Polyurethane Sealants: Properties and Applications

Polyurethane sealants are in great demand in many industries. The mixtures are of high quality, reliable grip and long service life. The properties and application of this sealant make it the best way to work with seams on various surfaces.

What it is?

Sealant based on polyurethane belongs to the category of viscous polymer elements, the production of which is carried out at the expense of synthetic elastomers. Polyurethane sealants are considered a new technology. They can guarantee a high-quality and reliable level of waterproofing joints and cope with the most vulnerable places on the roof.

The material is often used to interact with the abutments on the roof, endovaya, individual sheets and other components that belong to the attachment points.

Up to the middle of the last century, cork or rubber was used to ensure the tightness of various types of joints, as well as to seal the seams. They were considered expensive materials that were quite difficult to replace. Engineers could not find a similar adhesive substance that could be made in unlimited circulation using available and inexhaustible resources.

The USA was the first state to experiment with the synthesis of polyamides. However, German scientists were able to cope with the task. They created a polyurethane elastomer by combining polyols with certain diisocyanates. As a result of their experiments, polyurethanes were obtained, which are known throughout the globe.

Properties and specifications

Polyurethane sealants are often used for bonding products made of brick, metal, concrete and plastic. During use, the product acts as a sealant and glue. When polyurethane hardens, the elements are glued together with each other.Polyurethane is resistant to moisture, corrosion and vibration. A high level of moisture has an effect on improving the properties of polyurethane.

The composition of the sealant forms one main substance, which is a polyurethane, the structure of which contains one component. But there are also products from polyurethane, the structure of which is formed by two components. They are characterized by improved sealing properties. The elasticity index is 99.9%. If you compare the material with foam for construction work, the technical qualities of both substances will be the same.

Polyurethane sealants have similarity with foam for mounting during polymerization, since the substance solidifies within a couple of seconds after being placed on the surface. The presence of a large amount of moisture allows the mixture to polymerize.

During use, please note that the sealant quickly hardens, so it should be applied carefully.

Store sealant in a cool place. If normal conditions are provided, the mixture can be stored in an open tube for about 10 months.The product is sold in tubes weighing 600 ml, 750 ml, in buckets, metal cartridges. When buying, make sure that the product has a certificate of conformity.

Positive qualities of polyurethane sealant:

- maximum rate of elasticity;

- quality level of adhesion in relation to surfaces made of metal, brick, concrete, plastic, ceramics;

- high degree of self-adhesion;

- operational polymerization;

- resistance to moisture;

- sealant can be used at a temperature of -50 degrees;

- hardness according to Shore A is 15-50 units;

- high tensile strengths;

- vibration resistance;

- resistance to chemicals;

- material can be painted;

- sealant density is 1200-1500 kg / cu. meter;

- resistance to UV rays;

- material does not shrink;

- no toxic components are present in the product;

- long service life.

Among the negative qualities can be noted their instability to temperatures above 100 degrees.

Kinds

Polyurethane sealants are classified into two categories: on the basis of one component and using two components.

One component polyurethane sealant

Such products are among the materials in the form of paste.The main component is a polyurethane type polymer polymer. Such adhesives are characterized by increased adhesion to various materials for construction. It exhibits good adhesion to glass and ceramic surfaces. After a one-component sealant is applied to the surface, it begins to harden due to contact with moisture, which is located in the air.

Single-component products are easy to operate, as this suture material does not require mixing components. For this reason, the seams will be of high quality.

Sealants are actively used during repair and construction, as well as to ensure the tightness of the following elements:

- different designs in construction;

- joints on the roof;

- vehicle body;

- for glasses in the car.

Often, polyurethane sealants are called glass, as they are in demand when gluing automotive glass, when installing fiberglass decorative parts. Single-component compositions suitable for glass with metal. Due to the fact that the material is waterproof, the area of its use increases.

The product can be used for bases that are affected by high-temperature mode and vibration. Ease of use lies in the fact that sealants foaming for dispensers are located in a convenient tube. Foam glue is quickly applied to different joints and hardens.

In demand high modulus sealant with a polyurethane base, which is of high quality.

One-component sealants have one drawback, which is that they cannot be used in the winter season, when the thermometer drops below 10 degrees.

This is due to several factors.

- Due to the decrease in temperature, a decrease in the humidity level is observed. This leads to the fact that the rate of polymerization means is significantly reduced.

- Due to the increase in the hardening period, the liquid sealant will lose its elastic characteristics along with adhesion and hardness.

- At negative temperatures, the viscosity of the mixture increases, therefore, the use of a sealant becomes difficult.

Two-component sealants

A package with such a product contains two elements that are in separate packages:

- pasta with polyols;

- hardener.

While the ingredients are not mixed, they can be stored for a long time, as they are not in contact with the environment.

The main advantage of two-component products is that they do not lose their properties at negative temperatures. This is due to the fact that during the polymerization they do not need moisture, which is contained in the air. The composition of the mixture provides a strong, elastic and durable seam.

Among the shortcomings are the following qualities:

- for the kneading of components requires additional time, which leads to an increase in the duration of the work;

- the quality of the seams depends on the correct choice of the proportions of ingredients during mixing;

- the adhesive mixture formed should be used immediately after mixing.

If you make a comparison of mixtures with two components with sealants, the structure of which consists of one substance, we can conclude that for household use it is best to buy sealants based on one component.

In construction, special polyurethane sealants are usually used, which are aimed at working with concrete surfaces.The peculiarity of such products is that there are no solvents in the composition. Wide demand is due to convenient operation and high quality seams, which are formed after the application of an airtight mixture.

If you want to get rid of various cracks and gaps that appeared during the construction of the house, a mixture of polyurethane provides high quality waterproofing.

Consumption

Polyurethane sealant is characterized by cost efficiency. For example, if it is necessary to process a seam with a depth of 10 mm, about 100 ml of the product should be spent on 1 m of this seam.

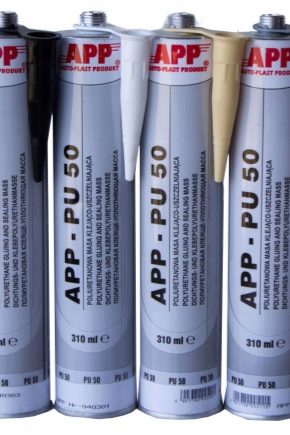

Colour

The color of the sealant may vary. Some users choose a clear sealant that is invisible on surfaces. However, there is a color material on sale that is suitable for surfaces of different colors. Black, gray, white and even brown sealants are common. They do not stand out from the general color solution of the treated surface and do not spoil the appearance of the object.

Colorless sealant is considered the best option for working with glass. It is invisible on the products and ensures the invisibility of the seam.

Application

Polyurethane-based sealants are renowned for their numerous positive qualities, therefore their scope of application is varied. Such material is able to cope with interpanel joints and ensure the proper quality of expansion joints. Products can provide tightness of good quality for the roof, are used for joints on logs and double-glazed windows.

Polyurethane sealants can be used as adhesivewhich effectively copes with seams in concrete surfaces, and also for interaction with the joints present between reinforced concrete plates.

When choosing mixtures for domestic use, it is recommended to remember its main quality, which is hardness. Due to her product resists deformation effects and shrinkage.

If the degree of hardness of the selected mixture reaches 15 units, it is allowed to choose to eliminate the seams, which are located between the panel material, as well as for processing corners and joints of different nature. Polyurethane mixtures are best suited for wood, sealing seams in a timber, connecting different parts of plastic.

With a hardness of 25 units, the sealant is relevant for interaction with joints, which are often affected by moisture. Such products are often used for bathrooms, gearboxes, roofs and other surfaces.

Hardness of 40 units makes it possible to exploit the mixture as a glass sealant. But it can also be used for concrete floors. The material is able to cope with the sealing of temperature joints that are present in structures made of reinforced concrete.

Polyurethane sealants whose hardness rating reaches 50 units can be used for working on metal. The highest hardness index reaches 60 units. Similar products are used for body work and in the field of shipbuilding.

Sealants of this type are in demand in various industries.

- Work with window and door structures, processing of interpanel joints on the facade of the building. When the mixture is open, the mixture should be used immediately. It should be applied to the seam itself, observing the thickness of the application, the maximum size of which is 0.5 cm. With this approach, you can get a tight connection and save on the consumable part.

- Polyurethane sealants are often used to work with products from natural stones.Due to such mixtures, you can get a practically invisible seam to the human eye. Products are available in various colors, so you can make a choice of shade that is as close as possible to the color of the surface. Silicone sealants for working with stone are not suitable, as they adversely affect the color and structure of the stone. Polyurethane mixtures - the best solution for this case.

- For areas affected by increased vibration, you must use a polyurethane-based sealant. Selection is based on strain and shrink resistance. The mixture is used in the automotive industry, when working with seams of metal surfaces. The material provides rapid drying and the required level of strength.

- And also such mixtures are used to work with seams, which are affected by high or low temperature conditions. High demand is due to good elasticity, resistance to punctures, destructive effects and abrasion.

- Polyurethane mixture - the best roofing sealant. And also it can be used to eliminate the seams when arranging a pond or fountain.After processing, polyurethane is characterized by a high level of strength along with resistance to moisture.

Manufacturers

Polyurethane-based sealants are manufactured by many brands, among which three manufacturers are in demand.

Buyers select company "Rastro", which has been producing construction materials for over 20 years. Brand specialization: production of materials for construction, repair work, waterproofing. The company was founded in St. Petersburg, and currently the company has branches and warehouses in different cities in the territory of the Russian Federation.

During the manufacture of products manufacturer uses only high quality materials, along with the use of new technologies. For this reason, most buyers choose this particular brand.

"Rastro" is available sealant based on polyurethane "Izhora". The mixture belongs to the category of two-component and is characterized by reliable sealing of seams, cracks at the joints and the front part. The product is characterized by a high level of elasticity and reliable adhesion with the base.The release is carried out in white and gray colors, but when ordering, you can specify the desired shade and get the desired option.

Widespread polyurethane sealant "Sazilast". Under this brand, they produce a whole line of mixtures consisting of one or two components, which are used in various industries.

"Sazilast" can be used in adverse conditions, which consist in temperature changes, constant humidity and exposure to chemicals. Sealants can be used for exterior work (when repairing the facade, roof), as well as for working with the foundation and roads. The certificate of conformity guarantees high quality products.

Herment "Moment" produces the company "Germent." The manufacturer produces not only polyurethane mixtures, but also other types of sealants. This brand is in great demand among consumers, as the manufacturer pays attention to the high quality of products, doing quality control.

"Moment" is characterized by a long service life, resistance to chemical reagents and other adverse factors.But also the mixtures demonstrate high elasticity, have good adhesion to different surfaces. The manufacturer provides a certificate of quality for its products.

Application Instructions

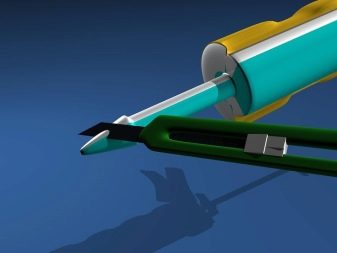

Since a component of the raw material is due to the use of only one main component, and there are no different types of solvents in its structure, the release of the sealant is carried out in foil tubes, metal cartridges and in buckets. Apply the mixture using special tools, which are called pistols.

Three varieties of spray guns are available.

- Mechanical pistols. They are made for private construction work, as they can cope with only a small amount of tasks.

- Pneumatic guns. The tool focuses on average amounts of work and is often acquired by professional builders.

- The gun equipped with the rechargeable battery. Such a tool is used in the construction of high-rise buildings.

Before work, you need to wear a special nozzle on the selected gun, cut the seam to the desired length.To sealant bonded surface quality, care should be taken to ensure that the size of the diameter of the mixture is twice the depth of the seam itself, which will be applied to the mixture.

Before using the sealant, it will be necessary to carry out preparatory measures: all dust deposits, paint and various oil materials should be removed from the surface to be treated. Masters do not advise using sealant in the open air when it is raining outside and during other precipitations. If there is rust on the base, it should be removed with a grinder or a skin. Due to such actions it is possible to increase adhesion indices several times.

Interpanel or interblock seams need to be warmed in advance. The action can be performed using construction foam for installation or use foamed polyethylene. The sealant is recommended to be applied over the insulating material. To do this, use a hand-type pneumatic pistol or spatula. The mixture should be placed on the surface measured. No voids or tears are allowed.

To level the applied material, need jointing from steel or wood. The base must be L-shaped. The sealant dries quite quickly, but after three hours after application, it turns into a mixture that is resistant to negative temperatures, moisture, and the effects of precipitation. Up to this point, the sealant cannot be exposed to such irritants.

What to dissolve and dilute?

Not every user can gently apply a polyurethane-based sealant to seams or joints. Since the tool hardens very quickly, many people are looking for information about how you can scrub a polyurethane-based sealant and soften the mixture.

Single-component and two-component mixtures can be removed with alkaline materials. However, please note that you should start cleaning immediately. Otherwise, remove the extra particles of matter will not work.

Some manufacturers produce special products to remove polyurethane sealant. AcesolvePUN is in demand. It showed itself well in cleaning the mixer (special mixing machine), hoses and gun.The product is able to cope with uncured parts of the sealant.

Polymerized sealant is not removed. The use of solvents will cause the mixture to swell.

For more information on the use of polyurethane sealants, see the following video.