a length of 2200 mm made of pine - 15 pieces. Also needed pine board (2000 mm per 100 mm with a thickness of 20 mm) in the amount of 22 pieces.

After collecting all the basic materials for the work and you can proceed to the assembly. If the boards are not processed, then you need to cover the wood with wood stain in advance so that it does not mold and deteriorate during operation.

How to collect?

The standard main box has a height of 150 mm, and the width of the timber should be 50 mm. In this regard, you need to glue 3 bars together. Further, the procedure is as follows:

- Connected surfaces are treated with glue and compressedIt is advisable to put a load on top for better materials hitch.Should wait a day to complete drying. The resulting part must be measured again and eliminate irregularities after gluing.

- For a holistic frame needed: 2 side boards (length 2200 mm), another board (2100 mm) for a longitudinal lintel in the middle, as well as 2 wood panels for the headboard and the end part (1610 mm each).

- For a reliable and durable connection of the corners at the edges of the bars, a small fragment is sawn off - 40-50 mm. As a result, the corners are firmly fastened, but the parts still need to be greased with glue. Parts also need to be strongly compressed or press down with a load until the glue fully hardens.

- There is another way to connect the bars in the corners, namely the internal gluing of the trimmed parts. To do this, you must first assemble a rectangular frame on the floor. Next, the end parts are coated with glue and pressed firmly at both ends of the side panels. After that, the bars are screwed to each other with screws for a reliable joint. Do not forget about the evenness of the corners, so that the bed does not have bevels.

- After the main box is glued and fixed, you can install the internal lintel. It is needed in order to give greater rigidity and strength to the product.It should be mounted exactly in the middle, so the center of the box should be found on the reverse side, and not on the outside.

The correct position of the jumper is considered when it exactly coincides with the height and level of the future berth.

- Following installation of the central rail, you can begin to mount the thrust bars 150 mm long. They will keep the central jumper in an even position. If these stops for some reason were not included in the drawing, then they can be replaced with metal corners.

- When the frame is completely ready and fixed, it's time to mount the legs, if they are in the idea. They are made from the same wooden cuts 50 to 50 mm of the same length. The length is chosen under the person who will sleep on this bed. It is worth taking into account the fact that the higher the legs, the more unstable the sleeping place will be, but the optimum height will allow you to easily and quickly get under it.

- The supports are first fastened to the glue in the corners, and then fixed with screws.. Masters advise for greater reliability to strengthen the legs with metal corners, as well as to make additional in the middle of the side panels for greater stability and uniform distribution of the weight of a sleeping person. After the glue dries, you can put the body with the legs in the normal position.

- On the sides of the body of the bed on the place previously marked on the drawing are mounted internal rails 30-35 mm thick. They will serve as a future support for beam ceilings, which, in turn, will support the mattress. The supports are placed in such a way that they are on the same level with the center partition.

- Further actions are the installation of support transverse beams. It is very important that they do not lie flush with the side walls, as this may provoke a squeak when you lie down on the bed. Therefore, there should be a small space - 5 mm, which will ensure their free location. The bars themselves should not be placed close together and fastened. Ideally, the distance between the planks should be 30-50 mm. For reliability, the transverse bars are mounted in 3 places with ordinary nails or screws (to avoid cracks, it is better to pre-drill the holes for fasteners).

- After all the parts are installed, it is time to remove the errors.appeared during work. This may be the remnants of glue, cracks that need to be putty or install a new timber, sanding burrs.You should not miss this point, because it affects the aesthetic appearance and safety of the sleeper. If the originally purchased wood was not sanded, then it should be made absolutely smooth using a sanding machine or regular sandpaper.

- Ideally trimmed bed should be trimmed from sawdust and small chips. Then you can already varnish. For this it is better to use a brush or a special sprayer. Most importantly, during the process, observe the safety rules and put on a respiratory mask so as not to breathe in pairs. It is necessary to apply varnish layers on both sides, as it protects the wood from bark beetles and mold. Apply the next layer only after the first one is completely dry.

- In the process of drying the bed there is time for the manufacture of the backrest. It can have different shapes and sizes. Headboards are semicircular, rectangular, lattice, or completely absent, but with him the bed looks more succinctly and familiar. It is very easy to make. You can take 2 or 3 bars, glue them together, put under a press and wait for complete drying. Then the wood is processed, like the rest of the bed, and is attached to the main box with screws or the same PVA glue.

- Sometimes the headboard is screwed or hung on hooks above the bed.This is an element of decor. In this case, you can cut to order an unusual pattern on a solid piece of wood. Such a back will be a wonderful and unusual addition to the bed.

- When all parts are installed and the varnish is completely dry, it is time to put the mattress in its place. After that, the bed is ready for further use. If you want a wooden bed to be original and unusual, then an interesting idea would be to sheathe it with a fabric.

How to sheathe a cloth?

The process of sheathing and decorating the bed is not complicated, but it requires accuracy and accuracy of calculations. Before you begin the process, you need to decide on the textiles and the type of lining.

There are several types of fabrics for decorating the sofa or bed:

- Flock. This coating has been known for a long time and has a good reputation. The material is a non-woven fabric coated with a pile of acrylic, viscose, cotton, etc. The fabric is very durable in its characteristics, does not fade in the sun, and is also easy to clean.

- Velours. The material is very pleasant to the touch, has a vertical pile structure.Its composition is tight and durable. Such upholstery will last a long time and will delight with its practicality and price.

- Chenille Such a canvas is created by interweaving the pile between the threads. Pile can be acrylic, polyester, viscose or cotton. According to its characteristics, the material is very high quality and durable, it will give the bed an expensive look. The fabric does not attract dust and is easy to clean.

- Jacquard. This is a very beautiful, dense and unusual material. As a rule, it has a complex pattern, which is made with silk threads. The fabric is multi-layered; therefore, it is wear-resistant and keeps its desired shape well.

- Artificial leather. Modern leatherette, which is no worse in quality than genuine leather. The material will be pleased with its price, a variety of embossing and colors. Any dirt can be easily removed with a wet wipe.

- Genuine Leather. Leather fabric is very expensive and has several features. It must often be wiped with a wet towel and apply a special wax, otherwise the skin will crack. Otherwise, it is a quality and durable material.

After the bed is assembled, you can go to her trim:

- For work you will need decorative fabric and simple (for internal parts), foam rubber or batting, specialized glue for furniture, scissors, construction stapler, hammer, decorative nails, tape measure.

- Starting work is best with the headboard, if it is. It must be separated from the general body of the bed. Next, take a 5-centimeter foam rubber and cut into its shape. The process itself is not easy, so it is better to use a carpentry knife. The finished cut is attached to the wood with glue. It is necessary to apply it not on foam rubber, but on the front part of the wooden panel. For greater strength, the edges should be fixed with a stapler.

- While the glue dries, you can cut the selected fabric for upholstery. It is very important that there are 10-15 cm allowances on each side. Material fasteners should be started from the bottom corners with the help of a stapler, since then it will be easier to level the fabric over the entire surface area. When the fabric is stretched, it's time to hammer in the decorative nails so that the staples are not visible.

- When the headboard decoration is over, it's time to get down to the main building. To begin with, prepared foam strips.In size, they should be like the outside of the bed frame. They are also attached to the glue. In the place of attachment of the headboard foam rubber is not attached. Sheath frame can be technical fabric or decorative. The material is gradually tensioned and attached using the same stapler.

- If it is a technical fabric, then on top should wear a case. It must be sewn with a zipper or velcro, so that it does not crawl and is easy to put on.

- When the main box is covered with cloth, it is possible to fix the headboard.

- The above is an example of a simple cover with decorative fabric, but there are other ways of textile upholstery. The most popular and fashionable today is the four-piece bed screed. As a rule, only the headboard is decorated in this way, but the whole berth is also possible.

- For work you will need Foam thickness of 5 cm, frame made of plywood in the shape of the head of the bed, wood glue, scissors, upholstery fabric, decorative buttons or carnations, 2 thick needles, a drill with a round nozzle and a stapler.

- The first thing you need to do markup on foam rubber in the form of identical squares, rectangles or rhombuses. After that it is glued to plywood.At the docking points of rhombuses or squares, it is necessary to make round holes with a drill. The diameter should be about 10 mm.

- A covering material is applied on top. Next, the needles are taken, and with their help, decorative buttons are sewn through the fabric and holes and neat folds are formed at the same time, which are attached to the ends of the case. It is necessary to stitch slowly and carefully, otherwise a bevel of fabric may occur, and then you will have to redo the work first.

Spectacular examples in the interior

If it was decided to make a homemade bed in the bedroom, this does not mean that it should be boring and ordinary. Independent production initially implies a certain amount of creativity and creativity in the work. This is especially true for cots.

In this image you can see that the bed from the profile is not only a place for recreation, but also a small area for entertainment in the form of a slide, wall bars and a rope.

And on this example you can see the dream of many children. The bed is made in the form of a house where it is always calm and you can not be afraid of monsters under the bed.

In the image it is clear that this room is already an adult child.The bed is very functional, it is easy to clean and it will not take up extra space. For a more adult generation, a more ergonomic bed will fit, where you can sleep comfortably and hide things inside as needed.

Fans of magic and miracles can bring to life a soaring bed. It is done quite simply, but the result will be every time to please and inspire new achievements.

How to make a bed-podium with your own hands, see the next video.