DLS-tile laying system: features and technology

Laying tiles always required finding a good specialist. The finished result is often not pleased: one mismatch of fragments along the crosshair led to a deterioration in the appearance of the entire lining. However, modern technology has reached a new level.

Today it is not at all necessary to seek help from a tiler: there is a DLS system. Consider its features and the essence of technology based on a brief overview.

Special features

DLS-laying tile system is a special auxiliary elements, through which it is possible to perform masonry work no worse than a specialist.

The standard kit includes:

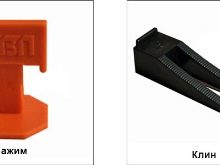

- tile wedges;

- bases for wedges;

- special clamp.

Outwardly, they look quite simple, the principle of use is clear and does not cause difficulties when creating a high-quality tiled coating. This system eliminates the fit of the tile "by eye".

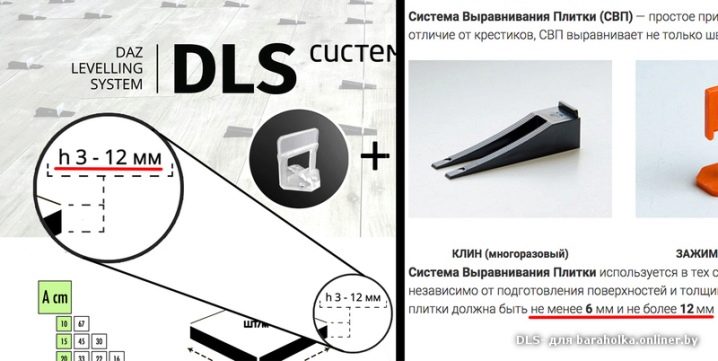

Bases and wedges are made of high impact plastic. Products of individual manufacturers can be made of a metal alloy. Such species imply multiple use.

Each base rectangular shape of a small size fits a specific wedge peg. The number of clips used is the same as the number of bases.

The clamp is designed to fix the wedges with the basics. Outwardly, it resembles thin curved tongs, although the modification of each brand may have a separate appearance.

Advantages and disadvantages

With seeming external simplicity, the DLS-installation system has a lot of advantages.

Denote the main ones:

- She successfully replaces the classic crosses for tiles. At the same time it is more reliable and provides the best result of facing.

- Her purchase will not hit the pocket. You can buy it at hardware stores for a reasonable price.

- With its help, anyone can put tiles. This will save on the call of the master (the cost of cladding is from 1000 rubles per square meter).

- It facilitates the workflow. You do not have to constantly adjust the tile and adjust it in the event of a shift.

- It is suitable for working with horizontal, vertical and inclined surface types. The result will be 100% good.

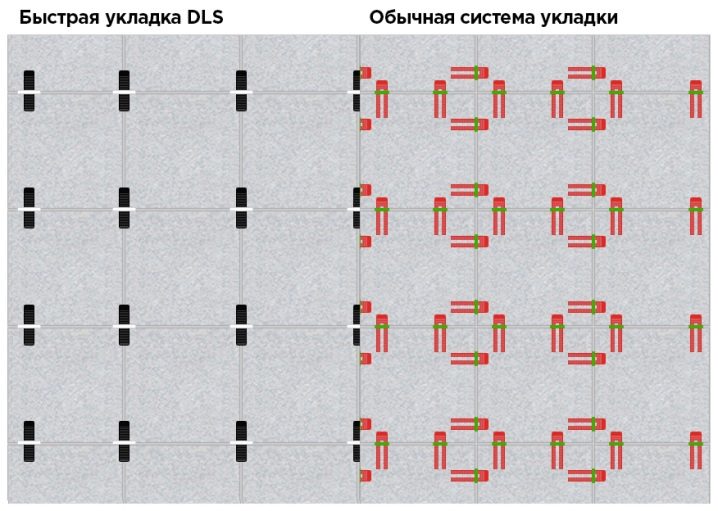

- DLS-laying system reduces the time for laying tiles about 4 times, even if it is a vertical base.

- You can use it absolutely with any tile material. Well she proved herself in working with large-sized tiles (for example, 60x60, 70x70 cm).

- Auxiliary items can be used several times. Due to the strength they are not deformed. If you need to finish several rooms with tiles, you do not need to buy new components.

- Performing tile laying with the DLS system is more accurate. Usually in this case there is less debris and excess glue.

- For such a system does not matter the thickness of the adhesive composition. It eliminates the displacement of the fragments, as well as their subsidence during the drying of tile glue.

Essentially, a DLS system is needed to maintain perfect accuracy between tiles. It does not matter if you use the floor or wall type.

The DLS system has several drawbacks.

Note them:

- She is not autonomous. You will have to create with your own help the necessary connections between the tiles.

- It does not exempt from the need to prepare the foundation.If you do not pay attention to the height difference, its use will not give the desired result. With each new tile skew may be more noticeable.

- You can use the elements of the system under consideration until the glue sets. Otherwise, it is possible to reduce its adhesion and durability of the coating.

Laying technology

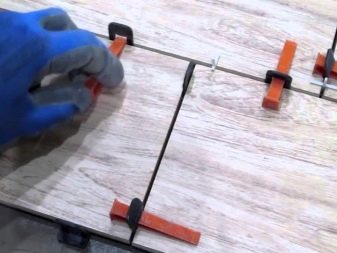

The DLS system can be used in three different ways:

- "minus" (work with identical tile);

- the letter "T" (facing the surface with two different tiles);

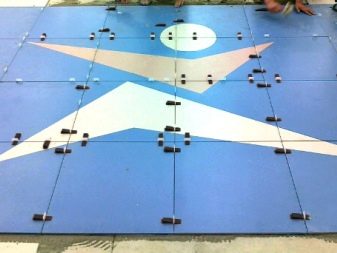

- "a plus" (simultaneous fixation of 4 elements at once).

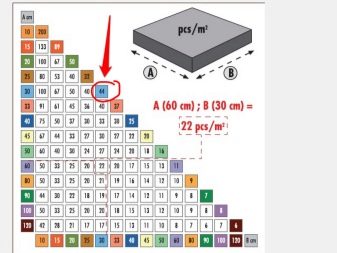

In fact, these are layouts in the form of a chessboard, offset and brickwork. Usually for the work may require up to 100 pieces of bases and wedges. The DLS system for leveling tiles is used when tile glue is applied to the substrate.

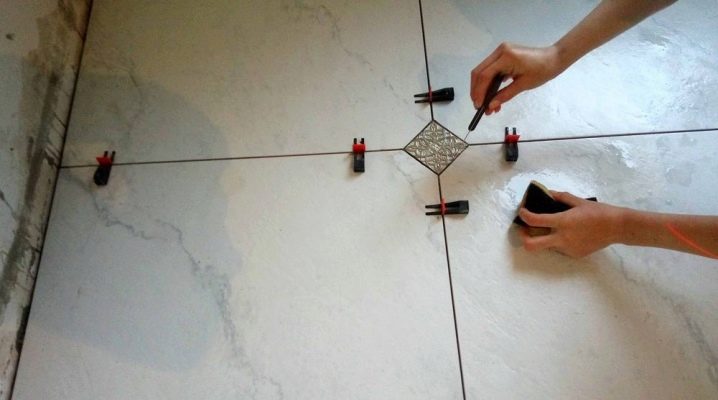

Consider a step-by-step technology based on the “plus” technique:

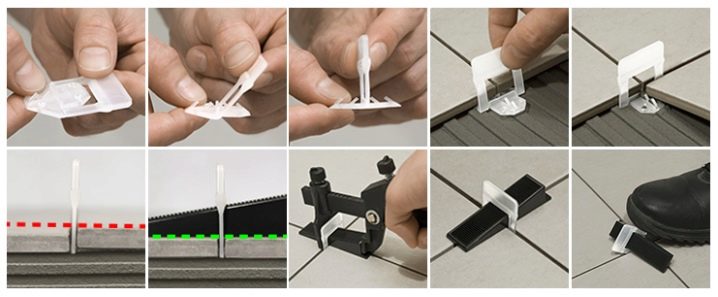

- Take the base, push the tongue. Turn it at a right angle with respect to the main part. This should be a part with a wall that has a square cut-out, and two identical parts of the base. In the middle of each there is a center mark: so skew markup is excluded.

- The base is placed under the tile, located between the two fragments. At the same time push up one side of the base.

- On the second basis put two more tiles. It turns out that the base is located in the crosshair of 4 tiles. The tiles are laid tightly, pressing together as much as possible.

- The ribbed wedge is inserted into the square hole. Trying to do it tightly. At the expense of the wedge, which is visually wider than standard plastic, it turns out to remove the height difference between a number of stacked fragments of tiles.

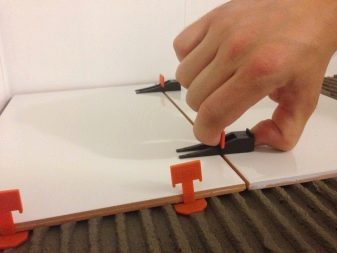

- For the same density, use a special clamp. It will fix the wedge at the base until the tile is dry.

- After attaching the DLS system, the tiles are not touched, the wedges do not move or change their position.

Drying time depends on the type of glue used, the size and thickness of the tile, as well as the temperature conditions. Usually it takes at least a day to dry.

After the glue has dried, the DLS system is removed.. Typically, the base wall thickness is 1.5 mm. When performing troweling work, the seam can be from 2 to 2.5 mm. It depends on the relief of the tile used and the skill of the master.

Note the nuance: the "plus" system is not the only method of laying tiles in the traditional way. Its constituent elements can be laid between tiles not only in crosshairs. At the same time, the accuracy of the finished work will not decrease. Besides, Do not forget about the corners. They can also be “preloaded” by the DLS system.. To do this, it is not necessary to press the tile on both sides: one edge is enough.

How to choose?

Among the offers of different brands is easy to get confused. Alarming buyers is the fact that such a system looks different from different manufacturers. For example, the shade of the wedge may be varied, with which the bases are fixed. Most often it is a white base and a black wedge slide.

In order to buy high-quality auxiliary material, which ensures an impeccable result in the future, do not give up the golden rules of choice:

- A good wedge is always ribbed. If you see a wedge bifurcated at the ends, and the base shape is not similar to the one described, it is not a DLS system in front of you. Look at the photo to not fall for the trick of the dishonest seller.

- Such systems are economical.They do not need to be pushed from 4 sides to get the perfect result: 1 attachment to the center is enough. Do not take too much.

- Look at the plastic. Any deviation from the norm: curved edges, visual defects - talking about marriage and low quality. With this material you can not count on a professional lining.

- Do not buy auxiliary materials in a questionable store. Contact a proven reputable point of sale. Do not hesitate to ask the seller documentation for the goods. A company respecting its reputation provides documents for each type of product.

- Pick up the tool. If he is suspiciously light, his purchase is in doubt. Try to squeeze the ends - the operation of the mechanism should not have obstacles.

- Look at the fasteners of the clamp and its body. No defects in the form of scratches, chips, irregularities of painting on it should not be.

- Choose a tool with convenient handles. This will reduce the load on the hands when squeezed.

- Pay attention to the cost. To understand the real price, first look on the Internet how much it can cost from different companies.

- If the seller is intrusive, think about the quality of the DLS system.Good goods in sweet speeches and verbose tirades does not need.

- In this system, a wedge enters a square hole. If you are offered a different system, this is an obvious deception.

Reviews

DLS-tile laying system is recognized as a good auxiliary element for professional craftsmen and ordinary heads of the family. This is evidenced by numerous reviews on the forums dedicated to the decoration of the house. It really helps to reduce the time for facing work.

The technology is considered convenient and accessible to everyone.

Professional masters say: DLS-system is better than classic plastic crosses. In contrast, its elements do not bend even when making small seams.

In the video below you will learn in detail about the DSL tile laying system.