Brick Varnishes: Features and Benefits

It is one thing to build a house, and another to make it beautiful and durable. Modern construction knows a lot of ways with which you can significantly increase the life of the building. Varnishes for bricks - one of them.

Properties

Previously, no one covered the brick walls. Not everyone today is concerned with the finishing of brickwork. Do I need a finish, if the brick and so it looks great, you can understand, appreciating its performance.

No matter how good the laying is, in regions with a harsh climate, and in Russia there are plenty of such territories, “lacquer assistance” to neatly laid out rectangles will not hurt. The facade of a private house, treated with lacquer, gets an additional appeal and does not require repair much longer than its raw "brothers".

Bricks, covered with a special varnish composition:

- protected from moisture penetration;

- become more durable due to the penetration of funds into the building material and a partial change in its structure;

- lose sensitivity to various chemicals, solvents;

- do not lose the original color under the influence of ultraviolet radiation;

- get high resistance to high and low temperatures;

- gain greater attractiveness;

- prolong service life;

- get protection from fungal diseases and mold;

- gain the ability to repel dirt.

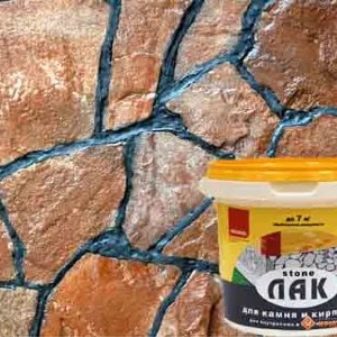

Lacquered surfaces are matte or glossy, and sometimes get the effect of "wet stone". The resulting decorative properties depend on the type of material used.

Advantages and disadvantages

The properties of the varnish are such that the product can be used both indoors and outdoors. LKM when drawing does not roll down and is not deformed. The varnish is used for any brick walls, including those located vertically, obliquely and horizontally. The presence of a large number of advantages led to a growing interest in the product. The demand for paintwork materials is growing steadily.

Untreated brick is constantly exposed to moisture. Over time, it loses strength, gradually collapses. Stronger from this "disease" suffer exterior walls. They are watered by rain streams, hail is beaten, snow falls on them, dust and dirt adhere. All year round, facades experience “attacks” by external forces. High-quality protection of the facade in the form of lacquer treatment gives it the ability to repel water, resist the destruction of the whole structure.

Masonry, varnished, receives protection from heat. This ability is especially important for stoves and fireplaces. A heating device made of brick or stone becomes truly beautiful, even exquisite. In addition, it receives long-term fire protection.

The paint-and-lacquer coating perfectly protects buildings from the development of salt stains of white color on brick walls that can disfigure masonry of houses and fences. Any stone surfaces are transformed after being coated with brick varnish, they appear smooth and shiny. Special properties of paintwork materials do not allow dust to accumulate on the wall.

If you take a varnish with a high gloss content, the walls get a wet effect.Country house with such treatment becomes like a fabulous tower. The use of "wet stone" inside the premises favorably distinguishes masonry. Designers often resort to this method to focus on a specific element of the room. Paints and varnishes on stone make facades more attractive, emphasize the richness of texture, speak about the viability of the owners of the building.

The disadvantages include the presence of specific odors, as well as the need to work with the use of personal protective equipment like skin, eyes and respiratory tract.

Kinds

According to their composition, brick varnishes are divided into four types:

- polymeric;

- solvent;

- acrylic;

- mantel (or stove).

The basis of polymeric varnishes are alkyd resins and acrylic polymers, as well as organic and inorganic additives. Each additive affects the enhancement of certain properties and characteristics. Some affect the durability, others - resistance to aggressive environments.

In solvent varnishes, silicone resins are taken as the basis. These coatings penetrate deep into the body of building materials, create an elastic coating.The transparent layer does not crack, and the presentable appearance of the masonry is maintained throughout the entire service life.

Solvent varnish is highly flammable. Work with him with extreme caution.

Acrylic varnishes differ in a multicomponent composition, and are intended for interior work. Acrylic mixtures are made on organic solvents that protect against the formation of efflorescence, prevent the formation of cracks and other mechanical damage.

Fireplace paints can be described as heat-resistant, fire-resistant and heat-resistant. Varnish prevents condensation. Used for decorative coating of fireplaces and stoves, suitable for cladding facades.

At will it is possible to receive a covering opaque or glossy with a certain quality of gloss. Special additives make it possible to treat the plane in such a way that a “wet effect” is formed. Produced paintwork in banks or buckets of various sizes, and as an aerosol in cans.

Brands

Among foreign brands, the most famous are German Pufas and American Petri. German varnishes are of high quality and the same value.American varnishes that create a “wet effect” are popular in our country.

Famous Russian brand - Neomid. Produces semi-matt varnishes for indoor use. Neomid STONE. The widespread demand is due to the complete absence of toxic toxic smell. Another domestic manufacturer - "Chief Technologist". Heat-resistant varnishes are made from foreign raw materials.

Selection rules

The choice of varnish depends on the place of its application. For the facades of houses and other street constructions, preference should be given to materials that form a film that is resistant to moisture. Varnish must have the ability to successfully withstand exposure to sunlight, as well as have a good decorative effect.

Other requirements are imposed on varnishes for the furnace. Here it is important the absence of toxicity, resistance to heat. Acrylic and silicone varnishes are suitable for interior decoration of brick, natural or artificial stone. In the construction market, the choice of varnishes is so large that it is not difficult to choose a mixture that is suitable for both the required characteristics and cost.

Coverage Features

The principle of working with varnishes is similar to painting.First of all, it is required to prepare the processed surface. The walls should be cleaned from dirt and dust, cracks putty, the build-up cut down, and the grooves filled with plaster or putty. If the facade was previously painted, the paint should be removed completely.

Aligned walls must be sanded with coarse sandpaper and then washed. Suitable for this household detergent. After drying, repeated inspection is carried out. Identified defects are eliminated. Dry clean surface primed. It is advisable to take a primer and varnish from the same manufacturer.

Drawing is made in several ways: brush, roller or spray. In the latter case, the mixture (if it is not in an aerosol can) must be mixed with a solvent to reduce the density. If this is not done, the spray gun will not cope with heavy varnish.

Work can be performed in a wide temperature range of -10 ... +30 degrees. But the best thing to do is repair in the summer with warm, dry weather.

Varnishing start from one of the upper corners, gradually moving down. For large areas, it is convenient to work with a roller with a nap of 20 mm length. Small elements are treated with a brush with natural hard bristles.Neighboring strokes should be applied with an overlap of several millimeters. The varnish is applied in two layers or more. Each subsequent layer is applied after complete drying (absorption) of the previous one.

Care of the lacquer coating is in the processing of a mild detergent with a frequency of 2 times a year.

Further you watch the review of heat-resistant varnish for a brick of the Rustins Brick brand warnish.