Door seals

In any room it is important to always keep warm, especially in cold seasons. Therefore, it is advisable to insulate on only the windows, but also the doors through which cold, wind and dust penetrate into the room no less, and even more. To this end, a variety of seals are made for doors that take care of maximum heat preservation in a house, apartment, office, or public institution.

Purpose

Door seals are designed to eliminate gaps and gaps, because of which cold air and winds enter the room. Without them it is impossible to do in a private house with doors that go directly onto the street. The door structure (especially if it is wooden or made of similar material) tends to dry out or, on the contrary, absorbs a large amount of moisture during rains and damp.The deformation of the door frames creates such conditions when the door cannot fit snugly to the door frame. It must either be replaced, which, of course, is not always possible, or use a saving, inexpensive option in the form of a good seal that will prolong the life of the door and help keep heat in a residential or work space.

In addition, there is another sealer function - depreciation, which is not directly related to the heat-saving function, but provides a softer contact of the door with the joint, preventing loud bangs and unnecessary creaking.

Requirements

Of course, in order to perform its main function, the seal must of course be of good quality.

Therefore, it must have the following properties:

- durable manufacturing materials - it depends on them the service life of the sealing tape. If the tape is not of very good quality, it will quickly fall behind the door and will simply be unusable;

- good insulation should be hermetically sealed to its surrounding surfaces. This provides an obstacle to the penetration into the room of cold air, winds and street dust;

- resistance to constant mechanical stress is also a necessary quality, because when opening and closing doors, as well as the impact of any external factors, poor quality materials will undergo rapid wear;

- the material should not only be durable, but also be good to bend, not to tear when you try to close the door gaps and crevices, to be as soft as possible in order to minimize the sound of the door hitting the box.

Kinds

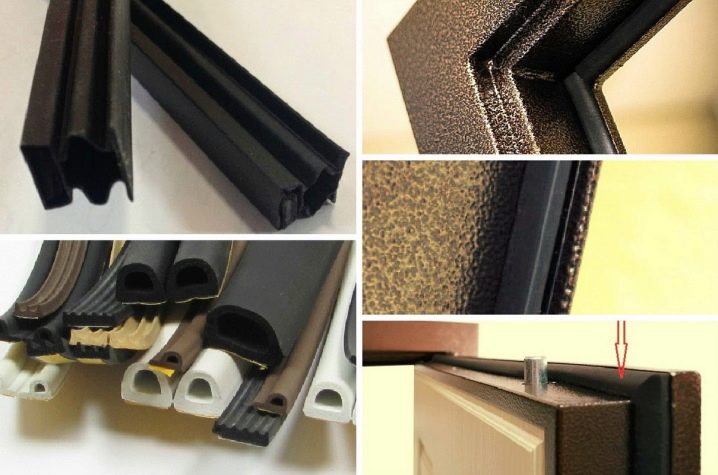

All types of door seals are made in the form of a tape, which has a different length, width, thickness and color, depending on the size of the slots and gaps, as well as the color of a particular door in order to preserve aesthetics. Types of profile seal can be different. A profile is a form of insulation that can have a cavity inside the material, whose task is to eliminate gaps and seal gaps of different sizes and shapes. Compressing, good insulation does not acquire any damage. High-quality polyvinyl chloride (PVC) or polyurethane possess this property. Profile shapes can be in the form of letters of the English alphabet: P, V, C, E, O, and other configurations.

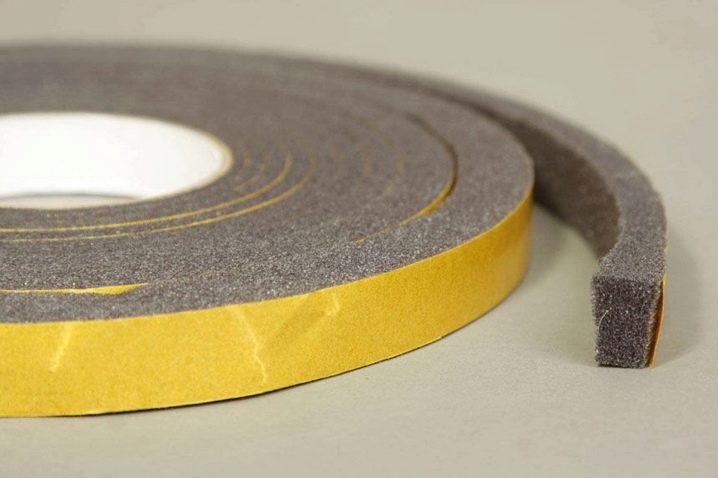

Sealing tapemade of foam rubber - the most popular and inexpensive form. The self-adhesive film fastens to foam rubber, its thickness can vary. Methods of mounting foam tape are different depending on the material from which the door frame is made. If it is wooden, foam rubber is fixed on it with wallpaper nails, and if the input structure is metal, you can use durable glue, which is suitable for working with metal with it. Among the drawbacks of the foam rubber tape, it should be noted that it does not differ in wear resistance and does not suffice for long. Also, foam rubber due to its porosity (especially when it comes to ribbons of large width) has the ability to pass cold air, therefore it is best to use it as a heater not for entrance doors, but for interior doors.

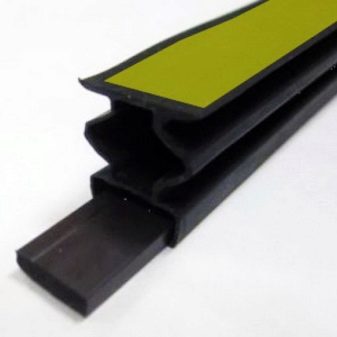

Tubular sealer It is a thick dense bundle, inside which there is a rather large cavity. It is due to the strength of the material in combination with the internal cavity that the door is fitted to the door frame without gaps and unnecessary gaps. The tubular seal is made of rubber, which has a porous structure,what provides heatsaving and sound insulation. Often it is self-adhesive, which makes it easy to install. Of course, any “self-bonding” will simply fall over time, but usually it will last from one to several seasons, and then it can also be easily replaced with another. Most often, rubber is used for doors that overlook the street.

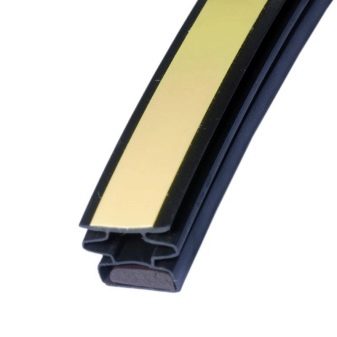

Slot seals manufactured specifically for plastic doors of various designs and are a product of softer rubber than a thick tubular seal. Installing such a product is more than simple: you just need to gently insert it into the door grooves. The slot method provides minimal external influence on the compactor itself and lasts much longer, withstanding bad weather and sudden changes in temperature. This type of insulation can only be used for plastic doors. For other door designs, he, unfortunately, will not work. By the way, an interesting fact that should be taken into account to all owners of plastic doors is that each manufacturer, in addition to selling and installing doors, is also engaged in the manufacture of seals, which can be immediately purchased as an additional and useful accessory.

Glass sealant It is also a separate type of seal, designed specifically for the glass elements of doors of different sizes. Their profile has an individual cross section, and the material of manufacture is a flexible and soft silicone. It is enough just to moisten such material in water, after which you immediately install the door to the right place. This type of silicone differs in that after soaking after a certain amount of time has elapsed, it is firmly glued to glass surfaces and does not “stick out”, unlike simple seals on a self-adhesive basis.

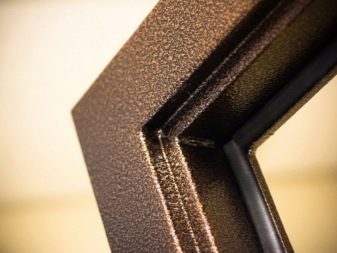

Magnetic seals made in the form of a frame with an accuracy of a millimeter repeating door contours. They are used for metal doors and are recommended by experts as the highest quality and durable. Each of them has two components: an insert with a magnet and a soft material. Such a seal is not cheap, and certain rules should be observed during its installation, but durability and high quality can contribute to its acquisition.

Magnetic products have a high degree of tightness and shock absorption, so the door will not make noise when opening and closing, and the attraction of the door to the door jamb will ensure the complete absence of cracks and gaps.The only disadvantage is that, due to magnetic attraction, additional physical effort will sometimes have to be applied to open the door. A special place among the seals takes a threshold, the purpose of which is not only the insulation at the bottom of the door, but also the increased load that the dense rubber or rubber can withstand from which it is made. When purchasing such products, you need to pay special attention to the quality of rubber.

Contour Seal good in its ease of use: it is fixed to the door along its perimeter. If there is a special groove, it can be inserted there, and it is possible to lay it just along the edge, if there is no gap or groove. Contour insulation is often made of rubber and foam rubber. For rooms with increased fire risk, a thermally expanding type of insulation is often used. Visually, it looks like the most common, but with a sharp increase in temperature during ignition and smoke, it tends to immediately expand and foam. Thus, the air does not penetrate the room, and the flame can go out quickly.

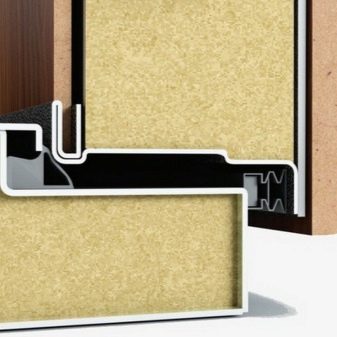

Also for fire doors a triple was developed, or three-contour view of the seal, providing an additional sound and noise insulation effect. A compactor consisting of three layers (or circuits) can be used both in apartments and offices for optimal preservation of comfort and safety. Additional rigid edges make the door leaf much thicker and increase its weight, so it is important to ensure that the door frame and its accessories are as strong as possible. This heater, perhaps, best of all retains heat when using it for entrance doors.

Liquid option heater used for metal doors and requires certain conditions of use. It is produced in metal cylinders and applied to the required places by spraying. In fact, it is liquid foam rubber, which, when applied under gas pressure, quickly hardens, providing good thermal insulation properties. Its peculiarity is that it does not like places with a high level of humidity. Also, when spraying requires a certain skill in order to apply it as accurately as possible so that the door does not acquire unnecessary cosmetic defects.

Liquid insulation is made from neutralized chemical compounds and is absolutely safe for humans and animals.

Pile or fleecy species Insulators are known to many people since childhood, mainly because their main representative to this day is felt. At the present stage, there are synthetic analogues of fleece insulation, but since the felt is made from pure wool, despite its certain features (in particular, it is not so easy to attach it to the doors), this is still its indisputable advantage. There are different types of felt that have a certain designation, but any option is suitable for the doors, the main thing is to cut the material correctly, making the necessary measurements before that.

Of synthetic pile materials, it is often popular. thin pile tape on a sticky basis. Her task is not to let dust into the room. It is rarely used as a door seal, but it is often used for installation on the doors of wardrobes.

There is still the most expensive, but at the same time reliable TEC-sealIn the production of which thermoplastic elastomers are used. These materials have high wear resistance, and therefore the manufacturers claim that they can serve without replacement from 15 to 20 years. High-tech flexible plastic is able to withstand extremely low temperatures and provides excellent thermal insulation, even when the frost is below 50 degrees. In addition to the high cost, such a compactor is distinguished by a certain complexity in its installation, but if all the conditions are met, its price will pay off very quickly.

Dimensions

Seals come in different sizes: thin, thick, wide. Dimensions are selected based on what size the gap or gap. With a slit width of 1-4 mm, a rectangular profile is used, and the material can be PVC, foam rubber or polyethylene. For smaller gaps - up to 3 mm, a C-profile seal is suitable, as well as K or E. P-and V-profile products cover holes from 3 to 5 mm. Seals with wide cavities inside O and D are designed primarily for entrance doors and are installed in the gap between the door and the joint, whose dimensions can be up to 7 mm.

These products are produced, as a rule, in large rolls. Metric area can be different, depending on the manufacturer and type of sealing material.When buying, you should be guided by the fact that you need to purchase from 5 to 6 meters of insulation to one entrance door. Slightly less can go to interior doors, but it is better to take it always with a small margin: it will never be superfluous in the household, and if any part of the sealing tape is worn out, it can always be replaced.

If you want to seal the gap between the door leaf and the jamb, the gap size can be removed very simply: you need to insert between them a piece of clay wrapped in plastic wrap. A copy will be obtained, which will help to correctly determine the desired width of the seal.

Materials

Foam seal - one of the most popular and simple. It has a self-adhesive base, with which it is easily mounted on the door. The thickness and texture of the tape may be different. Foam rubber is nailed to wooden door constructions with wallpaper nails, and if the entrance door is made of metal, you can fix the foam rubber with special glue intended for working with metal. The advantage of foam rubber has always been in its low cost and accessibility for all, but it is knownthat its service life ends very quickly: often foam insulation is barely enough for one season, and under particularly adverse weather conditions it can wear out much earlier. Of course, you can always buy it with a margin, but these features should be borne in mind when buying.

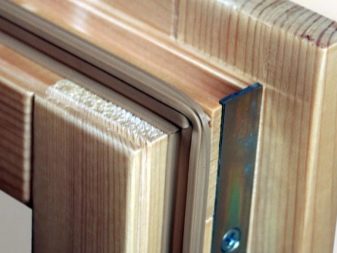

Rubber insulation is rightly called universal, because it is used to eliminate the gap gaps in both interior and entrance doors. You can work with it, warming the doors of wood, chipboard and any metal. It is of two types: either on a sticky basis or intended for installation in a door profile specially prepared for it. As you know, there are models of doors that are made already with inserts designed to install the future seal.

The undoubted advantage of rubber seals - in their wide range: they are available in the form of bundles of different diameters or tubular products with a cavity inside. Along with the low cost of rubber has excellent hermetic properties. When buying it is very important to pay attention to its shelf life, as over time, the rubber loses its elasticity.

Silicone is similar to rubber, but it is softer, plastic, quickly breaks and abrades due to constant mechanical stress. In addition, after some time, it acquires unnecessary stickiness, which is also an inconvenience. However, it also has its obvious advantages: silicone is very light and aesthetic in appearance, and is also considered an environmentally friendly material. Therefore, it is he who is most often used for insulating doors in kindergartens, schools, hospitals and clinics, and ease of use always ensures the absence of serious technical problems when it is necessary to replace it.

Felt compactor is certainly familiar to everyone. Along with foam rubber, it is the most popular and well-known material that was widely used in the Soviet era. Felt is no less popular in application now, and even against the background of modern high-tech materials, it still has its obvious advantages. Now the felt is easy to install and affordable, if you compare its cost with TEP-seals.

The main advantage of felt is high wear resistance during operation.This natural and sturdy material is able to withstand harsh weather conditions and does not wear out for a long amount of time, especially if the installation was carried out correctly and in good faith. Due to the fact that real felts are still made of pure wool, its internal structure does not collapse over time, unlike synthetic types of seals, and it can serve for years without losing its original qualities. Felt is very dense, it ideally absorbs sounds, retains heat excellently and, contrary to general ideas, is a fireproof material precisely because of the density of its structure.

Previously, felt was widely used for insulating any doors and even windows. However, it has several features, because of which many consumers still prefer the more modern types of materials. Since it is still made from natural wool, following centuries-old traditions with the use of complex technologies, its price is often quite high. In addition, the process of installing felt on the door is not easy, and the master should have certain skills in order to do everything as correctly and accurately as possible.First of all, you will need to cut the felt strips out of sheet material yourself, while other types of seals are already sold in ready-made form and are mortise-free, requiring no special preparation.

Colors

At the present stage, you can choose for every taste and color not only a window or a door, but also a heater for it. The color range of seals made of silicone, PVC and rubber is unlimited: a white seal is ideal for plastic doors of the same color, and black rubber material will become a reliable protector from cold weather and extraneous sounds if fastened to the front door. Classic black and white colors have their own specific field of application: it is clear that black seals are better suited for massive doors made of iron or any other metal, and whites can hide cosmetic defects and gaps in the interior doors.

For colored metal-plastic doors there are multi-colored seals, which, as already mentioned, can always be purchased from the same manufacturers that produce doors. Transparent silicone views will suit those who wish to door, who wish toso that the material used is as noticeable as possible on the surface and at the same time fulfills its main functions.

Manufacturers

The leading manufacturer of expensive but reliable seals is LLC "Gasket" - Russian company specializing in thermoplastic elastomers. In the assortment there are not only seals of the finished form: at the request of the customer, you can make measurements and provide a product of any non-standard sizes, taking into account the peculiarities of a particular door structure.

Volzhsky plant RTI since soviet time it has been manufacturing silicon rubber products. Now this plant produces rubber door insulation of various sizes and profiles, intended for wide consumption. The quality of rubber is high, such materials serve for a long time, and their price is very moderate.

PKF Kazpolimer LLC - an enterprise that is located in Kazan and is engaged in the production of all spectra of PVC and plastic seals. The range includes insulators for both entrance and interior doors, as well as materials with which you can eliminate cracks not only in the doors, but also in furniture, both new and old.

Firm "Leopard Profile" from St. Petersburg has long been engaged in the production of various seals from wear-resistant PVC materials for doors of any type. The company primarily specializes in European-style insulation for doors and windows, producing products of virtually any color and profile, already prepared for doors of various types. This company works in full compliance with the requirements of quality according to GOST.

Kazan company "Polinor" It specializes in paintwork materials and goods for construction, however, it is this company that produces high-quality liquid sealer for metal entrance doors with the same name. It is environmentally safe and easy to use: in order to properly put it in the right place, it will be enough to carefully read the instructions.

Which to choose?

Before buying, it will not hurt to independently test the compactor for its quality. To do this, just lightly press it. If the quality is good, then the material returns to its former form after a few seconds, and if it is bad, it will remain in a “squeezed” position or straighten out, but already with signs of obvious deformation.It is not recommended to buy such a compactor, and you should not look at the fact that it can be cheap: it will wear out or tear very quickly when it comes into contact with the door structure, without sustaining a constant mechanical effect.

As a rule, dense rubber seals are used for the entrance door, which have both tubular and rectangular shapes, depending on the size of the slots and the “age” of the door. If we are talking about the metal solid design of the door frame, it can be insulated with liquid material, neatly spraying it from the container. Magnetic insulators are ideal for steel and iron doors - they will provide the closest possible closure, but will make the already weighty structure somewhat heavier. Magnetic insulators, as well as TEP-options will long serve, being fixed on moving pendulum structures.

External and street doors can be insulated with felt, of course, by inviting an experienced master for this and taking into account all the necessary costs associated with the material and the work process itself. Also, magnetic insulation (in the case of external metal doors) will be an excellent and less energy-consuming option.It should be borne in mind that the felt can be used for insulation of door porch, its dimensions, due to the specific material, can be "customized" in the course of work.

In a log house, you should especially take care of fire safety, therefore for any wooden door (made of oak or other wood material), a good alternative is the use of thermally expanding insulation, which, in case of fire hazard, will prevent oxygen from entering the room, which can prevent the rapid spread of flame.

As for interior doors in general (including sliding and coupe), in this case, you can use seals more aesthetic appearance, made of soft silicone or plastic of the corresponding color. Since we are talking about moving structures, it will be better, in addition to the adhesive base of the seals, to additionally fix it with glue on wood or particle board, depending on the material from which the door is made.

By the way, to prevent the accumulation of dust and dirt in sliding doors of a cassette type, a not very popular among door seals, a fleece tape on self-adhesive basis is ideal,which is used to eliminate small gaps in wardrobes, dressers and other furniture.

A narrow rubber insulation on a sticky basis is usually used for a balcony door, and if you still want to save money, you can use foam rubber. If the balcony door is a part of a double-glazed window, it will be easy to install any plastic seal on it. If the balcony door is old, wooden, with many gaps and gaps - wide strips of felt can be fixed around the perimeter of the door, following the dimensions of the gaps, and small cracks can be eliminated with the help of specially cut felt pads.

For information on how to choose a seal for the door, see the following video.