Bed frames

Any bed consists of a frame and base. High headboard, footboard, legs - its optional elements, but, of course, nice and useful. The bed frame is a box or a closed rectangle on which the rack bottom is laid with a mattress that is held by the legs (if any) and which performs an aesthetic function.

Bed frames are different: metal, wood, thick, thin, soft, hard, even high and low, but they are distinguished from each other by the quality and the ability to self-assemble.

Special features

Any bed is a frame with a base for the mattress and elements like the back and legs. Of course, the bed can only have an orthopedic base on the legs and a mattress, and this is quite enough for a comfortable sleep. But in the "bare" bed there is no aesthetics, there is no home comfort that we expect from the bed. So, the frame has a number of significant advantages and minor drawbacks:

- Aesthetic function - one of the main for the frame. It hides the skeleton of the bed (or its metal base), can hide the storage boxes or externally ennoble the room;

- The frame supports the base - the bottom of the bed on which the mattress is placed. It does not assume the weight of a person and a mattress, does not distribute the load and does not have orthopedic properties, however, it is indispensable in the device of a full bed;

- The frame allows you to store things under the bed (if it is equipped with a lifting mechanism or has storage boxes) and hides this horizontal cabinet;

- The frame of the bed with a high back can significantly transform the image of the room;

- It can be soft, and therefore safe for a family with a small child;

- The bed frame can be replaced, for example, change spoiled for a similar new or similar from solid wood. In this case, the orthopedic base and mattress can be left unchanged.

The bed frame is its outer shell and an almost irreplaceable part of the bed. It can be made of any material, whether wood or metal, painted in any color or upholstered with textiles.Imagine a full bed without a frame is impossible.

Consumers can save on the frame and purchase a good orthopedic base with a slatted bottom and a durable aluminum frame, but this cannot replace the usual and cozy bed model.

Frame, firstly, is safer in its design: between the bottom laths, the hand or foot will not easily get stuck, and secondly, there will be no foreign objects under the base, and the room will play with new cozy colors.

Species

The beds are conventionally divided into separate frames (without a slatted bottom) and full-fledged models with a base, back and footrests, possibly with legs and storage boxes.

A separate bed frame has a significant advantage: under it you can choose any base - orthopedic with lamellae or a classic flat one, and to focus not on the bed itself, but on its frame. It is possible to mount storage boxes in it or make it yourself, taking into account the complexities (high growth, for example), choose suitable materials (solid wood instead of chipboard) or simply save on the purchase.

The finished bed with a frame and base can be made of solid wood, chipboard, metal, or a combination of these. Its upholstery can be soft, which will create coziness in the bedroom, and the body will be made of wood, which will also have a positive effect on the atmosphere of the room. The advantage of full beds is the fact that they are already all included and do not have to run around in search of a separate foundation. Plus, ready-made models are often suitable for people with a lot of weight, because they have a full-fledged metal base frame and high-quality lamellae.

Materials

Long since people created furniture from a tree, and today such tendency is still popular. Elite manufacturers often use teak or mahogany and other expensive materials. Raw materials are simpler - an array of oak, beech, ash, but such frames also have a high price. The most inexpensive natural material is pine and birch, from which manufacturers can make a bed frame that is durable and environmentally friendly.

The tree has a beautiful texture, rich finish and the comfort that it gives the bedroom. Manufacturers often paint birch or pine in more expensive colors or decorate with natural veneer - ash, beech, and oak.

Such a bed does not outwardly differ from the similar, but made from 100% solid wood, and in operation behaves in the best way and serves for several decades.

Pressed wood is also actively used to create a bed frame.. It is distinguished by its relative cheapness and rich color palette: here you are both white, and black, and red, and classic “wooden” shades. The disadvantage of chipboard and MDF can be called some toxicity: after all, this material is “boiled” on the basis of glue and chemical compounds with formaldehydes. Therefore, when buying furniture, ask the seller for a quality certificate and just smell the bed, because it will exude this smell for a long time.

Wood-based panels are the most popular among manufacturers and buyers. A noble exterior finish from natural veneer or lamination transforms a bed from another boring one into a stylish and modern solution for the bedroom, and that same finish, by the way, “locks” possible unpleasant smells from the adhesive on the lock.

Iron beds are firmly established in modern interiors and all because they are durable. Metal frame - the most durable of all designs. The only thing that can fail in such a model is an orthopedic foundation.

Chromed beds or artificially aged “naked” models, as well as covered with fabric or eco-leather, with a decorative soft back that do not differ in aesthetics and convenience from similar ones from chipboard, look good in a classic or Country interior.

Masters often make a bed of their own from scrap materials, which allows you to significantly save the budget. For example, you can create a durable podium with drywall with your own hands, which is also a bed frame with a recess for the mattress. You can also make a bed from a board or plywood, in which case you will have to choose a thicker material so that the design is strong. The base of the bed can be made of shaped pipe, brass, steel and other "cold" materials.

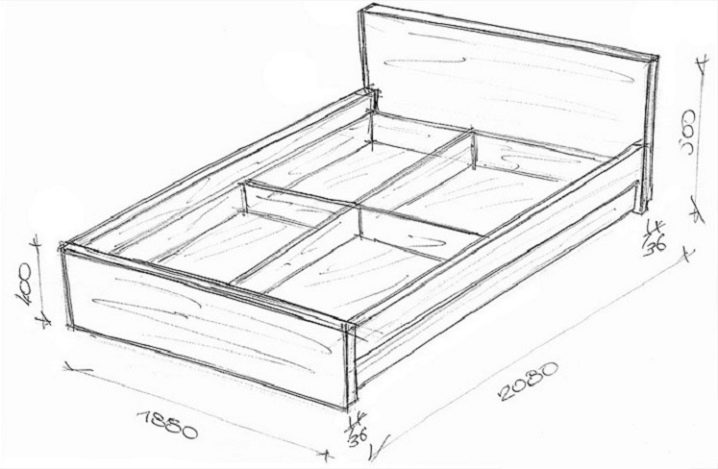

Dimensions

Standard dimensions of a single frame (respectively, and a berth):

- 90 x 190, 80 x 190, 80 x 200, 90 x 200, 100 x 200, 70 x 160 cm for the nursery.

- Double bed: 160 x 200, 180 x 200, 140 x 200, 160 x 190, 200 x 200 cm.

- One-and-a-half: 120 x 190, 120 x 200, 200 x 200 cm.

Note that the parameters of the frame itself may exceed the size of the bed in length and width, because it additionally accommodates an orthopedic base.This difference can be quite minimal (4-6 cm) or much larger (from 10 cm or more). Some brands have large beds 200 x 210 and 200 x 220 cm.

Manufacturers review: which one is better?

Among the manufacturers of bed frames are the following:

- Ikea The Swedish manufacturer makes frames for beds from solid pine, chipboard or laminated chipboard (chipboard). Models from the massif - frameworks "Hamnes", "Fjelse", "Rikene", "Tissedal." From LDSP or DVP - a series "Malm", "Brusali", "Trisil", "Oppland", "Undredal". From metal - "Leyrvik", "Kopardal", "Nesttun".

- Anrex. Belarusian manufacturer with ready-made beds - a chipboard frame and a rack and bottom.

- Berto salotti. Italy is famous for exquisite bedroom furniture. European beds already have a body, back, footboard and orthopedic bottom, rare representatives sell the parts separately.

- Zeitraum Moebel. Germany also makes ready-made furniture, which is practical. Despite the fact that German manufacturers are not so popular with us, these European beds promise to serve for a long time.

- American brands: Ashley, Stanley Furniture, Caracole differ in elite full-fledged frameworks from the massif of a tree.

The cost depends on the basic material: solid wood will cost more than wood panels (chipboard, MDF).Ikea offers the most budget cases - a birch frame will cost 1,399 rubles.

How to choose?

The optimal choice is a bed 200 cm long (or at least +10 cm in stock from your height). For a small room, a rectangular shape is suitable; for a spacious one, you can choose a semi-circular / round model.

The frame may be in the form of a box and have two supporting backs and a pair of side panels or with four side panels and two backs with legs supported.

It is believed that the models on the legs are less durable, but the material and the assembly of furniture play an equally important role: the array and the metal will live longer than chipboard and MDF.

Of course, there is nothing stronger than the metal case of the bed. It is not inferior to an array of wood - oak, beech or any other solid breed. A good choice is a skeleton made of solid pine, a little inferior in strength to birch and fir-tree (their wood is soft).

The frame of chipboard can also be of high quality, if it is lined with veneer and its panels are firmly fixed to each other. These beds are cheaper than 100% of the array, and they are more unpretentious in the care.

Finishing and upholstery also plays an important role. The body of the bed can be completely soft or have a very comfortable back.In any case, textile upholstery will give the room more comfort and significantly transforms the body of wood-based panels.

How to collect?

It is necessary to assemble the frame according to the attached instructions or the scheme according to which the materials were cut. Before fixing each bar, it is necessary to measure 2-3 times so that the angle of the frame is smooth and correct. When assembling it is important to pay attention to the length of the screws: it should not be greater than the width of the bar and the board attached to it.

How to do it yourself?

Creating a bed frame begins with a sketch and determining the size of the future bed - whether it is a full-fledged "double" or a single model. This will require the purchase of lumber (pine - great):

- 4 boards 25 x 200 x 2400 mm to create a frame;

- 3 boards 25 x 50 x 240 mm for decoration;

- 3 boards 50 x 100 x 2400 mm for the base;

- Bar 100 x 100 x 2400 mm for legs;

- 19 boards 25 x 75 x 2400 mm for the manufacture of the rack bottom (orthopedic base).

Choose pre-polished smooth wood without knots and chips, it will have fewer problems, and it will look better in finished form.

You will need tools and additional materials like roulette, drill, screwdriver, belt grinder, sandpaper, putty, self-tapping screws,wood glue, circular saw, bed varnish.

Production begins with the cutting of materials to the standards and design and the collection of the frame - the frame bed. The panels are fastened together by self-tapping screws, which are screwed at an angle for the strength of the structure and fixed with wood glue. Masters advise to make measurements on correct angles at each stage of the assembly, since it is easier to correct the defect at the initial level than to adjust the frame to the standards later.

After creating a homemade frame, you need to install the legs and make a rack base with lamellae. The frame is pre-installed with staples or rivets, a metal stand with a hole for fixing the slats. A special plastic or rubber tip is put on the panel; it is then inserted into the stand on the case.

The frame of the pallets is an unusual, bold and very popular solution. A bed of pallets will be inexpensive, and making it yourself will not be difficult. This will require:

- 3 identical pallet sizes (for example, 1200 x 800 mm);

- Drill;

- Screws and nails;

- Sandpaper;

- Screwdrivers or screwdriver;

- Hammer;

- Brushes and rollers;

- Paint or varnish.

The first thing is to clean the pallets of dirt and dust, dry them and polish them. It is important that they be the same size. So the bed will be safe to use and look harmonious. After you need to cover the pallets with a primer for wood and only then with varnish or paint (so they will form a uniform layer). It is necessary to connect pallets on their long side with the help of screws and nails. You can pre-fasten them together with a rubber band so that they do not “run away” during the assembly process.

If you want to make a high frame, you can put pallets in two or three layers. To fix the bed will have metal locks: reinforced, they will save it from free movement and preserve service life.

Modification associated with the creation of a recess under the mattress is done simply by yourself: 3-4 beds should be built vertically on the bed body.

Reviews

A large number of reviews on the frameworks Ikea. They have good ratings on the web, regardless of the material (array or chipboard). But there are also dissatisfied buyers. Positive reviews say that Ikea frames, even sliding ones, are easily assembled on their own without special tools and skills.Understandable instructions included, simple details allow you to assemble furniture without a master, and such beds serve for quite a long time.

Buyers note the affordable price of cases - from 1400 rubles (for the frame of solid birch) and the choice of the base - orthopedic or ordinary plywood. If we talk about Russian manufacturers, then buyers prefer to take ready-made beds with a body and with a base for a mattress, for example, Askona, Ormatek, Lazurit.

How to build a double bed with their own hands, see the next video.