Sealing tape: the pros and cons of using

The rapid development of technology still does not allow to exclude some of the problems faced by any master in the process of building or performing repair work. To such tasks it is necessary to include the sealing of cracks and sealing joints.

Among the list of material required for such work, a sealing tape should be highlighted.

Special features

Almost all construction materials and structures need additional components, since construction products themselves provide the erection of a rough structure that needs processing, in particular, this concerns the sealing of various joints. Previously, gypsum, tow and various putties made independently were used for such works.

But technical progress has made its own adjustments in this area of construction and repair tasks, offering consumers a large assortment of new products, whose functionality many times exceeds similar indicators of materials from the past.In place of such outdated products came sealing tape.

Today you can find on sale various types of tapes, due to which the products have a wide range of applications. This feature is explained by the fact that moisture adversely affects the durability of various structures, buildings, including communications, devices and parts, which are present not only in the residential sphere, but also everywhere in industrial facilities. Based on this, the question of protection against contact with moisture is always relevant. This trend is forcing manufacturers to constantly work on creating high-quality insulation products.

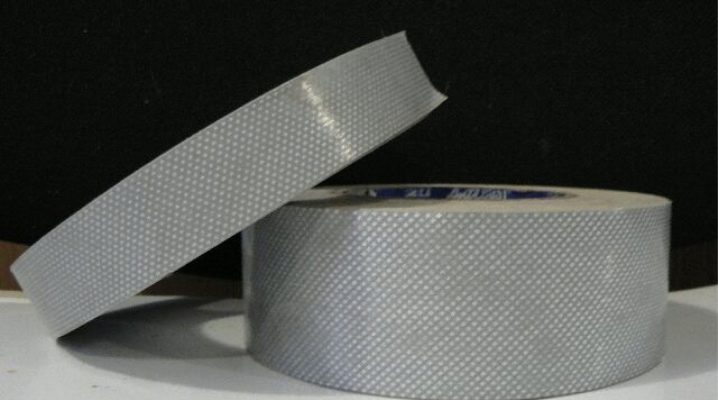

Sealing tape is a multifunctional product based on a composition of various raw materials, where bitumen is the main component. Products are distinguished by the ability of self-gluing on the base, which is its main advantage. Due to the special mesh structure, the material acquires the possibility of reliable adhesion with most construction products.

The product has inherent water-repellent properties, the material easily takes the form of a working base., which greatly simplifies its operation and installation. The tape has high elasticity, even at low temperatures, the material prevents the development and reproduction of harmful microorganisms, and does not lose its properties during contact with aggressive chemical compounds.

Due to its environmental friendliness, products are allowed to operate both outside and inside the premises.

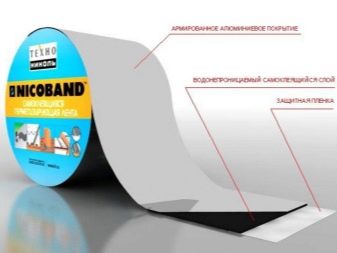

The composition of the elements included in the tape, includes several materials.

- A basis from rubber or bitumen with glue substance. These components provide the product with water resistance and are responsible for fixing and sealing the working surface.

- Durable high-strength aluminum foil. It provides a tear resistance to the tape product.

- Special film edge layer, which is removed before fixing the tape to the surface.

The presence of the above components allows you to perform high-quality sealing seams and joints in any design made from a variety of materials. Based on the field of use, the self-adhesive sealant can be supplemented with layers from other raw materials.Most often, such measures are resorted to to increase any properties of the product.

Kinds

Taking into account the scope of operation, sticky sealing tapes classified as follows:

- unilateral products;

- double-sided products.

In the latter case, the material has a working surface on both sides.

In addition, products are divided into several types.

Butylene tape

This product refers to the universal products made on the basis of butyl rubber. During production, such products are covered with a thin sheet of aluminum. The adhesive layer has a silicone-based protective film. The main component of the product is considered an excellent composition for insulation, in addition, it is used as a protective material for such raw materials as wood, plastic or metal. Double-sided products are compatible with most polyvinyl chloride materials due to the chemical inertness of butylene. Products are recommended for use in different temperature conditions, products are resistant to negative temperatures. The working temperature range is from + 120С to -60С. The tape is odorless.

The metal layer, which has a tape, provides it with resistance to ultraviolet light, alkali and various acids. Butylene elastic products are manufactured in lengths of 10 meters, the width of goods on the market is from 5 cm to 30 cm with a thickness of up to 1 mm.

The product is recommended for exterior and interior work with wood, polycarbonate, PVC systems, concrete and others.

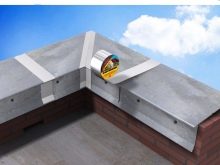

Bitumen-polymer products

This kind has a special layer of polyethylene. The product is manufactured to provide dielectric and anticorrosive protection of the bases, in addition, bitumen tape is made to isolate the underground water supply and other purposes. Production is allowed for use with other types of bitumen raw materials, for example, it can be involved in the repair of bitumen roofing.

Among the features of the product is to highlight the possibility of the material to repeat the shape of any surfaces.inherent irregularities. In addition, when a mechanical impact on the tape, for example, when cuts, it is released self-sealing the surface. The product is sold in rolls of 10 meters, the width of the product is 20 cm.

Polycarbonate Tape

The material is used to seal seams and isolate cracks in this raw material. Products do not pass air and do not lose their properties from exposure to ultraviolet radiation.

To ensure a high level of fastening of the tape with the surface, it is recommended to degrease it first and clean it of all possible contamination.

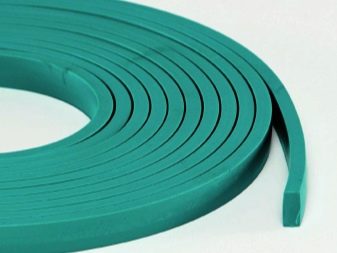

The second name of this product is a swelling cord. The material may have a rectangular or circular cross section. For the production of products used hydrophilic rubber. The process of increasing in size occurs after contact of the raw material with water. Products are resistant to mechanical stress. It is recommended for use on surfaces made of metal, glass, natural stone and concrete, as well as for working with various composite materials.

Such products are necessary in industrial facilities, they are often used in underground structures and on bridges. In addition, the tape is necessary for the insulation of the basement, underground parking lots, in pools and tanks with water. As practice shows, the products increase in size after contact with water 6 times.

The swelling tape is characterized by a long service life, and in comparison with other materials for insulation is characterized by low cost. Products are completely safe for humans and the environment.

Most often products are necessary for works with bathroom equipment and pipes in a bathroom and in kitchen. When choosing waterproof products for use in apartments and private homes, it is worth carefully selecting products from the presented range, since fewer quality requirements may be imposed on materials for sealing joints and joints in the household sphere. However, issues related to plumbing and sewage in the dwelling are also responsible and serious tasks.

Among the shortcomings of all the above varieties of products it is worth highlighting the need for periodic replacement of materials that will become unusable faster than the foundation itself. In some cases, experts recommend pre-treatment of seams or joints with liquid sealants.

Attention should be paid to the temperature range of use, since not all products are resistant to cold.

Scope of application

Consider the areas where sealing tape is most often used.

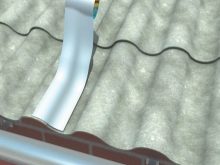

- In construction work, in the field of public utilities, among the list of tasks that the product solves, the sealing of joints between building materials, the tightness of windows, balconies and loggias, works related to the arrangement of a folded roof, laying of roll materials, installation of water and sewer systems, installation of plumbing equipment and equipment for ventilation, laying of heat-insulating raw materials on the pipeline.

- In the field of engineering - performance of isolation of various structures, cabs of cars or trucks, repair work on ships, sealing of railway transport.

- Oil industry - using tapes to seal joints in piping systems to protect the constituent elements from corrosion.

- Household sphere - performance of small and large repairs in the dwelling, including internal and external structures, for example, sealing window blocks, working with sanitary appliances, as well as clothing repair.

Manufacturers

On the shelves of modern building supermarkets you can find products of domestic and foreign manufacturers.

The range of products should be noted the following brands that implement sealing tape.

- Nicoband - presented products belong to the group of bitumen-polymer products. Double-sided products are available in different colors. When choosing a shade as a guideline, it is based on the most common colors in which roofing materials are made. The composition of the products makes it possible to apply them both for exterior and for internal work. In addition to sealing the roof and waterproofing membranes, the tape treats the joints of cold water pipes, the seams between polycarbonate products, is used for wooden and concrete structures for various purposes.

- Ribbon "Gerlen" - it is demanded for works with a roof of structures, sealing of automobile details and so on. Under this brand, several tape sealants are produced, for example, Gerlen-D, Gerlen-AG, Gerlen-FA, which differ in composition and field of use, vapor-permeable products are found.

- "Liplent" - basically it is necessary for work with seams of structures from metal or concrete in the industrial field.

- Self-adhesive products brand "Vikar" It can be used not only for sealing roofing materials, but also for removing ventilation and chimneys.

- FUM tape in demand in the domestic sphere. Products are made in various colors and sizes.

- Ekobit - recommended for insulation of ventilation and chimney, also showed itself well in the process of sealing window blocks. In addition, the product can be used for tiles, glass and plastic.

- "Outline" - tape sealant used for work with a brick base, wood and metal. Products used in the domestic and industrial field.

- Ceresit CL - sealing tape for construction work, has a high level of elasticity and resistance to loss of shape, due to which it is often used instead of liquid sealant during repair.

Tips

To make a reliable and high-quality connection using sealing tapes, It is necessary to adhere to the general recommendations for installation of products.

- First of all, you need to take care of the cleanliness of the working area - you need to work with a clean and degreased surface.

- Experts recommend treating the junction with a waterproofing agent, and then sticking tape on the wet composition.

- The material is pressed tightly to the surface with a spatula so that all air is released.

- Corner joints of elements need to be isolated with a spade.

Overview and method of applying the ribbon Abris C-LTNP - in the next video.