Two-component sealants: features and their scope

Without the use of sealant is almost impossible to carry out most types of construction work. It is an indispensable material for hydro, heat and vapor insulation, as well as for connecting various fragments. The two-component version of the sealant is mainly used in industry.

A special feature is the need to mix the two components before starting work.

Kinds

Two substances of a two-component sealant are combined in certain proportions according to the instructions, then mixed. After vulcanization, the mass is a rubber-like material capable of elongation in case of rupture.

The most common two-component version is polyurethane. The product contains a paste with a polyol content and a special hardener. These substances do not interact with the environment, and therefore have a long shelf life before mixing.

Another type is polysulfide sealant.The composition of the material includes thiokol, which by its structure can be compared with rubber. One of the components contains a polymer, a plasticizer and a filler, and the second is a structuring substance, a plasticizer and a pigment. Sealant is an artificial rubber, characterized by good adhesive qualities. Often used in shipbuilding.

Special attention should be paid to two-component silicone sealant, since it is he who is the most common of all the options.

Its versatility is due to its wide scope.

Can be used:

- at installation of double-glazed windows;

- for work with polycarbonate structures, wall panels;

- for sealing seams formwork and air ducts;

- when installing industrial and outdoor lighting equipment, gaskets in engines and radiators;

- for sealing components of household appliances, electronic devices and circuit boards;

- in the manufacture of aquariums and glass products;

- for sealing of artificial reservoirs.

Benefits

As already noted, two-component sealants have a long service life.

This is not the only advantage - there are other advantages:

- possibility of use at low temperatures;

- strength, elasticity and durability of seams;

- excellent adhesion properties;

- indicative physicomechanical qualities;

- exact time of curing;

- UV resistance;

- the possibility of staining with organic and aqueous paints;

- wide scope of application.

The main advantage of polyurethane two-component sealants is reliable frost resistance. This is due to the fact that moisture contained in the atmosphere does not participate in the process of solidification of the material, and therefore this option is perfect for outdoor work.

disadvantages

Despite the many advantages You can not ignore some of the shortcomings of two-component sealants:

- due to mixing of components, the working time increases;

- Care must be taken when mixing the compound;

- glue must be applied immediately after preparation - delays and “smoke breaks” are unacceptable.

Areas of use

Before buying a two component sealant Pay attention to the options recommended by the masters in the field of construction and repair.

- "Neftezol" NF 88 (16 kg) - bitumen-polyurethane glue. Scope of application - pasting of materials from metal, blocks, foamglass. Also suitable for seams.

- Ecoroom PU-20 designed to seal the expansion joints, cracks and crevices on the facade. It is characterized by excellent adhesion to concrete, metal and wood surfaces.

- Tektor 201 It is a two-component mastic for sealing joints of fencing structures, panel plates, during construction and repair work.

- Germotex it is used for sealing deformation joints and cracks on concrete floors and slabs. Contains synthetic rubber, which provides good adhesion, reliability and integrity of structures.

- "Sazilast 22" provides sealing of expansion joints, joints and gaps on the facade covering. Suitable for concrete, polymer concrete, foam concrete, brick. Differs in light gray color.

- Polikad m - A good tool for sealing glass. Contains polysulfide, plasticizer, pigment, fillers. Considered an effective vapor barrier.

Shore hardness

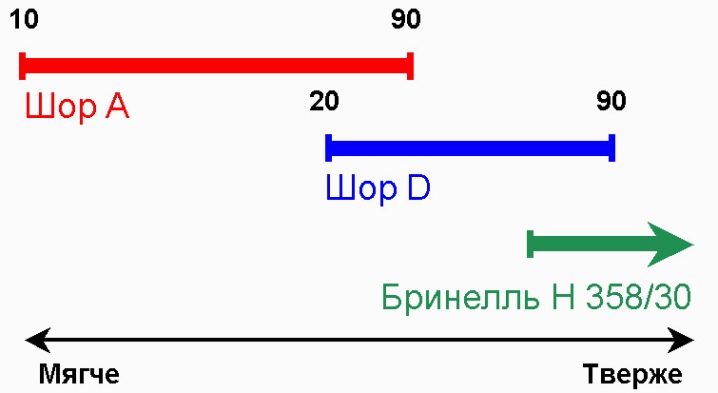

The most important indicator specified in the list of technical characteristics of the sealant is Shore hardness. It is a method for measuring the hardness of a composition.The results are represented by a numerical value with a letter corresponding to the scale. High hardness is determined by a large number. The letter A indicates softer indicators, the letter D - more solid.

The result is achieved by identifying the material's resistance to pressing a tip of a certain shape under the action of a spring pressure force.

For example, the company Germet, popular in the construction industry. pro offers polyurethane two-component sealants, which already have Shore hardness in their names: Germet. Pro 20 has a score of 20A, respectively, Germet. Pro 40 - 40A.

Recommendations

For the operation of the components of the sealant, which must be stored in special separate containers before use, it is necessary to mix it up using a special technology. Care must be taken to ensure that the environment does not adversely affect the product. When storing it is necessary to secure the container with hardener from moisture.

For cooking, use a special mixer.which is a construction mixer or electric drill. On the device put on the nozzle, then you need to use a spatula or a special gun.

When working with a two-component sealant, a few more tips should be taken into account:

- comply with all the proportions specified in the instructions;

- monitor the air temperature during operation - it should not be lower than indicated on the package;

- clean and wipe the surface thoroughly before handling;

- mix only the right amount - no more, as the sealant hardens very quickly;

- do not take breaks and delays, as the prepared material can solidify again during its inactivity;

- in the case of inappropriate consistency, one of the components cannot be added - a new composition should be made.

Thus, two-component sealants have a wide range of applications.and the modern market offers many options from different manufacturers. However, in order to obtain the highest quality result from the use of two-component varieties, it is necessary to observe all the conditions of preparation.

For how to use a two-component sealant, see the following video.