Features of silicone heat-resistant sealants

Silicone heat-resistant sealant has an important feature - it increases the reliability of furnace structures. It is convenient to seal the mixture with chips and crevices, therefore, as a repair agent, sealants are very effective. Tightness is an important condition for safety.

Special features

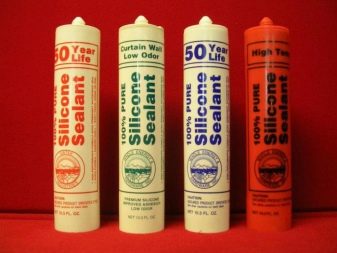

Silicone heat-resistant sealant is a polymer product with a pasty structure. Glue is one-component or consisting of two substances. A one-component mixture is considered the best option for home use, as it is used to work in special tubes already in ready-to-use form.

Two-component formulations require thoroughness when mixing, as the working material must be mixed only when used. Errors in the manufacture of formulations entail negative consequences.These mixtures are rarely used by amateurs, mainly professional stoppers.

It is known that brick and chimney masonry can crack, because the surface rarely warms up evenly. This phenomenon is often observed when there is no plaster or other finish.

Occurring crevices inside the furnace can cause the following phenomena:

- increased fuel consumption due to excessive air intake;

- soot ingress into the room and its subsidence on verticals;

- getting into the room of carbon dioxide, as a result - poisoning.

If the crevices in the furnace lead to fuel consumption, then the appeared cracks in the pipe cause a decrease in thrust. The oven unit also can not work normally. In addition, because of the cracks inside the chimney, more thrust is generated.

If too much soot is formed on a leaky chimney, the incoming air can be the result of its ignition. And when there is little thermal insulation around the pipe and wooden elements are present, there is a significant risk of a building igniting.

The leakage of gas units also entails many problems.For example, due to the excessive access of oxygen, the gas burner may go out. Therefore, the use of heat-resistant sealant is also relevant for the gas unit pipe.

What temperature can withstand?

High-temperature sealants are divided according to the area of use and the content of the composition. For example, heat-resistant sealants are needed for areas with heating not higher than 350 degrees. These compounds are suitable for sealing crevices on the outer part of stoves and fireplaces.

Heat-resistant sealants with such characteristics are used for embedding brick pipes, sandwich pipes. Heat-resistant substances are allowed for use for metal chimneys. And also use is allowed on chimneys of the pyrolysis unit in case the temperature range of gases is not higher than 150 degrees.

There are still heat-resistant and refractory substances that are designed for use inside the furnaces. During operation, these compounds withstand over 1000 C. A flame-retardant substance keeps direct contact with combustion products, however, not all heat-resistant sealants possess such characteristics. On the characteristics of the acquisition is better to check with the sellers.You can also carefully read what is written on the package with the selected substance.

It turns out that heat-resistant sealants work in the temperature range of 200-300 degrees, and fire-resistant sealants operate within the limits of 1200-1500 degrees. All sealants look like a pasty substance that hardens after use.

The ability of the sealant to maintain temperature is associated with the substrate, which is included in its composition. The basis for the production of sealants are silicate, silicone or bitumen constituents of the substance. Heat-resistant silicone sealants are used, in addition to the construction sector, also in the automotive.

It is argued that a clear boundary of separation between the areas of application of some compositions is absent. The main thing - the coincidence of characteristics with the purposes of use. Silicone is part of thermograms. Possible thermoporus specific means indicated by the manufacturer.

Just a silicone thermo sealant used in the automotive field cannot be used to repair stoves and chimneys. Acid, which is the basis of the substance, is incompatible with certain types of cements, as well as with materials prone to corrosion.The sealing layer is brittle, so it will quickly collapse.

The heat-resistant silicone sealant of neutral composition is resistant to temperature differences from -60 degrees to 300 degrees. This quality allows the use of heat-resistant silicone sealant, not only in the design of heating systems. The substance is suitable for arranging highways that hold for hot and cold water.

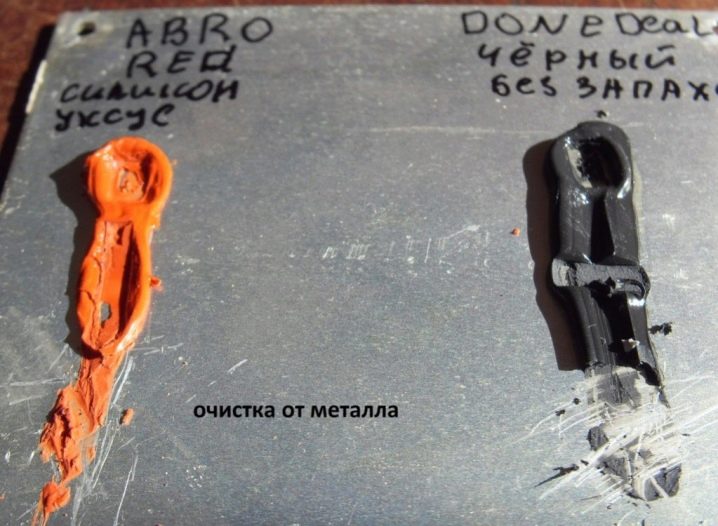

If silicate is based on a sealant, it can withstand heat up to 1200 degrees. This tool is ideal for sealing furnace joints inside units. High-temperature and heat-resistant sealants differ in appearance. The first is usually black, and the second becomes red when applied to the surface.

Kinds

Heat-resistant silicone glue includes different polymers, which gives the final product different characteristics. But also types of sealants differ in the volumes sold and packaging.

Heat resistant silicone based sealant can be acidic or neutral. In the acidic sealant there is an additive - acetic acid. It makes the compound capable of setting on certain surfaces.For example, adhesion will be best where surfaces are not afraid of oxidation and corrosion. This may be stainless steel or aluminum.

If acetic acid will affect other types of surface, rust will inevitably arise, which will ruin everything.

Neutral and acid sealants differ in odor. Neutral varieties can be applied on different bases, they do not have a strong odor. Neutral universal polyurethane sealants are expensive blends.

In addition to acetic acid, colored pigments and mechanical additives can be added to the sealants. Even in the formulations may contain additives that reduce the viscosity of the silicone. Also, some manufacturers add fungicides that eliminate fungus and mold.

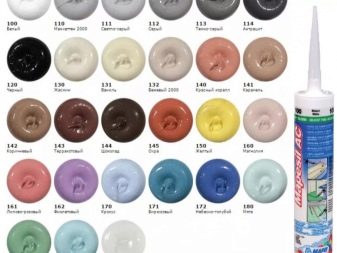

Choosing a sealant under the surface of a certain color, it should be borne in mind that in their composition they have a large amount of organic matter, which is not subject to staining. Since the usual dyes do not change the color of the sealant, it must first be selected for the shade of the treated surface.

Viscosity is an important characteristic of a material on which the fluidity of a polymer base depends.It is believed that the more liquid material is better degassed.

Silicone with low viscosity is more convenient to fill out forms. For example, it is suitable for the oven hob. It is worth considering the melting temperature of the product.

High viscosity silicone is more convenient to work with stove and fireplace designs. For convenient use it is better to buy products in special tubes.

Oil and petrol resistant not only resistant to temperature effects, but also to the action of chemicals. Such a sealant seizes well even at low temperatures, as it has the ability to compress and stretch. The composition is usually red. In general, sealants are easily distinguished by their color characteristics. Typically, the color range of sealants corresponds to the purpose of the materials.

Color spectrum

In addition to the qualitative difference, you need to pay attention to the color tone of the substance. This is especially important if the gap is close to the visible area.

Heat-resistant sealant, suitable for stoves and fireplaces, usually red under the classic tone of the brick.

- Universal silicone sealant can be found in a white shade, it can also be transparent.

- Neutral sealant is transparent, white, brown, black, gray.

- Quite a wide range of colors in the parquet silicone sealant. It can be matched with the accuracy of the color of the boards (beech, oak, maple, spruce, cherry).

Take time to choose the color of the sealant is due to aesthetic considerations.

After all, it is assumed that high-quality repairs should be durable. The need to replace the sealant only because of the wrong color will mean unnecessary expenses that can be avoided with a competent approach to the choice. This process is complicated due to the multitude of manufacturers offering products of various quality and price.

Manufacturers

Based on consumer feedback, we offer you a list of popular brands.

- Tytan - Polish manufacturer, whose products are of high quality characteristics. The cost of products starts from 300 rubles.

- "Moment" - domestic manufacturer of sealants, which are of high quality and low price, on average, pastes cost from 150 rubles. For example, users allocate means "Germent". Commercially available tubes differ in packaging from 310 ml to 1500 ml.You can choose the desired option for the implementation of their own goals.

- Makroflex - Finnish manufacturer, whose products are also valued for their excellent quality in operation.

- "Pentelast" - a two-component tool that is appreciated by professionals, but the mixture is expensive - from 1000 rubles.

- Penoseal - high-quality acid silicone sealant, colorless. Shows excellent adhesion with materials such as glass, plastic, ceramics, wood.

- Abro - substances of multi-purpose use, intended for repair work in automotive services. Substance is considered resistant to the action of oils, antifreeze, water. Abro sealants differ in tone, are black, red, gray, blue, transparent. Depending on the color, the physical properties of the products also differ.

Tips

Before applying the selected tool, familiarize yourself with the technique of its application. Without appropriate knowledge and skills, you are unlikely to get a clear, even and beautiful seams.

Some more tips from the experts.

- You should not put the silicone substance on your own without using a special gun.

- Secure yourself by wearing rubber gloves.The substance is difficult to wash off the skin.

- To make the seams even, keep a special napkin at hand, with which you will remove the excess.

Refrain from applying sealant over the same substance, especially if the seams are supposed to improve the decor. This technique is permissible if the tool is used to seal pipes, complex joints. However, such work should not affect the aesthetic quality of the surface.

About heat-resistant sealants PENOSIL, see the following video.