Floor tile thickness: selection rules

Among the technical parameters of the floor tile, its thickness is an indicator that should be taken into account in the process of working with it, since the strength characteristics and the service life of this ceramic coating directly depend on it.

Parameters of floor tiles

The thickness of the tile is the main criterion by which a tile laid on the floor differs from a similar coating for walls and ceiling. It is quite natural that ceramics for a floor is subjected to much greater mechanical loads than its wall and ceiling counterparts. Hence, more serious requirements for this type of coverage.

Attention to the thickness of the tile flooring should be paid only in the case when the base on which the flooring is mounted is not of sufficient strength. If tiled ceramics will be laid on a concrete base or on top of a layer of old tile, then it will be enough to apply for this a tile about 3 mm thick.

In those places where special wear resistance of the material is required, clinker is used for laying. This kind of ceramics is roasted at a temperature of 1200-1300 degrees Celsius, whereas for a simple tile the firing temperature is 800-1000 degrees.

Due to the considerably more intensive sintering of clay particles, clinker ceramics gains special strength. At the same time, the water-repellent properties of such ceramics significantly increase, due to which this tile becomes a frost-resistant coating and can be used for outdoor work.

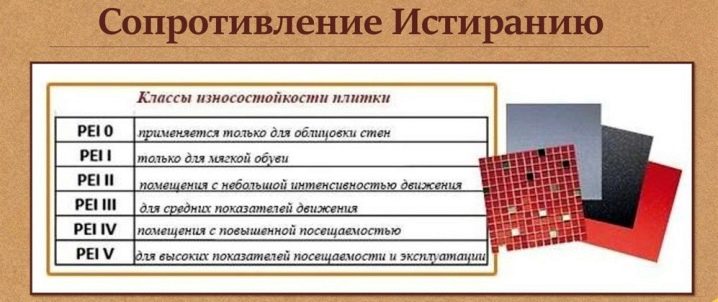

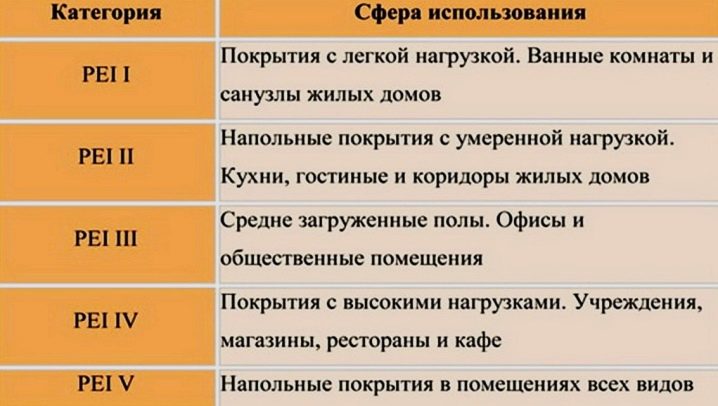

Regarding the wear resistance of tiled ceramics, it should be said that this indicator is understood by specialists as the ability of a surface to counteract a person’s abrasive material that simulates the load. This classification is applied to a ceramic tile with a glazed top layer, that is, an indicator of the strength of the actual glazed layer of the tile itself, and not its foundation, is considered.

The durability of glazed ceramics is measured on a scale in the form of five main classes, called PEI. For use in areas where they move with medium intensity and in ordinary shoes, as well as those who do not have contact with the street, tile of class 3 on this scale is used. It is designed for all areas of an apartment or a private house and can be used in small office or hotel buildings.

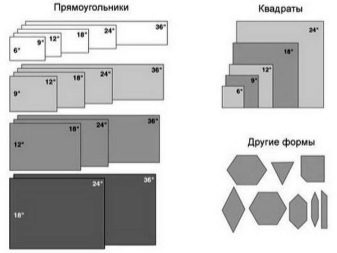

Shape and size

The most widespread, as you know, has a square-shaped tile with a side of 10 - 60 cm, although the modern market offers the consumer and diamond-shaped tiles, hexagons and so on. The minimum indicator of the thickness of floor ceramics offered for sale is 3 mm. However, a coating having such a thickness is not so common. Manufacturers and dealers mainly offer tiles with a thickness of 5 - 8 mm.

As for the maximum thickness of products of this class offered by the modern market, it can reach 25 mm. This indicator refers to the special tiled coatings used in industrial premises. For domestic use more often you can find tiles, the maximum thickness of which is equal to 13 mm.

Of course, a thicker tile will be more expensive. This is explained by the fact that the raw material costs for the manufacture of one unit of tile space with a higher fragment height and the fuel consumption for its thermal roasting will be much higher. Here you should add additional costs for its transportation.

The choice of the thickness of the floor cladding depends on the dimensions of the tile, the level of mechanical load on such a coating, strength characteristics of the base and the degree of its stability. This also includes the type of tile material used, its cost, the area of the surface to be coated and the amount of glue required.

When attempting to choose a tile for a certain type of repair, the consumer must take into account not only its thickness, but also other properties of this type of ceramic coating. This will allow him not only to give the floor the necessary strength, but also to create the desired design of the room.

Kinds

All floor tiles fall into two categories, namely, ceramic tile and porcelain stoneware.

Ordinary tiled ceramics with glue of any brand should not be used in areas where it will be subjected to severe mechanical stress, and where it will be walked a lot.Therefore, it is not so often used as a floor covering. For the most part, such lining is used in storerooms, bathrooms or toilets.

Unlike conventional ceramics, porcelain has a much greater density and mechanical strength, so it is much more resistant to high loads and can be used even in industrial premises.

Another difference of ceramic granite from classical ceramics is the method of its production. Porcelain tile is processed under much greater pressure and at higher temperature conditions.

Strength and other material properties

Often, tiled cladding is mounted on a wooden base of plywood, or put it on a dry gypsum-fiber screed. With a large tile area, a shock or static load can cause the tile to split or cause it to peel off from the base. It is possible to solve the problem either by selecting a tile of somewhat greater height, or using a smaller material.

In the first case, it is possible to lay tile or porcelain tile on an insufficiently stable base.whose height will be about 9-10 mm.Porcelain stoneware cladding with a height of 12 mm or more is mainly used in utility rooms such as garages, car washes or warehouses, as well as in industrial premises where floors get a load from people and equipment. The thickness of the adhesive layer for laying such a coating should not be higher than 20-22 mm.

In the second embodiment, a tile of a smaller area is taken to cover the floor. If this figure for one fragment will be 10 - 15 square meters. cm, then under a deforming load, it will only bend a little for a short period of time without completely damaging the tile, even if its thickness is about 6-7 mm. For this situation, the thickness of the adhesive layer should not be higher than 15 mm.

You need to know that laying tiles on a not completely stable base requires the use of troweling of elastic varieties in order to avoid rapid destruction of the coating.

If the tile is placed on a sufficiently rigid base such as a concrete screed or floor slab, then, subject to all the technological rules for its installation, the rigid base will completely absorb any load. Therefore, here the requirements for the strength of such a coating do not matter.

Design features

Often to enhance the visual effect of the volume of a room, tiles with a large area of one fragment of about 40 square meters are used. see. The explanation of this effect lies in the peculiarities of human visual perception, when the interior of the room is observed in two planes as the surface of the ceiling and the floor. It turns out that the larger outlines of the individual elements of the floor covering the human eye sees, the larger the size of the entire viewing space.

However, this decision does not always work. It can be used, for example, in a kitchen of about 5-6 square meters. m, whereas for a small room such as a bathroom tile with such dimensions simply ruin the interior.

A possible solution here can be the use of tiles of different sizes for one room, when an element with a side length of a square equal to 60 cm is placed in the center of a room, and its outer perimeter is made with a rectangular tile covering with dimensions of 30x20 cm. Such combinations are of different colors and dimensions of tile will give a floor additional originality.

Some features of the application

If the tile is intended for finishing a particular room, then the best option would be to use tiles belonging to the same batch. This is so essential for the reason that any batch with the same dimensions always includes fragments that have some deviations from the standard dimensions, which in some cases can go up to 4-5 mm. This is due to the heterogeneity of the structure of clay, which is the basis of tiled ceramics. Therefore, for each individual element with the unchanged firing parameters, the shrinkage will still be different. In addition, the tile in the same party may vary somewhat in hue.

It is also possible deviations in thickness, which differ from those stated. This indicator, however, is not among the critical ones, since the total thickness of the coating is always leveled off due to the layer of glue to the required height of the base.

The optimal seam thickness indicator for a tile with a side of a square equal to 30 cm is 2-3 mm, and for a tiled ceramic coating of size 50x50 cm, it is 4-5 mm. Deviations in dimensions increase with increasing tile sizes.This difference can be compensated for by varying the gap between the seams.

Adhesive layer

The total thickness of the application of the adhesive composition during flooring is planned together with tiled ceramics. At the same time, the volume of the solution depends on both the material used and its dimensions. The larger the tile, the more glue is applied. It is not recommended to use too large amount of solution, so instead of recruiting the stated strength, it will become exfoliated. It also slows down its drying time. For a standard tiled lining, it will be sufficient to apply an adhesive composition 4-8 mm thick.

How not to make a mistake when choosing a floor tile, see the following video.