Putty walls for wallpaper: the choice of material, especially the application

Anyone doing their own repairs, faced with the fact that wallpaper canvases on a curved surface are not glued strictly parallel to each other. From the side of such a repair looks depressing. To avoid this, plasterer-painters are advised to carry out the process of puttying.

What it is?

Puttying is the alignment of the walls for wallpaper or painting. To do this, putty is used - plastic material that fills all the pits, cracks and chips, compares the protruding parts of the wall with the base.

By the way, if the liquid wallpaper is used as a finishing, then you do not need to level the base. Liquid wallpaper - is a decorative plaster, which itself is able to produce this procedure.But before pasting walls with paper, vinyl or non-woven wallpaper putty irregularities necessary.

Many people, repairing the room, erect partitions of metal frame, sheathed with sheets of drywall. And they have a reasonable question, whether it is necessary to seal the seams and joints between the sheets of drywall putty. In fact, the wallpaper can be glued to the plaster, but if you close up the seams and use fiberglass as the base, then pasting will happen faster and better.

Kinds

Putty or, as it is also called, putty, is found in several stores in hardware stores. As a rule, mixtures are sold, which can be leveling, finishing and universal.

The first mixture is intended for leveling surfaces, starting treatment is done in both residential and non-residential premises. It is suitable for walls, ceilings, and for erected plasterboard structures. The structure of the leveling mixture contains large grains, therefore apply it should be a thick layer.

The finishing mixture contains fine grain in its structure, which is capable of making the surface completely smooth.Due to this, it is applied with a thin layer on the walls and ceilings, after which the base can be painted or pasted wallpaper rolls.

By the way, decorative plaster is perfectly placed under the finish, It can be used instead of paint.

Universal putty can align not only plaster, but also brick and reinforced concrete base. It is able to replace the leveling and finishing putty, so you can save a lot.

The main advantages of dry mixes are relatively low cost, long shelf life, and they can be stored at all temperatures. But at the same time for the preparation of mixtures to a certain mass, skill and experience are needed, and a special mixing tool is required. It is important to calculate the amount that is necessary, because the finished mass dries quickly and re-use it will not work. If you do not follow the recommendations of the manufacturer, the finished mixture will be unsuitable for work.

It is found in hardware stores and ready-to-work consistency. Sell it in plastic containers. Usually on the shelves of construction shops there is an oily variety.It is fireproof, explosion-proof and also moisture-resistant, which means that it can be used in rooms with high humidity - in bathrooms, bathrooms and in kitchens. It is easy to apply, does not require dilution in liquid and kneading, has a long shelf life. But, unfortunately, this plastic building material is more expensive than dry mixes.

At the same time it is important to distinguish that certain putties are suitable for interior work, in particular:

- Oil-adhesive. It is intended for leveling works on wooden and reinforced concrete foundations. After its application it is allowed to paint the surfaces with oil, water-dispersion paints and enamels.

- Gypsum. It is used in dry residential and non-residential premises. Plasters apply it when working with cement, plasterboard and gypsum-fiber sheets. The mixture is easy to prepare, even an inexperienced person can handle it, it is cheaper than its competitors. In addition, it is environmentally friendly because it is made from natural ingredients. Therefore, it can be used in rooms where there are young children and allergies.Gypsum does not form cracks over time, which means that it can be used not only for leveling, but also for finishing.

- Cement. Perfectly is suitable for technical rooms - cellars, storerooms and for rooms with high humidity - bathrooms, kitchens. But, unfortunately, after a certain time it shrinks, as a result of which cracks are formed. If over it were hung wallpaper, most likely, they will come off. Often it is used for repairs in the porches, it is sold at an affordable price.

- Water dispersion. With its help it is possible to partially make even many bases, including brick, concrete, wooden. Do not exclude use on stained, stone and fiber surfaces.

- Polymer Universal putty, buy it for leveling cement, concrete, plaster and polyurethane structures. It has a high cost, so using it for finishing large premises is impractical. Since the polymer putty makes the surface perfectly smooth, it is recommended to apply it to prepare the bases before applying decorative plaster.

Keep in mind that the polymeric variety is able to act as a noise-absorbing, vapor-proof and water-repellent layer. On such a decoration moldy fungi and microorganisms are not populated. Due to these properties, polymers are widely used in the repair of bathrooms, toilets and swimming pools.

Where is it used?

Filling work is carried out in cases when it is necessary to cover the joints, to level the panel or plasterboard walls, to decorate the cracks and seams. As noted earlier, to seal the seams on the walls in wet areas, use either cement or polymer putty.

Experts recommend to expand small cracks with a punch to a centimeter. Due to this, the putty will become clogged up more tightly, and no voids will be formed.

According to its purpose, putty can be specialized, construction and for everyday use. For everyday use, acrylic-based putty is used, its protective layer does not let moisture through, so you can buy it for finishing of bathrooms, kitchens and balconies.

Specialized varieties are designed for certain natural materials. It can be wood, stone or metal. They not only close up cracks, but after applying them you can start painting or apply liquid wallpaper.

For all other cases, construction options are used - to level the ceiling, for curved or painted walls. I would especially like to note that even hardboard can be filled. You can glue paper, vinyl, glass cloth wallpaper on top of construction putties, and if you align the corners, the wallpaper strips will be glued without joints.

Tips for choosing

Two types of putty are commonly used in a pair - starting and finishing. They differ in grain size - in the starting putty a mixture of coarse grinding. This ensures good durability. Finishing is used to secure the result and make a smooth layer.

Analyzing customer reviews and recommendations of painters, plasterers, specifically in this section, an improvised rating was compiled, which included the best manufacturers of dry and ready putties.

Best of all was gypsum plaster "HP Start" from the manufacturer Knauf. It is sold in bags of 30 kg, used in dry rooms. The finished mass does not solidify within 20 minutes, the ideal layer should be 4-15 mm thick. Perfect for leveling the base before finishing. During the life of the putty does not shrink, cracks do not appear. High durability and affordable price influence in a positive way on the choice of many of this particular instance.

By the way, you can choose and products HP Finish of this manufacturer. It is suitable for leveling walls for painting, the surface is smooth. But, unfortunately, it is not suitable for wet rooms. Sold in bags with the same weight as the previous version. The manufacturer advises to apply it in a small layer equal to 4 mm. The walls will be ready for the next stage in a day. Of the benefits can be noted low cost, durability and a good result after application. But keep in mind, as part of this putty there are solid elements, so you need to work with it with caution.

On the third line of the ranking is located starting gypsum plaster CT 29 from company Ceresit, which is sold in bags of 25 kg.It combines perfectly with a brick and a concrete wall, embeds chipped and dredged, but is not suitable for leveling floors. Since gypsum is afraid of moisture, it is not advisable to buy it for bathrooms and kitchens. But unlike its predecessors, the finished mass can be used within an hour, the final drying takes place after 15 hours.

Increased strength provide reinforcing components that make up this building material.

The manufacturer advises to knead the mass before applying for about three minutes.

The advantages are resistance to low temperatures - up to +5 degreesbut you have to pay a little more for it.

Gypsum finish plaster CT 225 from the manufacturer Ceresit suitable for the final stage after using a primer. The basis turns out strong and equal, but the main minus is the price.

Company Kreisel produces several good universal fillers, among them are a dry mixture at number 662 - it is cement, fine-grained, suitable for typical city apartments. Due to its highly resistant qualities, the mixture is intended not only for indoor use, but also for outdoor use. Sold in standard bags of 25 kg.Of the advantages there are a low price and versatility, of the minuses - it shrinks, so the minimum layer should be equal to 3 mm.

High performance differs starting cement putty Scanmix TT. It is universal, suitable for exterior and interior decoration, resistant to low temperatures, moisture resistant, while sold at a reasonable price. The disadvantages are the drying time - 24 hours, shrinkage and the fact that it should be applied on a perfectly clean surface.

Suitable for finishing Scanmix LH Standart. The most amazing thing is that this putty after curing forms a smooth surface of white color, which does not require painting. It can be used in wet areas, it does not shrink.

In addition, the advantage is a universal application for any reason - brick, concrete, cement. And the minus is, of course, the cost.

A special place in the rating is taken by the manufacturer. Weber-Vetonit. Its products are the benchmark in the construction market, it has good plastic qualities and a long service life. I would especially like to note the dry mixture under the brand name Veronit KR, It is made from organic glue - an environmentally friendly material that is suitable for children's rooms.

Polish company Stabill lets out not only starting, but also finishing plaster. Painters mark dry mixtures under the brand name PG 41, PSZ 11, PG-007. Properties and indicators of building materials are comparable with products from competitors, the price tag is slightly higher, but it was impossible not to mention this company. By the way, she releases and ready-made options.

Of the manufacturers of putty ready undisputed leader is the company Sheetrock. The company is originally from the United States of America, but it is worth noting that the production is established in the Russian Federation. In order to save, apply it only to eliminate defects. Mark ready pasta called "SuperFinish", "Fill & Finish Light", "ProSpray" and "Dust Control". Each of them is suitable for specific purposes and surfaces. Latex, polymer and oil based pastes are available.

Although ready-made putties are more expensive than dry mixes, they have a number of advantages, among which are the fact that they do not need to be diluted, respectively, no dirt appears.

Plastic containers can always be covered with a lid so as not to take out the garbage. Moreover, the processing process can be interrupted and go about their business, because the finished pasta does not wither.

In general, you need to choose plaster, starting from the base - brick, concrete, drywall or cement. For concrete and brick walls suitable cement mixture. And for drywall constructions - gypsum. Polymer paste suitable for filling up small cracks.

How much material is required for surface treatment will depend on the size and curvature of the walls. Typically, up to three kilograms is consumed per square meter when applying a 5 mm layer, respectively, if the layer is 10 mm, up to six kilograms. The finishing layer should not exceed 1.1 mm, then up to two kilograms will be required per square meter.

remember, that Before you buy, you need to study in detail the instructions and shelf life of building materials. It is important, and in what room was stored putty. Chances are that it is damp under the action of moisture. It is advisable to use the starting and finishing putty from one manufacturer, only in this case a good result can be guaranteed. Otherwise, building materials may be incompatible with each other - this is rare, but out of harm's way, as they say.

Stages of work

After choosing building materials, it will not be possible to start work immediately, but first things first.

Instruments

First of all, you need to prepare "assistants" - tools. Professionals use a construction mixer. But a drill is used at home, but, in principle, both a puncher and a screwdriver will do. The main thing that the tool was equipped with a special nozzle.

This special tool will be needed to mix the dry mixture with the liquid. After all, only the finished mass is used for application to the substrate. Unfortunately, it is impossible to prepare a consistency without a drill; there will be either a slurry or lumps.

Knead the mixture in the container, it must be prepared in advance.

In order to save, you can use the old waste plastic bucket or other large containers. But since the composition dries quickly, it is not recommended to plant the entire bag at once.

Putty can be applied with a small sheet of plywood, but to create a thin layer it will not work, moreover, it will quickly become unusable under the action of moisture. Therefore, it is necessary to buy a set of spatulas in the household store. A wide variation is used for the walls.and for corners and hard to reach places - small or angular. This tool can be not only with a smooth surface, but also with a gear.

There is a special spatula for painting and facade work, they differ in size. It is important that the blade is made of high quality metal.otherwise it will bend after the first use. The handle should fit comfortably in the palm, this eliminates the likelihood of corns - remember, the front of the work to be big.

Do not forget about such a tool as a building rule. He is able to correct deficiencies, leveling the walls after applying putty. And due to its size, this work is done faster than using spatulas.

Make a rule of aluminum. Despite the weight of the product, it is durable. Aluminum is a cheap metal, so its final cost is low. Release it in the form of a trapezoid or cone. The length may be 1-3 m.

After applying the plaster ideal smooth surface does not work, to eliminate this drawback is used sandpaper or hand skinner.Thanks to these devices, you can remove the frozen mixture, clean the surface. What kind of sandpaper to choose, to be sorted out on the spot. Fine-grained sandpaper is used for cosmetic work.

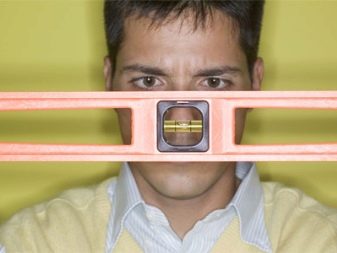

To measure the differences used building level. In the Soviet years, men made it their own hands from laths and cargo; today, this special tool can be bought without problems at the construction base.

Bubble construction levels, they are also alcohol and oil, popularly called box-and rail. In finished form it is a plastic, metal or wooden lath in which ampoules with liquid and air are mounted. When using this species, attention is paid to the bubble: if the surface is flat, it will be located clearly in the middle of the ampoule, and if there are drops, then you need to fix it until the bubble is located in the center.

In turn, the ampoules on the rail can be from one to three. The latter option is used to check horizontal, vertical surfaces and inclined planes. But to test the walls and the first two options are suitable.

Due to the fact that alcohol and oil do not freeze at negative temperatures, the bubble level can also be used in cold rooms.

Some manufacturers equip their products with lighting, in this regard, it is possible to work with this tool in dimly lit rooms, and some models are available in electronic form - the deviation in this case is determined as accurately as possible.

The building level is different in length, there are options on sale from 0.4 m to 2.5 m. For finishing work, an instrument whose length does not exceed one meter is excellent.

The final part of the work, namely the priming, is to be performed with a roller and a brush. The protective primer coat has a positive effect on adhesion. The surface is durable, perfectly combined with the finishing finish. The roller should be selected with a nap whose length is 3 mm. Applying a primer is not much different from painting - the roller is dipped into the container, the layer is pressed and applied onto the substrate. For the same purpose and use the brush. If you need to process large areas, the brush should be wide, and for corners the small brush will approach.

In some cases, you may need additional brushes, sponges and other tools.

Surface preparation

Before you begin construction work, you need to remove all appliances and electronics from the room. Dust particles can ruin the chips and equipment will become unusable. With the same purpose, carpets, decorative items and furniture are removed from the premises. It is permissible to leave only large-sized furniture, but at the same time it must be moved to the center in order to provide access to the wall.

The remaining interior items are covered with unnecessary rags or polyethylene. The floor is covered with cellophane or old newspapers - depending on the flooring. This will not only save the parquet or laminate, but also facilitate cleaning in the future.

Personal protective equipment should be used - respirator, goggles, gloves and special clothing. Alternatively, unnecessary clothing and gauze bandage will do.

After the construction materials are prepared, the surface must be leveled before applying the plaster. If old wallpaper is stuck on the walls, then a spatula is used.With its sharp angle, the edge of the wallpaper strips is grabbed and the entire canvas comes off.

Modern wallpaper is well torn off, but with the old will have to tinker. Keep in mind, start the procedure preferably from the bottom upso you can tear off whole strips. If you tear to the side, the work will take longer.

The wall should not contain any wallpaper residues or cellulose residues, so the paper is thoroughly moistened with water, either from a spray bottle or with a wet rag. In this case, the spatula easily removes the remnants of wallpaper to the ground.

It is necessary to carefully clean the areas near sockets, switches and security sensors. In addition to the fact that products can be damaged, there is a high probability of electric shock. It is better to de-energize the room in advance.

In hard-to-reach places - corners, near interior door trim panels and plastic baseboards, you need to do work with a small trowel. Keep in mind that they do not hammer nails and do not unscrew the screws - it is easy to break.

The surface is completely cleaned from dust, dirt and from old paint, whitewash. For removal of paint using special tools.The emulsion paint is pre-wetted, it swells under the action of moisture and is easily dismantled with a spatula.

If the paint is oily and adheres well, then a metal brush and sandpaper will be required. These devices will make the surface rough. Walls must be treated with antifungal agents to prevent mold. Additionally, the surface can be degreased.

Choosing a primer, experts recommend to look at the options, which include additives against mold. It is especially important to use such a primer in rooms with high humidity - in bathrooms and kitchens.

After all the preparatory work, using the building level, ground drops are checked. If the irregularity is equal to or greater than 5 mm, then before applying the walls, put plaster in two layers, if it is equal to 2 mm, one is enough.

For large areas, experts recommend using either cement or plaster putty. Despite the fact that cement plaster is cheaper, gypsum is preferable, by the way, it can also be used for plasterboard plastering.

Drywall sheets have a flat surface, but weak point in this case are the joints. They will have to repair. It is necessary to drown the caps of the screws so that they do not protrude above the base.

For brick walls suitable cement mortar. On the degreased and cleaned surface are attached beacons, which control the thickness of the application and evenness. The brickwork should be moistened with water, the cement pounced on the wall and pulled to the lighthouses. After drying, grouting and priming are performed.

OSB-plate before the process of puttying primed. Since the strand boards are easily processed, the primer is chosen for quick-drying, non-affecting adhesion and deep penetrating.

The first stage of applying the primer is characterized by abundant wetting of the OSB-plates, complete drying occurs after 12 hours, after which the second layer is applied, which dries twice as long. The seams and joints are sealed with a special mixture, mass release to the surface is not allowed. It is very important to prime not only the front side, but also the wrong side, as well as the ends of the plates. If this is not done, then under the action of moisture building material will become unusable.For the same reason, the composition of the primer should not be water. The next step is to reinforce the surface. It can be combined with filler.

The preparatory work of chipboard or plywood sheets involves the sealing of joints. To do this, use a special putty for wood, it is sold in tubes and is easy to apply. If the joints are not sealed, then over time the paint will crack, and the wallpaper may fall altogether.

Putty is applied across the seams with a thick layer, the spatula should be used with a small one. Since acrylic dries quickly, it is necessary to periodically water the surface with water. In the subsequent the basis is processed by a grinder. Subsequent application is possible. only after complete drying of the previous one.

On the plastered wooden surfaces putty holds better, but for this it is necessary to remove all the knots with a chisel, to expand the cracks. If the tree does not have a lacquer coating, it should be soaked with oil, for this is used linseed oil.

Drawing

Correctly putty everyone can learn. It is easiest to apply putty without experience on concrete walls in panel houses.Since their surface is usually even, problems can arise only with inter tile joints.

In monolithic houses, reinforced concrete slabs and blocks of expanded clay are most often used. On their surface there are chips, grooves and drops that require corrective action. To level such surfaces with your own hands is best, you can save a lot on this. Provided that the technology and rules are observed, the filler will be properly executed.

But let's move from theory to practice. Water is poured into a plastic bucket, usually 10 kg of dry mix is added to two liters.

Keep in mind that often the mass becomes unusable after 20 minutes, so it is important to correctly calculate the proportions so that there is no surplus.

Having attached a nozzle to the perforator, kneading is performed. The packing is lowered into the container and the dry mix is gradually added. Knead until the lumps remain in consistency.

The resulting mass level but the surface with a spatula. The smaller the angle of inclination of the trowel, the thicker the layer is, and vice versa, the smaller - thinner. For high-quality putty concrete walls using fiberglass.With it, gluing non-woven or vinyl wallpaper will happen faster. The second layer is applied only after the first one has dried., it is necessary to change the direction of application.

The surface will be ready for subsequent finishing after 24 hours. After that, you need to clean the base with sandpaper. If the house has a grinding machine, this procedure will take less time.

Keep in mind that shpatlevanie must be done in the daytime and in good light, only in this case, you can see defects.

Provided that the brickwork is leveled with cement mortar and primed, the putty is applied in the same way. The number of layers is selected individually depending on the subsequent actions.

Moisture-resistant plasterboard sheets can be painted, but the surface must be pre-filled. If it is planned to paint with enamel, then the wall must necessarily be white, for this purpose a finishing mixture of this color is used. Wherein it is unacceptable that there are large patches in the plaster, the base must be smooth. To give a mirror shine the wall is additionally polished and primed.

Putting putty on plywood is not much different from putty concrete or brick. A spatula and a rule for checking smoothness are applied. The layer must not exceed 3 mm. Grains are removed in the process of sanding. To exclude this stage, experts advise to strain the mixture through a sieve before kneading.

When you need to putty corners, then beginners are advised to apply more mixture, and then it should be wiped with sandpaper. This is justified in most cases, but if a follow-up procedure is required - siliconing is required, then the stage of work is slightly modified. In particular, when applying putty angle is bypassed. Subsequently, the finished mass is added to the empty silicone tube and applied in the corners. It is very important in this case that in a tube there were no particles of silicone and it was treated with vinegar. The applied layer is treated with a small or angular spatula, after which the surface is sanded.

Drying should be done at room temperature, windows should not be opened, heaters or air conditioners should be turned on.With regards to sanding, painters recommend using fine-grained sandpaper attached to a wooden block. And for grinding the corners apply special sponge.

When to glue wallpaper?

The answer to this question will depend on the type of putty, the varieties of wallpaper rolls and on their purpose. With regards to the purpose, the wallpaper can be used as a separate building material with a pattern, and for painting.

In hardware stores you can find paper, non-woven and vinyl wallpaper. Anyone can understand that paint paper wallpaper strips will not work, because the paper, having absorbed moisture, quickly becomes useless. As a result, the wallpaper can peel off and slide down.

Non-woven wallpaper produced on the basis of cellulose or non-woven. The first option is not suitable for painting work, and in the second there are special polymers that can be painted. These wallpapers are sold in a universal white color, and the choice of the final color remains with the owner of the apartment.

If non-woven wallpapers have a protective PVC layer, then they are sold as vinyl.This variety is resistant to moisture, so sticking is allowed in rooms with high humidity. You can take care of them, even using strong chemicals.

By the way, the wallpaper with color drawings, are not suitable for painting. But the relief varieties can be painted over up to 12 times. But in order not to rub relief, it is recommended to paint a maximum of five times.

Keep in mind that the base, putty and wallpaper must be moisture resistant and suitable for damp rooms. For example, if you use regular drywall, it absorbs the paint and will deteriorate, the same applies to the putty.

It is also important that if the gypsum cardboard is not pre-filled and wallpaper is stuck on it, then later when removing them there is a high probability of damage to the drywall itself. And from this it follows that it will require dismantling and subsequent restoration of the structure. Is it worth saving? Probably not.

If the wallpaper is glued to a dry wall, chances of forming colonies of fungi are likely. You need to wait for complete drying, usually it takes up to two weeks. When using a gypsum variety, the walls should change color, become not dark,and light. Cement putty dries in a day, and if you use acrylic, then in a few hours.

Wallpaper glue is applied to the base surface only when using non-woven wallpaper. If paper rolls are bought, then the glue should be applied evenly on the prepared strips. Similarly, glued and natural wallpaper of bamboo and silk.

As noted earlierLiquid wallpapers do not require a perfectly aligned base., in their consistency, they are more like decorative plaster, which itself is able to hide the defects of the walls. But for the application of liquid wallpaper is required to wait for complete drying.

About all the intricacies of plastering the walls under the wallpaper you will learn from the following video.