Features of acrylic sealants for wood

Often in the repair process there is a need to seal the seams, gaps and cracks. Acrylic sealant will be the best solution to this problem if you are dealing with wood. It is distinguished by durability, reliability and durability, and in addition, it is easy to use and is available for any consumer.

Specifications

Sealants are irreplaceable substances during the finishing works and in the repair of any structures, including wood. The compositions can be applied at various stages of finishing, and the sealing effect appears immediately after the mass is solidified.

For sealants designed to work with wood surfaces, special requirements are imposed:

- creation of reliable protection against wind gusts and drafts;

- minimizing heat loss;

- effective elimination of cracks and crevices in logs and boards;

- the durability of the composition - the minimum term of its service should be 20 years;

- high adhesion to wood surfaces;

- lack of special skills and experience for work;

- equally high quality of the composition both in exterior and in interior work;

- environmental and health safety;

- preservation of decorative and aesthetics of wooden buildings;

- preservation of physico-technical parameters at seasonal fluctuations in temperature.

Manufacturers nowadays offer a large selection of wood compositions, however, experts believe that the best option would be acrylic sealant, which is the most practical when working with materials of this type.

Special features

Sealants made on the basis of acrylic, have high adhesion with fibrous and porous coatings, they are easy to work and at the same time have a relatively low cost. Such compositions comply with all hygienic standards, do not emit harmful and toxic substances, therefore, are recognized to be completely safe for use in residential premises.

The scope of application of any building material due to its main technical features.

Acrylic sealant is characterized by the following properties:

- seam width - not more than 5 cm;

- the thickness of the seam should not exceed half its width;

- consumption - a tube with a mass of 325 ml can be used to seal 5 m of seams with a thickness of not more than 6 mm;

- working temperature range - from -40 to +80 degrees;

- the possibility of staining after 21 days after application of the composition;

- hardening rate - up to 30 days at a humidity level of 45-60%;

- setting time with a covering - till 1 o'clock;

- resistance to frost - up to 5 cycles of freezing and thawing.

In addition to these characteristics, it is important to note a few material properties that are very important for its use.

Acrylic sealant has in its structure special components that enhance its resistance to the effects of mold. As the experience of using the material by consumers shows, silicone compounds begin to turn yellow as early as 1.5-2 years after application, while acrylics retain their original color for much longer.

Acrylic composition is versatile, and wood is by no means the only type of surface on which it is effective.Substances can be used to work with plastic, laminate, chipboard and other coatings, which is very convenient if during repair there is a need to process different types of structures.

The composition does not undergo oxidation under the influence of an aggressive environment, it can work in unheated areas even in winter, however, under the influence of direct sunlight, the composition of acrylic rather quickly collapses, therefore, for facade works such sealant should be used only as a temporary measure.

Acrylic sealant does not become cloudy at the end of curingtherefore, it can be used in those situations if the work requires the use of colorless compounds - over time it becomes similar to glass and is almost imperceptible to the human eye.

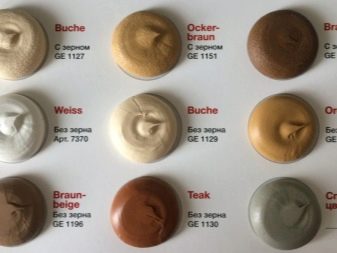

However, the modern industry also offers a large assortment of colored acrylic compositions, which allows you to choose an option that will be best combined with shades of the interior.

Advantages and disadvantages

The undoubted advantage of the acrylic composition is its reasonable price - putty from acrylic-based wood are many times cheaper than their counterparts, even the most expensive option will in any case be cheaper than silicone compounds.

The material is safe, since no dangerous volatile substances are emitted upon contact. When applying acrylic there will be no harmful fumes and an unpleasant odor, so you can safely apply the composition in closed rooms, where there is no possibility for full ventilation.

The sealant is quite easy to use, any gaps can be quickly and easily repaired with your own hands, and you will not need to turn to specialists in this case. The composition is already implemented in a ready-to-use form, so there should be no difficulties with its use.

The great advantage of acrylic sealant, unlike silicone, is the possibility of its staining, and this is especially true when it comes to wood.

Moreover, after curing, the treated surface can be sanded, primed and painted, the material due to its high adhesion will keep the paint layer in an aesthetic state.

However, acrylic compositions have disadvantages, among which should be highlighted:

- Low resistance to moisture - according to this indicator, acrylic sealants are significantly inferior to silicone.With prolonged contact with water, their physico-technical parameters are reduced and the material begins to break down. That is why the compositions applied in rooms with low humidity, as in the bathroom or shower, they will not be effective.

- It is not necessary to use the material when sealing systems with increased loads, since regular or periodic, but significant tightening or stretching can quickly lead to the resolution of the seams.

- The relationship between acrylic sealants with temperature changes is not easy. Manufacturers today have launched the production of universal cold-resistant components that can withstand temperatures as low as -80 degrees. However, when used in conditions where fluctuations do not exceed 10-15%, such grouting starts to crack and crumble very quickly, which significantly reduces the range of use of acrylic universal sealant.

Spheres of application

All work on the interior and exterior of the room, as a rule, are carried out with the use of water- and non-waterproof sealants. Experts advise taking them for indoor work, and for facades to acquire specialized cold-resistant compounds.

A one-component non-moisture resistant sealant is recommended for use in dry rooms with regulatory humidity parameters. It is universally used in the installation of wood baseboards and panels.

Acrylic sealant is often purchased for the walls, it perfectly seals the gaps and seams in the floorboard and laminate, and modern manufacturers offer a large selection of sealants, which in their tone are close to the shades of natural wood.

Due to this property, as well as reliable adhesion, acrylic sealants can be used when working with logs, which in recent years have become especially popular in the construction of environmentally friendly and energy-efficient housing.

In previous years, hemp was used for sealing seams and gaps, but such sealing can not be called qualitative and durable, therefore, the use of such material was gradually abandoned in favor of acrylic sealant.

The material is also ideal for working with a log house, it allows for a high-quality finishing lining. The composition with a natural shade, imitating wood, is often used for finishing and repairing buildings from a profiled bar or for decorating private houses with clapboard or a block house.

The sealant is excellent for sealing holes that appear after knots fall out, as well as other defects of the wooden coating.

During the service, the tree often cracks, so there are cracks between its individual panels - they can also be quickly repaired with acrylic sealing compounds.

Sealant buy to fix ceramic tiles to a variety of surfaces, including wood, and this material is easier to use than the standard adhesive mass.

Many experts recommend applying the compound to seal the wooden windows from the outside, but this is a rather dangerous delusion, because the sealant has poor resistance to falling rainwater flows, which can gradually drain it, and significant temperature fluctuations. For the same reason, it is not recommended for work on the roof, as the roof under the scorching sun can heat up to 90 degrees, and this threshold is critical for acrylic.

Browse popular brands

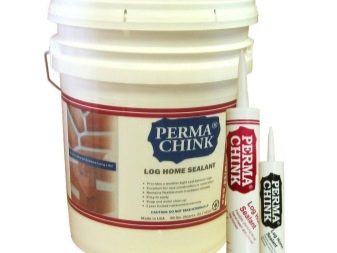

Perma chink - products of this brand are designed to work with seams more than 2.5 cm wide. Such a sealant has a good elasticity, which is maintained throughout the entire period of use.

The material can be applied at temperatures from +5 to + 32 degrees, setting with the surface takes 2-3 hours, and for the final polymerization it will take up to 8-10 weeks.

The sealant is sold in 325 ml tubes or 19-liter plastic buckets and in 11 color variants.

Energy seal - suture sealant based on acrylic, which is used for sealing narrow seams, whose width does not exceed 2.5 cm. At the end of hardening, it can withstand plastic deformations up to 150% of the original dimensions, it is characterized by increased resistance to fading, as well as durability and impermeability of steam.

It is used at temperatures from 5 to 32 degrees above zero, setting takes 2 hours, and it takes about one and a half months to fully adhere to the coating.

"Remmers Acryl 100" - the German structure developed for works with seams less than 5 cm wide. Differs in excellent resistance to loadings to compression and stretching, and also good adhesion and resistance to direct sunshine. The service life of such material is 20 years.

The product is made in a wide range of colors, numbering 11 shades, applied at temperatures from 15 to 45 degrees.On setting with the coating takes 2 hours, and full polymerization occurs in just 7 days.

Eurotex - highly elastic composition, which at the end of solidification withstands deformations up to 200%. This sealant is resistant to UV rays, and also has a wide temperature operating range - from -50 to +70 degrees.

The product is notable for its convenience of use, it forms durable and beautiful stitches of the most various forms, it does not shrink and does not spread. Available in 4 colors.

Zobel - products of another German manufacturer, which due to the addition of silicone components, acquires increased elasticity and resistance to deformation up to 600%, and also has a high curing rate. It is possible to paint such sealant after 20 minutes after hardening.

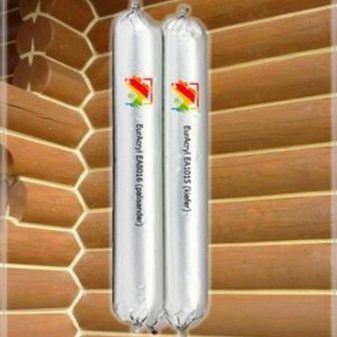

"EurAcryl" - this composition has found wide use for the effective sealing of mezhventsovyh seams, as well as window frames and door jambs. As the reviews show, the material is characterized by exceptional elasticity, which reaches 500%, can withstand temperatures from -30 to +75 degrees.

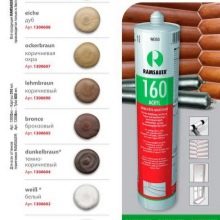

"Ramsauer Acryl 160" - this composition is often used when it is necessary to seal joints between wooden and concrete surfaces, the setting and formation of a protective film is manifested after 15 minutes.After hardening, the mass is characterized by high plasticity - elongation to rupture can reach 500%.

Consumers also emit sealants "Accent-125" and VGT both high quality and practical.

Acrylic sealants are very often used in everyday life by home craftsmen. They are distinguished by low cost and availability, but at the same time high efficiency and reliability of the sealing seam.

On the peculiarities of using acrylic sealant for wood Remmers Acryl 100, see the following video.