What and how to cut the tile?

Ceramic tile is a very popular building material that is used for finishing any surface. In the modern construction market there is a huge number of devices to work with him. In this article will be discussed in detail all kinds of tile cutters for tile and how to trim.

Kinds

Working with any kind of ceramic tile, it is impossible to make the perfect laying, without using a special tool. And since the tile consists of a clay base and glaze, then, first of all, during finishing work, it is desirable to first cut the glaze layer, and then divide the tile into necessary parts.

Unusual ways of laying tile - diagonally, with a shift, according to the finished drawing or pattern suggest cutting. And in the decorative works with tile tile cutter is simply irreplaceable.

Consider the possible ways and types of work on cutting ceramics:

- Mechanical method - cutting of material of softer density with a knife from dense material by deep or not very deep pressing or notching, and then breaking manually. Hand tools that will help cut the tile - glass cutter, hand tile cutter.

- Method using power tools. In this case, the cut is made with the same material as when using hand tools, only the cutting element drives the motor operating from the mains.

- Method using a powerful jet of water and a strong abrasive materialwhich enters the tile surface. Used for cutting porcelain stoneware.

- Method using laser beams - suitable for dense tile material.

Tile trimming may be necessary in the following cases:

- working with tiled masonry on a limited surface, it is necessary to trim the initial and extreme elements for its more beautiful placement;

- when placing it on a specific pattern;

- if there are functional devices on the cladding surface - sockets, pipes, lamps, exit to the sewer system, a hole must be made under them;

- To create beautifully carved ceramic elements, curly cutting of tiles is necessary with suitable tools.

The type of trimming of the product depends on the tool that will be used for this:

- a small tile cut can be done with a diamond disc of the grinder, even if the tile is already laid on the surface;

- for trimming classic smooth tiles at home in the implementation of a small area of repair suitable manual tile cutter with a diamond knife;

- if the amount of finishing work is large or further work with thick tile material is expected, it is better to purchase an electric tile cutter;

- if there is a desire to save on repairs, then a simple manual glass cutter will help to cut the ceramic tile without a tile cutter. It is cheap, easy to use and the safest among all types of tools, but this type of pruning requires more time and is only suitable for thin finishing tiles;

- also for the implementation of tile work will require special diamond wheels, attachments to a conventional drill, if necessary, to make a hole under the socket, for example;

- For art and decorative cutting there is a special way - WaterJet hydroabrasive cutting. This high-precision waterjet is performed with the lowest temperature of the contacting surfaces and allows you to make beautiful ornaments from any solid dense material, such as porcelain stoneware and natural stone. At the base of the cutting is a directional flow of water with special abrasive sand particles, which may consist of such dense material as garnet;

- laser cutting - there is a high-power beam directed in a laser machine that makes an even deep cut of any building material without chipping;

- plasma cutting.

Water, laser and plasma cutting methods are good because you can cut and process a large number of tiles at once. At the same time, the edges of the tiles are perfectly even, the tiles do not break, all the cuts are accurate.

It is used on an industrial scale, since this method of cutting is of great value.

Materials

Each type of ceramic tile involves its own method of trimming.

The choice of tile cutter depends on the thickness and external data of the facing material. By density, you can select soft, medium and hard tiles. The most difficult material for cutting is, of course, natural stone and porcelain stoneware.

They have the highest density and maximum price compared to the rest of the tiles, so you need to carefully select the tool for cutting them.

Consider the possible types and options of tile materials that can be cut at home, starting with the softest:

- One of the well-processed facing materials - gypsum. It is very often used in construction, including for the manufacture of gypsum tiles. There are many types of such tiles, ranging from simple imitations of stone and brick and ending with all sorts of interesting textures. Such a tile has a number of advantages - it is light enough, its extra edges are easy to cut, but the only negative is that it is not moisture resistant and is only suitable for decorative trimmings. You can cut such tiles manually.

- Tile under the brick has a more dense structure than plaster, so working with it is more difficult than with plaster, but pruning is done the same way.

- Ceiling mounted the tile from polyfoam is easily cut off by a stationery knife.

- Ceramics smooth and bulk requires a tile cutter or grinder.

- Porcelain stoneware - the material is very dense, so for its cutting you will need a hydro-abrasive method or an electric tile cutter.

- Ceiling tiles from plastic As the most budget material in the New Year season, it is used to make decorative snowflakes.

Cut snowflakes from the ceiling tile will help a marker, cardboard template and a regular stationery knife.

Required tools

Knowing the properties of the material used and the properties of cutting tools, it will be much easier to choose the necessary one.

In order to trim the tile, the hardest natural material called diamond is used. All cutting elements are almost always made using it.

An easy-to-handle and low-priced glass cutter has a small diamond stone at the end for cutting. Jigsaw cuts with a special diamond-coated string.Circular saw with a special disc nozzle has a special spraying on the work item. Elektroplitkorez - the machine which cuts material with the help of a diamond wheel.

The main tools that are used for trimming tiles:

- glass cutter;

- pliers; pliers;

- hacksaw for ceramics;

- drill;

- drill on tile, nails;

- diamond nozzles;

- jigsaw with tungsten string;

- manual tile cutter;

- Bulgarian;

- ballerina;

- electric tile cutter;

- circular saw with a special diamond nozzle;

- a file, an emery paper, a paper adhesive tape, a construction pencil;

- stationery knife.

Subtleties of the process

First of all, before trimming the tile, you need to take care of protecting your eyes, face from dust, as well as hands - you need glasses, a mask and protective gloves, especially if you are supposed to work with dangerous power tools. Certain types of tools will help to cut tiles correctly, but each type of cutting has its own nuances.

Consider the main features of tile trimming for each type of tool:

- Simple glass cutter. Thin wall tiles should be marked with a marker, drawing a flat line.Lay the tile on a flat surface and make a cut along the outer edge. It is important to know that you need to cut the tile, slightly retreating from the edge of the line, otherwise the desired part of the tile will be shorter by a few millimeters. Also in this case, you can use an oil glass cutter, which will be more effective.

To break a tile, you need to put a long convex object under it.

- Manual tile cutter. If you want to cut tile, including for the decoration of tile baseboards, you can use a hand tile cutter with a sharp cutting element. The tile cutter consists of a guide roller and tongs that allow the tile to be broken at the end of the cut. The cutting element should be gently and evenly pressing, move along the tile away from you. Such a tool will help to do more work, but in this case the edge of the tile will not be very even and will need to be polished.

- Bulgarian. For fast cutting of dense tiles, the grinder can be used, but in this case, the edges of the tile will also not be very smooth and will need to be polished. The tool itself is easy to use, they need to be cut carefully, along a line made in advance, when the saw blade begins to rotate at a certain speed, approximately 3.5 thousand revolutions per minute.The cutting disc of the grinder must be diamond-coated, and under the grinder there must be free, even space.

It is necessary to cut continuously. The minus of this tool is a large amount of dust and chips, which fills all the space around. Also with this tool you will need to work very carefully in a respirator and glasses.

- Electric cutter. Universal tool that costs a lot of money, but it can also be rented. The advantages of the electric cutter are that the tile cut can be made at an angle, quickly and very smoothly. Also, the tile can be of any thickness and texture. The tool consists of a platform, a cutting element and a water supply device to the cutting line.

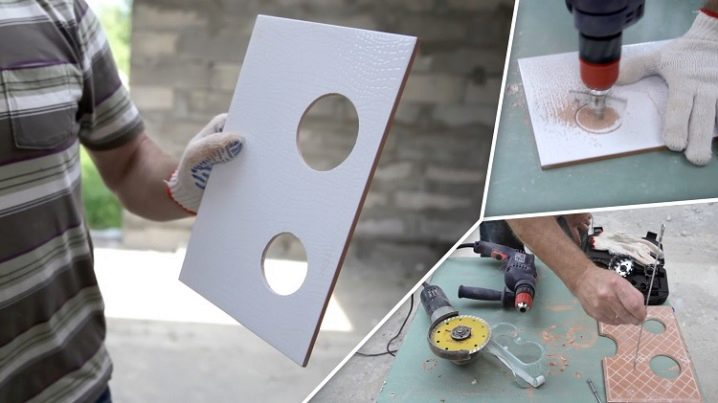

- Ballerina. A special tool that helps to make round holes in tile material with a drill.

If there is a need to make a figure cut through the pattern, you can use a glass cutter or electric hob; the choice in this case depends on the thickness of the tile.

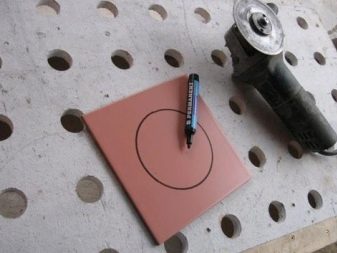

If you need to make a simple round or square hole for the socket, you must first outline the line along which the tile will be cut.To make a round hole, you can use a drill, jigsaw, a ballerina, a crown with a diamond-coated. For a square hole fit the same tools plus Bulgarian.

Consider the option of using a ballerina and drills:

- make a hole with a drill in the middle of the tile;

- to fix the diameter of the future circle on the ballerina, install it on the drill;

- then install a drill in the hole and drill it to the middle of the tile, then carefully cut it from the back until a circle falls out.

You can also make a round hole with a jigsaw. The disadvantage of this option is the high energy consumption of this work. For the implementation of the work you need to purchase a special string of tungsten, which will need to be installed on the instrument. Find a tungsten filament in any supermarket that sells construction materials. The cut should be made from the back of the tile, before making a special hole with a drill in the middle of the contour of the circle.

A round hole in the tile can be made using diamond spraying on a special nozzle, which come in different sizes. First of all, you need to make a markup and protect the tiles with scotch tape.Next you need to fix the diamond bit on the drill and begin to slowly drill. The minus of the variant with the nozzle is the rapid heating of the unit, therefore it is necessary to cool it during operation. After the hole is ready, you need to polish its edges with sandpaper.

Also a round hole can be made using a grinder. In this case, you also need to purchase a special disc, reinforced with diamond coating. Grinder can and cut and grind. When starting work, it is necessary to make a dotted contour with a marker, then with a disk with a grinder on your own, make a neat cut, gradually increasing the applied force. Next you should sand the edges.

A round hole can be made with a drill and pliers, but this will take more time. These tools are in almost every home. The option is suitable for already laid surface. If the tile is not laid yet, it is better to hold it in hot water for about forty minutes. In order to make the hole, you need to outline the contour and protect the remaining tile surface with duct tape. Next, stepping back from the edges, you need to systematically drill holes around the circumference.Then break the inner circle with pliers and polish the edges with a file.

Manual glass cutter is also suitable for cutting figured holes, but only on a thin tile. In order to make a hole, you need to outline the contours and drill a recess in the middle, then carefully cut a circle using a glass cutter using a ruler. Then with the help of pliers gently break the edges. All irregularities are overwritten by a file.

For curly cutting decorative parts that will be parts of a beautiful ceramic decorative panel, you need to use a special machine. This tile cutter is expensive and you need to work on it very carefully and precisely, following a certain technology.

This option is suitable for professionals. Working on such a machine, you first need to do the risks on the future details, then smoothly lead a special handle along the cutting line. Having finished the line, you need to methodically knock the entire surface with a wooden mallet to separate the decorative part from the main part of the tile.

Work on such a machine is very difficult for a beginner, and at the price without further use at home it will not pay off,therefore, most artists use grinders for decorative tile work.

Tips and tricks

As mentioned above, all cutting machines are divided into manual and electric.

When choosing an electric machine, you first need to pay attention to the manufacturer, because if you buy a cheap tile cutter, you will have to wear it for repair too often. The second point to which attention should be paid is the quality of the cutting element, because it is he who does all the basic work of cutting tile.

The cutter must be of high quality, made of hardened durable metal. Otherwise, the saw will wear out and break very quickly.

When the tile cutter is selected, it must be remembered that its cutting disc should be regularly checked for the presence of dirt, chip residues. The disc must be cleaned with a special grinding tool, which is usually used to polish the already cut edges of the tile.

When deciding to purchase a hand-held machine, remember that this option is only suitable for home interior decoration. However, some types of porcelain stoneware can also be cut with a manual machine.You also need to pay attention to the quality of the platform - it must be very stable and dense to withstand the pressure of the cutter. For large scale works, this tool will not work. This type of tile cutter can also cut at an angle and regular cutting of ceramics.

Starting work, it is necessary to check the condition of the roller and the density and clarity of the tile attached to the machine. The roller should easily move along the axis, and the width of the tile should be no more than fifteen millimeters.

When performing tile trimming work, be sure to consider the following tips:

- when choosing a tile, it is better to focus your attention on a tile of medium density - it will crumble less during processing;

- when working with tiles, it is better to wet them so that the material is more plastic;

- when handling a manual tile cutter, it is impossible to press hard on the handles, otherwise the tile will simply break;

- after cutting it is necessary to rub the tile with emery, so as not to cut the arms with a smooth edge;

- when cutting a round hole under the socket, it is necessary to retreat 2-4 cm from the edge of the tile, otherwise the tile will simply crumble when drilling;

- when using the grinder, under the surface of the tile, it is necessary to enclose the wooden flat bars for optimal performance;

- if it is necessary to cut a corner element, the slot of the rectangle with a grinder on both sides of the corner is not completely done, the unnecessary element is simply broken out with forceps, and the remaining surface needs to be simply polished;

- it is also better to make a hole under the narrow water supply pipe with a grinder, cutting out the edges first, then cutting the whole circle with stripes, grilling and cleaning the remnants with a cutter or file;

- You can also mark the circle under the drainpipe and, having made a diametrical marking, first cut it out from the outside, then from the inside. Next, the edges are machined with a special nozzle on the punch.

Use scraps

The most common question that arises after the completion of basic work with tile materials at home or professionally is how and where to use the remains, fragments and trimming of ceramic material.

Of course, there are many ways to find the application of the remaining uneven ceramic tile, and the main option here is mosaic.That is, all ceramic parts, if necessary, are cut by size and laid out on the principle of smalt. For this purpose, special schemes, drawings and patterns are being developed.

Moreover, it is possible to decorate such mosaic parts with any surface - from a concrete or brick wall to glass, wood or even chipboard. After such a finish, any surface will be unique, and the decoration of the room will be updated and transformed, because the creation of design is a creative work.

When finishing works from such a material, trimming and fragments in thickness should be customized to ensure the evenness of the pattern, as well as the color to create the desired pattern.

In this way, you can upgrade the porch at the house, the surface of the street shops, the walls and the floor on the veranda, the surface above the doors and between the windows, the window sill, the countertops, or even make new wall decorations in the bathroom. You can create a completely new design items - vases, pots, pallets, lamps.

There are cases when the usual tile cut along the contour of a circle, a square or just cut harder than hard and dense porcelain. Fragments from a glass-cutter on such a tile are practically invisible, manual tile cutting does not take it, and even the Bulgarian from the outside does not cut such a tile.

If the ceramic tile is hardened, it will not work to cut it on the front side, for this you need to make cuts with a grinder on the inside of 2-3 millimeters deep, then use tongs.

For a hole for a round socket, you can use two types of cutting with a grinder - first make a marking in a circle, cut diagonally with a grinder, then cut out the incisions from the inside, then circle them with pliers at the edges, wetting the edges.

When cutting tiles, the place of future fractures is better to draw with a glass cutter to avoid further chipping.. The best option for a glass cutter is oil (when cutting an oil liquid is fed to the circle of the stone), since it is easier to slip on the tile, including the glaze, and leaves behind a more even cut with fewer chips.

Successful examples and options

The examples presented demonstrate the location of communications and electrical equipment in the holes of ceramic tiles.

You can learn about how to cut ceramic tiles in the following video.