The subtleties of the choice of plastic lining

One of the main points of modern repair is the maximum cost savings during the work. The list of inexpensive, but well-proven during the operation of materials, it is necessary to allocate products from PVC, which includes plastic paneling.

Special features

Products owe their name to the scope in which it was first used. However, earlier only coniferous and deciduous varieties of wood were used as raw materials for the production of material, whose main feature was good resistance to moisture.

Lining, presented on the modern construction market, is made of polymer raw materials according to GOST.

The products have a long service life, are resistant to moisture, and also tolerate temperature fluctuations, which makes it possible to use plastic products for exterior and interior cladding of buildings.

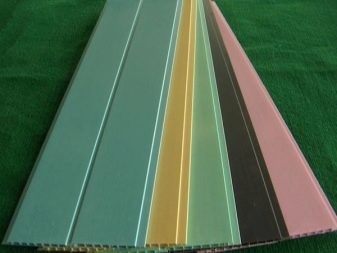

Panels come in different sizes, products are sold in a wide range of colors. In addition, plastic slats may have a different profile. In the assortment of such products are products that imitate the finish under natural materials: brick, tile, wood or stone. The material is quite durable and does not rot. In addition, plastic panels are low cost and ease of installation.

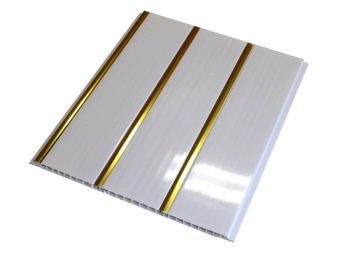

Products are panels with cells located inside - thanks to this structure, the product acquires high thermal insulation and sound insulation characteristics, and polyvinyl chloride acts as the main component of the material.

Lining has a number of positive features, which will be discussed below.

- Durability due to resistance to moisture and ultraviolet radiation.

- Products are easy to clean.

- Unlike wooden lining, plastic panels have a minimum weight, which provides ease of transportation and does not affect the bearing capacity of the walls of the building. On the basis of this, the material is often used for covering multi-storey buildings, as well as structures having a columnar foundation type.

- Products are characterized by high thermal insulation performance.This is explained by the specifics of manufacturing products, during which during the casting of plastics into raw materials pores are formed, where an air layer is formed that retains heat. In addition to reducing the level of heat loss, such a pillow acts as a sound insulation.

- The cost of PVC products is several times lower than wooden lining.

- Installation of panels can be done independently. Raw materials are easily and conveniently cut into products of the required size without using a specialized tool and attracting hired labor.

In addition to the advantages, plastic lining has some drawbacks.

- The main disadvantage is its flammability. For plastic products there are no compositions that reduce this property of the material.

- Some colored materials quickly lose their color saturation, but this largely depends on the manufacturer and the materials used to make the products.

Standard lining is a wide panel, equipped with stiffeners. In appearance plastic panels are the same as wooden counterparts.

Products are of two types:

- seamless elements;

- products with seams.

The latter type is used for outdoor work, as it has increased strength. Such products are easier to fasten, the material is more resistant to mechanical stress. In appearance, similar products are very similar to siding.

Seamless panels have large dimensions: the width of the panels can be about 2.5 m. Mostly seamless products are used for wall and ceiling cladding. The panels are smooth, and the seams between the elements are visually almost invisible. However, the products are several times more expensive than lining with seams.

How to choose?

To purchase high-quality and reliable material, you should adhere to the following recommendations:

- special attention should be paid to the uniformity of the painted surface;

- the strength of the panels can be checked by light pressure on the base - good products should not be pressed at the point of pressure;

- the content of chalk in the composition of the material should not be more than 20%;

- it is very important that the elements are tightly fixed with each other;

- Some manufacturers may use unsafe raw materials to reduce the cost of production of liningTherefore, before buying, you should be familiar with the quality certificates for products, as well as test products for the presence of specific odors.

Colors

The process of imparting color to plastic lining occurs by incorporating coloring pigments into the composition of the raw material. Today, manufacturers of these products offer the consumer about 70 different color solutions. But the white color of products does not lose its relevance, however, for interior work they often prefer bold bright shades, for example, for finishing bathrooms or in the interior of country houses and cottages.

For finishing loggias, balconies and facades often prefer lining, imitating natural wood - pine, oak and other breeds.

The surface of the panels can be glossy, semi-gloss or matte. The glossy base is formed by applying a varnish on the surface of the product, which acts as an additional protective layer.

Dimensions

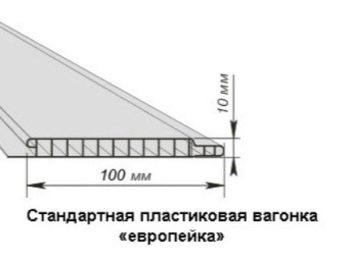

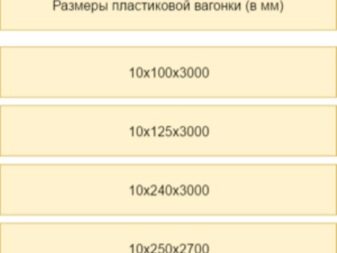

Plastic panels have the following dimensions:

- width varies in the range of 100-125 mm;

- the length of the panels is from 3000 mm to 6000 mm;

- thickness - from 7 mm to 10 mm.

Based on the division of products into wall and ceiling panels, the thickness of the products also varies. There is no strict restriction on the use of wall paneling, but in most cases it is not appropriate. In addition to thickness, wall and ceiling products differ from each other in length, because this value for some panels can reach 220 cm. You should also consider possible options for changing the size of products, taking into account the brand and manufacturer.

The strength of the material depends on the number of stiffeners - the more there will be, the higher the resistance of the lamella to mechanical stress will be. In addition, the distance between them is important. The optimal value is a step of no more than 10 mm.

When buying products you should pay special attention to the condition of the ribs - they should not be deformed, if they are damaged, a dent will be visually visible on the front side of the panels.

It is these components that take on themselves all the power directed at the material under any mechanical action. In addition, they connect together the layers of lining.

Scope of application

The main advantage of plastic lining is its versatility, so the products can be used in many areas.Sheathing of walls and ceilings is the most popular use of products. In addition, the panels are lined with balconies, bathrooms, verandas, as well as rooms with a high level of humidity.

In terms of the use of products for exterior cladding, it is worth highlighting the options for finishing the facades of country houses., outbuildings, residential buildings, trade pavilions, stops and other structures. The composition of the material includes special additives that provide panels with resistance to negative temperatures.

The flexibility of the wall panel makes it possible to use it in hard-to-reach places: both indoors and outdoors.

How to sheathe?

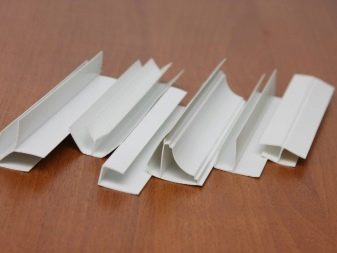

For reliable and high-quality installation of plastic lining, you must first prepare for work the basis for fixing the material - the surface must be cleaned of dirt and the old coating, if necessary, perform a primer. Installation of panels is carried out using special components. Decorative moldings used for fastening are of the following types: starting and connecting profile, outer and inner corner, ceiling plinth, universal profile.

Installation work with plastic panels can be performed in two ways:

- fastening products to a special frame;

- installation to the base without the construction of additional structures.

For installation, you will need the following materials and tools:

- hacksaw for woodwork or electric jigsaw;

- drill;

- screwdriver or screwdriver;

- stapler and hammer;

- building level;

- lining and a bar for an obreshetka;

- self-tapping screws;

- profiles for lining.

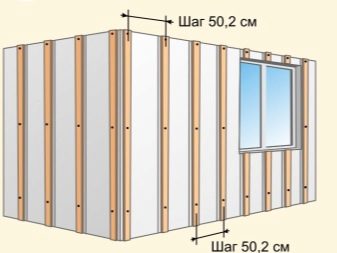

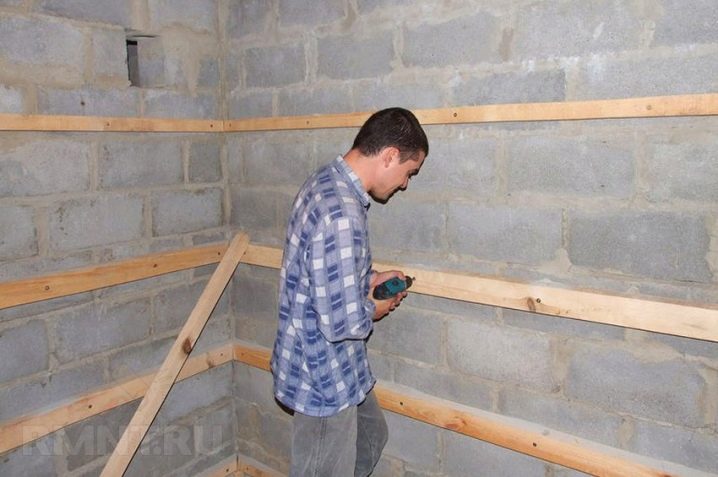

When choosing the method of mounting products on the frame, first of all, work is done with wooden bars - they must be drilled in 50 cm steps. To install the wall paneling in rooms with a high level of humidity, wooden products are previously covered with drying oil or paint.

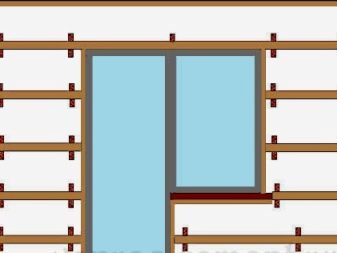

The fixing of the bars is performed in parallel with respect to the base, at a distance of no more than one meter from each other. Attachment technology is adjustable by level.

To avoid distortions, the parts should be located in the same plane, after which along the entire perimeter of the surface a baseboard or profile is attached to the base. The first plastic element of the structure is inserted one side into the profile,and the other is attached by a stapler to the uneven bars. The next panel is fixed in the groove of the first lamella, and the other side is attached to the frame. The same technology is used for the installation of the entire paneling.

During the external plating of surfaces, works are performed in a similar pattern. To connect the elements in different parts of the applied appropriate components.

Instead of a wooden frame, in some cases, a metal profile is used. When choosing a frame mounting method, it is worth considering that a similar variant of mounting material will reduce the area of the room. However, the fact that it can increase the strength and rigidity of the entire plastic construction is considered to be a significant advantage of the batten.

Covering with clapboard bases without arranging the frame is recommended to be carried out in wooden houses or in panel structures. In addition, it is often used for mounting panels inside buildings. This method is less time consuming, but after a time in the design small cracks between the elements, as well as gaps in the corners of the room, can occur, since these areas are under maximum pressure.Therefore, most experts advise to opt for the installation of lining on the frame of any material - it can be both wood and metal.

Beautiful examples

Attic space can be used with benefit, equipping them, for example, as a rest room. And to carry out inexpensive, but attractive finishing of this room plastic lining will help. White color will make the room bright and spacious, and the ceiling, even at the minimum height, will appear higher, without weighing down the space.

A bathroom lined with wood clapboard, even of small size, will become a room where you can truly relax and enjoy water treatments.

Balconies and loggias in apartments quite often serve as a continuation of the room. Due to the color diversity with the help of PVC lining in them, you can equip an attractive and useful area according to your interests, realizing the most ambitious ideas of arranging the interior of this zone in the residential space of the apartment.

On how to independently sheathe the ceiling of the bathroom with plastic clapboard, see below.