Foam mattresses

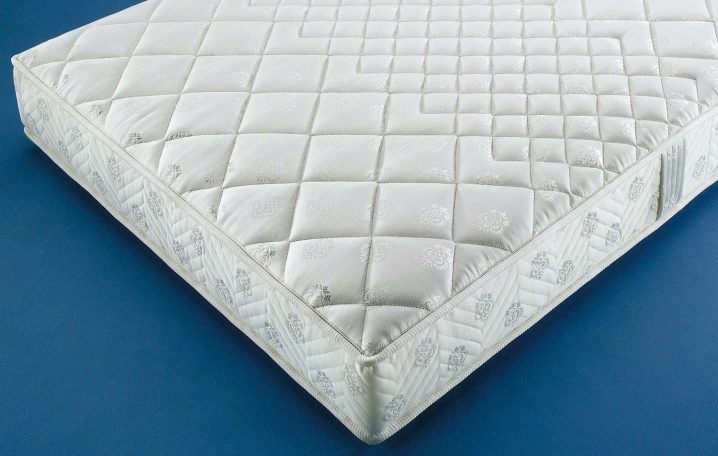

The quality of sleep depends on the surface on which the body rests at night. Today on the market there are quite a few varieties of mattresses, which differ in several technical characteristics. Among all this diversity, quite often people prefer foam mattresses. These products are distinguished by simplicity of construction and relatively low price.

When buying such a product, it is important to evaluate its orthopedic characteristics, on which comfort during sleep depends.

Special features

Foam rubber is a polymer product in the form of foam, which is used to solve specialized tasks in various fields of national economy. It should be understood that this product is a common polyurethane, which received the market name.

Foam mattresses today are quite popular, as they have several significant advantages:

- Surface of this substance absorbs practically all movements of people who sleep near.

- Mattress is different unique softness and elasticity.

- Foam completely hypoallergenic. Both adults and children can sleep on it.

- Quality material can serve up to 15 years without losing your technical indicators.

- Foam structure does not change when temperature drops.

- Inside the substance no mold and other harmful microorganisms are formed. This eliminates product rot.

Characteristic

Modern manufacturers often use foam rubber for the manufacture of mattresses. But it does not always indicate its quality.

The best option would be a product with a density of at least 35 kg / cu. m

If the mattress is made of furniture foam, then its service life will be relatively short.

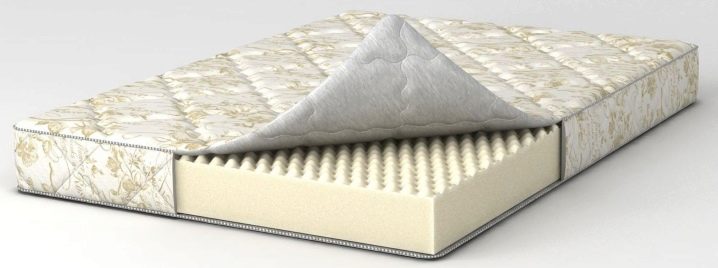

Many experts recommend the use of products in which foam rubber is made in the form of solid sheets. But there are models that use foam rubber.

It should be noted that it is not the main filler. It is used only to change the technical characteristics of the surface.

When buying it is important to assess the color of the filler.If the foam is white, then this indicates its low density (about 25 kg / cubic meter). Such products are forbidden to use for the production of mattresses. But unscrupulous manufacturers can specifically repaint the substance in a different color to confuse the buyer.

Therefore, be sure to check the documentation confirming certain characteristics of the product.

Kinds

Foam rubber is a piece of material, the properties of which can vary depending on its purpose. This led to the fact that for the production of mattresses using several types of this product.

Density

This characteristic of mattresses is quite important when choosing. Depending on the degree of rigidity, there are several types of such structures:

- Soft. The surface of the product is very similar to a feather bed. To lie on such a mattress is very nice and comfortable. It should be noted that experts do not recommend sleeping on them, as they poorly support the spine. This can lead to a violation of its form and the emergence of various diseases.

- Medium hardness. These products are relatively well able to restore their shape.Some models even have minimal orthopedic properties.

- Tough. Mattresses of this type are referred to as orthopedic models, as they perfectly support the back. It should be noted that the foam itself does not provide the desired rigidity. For this, it is supplemented with other substances, for example, coconut coir.

As for the density, foam rubber can be divided into several classes:

- 16-18 kg / cu. m The material is relatively soft, as it does not preserve the structure. According to the standards it is forbidden to use as a filler for mattresses. But unscrupulous manufacturers very often equip them with their products.

- 22-25 kg / cu. m Foam rubber of this brand also does not have sufficient indicators of density, therefore it is not recommended to use it as a filler. But the majority of cheap mattresses consist of just such material.

- 28-30 kg / cu. m Pretty dense product that can last up to 6 years. Differs in quite high price therefore mattresses from it meet seldom.

- 35-40 kg / cu. m. This type of foam rubber is very often used for the production of children's mattresses.The maximum weight that this product can withstand is 90 kg. Under such operating conditions, the mattress can be operated for 10 years.

- More than 45 kg / cu. m Foam rubber of such density is quite rare. They are often operated only by well-known manufacturers of mattresses. The service life of such products can reach 15 years. Often, such foam rubber is called artificial latex.

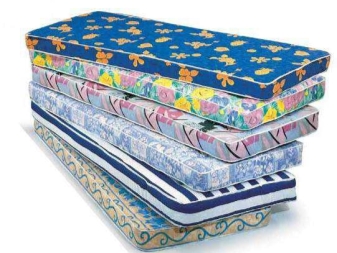

Dimensions

Foam mattresses are produced by many companies, which has led to the emergence of a large range of these products. One of the criteria for its separation is the size of the surface. On the market there are models with the following thickness values:

- 5 cm;

- 7 cm;

- 10 cm;

- 12 cm;

- 15 cm, etc.

It should be noted that the mattress thickness of 50 mm does not have high-quality orthopedic characteristics. Often such thin products are used as levelers of other surfaces.

As for the area of mattresses, they are of several types. These specifications vary by manufacturer. Today on the market you can find models with dimensions of 140 by 200 cm and 60 by 120 cm. Classical sizes for single constructions are such values:

- 80x185

- 90x200 cm;

- 90x190 cm

Double mattresses also come in various sizes:

- 135x200x10 cm;

- 130x200 cm;

- 160x200 cm;

- 140x200 cm;

- 180x200x10 cm

The most common modifications of mattresses are constructions with dimensions of 1600x2000 mm and 2000x1400 mm. They fit almost all beds. It is necessary to allocate one more intermediate class of mattresses - one-and-a-half. To it can be attributed products with dimensions of 100x200x10 cm.

Please note that these specifications are very easy to change. Therefore, many manufacturers can adapt the size of the mattress to a specific bed. But such an individual order will cost a little more than the standard version.

Which to choose?

A variety of foam products does not always allow the buyer to choose the optimal product. When purchasing such products, several characteristics should be evaluated:

- Rigidity. This is one of the main parameters to pay attention to. This indicator may vary in a wide range. So, soft polyurethane foam is perfectly combined with the chair-bed, which is used as a source of short-term rest. If it is a children's mattress, then it must be hard. It is important that he properly support the body of the child.

- Upholstery material. Almost all experts recommend the use of mattresses, in which the protective cover is made of natural fabrics. This minimizes the possibility of allergies and ensures optimal air exchange. Some models are equipped with oilcloth on top, which protects against moisture penetration.

- Health status. This indicator is very important when choosing a foam mattress. Most modifications are unable to provide orthopedic support for the spine. Therefore, it is desirable to use only ready-made combination products with a memory effect.

- Manufacturer. Today, many companies can be found on the market (Ivanovo Textiles, etc.) producing high-quality products. It is important to evaluate customer feedback about them in order to find the best price-quality ratio.

On how to choose the right foam mattress, see the following video.

How to do it yourself?

Foam rubber is a very soft substance that allows you to work with it even at home. Therefore, you can make a mattress from it yourself, having small skills in working with a sewing machine. The algorithm for the manufacture of this design consists of several consecutive steps:

- First of all follows buy foam sheet. Important pay attention to its rigidity and density, as the main characteristics of the product depend on it.

- At this stage frame cut out of the sheet. Its size can be different, and the shape adapts to a specific bed.

- Thereafter make a cover for foam rubber. You can make it from a variety of fabrics, as long as they are durable and natural.

It is important that the cover is completely repeated form of the workpiece. To simplify the work it is desirable to equip it with a lock. This will allow, if necessary, replace the foam with a new one.

The process of making a mattress only seems simple, but not always feasible at home. Therefore, it is better to buy ready-made quality products from trusted manufacturers.

Stamps

Polypropylene is a piece of synthesized material. This allows in the process of its production to change its main indicators. Today on the market there are several brands of foam rubber:

- ST. Standard foam rubberwhich are derived from base polyol.

- HL, EL. These stamps refer to materials with a hard surface. They perfectly withstand long-term loads, which allows them to be used in the manufacture of mattresses.

- HS. Soft foam. Many manufacturers use it to reduce the cost of products.

- HR. The material has a good viscosity, but has low stiffness.

- Lr. This substance is already withIt has softness and elasticity.. This foam has a memory effect.

- RTC. Products characterized by the presence of a large number of pores. It is rarely used in the manufacture of mattresses.

There is also a secondary foam, which is obtained as a result of recycling. Depending on the technology, products may have quality indicators of rigidity and density.

Reviews

Buyers of foam mattresses are gradually losing confidence in such products. This is due to the fact that this substance has been replaced by other materials with better properties (coconut coir, latex, etc.). Still, many owners say good indicators of rigidity (mark El 2842) and air exchange. This allows you to get a quality vacation for relatively little money.Another positive nuance that is noted by many owners is the low weight of the mattress. This allows you to easily transport it, twisting pre-roll.

Foam mattresses are versatile products that allow you to solve many standard tasks. But to use in everyday life you need only quality products from proven and well-known manufacturers.