How to choose a wall panel for a steam room?

You simply cannot think of a better material than lining for the interior lining of the steam room. It looks great and creates a unique atmosphere in the bath. In order to always enjoy the time spent in the steam room, it is important to choose the right one among the varieties of the finishing board.

Special features

Lining received its name due to the fact that it was originally used for covering passenger cars from the inside. Over time, it ceased to be an accessory of the railways, but has found application in the interior decoration of various premises, including the bath.

- Lining differs in environmental friendliness, simplicity and usability.

- Allows you to reduce costs and time for heating baths.

- It does not allow condensation to form and mold to develop in a room with high humidity.

- Hides bumps and cracks, electrical wiring.

- In a heated room, the tree gives substances that are beneficial to human health, which is an undoubted advantage for the steam room.

Kinds

The choice of lining of one type or another for a steam room depends on the properties of various wood species, preferences given in favor of one or another wood, as well as on the costs incurred when finishing the room. Pine wood board, as well as lining from other coniferous woods, with all its merits for a steam room, is not the best choice, since it gives off resin.

Deciduous species are preferable - aspen, linden, alder, oak, ash. They do not heat up in conditions of high temperature, which is important from the point of view of comfort and safety in the steam room.

Each breed has other virtues. The linden is capable to create the unique atmosphere in a sweating room, does not dry out, differs in durability, has beautiful color and invoice.

Aspen is a soft tree that is comfortable to work with. Its positive side is that over time it gains strength. Such material is easy to care for. If the aspen is getting dark, you can return it to its former color by sandpaper.It is also believed that this tree takes away negative energy coming from a person. Such an aspect is also taken into account when choosing the wall paneling by some people.

From the point of view of usefulness to the human body, the board from alder is interesting by the large number of tannins contained in this wood, which have anti-inflammatory effect, destroy bacteria. Alder absorbs moisture well and retains heat. But lining from this tree is notable for its high price and not everyone is willing to choose it for finishing work.

It will be even more expensive to use oak material. It is not easy to process, although it serves for a very long time.

Indoors with high humidity, oak wood can be used without special treatment - it will not rot. The same expensive and rarely used for finishing the steam room and the whole bath is ash.

Choosing the lining, you need to consider such factors as the grade of wood, which determines the durability of the material. The best grades are boards of the Extra, A and B level. Class “C” lining is not suitable for pairing. On the surface of high-quality specimens there are no traces of knots.This is a very important indicator, since boards with such “marks” will inevitably crack in the steam room conditions over time.

How to sheathe?

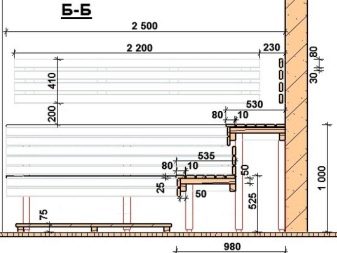

There are two ways to sheathe the walls of a pair of clapboard. It can be mounted horizontally or vertically. It is believed that the vertical fastening of the panels allows you to cope with the finish faster than with the horizontal method of their placement. This arrangement allows you to quickly clean the surface of the walls from condensation, because it easily flows down. With this approach to the finishing of a steam room, it is better to use a paneling, equipped with grooves and ridges, allowing you to securely and simply connect the boards together.

When the lining is laid horizontally, the connecting crest is at the top of the board, which also prevents the ingress of fluid under the skin. A vertical lathing, which is mounted under this installation, helps the air to circulate freely between the wall and the panels.

Also, the positive side of this method to trim the steam room from the inside can be called the convenience of further room maintenance. Boards, located near the floor, usually always remain wet, and therefore deteriorate before others.It is much easier to notice the bottom row of panels than to cut the vertically attached wall panel from the bottom, let alone change it completely.

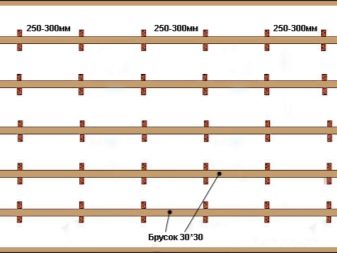

The quality of the finish clapboard in the steam room will largely depend on how correctly the crate is mounted under it. For its device is used timber, which must be coated with a primer.

Starting installation with their own hands, waterproofing is attached to the wall first. It can be nailed to the wall or fixed with battens. For waterproofing should be a layer of mineral wool, laid between the bars. The layer of cotton wool is covered with foil, which can “return” the heat to the steam room. It is put overlap and fixed with aluminum tape. Then the counter rail is nailed, which creates a ventilation gap between the vapor barrier and the facing board.

In the course of insulation under the wall paneling it is necessary to provide points for ventilation holes. One of them should be under the ceiling, and the other at the level of 15-30 centimeters from the floor near the stove.

The clapboard is fastened secretly, since the metal product chosen for fastening and twisted by an open method is heated up in the steam room.Touching it you can get, if not a burn, then a very unpleasant feeling on the skin. In addition, such clamps can rust, ruining the lining itself, and look open mount will be very ugly.

Options for fasteners can be different - screws, klyammery and nails. If you use a self-tapping screw, you can fasten it on the front side of the wall panel, but close it with a special wooden cap, although this is not very convenient, therefore, more often use clamps and nails. Lining should be nailed to the crate (as well as screwed on the screws). Due to the fastening of the boards between each other with grooves and spikes, the clamps are hidden. The fastening material itself must be galvanized to prevent corrosive processes.

As for the additional processing of the wall panel after its installation, there is no unequivocal opinion on this. Some believe that this is harmful, since at high temperatures in the room, the smell of impregnation itself will appear, which negatively affects the state of the human body. Others argue that it is necessary to process the lining, because without it the tree will quickly begin to rot.At the same time should use materials on a natural basis.

It is best to process the boards with natural oils or wax. If you soak them with the same linseed or sunflower oil, the well-being of people who came to relax in the bath, his couples will not affect, and the lining itself will maintain a "healthy state" for a very long time.

It will always be comfortable and useful to be inside a steam room that is well-warmed and finished with such a covering.

Tips and tricks

In the formation of the internal space of the steam room should be borne in mind some features of work with clapboard and its physical properties.

- With a vertical arrangement of boards, the service life of such a coating may be less than at horizontal, because the temperature at the top and bottom of the board during operation of the room is very different.

- Vertically placed lining is appropriate in saunas, where the air is always dry. There the wood does not darken and retains its original beauty for a long time.

- When placing the boards horizontally, the walls appear wider, as if the internal space is increasing. If the steam room is small, this is a significant plus.Also, air passes better behind horizontal boards, since a vertical frame is used to fix the finishing material.

- So that over time, the wall paneling in the steam room and in all other parts of the bath house does not darken, rot, or become covered with mold, as well as with lime deposits, it is advised to use modern means of processing its surface. These are acrylic water impregnations, oil-based impregnations and antiseptics of foreign and domestic production.

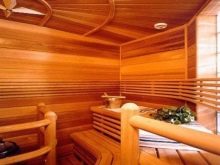

Beautiful examples

- Horizontally located boards on the walls of the steam room, elegantly designed ceiling design, comfortable rounded shelves create a cozy and comfortable atmosphere in this room. The game in shades of boards gives the finish mobility.

- Through the use of carved platbands on the window, wooden utensils and a simple bench, a steam room decorated with clapboard can be made in the old Russian style.

- Proper use of wood texture, a well-thought game with geometry and color allow you to perform a steam room in a modern style.

On how to choose and fix the wall paneling in the bath, see the following video.