How to choose the substrate for the wallpaper?

Modern new buildings and secondary housing can not always boast of high quality. The smallest problems faced by the owners are uneven walls and ceilings. Noise from the street, loud neighbors - the walls, like a paper sheet, let through any sound. However, each problem is solved, and therefore the modern market of building materials can offer a special substrate for wallpaper, which will solve these and many problems.

What it is?

The substrate is a special intermediate layer that serves to level the wall, as well as enhances the adhesion between the wallpaper and plaster. There are ordinary, standard substrates and materials with specific properties, such as vibration reduction and noise reduction.

Substrates are made from synthetic materials and natural raw materials. Often synthetics are represented by a layer of polyethylene and paper fused with it.

Natural products are most often made from the bark of cork oak and other materials that have a pronounced property of absorption and damping of vibration.

Special features

Modern substrates are made from environmentally friendly raw materials, therefore, allow for finishing work both inside the premises and in public places. These materials are able to compensate for base defects, as well as disguise and strengthen cracks.

Specific features such as sound insulation, heat insulation and sound insulating ability, will help to create the necessary comfort and coziness in the house, as well as to protect the working room. And the topcoat will be smooth, even and will last much longer than without the use of a substrate.

The following positive points should also be noted:

- The finish coating has a smooth surface that does not have bubbles. The substrate absorbs a certain amount of glue, so it is distributed evenly across the wall.

- The process of pasting itself becomes much easier and more practical. Insulation due to its structure helps to firmly fix the canvas in the area of the seam and corners.

- Achieved a long life of the walls.Enhanced adhesion allows you to firmly take the base and coating.

- A substrate that has good breathability will prevent mold from forming on the wallpaper.

- Significant savings in time, materials, strength and financial resources.

Substrates may have different characteristics, but you can use the same look for different types of wallpaper.

Of course, the intermediate layer between the finish coating and plaster is not necessary, but advisable.

Popular materials

There are several types of substrates, depending on the feedstock:

- Paper. Thick paper allows you to correct the wall in the event that it is not possible to dismantle the old, damaged plaster.

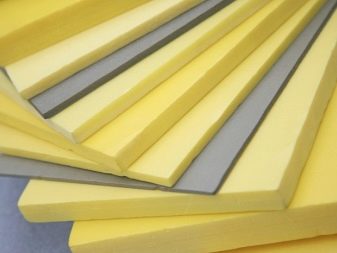

- Flizelin. The basis is similar to ordinary non-woven wallpaper. They are durable, but light and have good sound insulation characteristics. However, they are quite expensive materials.

- Bung. An inexpensive technical cork is used as a raw material, which is why the material obtained is distinguished by its budget. The substrate has excellent heat and sound insulation characteristics, it aligns walls well, but requires installation skills and a special adhesive composition.

- Polyethylene. It is a foamed polyethylene.It hides well the defects of the walls, has such a characteristic as noise insulation, and retains heat in the house.

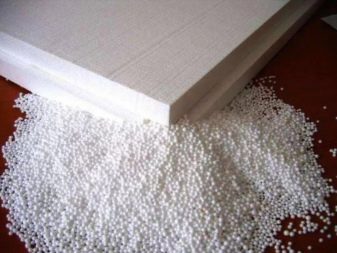

Styrofoam or its more common name - foam. The simplest and most widely known consumer insulation material. Is different low cost and good thermal insulation qualitiestherefore has a wide scope of application. With its help, they insulate walls, floors, ceilings, and even the facades of houses.

Polyfoam is a good and proven option for insulation of residential and industrial premises.

However, it is absolutely inappropriate for pasting wallpaper. This conclusion can be made on the basis of The following features of styrofoam:

- The foam has a loose structure, its surface is very fragile and not tough enough for wallpaper. In other words, if someone suddenly puts pressure on the wall or rests on it, then a dent will form in this place, and the wallpaper will tear. Also during the operation on the canvas can form blunders.

- In stores, foam plastic is sold in the form of plates, therefore, in order to ensure high-quality thermal insulation, the foam layer must be at least 5 cm.The main problem is the seams - they protrude too much above the surface of the wall and will be noticeable under the wallpaper.

- Conducting redecorating, dismantle old wallpaper can only be with insulation. This is not very convenient and adds additional work, as it is necessary to glue not only wallpaper, but also a new substrate.

- And the last, most important factor is fire safety. To comply with all the rules, you must first cover the foam and trim it with non-combustible material, which is also impractical.

If, nevertheless, the choice stopped on polystyrene foam, then to give a rigid base for wallpaper You can use three additional coatings:

- Sheathe his drywall.

- To cover with special plaster, with the reinforcing property.

- Be sure to use plaster mesh, based on fiberglass.

Insulation can be made of various materials. However, the most common polyphis. It is a foamed polyethylene. Its thickness can vary from 4 to 8 mm. Polifom is an eco-friendly material. On both sides there is a paper lining.You can buy polyforms in the form of rolls in a specialized store. Roll parameters:

- Length - 14 m.

- Width - 0.5 m.

- Thickness - 5 mm.

- Density - 30 kg / cubic meter.

Penolone is a polymer and is chemically crosslinked. It is characterized by elasticity, low weight and hygienic. The material tolerates the effects of aggressive environments such as acid, alkali, alcohol and gasoline. It is not subject to deformation, and also has a low coefficient of vapor permeability and heat conductivity. Applications of Penolon:

- Aligns the walls.

- Suppresses noise and vibrations.

- Lowers the spread of cold from the walls.

- Facilitates work on pasting walls.

- Eliminates the phenomenon of "weeping walls"

Polyform and polyphone, which have similar characteristics with the above materials, are also referred to polyethylene foam. Even if the layer is thin.

Penohome is a versatile material with different densities.. It is a Euro block. It has excellent sound insulation properties. It copes well with high humidity and helps to warm the room.

Cork substrate is characterized by high levels of heat and sound insulation.Significantly increases the degree of adhesion of the topcoat and base. In addition, the material is made of natural raw materials and is an ecological, natural and safe for health product. Technical features of the material:

- Heat conductivity coefficient - 0.04 W / mk.

- The density of the material is 100-130 kg / m.

- Treat the material of normal combustibility (class - G3).

- Weight - 200 kg / m cube.

Popular and non-woven substrate. Its main feature is good vapor permeability.

This provides excellent ventilation for the walls and the room itself. Also, this material is very elastic, so it easily masks non-critical base defects and has a small price. Rolled flizelin has the following characteristics: length - 10-12 m, width - 0.6-1 m. The canvas can be glued vertically and horizontally.

Installation

Before you finish the walls with a finishing coating, you must first prepare them. This statement has long been an axiom. However, some owners for some reason do not want to engage in the preparation of the walls, but you need to understand - to glue the wallpaper literally on bare surfaces - a waste of money and energy.

Installation of insulation is not a difficult process and takes place in several main stages. In most cases, there is no need to call masters.

First you need to prepare the work surface itself (i.e. the wall). Dismantle the old canvas, waste plaster, paint and remove dirt. After that, it is necessary to putty the walls, to level all the irregularities and small cavities. Plaster is covered with a deep penetration primer, so that it becomes stronger and does not crumble. It is necessary to wait until the primer completely dry. Will have to wait about 24 hours. Only after this time, you can proceed to installation.

Now you need to measure the wall and cut insulation to the desired length of the pieces. Begin sticking. You will need either special adhesives (cork insulation), or just all-purpose adhesive. Simply put, glue must be selected depending on the material taken. If the room has a high level of humidity, you can use the composition for baguettes or liquid nails. They are quite expensive, but will not allow the lining to move away from the wall with strong fluctuations in temperature. The most optimal values of temperature and humidity + 10 degrees, 70% humidity.

Using a roller, distribute the adhesive composition on the substrate and the wall. We wait about 5 minutes, fix it on the base, smooth it with a rubber trowel. We do not allow drafts at the time of sticking. The joints are glued with a wide masking tape to prevent discrepancies or bulging. If not a glue for wallpaper is used, but another composition, then the installation is carried out according to the instructions on the packaging. We are waiting for the glue to dry for 3 days.

While the composition dries, you need to ensure good ventilation.

Recommendations for selection and installation

Choosing a polymer insulation, it is worth knowing that according to the method of manufacture, they are divided into:

- Unstitched gas foam.

- Stitched: chemically and physically.

The easiest is unstitched polyethylene. Its manufacturing technology is the simplest. The strength and thermal insulation properties of this material is 1/4 less and worse than the rest.

Both chemically and physically cross-linked polyethylene are similar in their properties, therefore, buying insulation, need to focus on:

- Coloring swore (uniform, white or light gray).

- How tightly the paper is attached to the base.

- Presence of smell (normally it should not be).

- Elasticity (the surface is quickly restored after pressing with a finger).

- Structure

- The design of the edges.

- Durability and availability of the certificate.

Choosing the substrate, it is worth considering that the main difference between them is the thickness and density. Cork material is more dense, so before installation it does not require thorough alignment of the walls. Polifom allows not to putty walls thoroughly. A flizelin, which is a very durable material, will protect the wallpaper from the occurrence of tears, and the walls - from the appearance of cracks.

Some tips on laying material:

- The joints must be treated with a wide masking tape to stabilize the canvas and prevent the formation of hills on the seams.

- It is impossible that the seam of the wallpaper coincides with the place of the seam insulation.

- If there is a suspicion of the presence of a fungus, the necessary antiseptic measures are urgently taken.

These tips will help preserve the integrity of the wallpaper and will not allow the seams to disperse. Better to use a primer, which consists of antiseptic substances.This is to prevent the reproduction of various microorganisms. The finished surface should be dry and smooth.

Customer Reviews

In general, buyers are satisfied with the polystyrene and polystyrene. It is noted that, although these materials do not completely drown out the noise, they perfectly retain heat in the house. Also distinguish such heaters as penofol and penoplex.

According to the testimony of buyers, cork insulation contributes to the creation and retention of the optimum temperature in the room. In winter, the material creates a temperature in the house with the usual heating a couple of degrees higher than in a room without insulation. In the summer, the cork does not allow heat to pass from the heated walls to the air, allowing you to provide a cool place in the house.

Successful examples and options

Cork material is comparable in ratio to foam. This allows finishing works in corner houses, apartments or houses, which are located in an open area at the accession of a balcony, loggia or after the redevelopment. Also, cork insulation is used in the finishing of recording studios and other working premises to achieve maximum sound insulation.You can use a special soundproof and Anti-sound noise insulation membraneif necessary.

More strongly the effect of warming and redemption of sound will be noticeable in the room, the wall of which goes, for example, into the entrance. Prefabricated houses with concrete walls do not keep heat well, so if one floor of the apartment is facing the entrance, then a lot of heat will leak from the house and it will be cool. In winter, the time may become very cold.

Sometimes solutions are found in the interior when the walls are made out of a cork substrate instead of pasting wallpaper. It looks quite interesting and harmonious.

For more on wall insulation with the substrate, see the following video.