How to make a liquid wallpaper with your own hands?

Liquid wallpaper - one of the most modern and versatile finishing materials for walls and ceilings. They have an interesting texture, beautiful appearance and excellent performance. Another characteristic feature of European quality liquid wallpaper is a high price. Over time, their cost pays off due to the unique properties of the material, but the repair can hardly be called economical.

Is it possible to replace factory material with home-made analogue, as well as how to make liquid wallpaper with your own hands, this article will discuss.After all, liquid wallpaper is easy to do yourself, using improvised and waste materials.

Liquid wallpaper is a symbiosis of two finishing materials - wallpaper and plaster. In some countries, this decorative coating is labeled as “decorative plaster”, “Danish plaster”, “silk plaster” and “cotton wallpaper”. The title often reflects the main components of the composition. For the manufacture of a dry mixture in factories used two components: a filler and a binder. To make the wallpaper become liquid, just before applying to the surface they add liquid - water of the temperature specified by the manufacturer in the instructions.

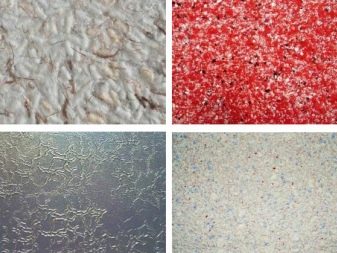

The main components have many variations. Depending on what exactly is the basis of the wallpaper, they are distinguished by certain operational and aesthetic characteristics.

Materials for the manufacture of filler:

- Cellulose fibers. From the name it is clear that this is a product of woodworking production, and the fibers in their properties are similar to high-density paper wallpaper. Pulp is ideal for the production of liquid wallpaper due to the low cost of raw materials(This is wood waste), small size and white color, which is easy to paint in any desired shade.

- Cotton fiber. Or easier - all familiar sterile cotton white. In the composition of liquid wallpaper, cotton fibers are responsible for imparting a decorative cover to the volume and eliminating surface irregularities. Neutral color makes cotton comfortable for further coloring.

- Silk fiber. Mostly distributed in the countries of the Asian region. Namely wallpaper with the addition of expensive silk fibers instead of cotton is the name of the silk plaster. Of course, it’s not the material for textile production that is added to the composition, but the “turns” of low-quality fibers. Such raw material is called a burret.

- Decorative components. From a technological point of view, they do not play any role and do not affect the material properties, but it is the addition of decorative components that is responsible for the aesthetic qualities of the coating. These include: fibers of natural (wool) and synthetic origin (polyester), glitters, rhinestones, crystals, stone powder, mica, dyes.

Materials for the manufacture of binders:

- Glue base. Each manufacturer has its own secrets of production, but the properties of the base is similar to ordinary wallpaper glue.

- Plasticizers. This is a series of substances that are introduced into the composition to facilitate the application of wallpaper on the surface.

- Antifungal supplements. They are designed to increase the biostability of the coating, because liquid wallpaper can absorb moisture, which means there is a risk of fungi, bacteria, microorganisms.

Liquid wallpaper comes in the form of a colored or white mixture of dry ingredients. Before use, they are diluted according to the instructions. Repeating this procedure with factory wallpaper can be many times, as the binders tend to harden without water and again take the liquid consistency when it is added.

The finished mixture can be painted during production, and may be white. For white wallpaper, you must separately purchase special colors for liquid wallpaper.

Pros and cons of coverage

Combining the two materials for decorative finishing in one gave the corresponding Advantages of liquid wallpaper:

- repair using “decorative” or “silk plaster” is easier and cleaner than using rolled wallpaper and ordinary plaster. Only two containers are required - one with water, the second with a diluted mixture. You do not need to prepare a clean surface to measure off the wallpaper and launder the whitish coating after sanding the plaster;

- there is no need to customize the pattern of wallpaper, because in liquid wallpaper color and decorative elements are evenly distributed on the surface of the wall with a spatula and a special "grater";

- Work is done with easy-to-use tools. You can apply the coating with your own hands. This may require some skills with a spatula, but training on a small section of the wall is enough;

- easy to correct defects when applied. Damaged area of the coating should be moistened with water, remove the solution with a spatula and apply a new one. After drying, no adjustment will be noticeable. Defects resulting from mechanical damage already in process are also eliminated;

- convenient to bypass protruding places on the wall: sockets, switches, non-removable decorative elements;

- the covering will be integral, without joints;

- by their properties, liquid wallpapers are close to plastering by leveling the unevenness of the working surface, you can also fill cracks and crevices with them;

- it is possible to create a unique decor, three-dimensional details, relief, drawings according to individual sketches;

- can be used on walls and ceilings;

- a wide color range, a variety of decorative elements, which makes them versatile for any interior styles and design ideas;

- the coating is odorless, safe for allergies;

- liquid wallpaper is good to use under the varnish, which will protect them from scratches, dust and moisture, and also make them washable;

- in the mixture is dominated by components of organic origin;

- liquid wallpaper improves sound insulation and insulation in the room;

- "Breathable" surface of the walls, absorbing moisture.

Not only advantages, but also disadvantages of liquid wallpaper associated with the combination of materials. Customer reviews confirm that in practice their use is not always successful. This largely depends on the manufacturer’s good faith and proper handling of the material.

Weak places of liquid wallpaper:

- high price.The market leaders in this area are French manufacturers. High production technologies and special secrets make their products practically without any complaints, but their price is greatly overestimated;

- liquid wallpaper does not belong to the most durable materials. Their service life is 5-10 years. However, the usual wallpaper also needs to be changed every 5 years for a fresh repair;

- dust settles on the wallpaper. Reviews confirm that the uncoated surface, despite the manufacturer's warranty, does not have an antistatic effect, and dust accumulates over time;

- liquid wallpaper without a protective layer are afraid of moisture. They can not be washed, and even more use in the bathroom or kitchen;

- Application technology does not all seem simple. Some opinions of those who have tried wallpaper show the difficulty of applying the mixture to the surface;

- high rates of material consumption. Given the high cost of wallpaper, this is a significant minus. Manufacturers promise that 1 pack is enough for 6 squares. Reviews confirm that this figure is greatly exaggerated. At best - by 4 square meters;

- There is a risk to get a fake.

What can you do?

If, when comparing the number of advantages and disadvantages, there are doubts whether the expectations will justify such expensive coverage,It is worth using an alternative option - to make liquid wallpaper yourself at home.

Of course, their characteristics will not be as good as those of a high-quality European manufacturer, but There are a number of advantages for home-made wallpapers:

- cost savings. Liquid wallpaper made actually from waste materials: from paper for writing, from small thin sawdust, from egg trays, from the sleeves of toilet paper and paper towels. And if the eggs in the family in the right quantities do not eat, because paper trays need a lot, and the sleeves are flushed into the toilet, then everyone will have waste paper from old newspapers and magazines. All of these materials will serve as a substitute for cellulose fiber. Replacing cotton and silk is obtained from ecowool or conventional sterile cotton wool. In the final, instead of a binder, mixtures of PVA glue and other adhesive compositions for wallpaper are introduced;

- the manufacturing process does not require special skills;

- applied in the same way as factory-made liquid wallpaper;

- the composition is environmentally friendly through the use of components of organic origin;

- the ability to independently choose the shade and decorative components;

- improves the insulating quality of the room;

- wet wallpaper is convenient to use for filling joints and cracks;

- the ability to correct surface irregularities.

Disadvantages of homemade liquid wallpaper:

- the duration of the process;

- it is difficult to calculate the required volume of the mixture over the entire surface area in the room;

- if the mixture is not enough, even with an exact repetition of the proportions, the second batch after drying may differ in color;

- the result may not meet expectations;

- for the density of the mixture it is necessary to add plaster or plaster, but their number is difficult to calculate. If you add too much, the mixture hardens and it cannot be diluted again;

- the mixture shrinks over the area. It may turn out that there are empty areas between the layers;

- fractions of decorative elements in the composition must be finely crushed, otherwise they will create unnecessary unevenness and spoil the appearance of the coating;

- It is problematic to apply to some types of rough finish, including drywall. It takes a long preparation for finishing liquid wallpaper.

Manufacturing process: master class

To prepare liquid wallpaper at home, it is important to observe the proportions of the mixed components, to perform the steps step by step, as well as correctly calculate the required volume. Preparation of pulp and glue solution is performed in a certain sequence:

- Calculation of ideal proportions and the amount of material with a small margin. A universal recipe for the preparation of liquid wallpaper using cellulose fibers (with the addition of cotton) is: 5 liters of water per 1 kg of pulp. For this amount of water, it is permissible to use 500-600 g of wallpaper paste and up to 500 g of gypsum or plaster. Decorative additives have a small volume and are used, as they say, "by eye".

This volume is enough to cover a layer of average density of 3-3.5 square meters. m

- Testing. The stage is not obligatory, but for those who first take the finishing material themselves, it is recommended to take several containers with water, several types of paper and different types of additional components. Consistently prepare several mixtures, using first universal proportions, and then independently correcting them, if necessary, to obtain a thicker or liquid mixture, reduce the rate of its solidification, check the color of the resulting liquid wallpaper. It often happens that glossy magazines instead of newspapers give a dirty gray tint, and wallpaper can not be used, especially if you plan to make the walls light.

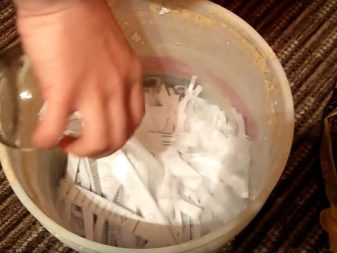

- Preparation of cellulosic material. When the proportions are calculated, and the ideal composition is determined, it is time to start mixing the composition. First of all, it is important to process those materials that replace cellulose fibers in the home composition. If these are newspapers, they should be cut or torn into small pieces of approximately the same size, after removing hard pages and metal clips and threads. If toilet paper, sleeves and egg containers are used, they are simply cut or torn in the right quantities. Sawdust must first be dried, because wet is heavier, and you can make a mistake when weighing, then the wallpaper is not enough for all surfaces.

White paper for printing is considered ideal.

- Adding water. It can be a cool temperature, from the tap. Pour paper 5 liters of water, you need to give the mixture to infuse from 3 to 5 hours. The thicker the paper, the longer it will soak. The tank must be closed so that the water does not evaporate.

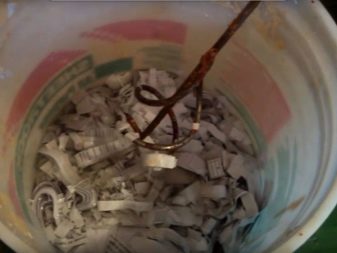

- Stirring After a few hours, the swollen pulp must be thoroughly mixed. This can be done with your hands, but for the best effect you should use an electric drill.It is enough to insert a mixing nozzle instead of a drill, immerse it in a container and mix well for a few minutes. If the nozzle does not reach to the bottom of the tank, the mixture periodically needs to be mixed by hand, raising the lower layers up.

- Adding glue, dye and decorative components. High quality wallpaper glue is used as a binder. Decorative components can be any, but they should not later succumb to rotting, molting, deteriorate. Kohler should choose a special acrylic, add to the container a little bit to obtain the desired shade. It is useful to add a small amount of protective equipment that will protect the wallpaper from fungi and microorganisms. The resulting mixture is again well stirred with a drill and let stand in a closed container for 12-14 hours.

- Adding gypsum, plaster or alabaster. Gypsum and alabaster at the same time freeze faster. This stage is carried out immediately before the application of wallpaper on the working surface. It is necessary to interfere with the last component in the household mixture of liquid wallpaper and immediately begin the finishing work,since all powder substances for leveling walls tend to harden rapidly in air.

What else is needed?

Covering the walls with liquid wallpaper is a time consuming process. It can be divided into four stages, each of which will require its own list of tools and materials, and even its own methods of work.

Preparatory work

Surface preparation is a very important step towards the application of a durable decorative coating. Its quality will determine how long the liquid wallpaper will last, whether there will be dark spots, fungus, dents and bumps on them, whether they will begin to peel off.

The complexity of the procedure is determined by the type of walls:

- Concrete, brick or block. These walls have two drawbacks for finishing with liquid wallpaper: a high level of material absorption and a dark color that is difficult to block. To fix them, you will need: colorless primer or PVA glue, plaster putty, white paint, paint brushes, spatulas of different sizes, fine sandpaper.

- The walls of old houses. They are often susceptible to darkening and rotting, so it is important to protect the wallpaper from the appearance of dark spots.Necessary tools and materials: protective impregnation from fungi, microorganisms and rot, universal primer, putty if necessary to level the walls, light paint on water or oil base, brushes, spatula.

- Drywall This is a sheet material that forms the joints when finishing the walls. Putting and leveling only them is a waste of time, it is necessary to level the entire work surface. For the works will need: primer, putty, a set of paint brushes, "skin", a set of spatulas, paint.

- Wooden: polished board, timber, fiberboard, chipboard, MDF. Smooth wooden surface is not necessary to putty. It is enough to apply a primer in several layers, since the tree has strong absorbing properties, and two layers of paint. You can use fleece rollers.

- Color paint coating. To paint the colored walls you will need: a white primer, oil-based white, brushes or rollers.

- Walls with protruding parts (nails, fittings). They tend to rust from moisture, and liquid wallpaper contains a lot of water. Metal should be treated with white paint, alkyd or oil.

Making liquid wallpaper with their own hands

Required tools and materials:

- capacity for 20-30 liters;

- a film to cover the container to prevent moisture from evaporating;

- Libra;

- waste paper or printing paper;

- water and measuring jug with graduations of 0.5 or 1 liter;

- scissors to cut threads and large sheets into several small ones. Small sheets easier to tear into small pieces;

- wallpaper paste;

- decorative elements: woolen, silk, acrylic threads of different colors, glitter and glitter, tinting, decorative crumb from different materials;

- dry putty or plaster;

- drill with mixing head.

Applying liquid wallpaper

Tools for work:

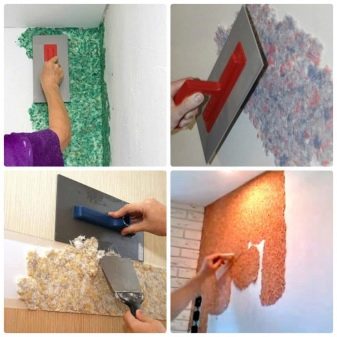

- painting "grater" - the device having a flat surface with the handle for convenient holding. The handle is located on the back of the float. In the process of work, she is wielded as an iron, smoothing out bumps on the wallpaper;

- spatulas of various sizes and shapes to level the mixture on large surfaces and to bend around small parts:

- plastic caps or adhesive tape for sealing sockets and switches;

- newspapers or film to protect the flooring;

- step-ladder for convenient work in the top part of a surface;

- a drill with a mixing nozzle to mix the solution from time to time;

- a container of water and a clean spatula for quick elimination of coating defects;

- gloves, work uniform, clean rag.

Complex decorative decoration (volumetric, multi-colored) is carried out simultaneously or in stages, layer by layer. It requires a sketch of the pattern and stencils.

Coating

It extends the life of the wallpaper and makes it possible to subject the surface of the walls and ceiling to wet cleaning. Yellow shades and aggressive nitrolacs are not suitable for this purpose - they corrode the wallpaper. The best option is acrylic lacquer. It does not cause harm to the coating, and after drying it becomes imperceptible., giving the surface only a light shine.

.

For fast and high-quality varnish coating it is necessary to use an aerosol agent or pour it from a can into a container with a spray. During work, protect the respiratory system with a respirator, and hands - with gloves. Varnish is harmless, but it will be problematic to wash it off.

How to apply?

Before the start of repair work, you need to prepare all the materials and tools, calculating their consumption.It is better to purchase materials with a small margin, since it is difficult for non-professionals to correctly calculate the application of a product to the working surface. A common mistake is the more the better. The quality of the finish is almost no effect, but the cost of materials increases significantly.

The method of application is determined by the type of agent. Proper use of their layers is as follows:

- Paint a brush of medium width, gradually pouring from the total capacity into the working one, cover the wall with two thin layers of primer. The first layer should dry before applying the second. The brush can be used from natural pile. It is more convenient, but the expense of funds will be more. Synthetic brush is less convenient, but does not absorb the soil in itself.

- If there is a need to level the wall and interrupt the dark color, two layers of white putty mortar are applied alternately with a spatula. When the putty dries, the wall must be machined with a grinder or manually using emery paper with fine grains to a relative smoothness. From above to put a thin layer of a transparent primer.

- Paint application in 1-2 layers.For even paint application it is convenient to use not a brush, which can leave streaks, but a wide fleece roller. You need to work quickly, leveling the layers of paint with a click on the roller.

- Dried paint can be treated with a means of fungi and germs.

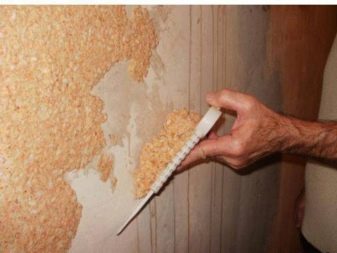

- Actually applying a liquid wallpaper mixture. The mass is lapped over the work surface and leveled with a transparent trowel. It is important to treat the joints at the walls, door jambs, baseboards and ceilings.

- The protective varnish from the spray can is sprayed onto the dry wall as a final step. Spray should be kept in an outstretched hand, at a distance of about 30 cm from the wall. To move it from top to bottom, not lingering on one site.

How to put liquid wallpaper on the wall, see the following video.

Drawings liquid wallpaper

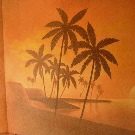

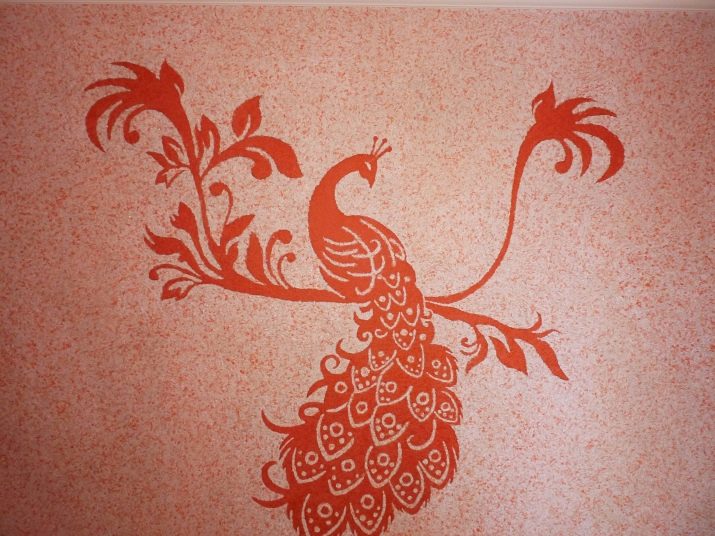

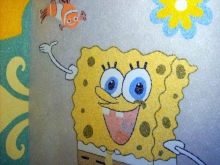

One of the undeniable advantages of liquid wallpaper is the ability to apply various patterns, drawings and textured details. In modern design, these techniques are very popular, especially when it is necessary to imitate stucco molding, create 3D images with a background that visually enlarges the space, and decorate the children's room.

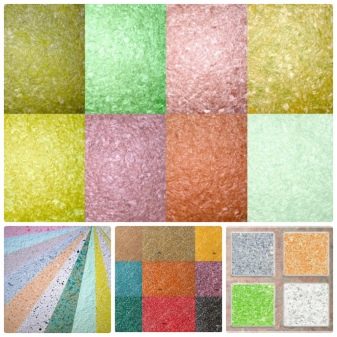

When we decorate a wall with liquid wallpaper, it is important to remember that the possibilities are practically unlimited. There are up to 150 possible finishes and different technologies. for mixing colors.

Turning to the professionals, you can get wallpaper with imitation of a brick or marble in the living room, voluminous fairy tales in the children's room, stucco in the bedroom.

But the process of creating drawings using liquid wallpaper is complex and time consuming. It can not be done without prior training, therefore, people who do not have great artistic skills and talents are recommended to practice in separate small formats. For example, on a sheet of fiberboard.

It needs to be prepared for work, primed in 1 layer, and then to show imagination and master the technology. Sketches and stencil making will come to the rescue. Ready-made stencils can be bought in stores with goods for repair. They do not have to be for liquid wallpaper. You can purchase stencils for other purposes and adapt them to your needs.

Those who are confident in their artistic abilities, you can get to work right away.

To draw a picture, you need:

- select a picture, draw a sketch on paper, then transfer it to the work surface with a simple pencil. Extra lines to delete;

- determine the number of colors used in the drawing, and choose the appropriate colors for adding them to the wallpaper;

- prepare pulp at the rate of 1 liter of cellulose per 5 liters of water is 4 square meters of the treated surface. When the mass is set for 3-5 hours, mix it up and divide it into several containers by the number of colors in the drawing. The less color is used, the smaller the capacity and volume of battles. At 1Q. m you need from 1.25 to 1.5 kg of wallpaper;

- add color to the container and the necessary decorative components. Knead and let stand up to full readiness, then add gypsum to each container just before using it;

- mark on the sketch, what color should be the details. Mixing the mass with plaster, finish all the details that have this color at once. For large surfaces, it is convenient to use a transparent rake-trap; for small surfaces, a trowel in the form of a lancet;

- color behind the color fill the picture and align the joints with a float or roller to roll the wallpaper.The small volumetric parts provided in the figure can be molded manually, like from plasticine.

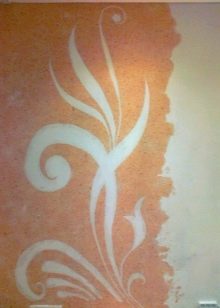

For a simplified version of the drawing is used stencil. Stencil impose on the wall and firmly fixed with mounting tape. If the color of the pattern is only one, the base and color layer of the wallpaper is applied, if it is two, the number of layers increases to three, and so on.

Types of stencils for liquid wallpaper:

- for monophonic drawing. This is a template of large sizes, suggesting the application of a repeating ornament in one contrasting color. The easiest to use;

- anti-stencil It is also intended to create drawings in bicolor, but here the emphasis is not on the convex details, but on those deepened in the base color, because everything that is not covered with a stencil is covered with wallpaper. It turns out the effect of "backlit";

- multicolor. Consists of several blanks that are alternately applied to the wall and filled with material. With its help, complex full-fledged drawings are created;

- volume. Allows you to make the accent detail more convex and voluminous. Wallpaper or plaster used in several layers.Such stencils are made not from cardboard, but from cork cloth or foam plastic.

Spectacular examples in the interior

Liquid wallpaper provides a wide scope for the embodiment of design ideas and bold ideas for decorating the interior. With their help, you can create different in color, texture and decor coating. Not only the walls, but also the ceiling, from the toilet to the living room, are suitable as a working surface.

Actual volumetric drawings on the theme of fairy tales and cartoons in children's rooms.

The simplest are monochrome wallpaper calm tones for classic and minimalist interiors: white, beige, ivory, creme brulee, peach, pistachio, blue, light gray. Imitation of stucco and volumetric details help to give them a more luxurious look.

A bright design with the addition of contrasting pigments is also possible: silk and wool yarn, fragments of mica, marble chips, large glitter particles. Beautifully look wallpaper with glitter in tone or one or two tones brighter, with gold and silver elements.

Liquid wallpaper combines well with other materials: silk upholstery, metal panels, mirror, chrome and glass surfaces, glossy and matte plastic parts. Liquid wallpaper decor allows you to visually change the boundaries of the room.

So, the white walls and ceiling decoration will make the room brighter and bigger, and the contrasting design of one wall with a different color will help bring it closer to the cherished square shape.